Komatsu Hydraulic Excavator PC30R, PC35R, PC40R, PC45R Repair Service Manual + Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC30R-8, PC35R-8, PC40R-8, PC45R-8 (Deluxe), with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 (Deluxe) workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,413 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEBM003000 - Hydraulic Excavator PC35R-8, PC45R-8 Shop Manual.pdf

WEBM003900 - Hydraulic Excavator PC35R-8, PC45R-8 Deluxe Shop Manual.pdf

SEBM012603 - Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Shop Manual.pdf

SEBM012604 - Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Shop Manual.pdf

SEAM015301 - Hydraulic Excavator PC30R-8, PC35R-8, PC40R-8, PC45R-8 Operation & Maintenance Manual.pdf

SEAM015304T - Hydraulic Excavator PC35R-8, PC45R-8 Operation & Maintenance Manual.pdf

WEAM003200 - Hydraulic Excavator PC35R-8, PC45R-8 Operation & Maintenance Manual.pdf

WEAM003202 - Hydraulic Excavator PC35R-8, PC45R-8 Deluxe Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

00 FOREWARD...6

SAFETY...6

FOREWARD...8

HOW TO READ THE SHOP MANUAL...9

HOISTING INSTRUCTIONS...10

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER...11

COATING MATERIALS...13

STANDARD TIGHTENING TORQUE...15

ELECTRIC WIRE CODE...18

CONVERSION TABLE...19

UNITS...25

01 GENERAL...26

GENERAL ASSEMBLY DRAWING...27

SPECIFICATIONS...35

WEIGHT TABLE...43

LIST OF LUBRICANT AND WATER...47

10 STRUCTURE AND FUNCTION...49

PTO (COUPLING)...50

RADIATOR, OIL COOLER...51

ENGINE CONTROL...52

POWER TRAIN...53

SWING CIRCLE...54

SWING MACHINERY...55

TRACK FRAME, RECOIL SPRING...56

HYDRAULIC PIPING...57

HYDRAULIC CIRCUIT DIAGRAM...58

HYDRAULIC PUMP...66

CENTER SWIVEL JOINT...73

SWING MOTOR...74

TRAVEL MOTOR...79

9-SPOOL CONTROL VALVE...90

CLSS...98

MULTI-CONTROL VALVE...122

ELECTRICAL WIRING DIAGRAM...123

VALVE CONTROL...125

WORK EQUIPMENT, SWING PPC VALVE...126

SOLENOID VALVE...130

WORK EQUIPMENT...132

MACHINE MONITOR SYSTEM...133

ELECTRICAL CIRCUIT DIAGRAM...137

HYDRAULIC CYLINDER...138

20 TESTING AND ADJUSTING...139

STANDARD VALUE TABLE...140

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...140

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...142

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...158

TESTING AND ADJUSTING...161

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING...162

MEASURING ENGINE SPEED...163

MEASURING EXHAUST COLOR...164

ADJUSTING VALVE CLEARANCE...165

MEASURING COMPRESSION PRESSURE...166

TESTING AND ADJUSTING FUEL INJECTION TIMING...167

MEASURING ENGINE OIL PRESSURE...168

TESTING AND ADJUSTING FAN BELT TENSION...169

ADJUSTING CONTROL LEVERS AND PEDALS...170

MEASURING SPROCKET WEAR...173

TESTING AND ADJUSTING TRACK SHOE TENSION...174

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT...175

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE...178

ADJUSTING PC VALVE...180

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE...181

TESTING OUTPUT PRESSURE OF SOLENOID VALVE...184

TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE (PC20R)...185

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE...187

TESTING AND ADJUSTING TRAVEL DEVIATION...188

TESTING OIL LEAKAGE...189

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT...190

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK...190

PRESSURIZING HYDRAULIC TANK...190

BLEEDING AIR...191

TROUBLESHOOTING...193

POINTS TO REMEMBER WHEN TROUBLESHOOTING...194

SEQUENCE OF EVENTS IN TROUBLESHOOTING...195

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...196

CHECKS BEFORE TROUBLESHOOTING...204

CONNECTOR TYPES AND MOUNTING LOCATIONS...205

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...208

METHOD OF USING TROUBLESHOOTING CHARTS...218

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...221

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM...222

E-1 ENGINE DOES NOT START...224

A) WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)...224

B) WHEN STARTING MOTOR TURNS (ENGINE STOPE SOLENOID SYSTEM)...227

E-2 ENGINE DOES NOT STOP...229

E-3 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS CANCELED...230

E-4 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED...231

E-5 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL BOOST PEDAL IS DEPRESSED...232

E-6 TRAVEL SPEED DOES NOT DECREASE EVEN WHEN TRAVEL BOOST PEDAL IS RELEASED...233

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)...235

TABLE OF FAILURE MODES AND CAUSES...236

H-1 SPEEDS OF ALL WORK EQUIPMENT, SWING TRAVEL ARE SLOW OR LACK POWER...238

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS...239

H-3 NO WORK EQUIPMENT, TRAVEL, SWING MOVE...240

H-4 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)...240

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR...241

H-6 BOOM IS SLOW OR LACKS POWER...242

H-7 ARM IS SLOW OR LACKS POWER...242

H-8 BUCKET IS SLOW OR LACKS POWER...243

H-9 BOOM SWING IS SLOW OR LACKS POWER...243

H-10 BLADE IS SLOW OR LACKS POWER...244

H-11 BOOM, ARM, BUCKET DO NOT MOVE (BOOM SWING, BLADE, TRAVEL AND SWING ARE NORMAL)...244

H-12 EXCESSIVE HYDRAULIC DRIFT (BOOM, ARM, BUCKET, BOOM SWING, BLADE)...245

A) BOOM...245

B) ARM, BUCKET, BOOM SWING...245

C) BLADE...245

H-13 EXCESSIVE TIME LAG (ENGINE AT LOW IDLING)...246

H-14 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW...246

H-15 TRAVEL DEVIATION...247

A) DEVIATION IN NORMAL TRAVEL...247

B) DEVEIATION WHEN STARTING...247

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER...248

H-17 STEERING DOES NOT TURN EASILY...248

H-18 TRAVEL SPEED DOES NOT SWITCH...249

H-19 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)...249

H-20 SWING SPEED IS SLOW OR LACKS POWER...250

A) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS...250

B) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY (LEFT OR RIGHT)...250

H-21 DOES NOT SWING...251

A) DOES NOT SWING IN EITHER DIRECTION...251

B) DOES NOT SWING N ONE DIRECTION (LEFT OR RIGHT)...251

H-22 SWING ACCELERATION IS POOR...252

A) ACCELERATION IS POOR IN BOTH DIRECTIONS...252

B) ACCELERATION IS POOR IN ONE DIRECTION ONLY (LEFT OR RIGHT)...252

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING...253

A) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS...253

B) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY (LEFT OR RIGHT)...253

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING (IN ONE DIRECTION ONLY)...254

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING...254

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING...254

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)...255

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS...256

M-1 WHEN STARTING SWITCH IS TURNED ON, NO DISPLAY IS GIVEN...257

M-2 WHEN STARTING SWITCH IS TURNED ON, EVEN WHEN SELF CHECK IS COMPLETED (ALL LAMPS LIGHT UP FOR 3 ECONDS), LAMPS DO NOT GO ...257

M-3 WHEN STARTING SWITCH IS TURNED ON, SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS...258

A) NO GAUGE LAMPS LIGHT UP (FUEL, COOLANT TEMPERATURE)...258

B) CAUTION LAMPS (ENGINE OIL PRESSURE, BATTERY CHARGE), PILOT LAMP (PREHEATING) DO NOT LIGHT UP...258

M-4 DURING SELF CHECK (ALL LAMPS LIGHT UP FOR 3 SECONDS), EVEN IF STARTING SWITCH IS TURNED TO START, SELF CHECK IS NOT COMP...258

M-5 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), ENGINE OIL PRESSURE CAUTION LAMP DOES OT LIGHT UP...259

M-6 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), CHARGE CAUTION LAMP DOES NOT LIGHT UP...259

M-7 WHEN STARTING SWITCH IS TURNED TO HEAT, PREHEATING PILOT LAMP DOES NOT LIGHT UP...260

M-8 WHEN ENGINE IS RUNNING , ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP...260

M-9 WHEN ENGINE IS RUNNING, CHARGE CAUTION LAMP LIGHTS UP...261

M-10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE...262

A) LEVEL DOES NOT RISE FROM SEGMENT C...262

B) LEVEL DOES NOT GO DOWN FROM SEGMENT H, OR ALL SEGMENTS GO OUT...262

C) COOLANT TEMPERATURE DOES NOT MATCH GAUGE DISPLAY...263

M-11 ABNORMALITY IN FUEL GAUGE...264

A) LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT...264

B) LEVEL DOES NOT GO DOWN FROM SEGMENT F...264

C) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY...265

M-12 DEFECTIVE OPERATION OF ALARM BUZZER...266

A) BUZZER DOES NOT SOUND...266

B) BUZZER CONTINUES TO SOUND AND DOES NOT STOP...266

M-13 WHEN ENGINE IS RUNNING, SERVICE METER DOES NOT ADVANCE...267

A) WHEN CHARGE CAUTION LAMP DOES NOT LIGHT UP...267

B) WHEN CHARGE CAUTION LAMP LIGHTS UP...267

C) PILOT LAMP DOES NOT FLASH (SERVICE METER IS ACTUATED)...267

M-14 NIGHT LIGHTING DOES NOT LIGHT UP...268

A) GAUGE LIGHTING DOES NOT LIGHT UP...268

B) SERVICE METER LIGHTING DOES NOT LIGHT UP...268

30 DISASSEMBLY AND ASSEMBLY...269

METHOD OF USING MANUAL...271

PRECAUTIONS WHEN CARRYING OUT OPERATION...272

SPECIAL TOOL LIST...274

SKETCHES OF SPECIAL TOOLS...279

STARTING MOTOR (REMOVAL, INSTALLATION)...285

ALTERNATOR (REMOVAL, INSTALLATION)...286

FUEL INJECTION PUMP (REMOVAL)...287

FUEL INJECTION PUMP (INSTALLATION)...288

NOZZEL HOLDER (REMOVAL, INSTALLATION)...291

WATER PUMP (REMOVAL)...292

WATER PUMP (INSTALLATION)...293

THERMOSTAT (REMOVAL, INSTALLATION)...294

ENGINE FRONT SEAL (REMOVAL, INSTALLATION)...295

ENGINE REAR SEAL (REMOVAL)...296

ENGINE REAR SEAL (INSTALLATION)...297

CYLINDER HEAD (REMOVAL)...298

CYLINDER HEAD (INSTALLATION)...300

RADIATOR, HYDRAULIC COOLER (REMOVAL...304

RADIATOR, HYDRAULIC COOLER (INSTALLATION)...305

ENGINE, HYDRAULIC PUMP (REMOVAL)...306

ENGINE, HYDRAULIC PUMP (INSTALLATION)...310

FUEL TANK (REMOVAL, INSTALLATION)...311

DAMPER (REMOVAL, INSTALLATION)...312

CENTER SWIVEL JOINT (REMOVAL, INSTALLATION)...313

CENTER SWIVEL JOINT (DISASSEMBLY, ASSEMBLY)...314

TRAVEL MOTOR (REMOVAL, INSTALLATION)...315

PHV-300 (FOR PC30R-8) DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR ...316

PHV-350 (FOR PC35R-8) DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR...331

PHV-500 (FOR PC40R-8) DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR...346

GM06VL (FOR PC45R-8) DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR...361

SAFETY...362

SECTIONAL DRAWING OF ASSEMBLY...363

PARTS LIST...365

TOOLS...366

TIGHTENING TORQUE...373

DISASSEMBLY...374

MAINTENANCE STANDARDS TABLE ...396

ASSEMBLY...398

DIMENSIONS TABLE OF CLEARANCE ADJUSTMENT PARTS...424

PERFORMANCE CONFIRMATION TEST...425

SPROCKET (REMOVAL, INSTALLATION)...426

SWING MOTOR, SWING MACHINERY (REMOVAL)...427

SWING MOTOR, SWING MACHINERY (INSTALLATION)...428

SWING MOTOR, SWING MACHINERY (DISASSEMBLY)...429

SWING MOTOR, SWING MACHINERY (ASSEMBLY)...432

DISASSEMBLY SWING MOTOR ASSEMBLY LMF 16AB...435

ASSEMBLY SWING MOTOR ASSEMBLY LMF 16AB...440

REVOLVING FRAME (REMOVAL)...448

REVOLVING FRAME (INSTALLATION)...450

SWING CIRCLE (REMOVAL, INSTALLATION)...451

IDLER (REMOVAL, INSTALLATION)...452

IDLER (DISASSEMBLY)...453

IDLER (ASSEMBLY)...454

RECOIL SPRING (REMOVAL, INSTALLATION)...455

RECOIL SPRING (DISASSEMBLY)...456

RECOIL SPRING (ASSEMBLY)...458

TRACK ROLLER (REMOVAL, INSTALLATION)...460

TRACK ROLLER (DISASSEMBLY)...461

TRACK ROLLER (ASSEMBLY)...462

CARRIER ROLLER (REMOVAL, INSTALLATON)...463

CARRIER ROLLER (DISASSEMBLY, ASSEMBLY)...464

RUBBER SHOE (REMOVAL, INSTALLATION)...465

STEEL SHOE (REMOVAL, INSTALLATION)...466

HYDRAULIC TANK (REMOVAL, INSTALLATION)...468

HYDRAULIC COOLER (REMOVAL, INSTALLATION)...469

HYDRAULIC PUMP (REMOVAL, INSTALLATION)...470

DISASSEMBLY OF MAIN PUMP ASSEMBLY (LPV 45)...471

ASSEMBLY OF MAIN PUMP ASSEMBLY (LPV 45)...479

CONTROL VALVE (REMOVAL)...490

CONTROL VALVE (INSTALLATION)...491

CONTROL VALVE (DISASSEMBLY)...492

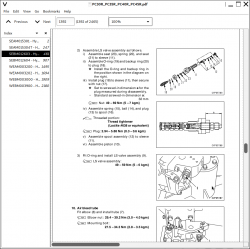

CONTROL VALVE (ASSEMBLY)...500

2-SPOOL SOLENOID VALVE (REMOVAL, INSTALLATION)...507

LEFT PPC VALVE (REMOVAL, INSTALLATION)...508

RIGHT PPC VALVE (REMOVAL, INSTALLATION)...509

PPC VALVE (DISASSEMBLY)...510

PPC VALVE (ASSEMBLY)...511

BOOM CYLINDER (REMOVAL)...512

BOOM CYLINDER (INSTALLATION)...513

ARM CYLINDER (REMOVAL)...514

ARM CYLINDER (INSTALLATION)...515

BUCKET CYLINDER (REMOVAL)...516

BUCKET CYLINDER (INSTALLATION)...517

BOOM SWING CYLINDER (REMOVAL)...518

BOOM SWING CYLINDER (INSTALLATION)...519

BLADE CYLINDER (REMOVAL)...520

BLADE CYLINDER (INSTALLATION)...521

HYDRAULIC CYLINDER (DISASSEMBLY)...522

HYDRAULIC CYLINDER (ASSEMBLY)...525

WORK EQUIPMENT (REMOVAL)...528

WORK EQUIPMENT (INSTALLATION)...529

BUCKET (REMOVAL, INSTALLATION)...530

ARM (REMOVAL)...531

ARM (INSTALLATION)...532

BUCKET, ARM (REMOVAL)...533

BUCKET, ARM (INSTALLATION)...534

BOOM (REMOVAL)...535

BOOM (INSTALLATION)...536

BOOM SWING BRACKET (REMOVAL)...537

BOOM SWING BRACKET (INSTALLATION)...538

BLADE (REMOVAL)...539

BLADE (INSTALLATION)...540

OPERATOR'S CAB (REMOVAL, INSTALLATION)...541

CANOPY (REMOVAL, INSTALLATION)...541

FLOOR FRAME (REMOVAL, INSTALLATION)...542

40 MAINTENANCE STANDARD...545

SWING CIRCLE...546

SWING MACHINERY...548

SPROCKET...550

TRACK FRAME, RECOIL SPRING...552

IDLER...554

TRACK ROLLER...555

CARRIER ROLLER...556

TRACK SHOE...557

CENTER SWIVEL JOINT...562

HYDRAULIC PUMP...563

WORK EQUIPMENT, SWING PPC VALVE...564

SWING MOTOR...565

9-SPOOL CONTROL VALVE...566

HYDRAULIC CYLINDER...572

WORK EQUIPMENT...576

90 OTHER...580

HYDRAULIC CIRCUIT DIAGRAM PC30R-8...581

HYDRAULIC CIRCUIT DIAGRAM PC35R-8...583

HYDRAULIC CIRCUIT DIAGRAM PC40R-8...584

HYDRAULIC CIRCUIT DIAGRAM PC45R-8...585

ELECTRICAL CIRCUIT DIAGRAM...586

HYDRAULIC PIPING DRAWING...587

SYSTEM DIAGRAM DRAWING...588

COVER...1

1.FOREWORD...2

2.SAFETY INFORMATION...5

3.INTRODUCTION...6

4.LOCATION OF PLATES,TABLE TO ENTER SERIAL NO.AND DISTRIBUTOR...7

5.CONTENTS...8

SAFETY...12

6.GENERAL PRECAUTIONS...13

7.PRECAUTIONS DURING OPERATION...18

7.1 BEFORE STARTING ENGINE...18

7.2 AFTER STARTING ENGINE...20

7.3 TRANSPORTATION...27

7.4 BATTERY...28

7.5 TOWING...30

8.PRECAUTIONS FOR MAINTENANCE...31

8.1 BEFORE CARRYING OUT MAINTENANCE...31

8.2 DURING MAINTENANCE...35

9.POSITION FOR ATTACHING SAFETY LABELS...40

OPERATION...44

10.GENERAL VIEW...45

10.1 GENERAL VIEW OF MACHINE...45

10.2 GENERAL VIEW OF CONTROLS AND GAUGES...46

11.EXPLANATION OF COMPONENTS...47

11.1 MACHINE MONITOR...47

11.2 SWITCHES...52

11.3 CONTROL LEVERS AND PEDALS...55

11.4 ENGINE HOOD ...58

11.5 FRONT WINDOW(MACHINES EQUIPPED WITH CAB)...60

11.6 SLIDING DOOR(MACHINES EQUIPPED WITH CAB)...62

11.7 HAMMER FOR EMERGENCY ESCAPE(MACHINES EQUIPPED WITH CAB)...63

11.8 FUSES...63

119. FUSIBLE LINK...64

11.10 CAP,COVER WITH LOCK...64

11.11 MANUAL POCKET...65

11.12 TOOL BOX...65

11.13 DUST INDICATOR...65

12.OPERATION...66

12.1 CHECK BEFORE STARTING ENGINE...66

12.2 STARTING ENGINE...75

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE...77

12.4 MOVING MACHINE OFF...79

12.5 STEERING MACHINE...82

12.6 STOPPING MACHINE...84

12.7 SWINGING...85

12.8 OPERATION OF WORK EQUIPMENT...86

12.9 PROHIBITIONS FOR OPERATION...87

12.10 PRECAUTIONS FOR OPERATION...90

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS...91

12.12 HOW TO ESCAPE FROM MUD...93

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR...94

12.14 REPLACEMENT OF BUCKET...96

12.15 PARKING MACHINE...99

12.16 CHECK AFTER FINISHING WORK...100

12.17 STOPPING ENGINE...100

12.18 CHECK AFTER STOPPING ENGINE...101

12.19 LOCKING...101

12.20 HANDLING OF RUBBER SHOE AND ROAD LINER (PC45R)(MACHINES WITH RUBBER SHOES OR ROAD LINER)...102

13.TRANSPORTATION...107

13.1 LOADING,UNLOADING WORK...107

13.2 METHOD FOR LIFTING MACHINE...109

13.3 PRECAUTIONS FOR LOADING AND SECURING MACHINE...111

13.4 PRECAUTIONS FOR TRANSPORTATION...112

14.COLD WEATHER OPERATION...113

14.1 PRECAUTIONS FOR LOW TEMPERATURE...113

14.2 PRECAUTIONS AFTER COMPLETION OF WORK...115

14.3 PREPARING THE CAB HEATER(MACHINES EQUIPPED WITH CAB)...115

14.4 AFTER COLD WEATHER...115

15.LONG-TERM STORAGE...116

15.1 BEFORE STORAGE...116

15.2 DURING STORAGE...117

15.3 AFTER STORAGE...117

16.TROUBLESHOOTING...118

16.1 PHENOMENA THAT ARE NOT FAILURES...118

16.2 METHOD OF TOWING MACHINE...118

16.3 PRECAUTIONS ON PARTICULAR JOBSITES...118

16.4 IF BATTERY IS DISCHARGED...119

16.5 OTHER TROUBLE...123

MAINTENANCE ...127

17.GUIDES TO MAINTENANCE...128

18.OUTLINES OF SERVICE...130

18.1 OUTLINE OF OIL,FUEL,COOLANT...130

18.2 OUTLINE OF ELECTRIC SYSTEM...133

18.3 OUTLINE OF HYDRAULIC SYSTEM...134

19.WEAR PARTS LIST...135

20.USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE...136

21.STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS...140

21.1 INTRODUCTION OF NECESSARY TOOLS...140

21.2 TORQUE LIST...141

22.PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...142

23.MAINTENANCE SCHEDULE CHART...145

23.1 MAINTENANCE SCHEDULE CHART...145

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER...147

24.SERVICE PROCEDURE...148

24.1 INITIAL 250 HOURS SERVICE...148

24.2 WHEN REQUIRED...149

24.3 CHECK BEFORE STARTING...171

24.4 EVERY 100 HOURS SERVICE...175

24.5 EVERY 250 HOURS SERVICE...176

24.6 EVERY 500 HOURS SERVICE...178

24.7 EVERY 1000 HOURS SERVICE...189

24.8 EVERY 2000 HOURS SERVICE...191

24.9 EVERY 4000 HOURS SERVICE...192

SPECIFICATIONS...196

25.SPECIFICATIONS...197

OPTIONS,ATTACHMENTS...205

26.GENERAL PRECAUTIONS...206

26.1 PRECAUTIONS RELATED TO SAFETY...206

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS...207

27.HANDLING BUCKET WITH HOOK...208

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK...208

27.2 PROHIBITED OPERATIONS...208

27.3 PRECAUTIONS DURING OPERATIONS...208

28.USING SEAT BELT...209

28.1 SEAT BELT...209

29.OPERATION OF CAR RADIO(MACHINE EQUIPPED WITH CAB)...211

29.1 EXPLANATION OF CONTROLS...211

29.2 OPERATION METHOD...213

29.3 PRECAUTIONS FOR USE...215

29.4 SPECIFICATIONS...216

30.OPERATION OF WINDOW WASHER(MACHINE EQUIPPED WITH CAB)...217

30.1 OPERATION OF WINDOW WASHER...217

30.2 CHECK AND REFILING OF WINDOW WASHER FLUID...217

31.INTRODUCTION OF ATTACHMENTS...218

31.1 SPECIFICATIONS AND USES...218

31.2 COMBINATIONS TABLE OF ATTACHMENTS...219

31.3 SELECTION OF TRACK SHOES(RUBBER SHOE,ROAD LINER)...220

31.4 CONSUMABLE PARTS OF BUCKET...221

31.5 HANDLING OF POWER ANGLE/POWER TILT BLADE...222

31.6 PRECAUTIONS FOR OPERATING WITH HYDRAULIC BREAKER...225

31.7 OPERATION OF MACHINE WHICH CAN BE EQUIPPED WITH ATTACHMENTS...228