Komatsu Hydraulic Excavator MX352, MX502 Repair Service Manual + Operator's Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator MX352, MX502, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator MX352, MX502 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,956 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

054-107-10 - MX45 Operator's Manual.pdf

054-108-10 - MX27, MX35 Opetator's Manual.pdf

054-109-10 - MX15 Operatoer's Manual.pdf

054-110-10 - MX9 Operator's Manual.pdf

SEAM061600 - Hydraulic Excavator MX352 Operation & Maintenance Manual.pdf

SEAM061700 - Hydraulic Excavator MX502 Operation & Maintenance Manual.pdf

SEBM035400 - MX352, MX502 Shop Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...3

SAFETY NOTICE...3

FOREWORD...5

GENERAL...5

HOW TO READ THE SHOP MANUAL...6

HOISTING INSTRUCTIONS...7

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER...8

COATING MATERIALS...10

STANDARD TIGHTENING TORQUE...12

ELECTRIC WIRE CODE...15

CONVERSION TABLE...16

UNITS...22

01 GENERAL...23

SPECIFICATION DIMENSION DRAWING...24

WORKING RANGE DRAWING...25

SPECIFICATIONS...26

WEIGHT TABLE...32

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS...34

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD...37

PTO...38

COOLING SYSTEM...40

POWER TRAIN...42

SWING CIRCLE...43

SWING MACHINERY...44

TRACK FRAME...48

IDLER CUSHION...49

IDLER...50

TRACK ROLLER...52

CARRIER ROLLER...54

SPROCKET...55

TRACK SHOE...56

HYDRAULIC COMPONENTS LAYOUT DRAWING...64

HYDRAULIC TANK...66

CENTER SWIVEL JOINT...69

TRAVEL MOTOR...71

HYDRAULIC CYLINDER...79

SOLENOID VALVE...83

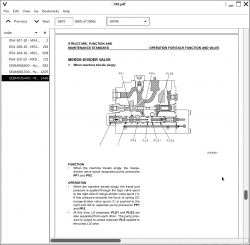

MULTI-CONTROL VALVE...86

HYDRAULIC PUMP...87

CONTROL VALVE...98

CLSS...112

OPERATION FOR EACH FUNCTION AND VALVE...116

SWING MOTOR...138

PPC VALVE...147

WORK EQUIPMENT...155

DIMENSIONS OF EACH PART OF WORK EQUIPMENT...158

FLOOR...164

AIR CONDITIONER...165

ENGINE CONTROL...166

ELECTRIC CONTROL SYSTEM...168

COMPONENT PARTS OF SYSTEM...173

MONITOR SYSTEM...174

MONITOR PANEL...175

SENSORS...177

20 TESTING AND ADJUSTING...179

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...180

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...182

TESTING AND ADJUSTING...197

LIST OF TESTING, ADJUSTING, AND TROUBLESHOOTING TOOLS...198

MEASURING ENGINE SPEED...200

MEASUREMENT OF EXHAUST GAS COLOR...201

ADJUSTING VALVE CLEARANCE...202

MEASURING COMPRESSION PRESSURE...205

MEASURING ENGINE OIL PRESSURE...206

TESTING AND ADJUSTING FUEL INJECTION TIMING...207

TESTING AND ADJUSTING ALTERNATOR BELT TENSION...209

ADJUSTING FUEL CONTROL LEVER...210

TESTING WEAR OF SPROCKET...211

TESTING AND ADJUSTING TRACK SHOE TENSION...212

MEASURING AND ADJUSTING OIL PRESSURES IN WORK EQUIPMENT, TRAVEL, BOOM SWING, SWING, AND BLADE CIRCUITS...213

MEASURING AND ADJUSTING LS DIFFERENTIAL PRESSURE...217

ADJUSTING PC VALVE...221

MEASURING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE...222

MEASURING SOLENOID VALVE OUTPUT PRESSURE...224

MEASURING PPC VALVE OUTPUT PRESSURE...226

ADJUSTING PPC VALVE...229

MEASURING SWING HOLDING BRAKE RELEASE PRESSURE...230

TESTING AND ADJUSTING TRAVEL DEVIATION...231

MEASUREMENT OF OIL LEAKAGE FROM WORK EQUIPMENT CYLINDER...233

BLEEDING AIR FROM EACH PART...235

RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT...238

RELEASING RESIDUAL PRESSURE FROM HYDRAULIC TANK...238

PRESSURIZING HYDRAULIC TANK...239

INSPECTION PROCEDURES FOR DIODE...240

TROUBLESHOOTING...241

POINTS TO REMEMBER WHEN TROUBLESHOOTING...242

SEQUENCE OF EVENTS IN TROUBLESHOOTING...243

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...244

CHECKS BEFORE TROUBLESHOOTING...252

CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING...253

TYPES AND LOCATIONS OF CONNECTORS...256

CONNECTOR ARRANGEMENT DIAGRAM...262

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...270

T-ADAPTER - BOXES AND T-ADAPTER TABLE...292

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...295

BEFORE STARTING E-MODE TROUBLESHOOTING...296

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...297

E-1 ENGINE DOES NOT START...298

E-2 ENGINE DOES NOT STOP...306

E-3 WHEN WORK EQUIPMENT LOCK (PPC BASIC PRESSURE LOCK) LEVER IS SET IN LOCK POSITION, WORK EQUIPMENT STILL MOVES...310

E-4 WINDSHIELD WIPER DOES NOT OPERATE...314

E-5 WINDSHIELD WASHER DOES NOT OPERATE...316

E-6 TRAVEL ALARM DOES NOT SOUND...320

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...323

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...324

H-1 SPEED OR POWER OF WHOLE WORK EQUIPMENT, TRAVEL, SWING, AND BLADE IS LOW...325

H-2 ENGINE SPEED LOWERS EXTREMELY OR ENGINE STALLS...329

H-3 WHOLE WORK EQUIPMENT, TRAVEL SYSTEM, SWING SYSTEM, AND BLADE DO NOT WORK...330

H-4 ABNORMAL SOUND COMES OUT FROM AROUND HYDRAULIC PUMP...333

H-5 FINE CONTROL PERFORMANCE OR RESPONSE IS LOW...333

H-6 SPEED OR POWER OF BOOM IS LOW...334

H-7 SPEED OR POWER OF ARM IS LOW...335

H-8 SPEED OR POWER OF BUCKET IS LOW...336

H-9 SPEED OR POWER OF BOOM SWING IS LOW...337

H-10 WORK EQUIPMENT DOES NOT MOVE SINGLY...338

H-11 WORK EQUIPMENT HYDRAULIC DRIFT IS LARGE...339

H-12 TIME LAG OF WORK EQUIPMENT IS LARGE...340

H-13 IN COMPOUND OPERATION OF WORK EQUIPMENT, SPEED OF PART LOADED MORE IS LOW...340

H-14 MACHINE DEVIATES DURING TRAVEL...341

H-15 TRAVEL SPEED OR TRAVEL POWER IS LOW (WHILE WORK EQUIPMENT IS NORMAL)...343

H-16 MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW...344

H-17 TRAVEL SPEED DOES NOT CHANGE...345

H-18 TRAVEL MOTOR DOES NOT WORK...346

H-19 SPEED OR POWER OF SWING IS LOW...348

H-20 MACHINE DOES NOT SWING...350

H-21 SWING ACCELERATION PERFORMANCE IS LOW...352

H-22 MACHINE OVERRUNS WHEN IT STOPS SWINGING...354

H-23 LARGE SHOCK IS MADE WHEN MACHINE STOPS SWINGING...355

H-24 WHEN UPPER STRUCTURE STOPS SWINGING, IT MAKES LARGE SOUND...355

H-25 HYDRAULIC DRIFT OF SWING IS LARGE...356

H-26 SPEED OR POWER OF BLADE IS LOW...357

H-27 BLADE DOES NOT MOVE...358

H-28 HYDRAULIC DRIFT OF BLADE IS LARGE...358

TROUBLESHOOTING OF MONITOR PANEL SYSTEM (M MODE)...359

BEFORE STARTING M-MODE TROUBLESHOOTING...360

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...361

SYSTEM DIAGRAM RELATED TO MONITOR PANEL...362

M-1 WHEN STARTING SWITCH IS TURNED ON, ANY ITEM DOES NOT OPERATE...364

M-2 WHEN STARTING SWITCH IS TURNED ON, SOME ITEMS DO NOT OPERATE...366

M-3 ALARM BUZZER IS ABNORMAL...367

M-4 ENGINE OIL PRESSURE CAUTION IS TURNED ON...369

M-5 CHARGE LEVEL CAUTION IS TURNED ON...370

M-6 PREHEATING SYSTEM DOES NOT OPERATE OR PREHEATER DOES NOT BECOME HOT...374

M-7 COOLANT TEMPERATURE GAUGE IS ABNORMAL...376

M-8 FUEL LEVEL GAUGE IS ABNORMAL...381

M-9 SERVICE METER DOES NOT OPERATE WHILE ENGINE IS RUNNING...385

M-10 2ND TRAVEL SPEED IS NOT SELECTED...387

M-11 WORKING LAMP DOES NOT LIGHT UP...392

TROUBLESHOOTING OF ENGINE (S MODE)...395

METHOD OF USING TROUBLESHOOTING CHARTS...396

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)...400

S-2 ENGINE DOES NOT START...402

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)...405

S-4 ENGINE STOPS DURING OPERATIONS...406

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)...407

S-6 ENGINE LACKS OUTPUT OR LACKS POWER...408

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)...409

S-8 OIL CONSUMPTION IS EXCESSIVE OR EXHAUST SMOKE IS BLUE...410

S-9 OIL BECOMES CONTAMINATED QUICKLY...411

S-10 FUEL CONSUMPTION IS EXCESSIVE...412

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN...413

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)...414

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)...415

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)...416

S-15 ABNORMAL NOISE IS MADE...417

S-16 VIBRATION IS EXCESSIVE...418

30 DISASSEMBLY AND ASSEMBLY...419

HOW TO READ THIS MANUAL...420

PRECAUTIONS WHEN PERFORMING OPERATION...422

SPECIAL TOOL LIST...424

SKETCHES OF SPECIAL TOOLS...428

REMOVAL AND INSTALLATION OF RADIATOR AND HYDRAULIC OIL COOLER...429

REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP...438

REMOVAL AND INSTALLATION OF TRACK SHOE...445

DISASSEMBLY AND ASSEMBLY OF IDLER...446

DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING...448

DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER...451

DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ...453

REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT...454

DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT...457

REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY...459

REMOVAL AND INSTALLATION OF SWING MOTOR AND SWING MACHINERY...463

DISASSEMBLY AND ASSEMBLY OF SWING MOTOR AND SWING MACHINERY...464

REMOVAL AND INSTALLATION OF WORK EQUIPMENT...470

REMOVAL AND INSTALLATION OF REVOLVING FRAME...472

REMOVAL AND INSTALLATION OF SWING CIRCLE...474

DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE...475

DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY...476

REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT...480

90 OTHERS...483

HYDRAULIC CIRCUIT DIAGRAM MX352...484

HYDRAULIC CIRCUIT DIAGRAM MX502...485

HYDRAULIC CIRCUIT DIAGRAM (Additional attachment circuit) MX502...486

ELECTRICAL CIRCUIT DIAGRAM MX352 (1/2)...487

ELECTRICAL CIRCUIT DIAGRAM MX352 (2/2)...488

ELECTRICAL CIRCUIT DIAGRAM MX502 (1/2)...489