YANMAR ViO45-5, ViO55-5 Excavators Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for YANMAR ViO45-5, ViO55-5 Excavators, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

YANMAR ViO45-5, ViO55-5 Excavators workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 568 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

YANMAR ViO45-5, ViO55-5 Excavators Service Manual.pdf

MAIN SECTIONS

CHAPTER 1

GENERAL CAUTIONS FOR MAINTENANCE WORK

1-1 Correct Work ..1-1

1-2 Safety Precautions ..1-1

1-3 Preparations ..1-1

1-4 Cautions for Disassembly and Reassembly..1-1

1-5 Cautions for Removal and Installation of Hydraulic Equipment ..1-2

1-6 Cautions for Removal and Installation of Hydraulic Piping..1-2

1-7 Cautions for Handling Seals..1-3

1-8 Correct Installation of Hydraulic Hose ..1-3

1-9 Specifications of Hydraulic Hose..1-6

1-10 Air Release of Hydraulic Equipment..1-11

CHAPTER 2

TECHNICAL DATA

2-1 Specifications .. 2-1-1

2-2 Outline Drawing and Working Area .. 2-2-1

2-2-1 Canopy type .. 2-2-1

2-2-2 Cabin type .. 2-2-2

2-3 Weight List of Main Parts .. 2-3-1

2-4 Lifting Capacity List .. 2-4-1

CHAPTER 3

SERVICE STANDARDS

3-1 Machine Performance .. 3-1-1

3-2 Engine .. 3-2-1

3-3 Undercarriage .. 3-3-1

3-3-1 Rubber Track Specifications .. 3-3-1

3-3-2 Steel Track Specifications .. 3-3-2

3-3-3 Common Specifications of Steel & Rubber Tracks .. 3-3-3

3-4 Controls .. 3-4-1

3-5 Hydraulic Equipment .. 3-5-1

3-5-1 Hydraulic Cylinders .. 3-5-1

3-6 Implement .. 3-6-1

3-6-1 Front Attachments .. 3-6-1

3-6-2 Blade Moving Device.. 3-6-2

3-6-3 Bucket Teeth .. 3-6-2

3-7 List of Tightening Torque .. 3-7-1

3-7-1 Machine.. 3-7-1

3-7-2 Engine .. 3-7-4

3-7-3 Tightening Torque for General Bolts and Nuts.. 3-7-4CHAPTER 4

ENGINE

4-1 General .. 4-1-1

4-1-1 How to Read This Manual .. 4-1-1

4-1-2 Precautions for Service Work.. 4-1-3

4-1-3 Engine External Views .. 4-1-4

4-1-4 Structural Description .. 4-1-4

4-1-5 Exhaust Gas Emission Regulation .. 4-1-5

4-2 Troubleshooting .. 4-2-1

4-2-1 Quick Reference Table for Troubleshooting.. 4-2-1

4-2-2 Troubleshooting by Measuring Compression Pressure .. 4-2-4

4-3 Inspection and Adjustment ..4-1

4-3-1 Oil Inspection.. 4-3-1

4-3-2 Cooling Water Inspection .. 4-3-1

4-3-3 Inspecting Water Leak from Cooling Water System and Radiator .. 4-3-1

4-3-4 Fan Belt Tension Inspection and Adjustment.. 4-3-2

4-3-5 Adjusting the Valve Clearance .. 4-3-3

4-3-6 Inspecting the Fuel Injection Valve Injection Pressure and Spray Pattern.. 4-3-5

4-3-7 Fuel Injection Timing Adjustment / Fuel Injection Pump Inspection and Adjustment .. 4-3-9

4-3-8 Sensor Inspection.. 4-3-12

4-3-9 Battery Inspection.. 4-3-13

4-3-10 Adjusting Operation.. 4-3-15

4-3-11 Long Storage.. 4-3-16

4-3-12 Periodic Maintenance Schedule.. 4-3-17

4-4 Engine Body.. 4-4-1

4-4-1 Introduction.. 4-4-1

4-4-2 Cylinder Head.. 4-4-2

4-4-3 Gear Train and Camshaft.. 4-4-11

4-4-4 Cylinder Block .. 4-4-16

4-5 Lubrication System.. 4-5-1

4-5-1 Lubrication System Diagram .. 4-5-1

4-5-2 Trochoid Pump Components.. 4-5-1

4-5-3 Disassembly (Reverse the Procedure Below for Assembly) .. 4-5-1

4-5-4 Servicing Points.. 4-5-2

4-5-5 Parts Inspection and Measurement.. 4-5-2

4-6 Cooling System .. 4-6-1

4-6-1 Cooling Water System.. 4-6-1

4-6-2 Cooling Water Pump Components.. 4-6-1

4-6-3 Disassembly (Reverse the Procedure Below for Assembly) .. 4-6-2

4-6-4 Servicing Points.. 4-6-2

4-7 Fuel Injection Pump / Governor.. 4-7-1

4-7-1 Introduction.. 4-7-1

4-7-2 Fuel Injection Pump.. 4-7-1

4-8 Electrical Equipment .. 4-8-1

4-8-1 Starter Motor .. 4-8-1

4-8-2 Alternator.. 4-8-3

4-8-3 Air Heater .. 4-8-6CHAPTER 5

HYDRAULIC SYSTEM

5-1 Outline .. 5-1-1

5-1-1 Control Valve Operation .. 5-1-4

5-1-2 Additional Operation of Control Valve .. 5-1-6

5-2 Hydraulic Circuit Schematic .. 5-2-1

5-2-1 Quick Coupler.. 5-2-1

5-2-2 W/O Quick Coupler .. 5-2-2

5-3 Circuit Operation .. 5-3-1

5-3-1 Boom .. 5-3-1

5-3-2 Arm.. 5-3-3

5-3-3 Bucket .. 5-3-5

5-3-4 Swing.. 5-3-7

5-3-5 Boom Swing .. 5-3-9

5-3-6 Blade .. 5-3-11

5-3-7 Travel .. 5-3-13

5-3-8 Non-Deviation Travel (with Boom, Arm or Boom Swing Operation).. 5-3-15

5-3-9 Non-Deviation Travel (with Bucket Operation) .. 5-3-17

5-3-10 Simultaneous Operation of Boom Up and Arm Retract.. 5-3-19

5-3-11 Simultaneous Operation of Boom Up and Bucket.. 5-3-21

5-3-12 Simultaneous Operation of Boom Up and Swing .. 5-3-23

5-3-13 Simultaneous Operation of Arm and Bucket .. 5-3-25

5-3-14 Hydraulic P.T.O. .. 5-3-27

5-3-15 Quick Coupler.. 5-3-29

5-4 Pressure Adjustment .. 5-4-1

5-4-1 Relief Valves .. 5-4-1

5-4-2 Swing Brake Valve .. 5-4-3

5-4-3 Cut-Off Valve.. 5-4-4

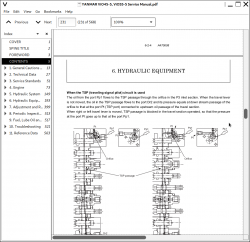

CHAPTER 6

HYDRAULIC EQUIPMENT

6-1 Hydraulic Pump .. 6-1-1

6-2 Control Valve.. 6-2-1

6-3 Pilot Valve .. 6-3-1

6-4 Swing Motor .. 6-4-1

6-5 Travel Motor .. 6-5-1

6-6 Blade Control Pilot Valve .. 6-6-1

6-7 Solenoid Valve for P.T.O. Operation .. 6-7-1

6-8 Pilot Check Valve (For Quick Coupler Circuit) .. 6-8-1CHAPTER 7

ADJUSTMENT AND REPAIR

7-1 Electric Equipment of Machine.. 7-1-1

7-1-1 Parts Layout of Electrical Equipment .. 7-1-1

7-1-2 Monitor and Alarm Systems .. 7-1-3

7-1-3 Wiring Diagram.. 7-1-6

7-1-4 Circuit Description of Engine Start and Stop, and Battery Charging .. 7-1-7

7-1-5 Removal and Reinstallation of Engine .. 7-1-9

7-1-6 Removal and Reassembly of Starter Motor .. 7-1-18

7-1-7 Removal and Reassembly of Drive Belts for Generator and Compressor .. 7-1-19

7-2 Undercarriage .. 7-2-1

7-2-1 Outline .. 7-2-1

7-2-2 Main Parts .. 7-2-1

7-2-3 Points of Reassembly (Rubber Track) .. 7-2-2

7-2-4 Points of Reassembly (Steel Track) .. 7-2-3

7-2-5 Removal and Reinstallation of Track.. 7-2-4

7-2-6 Removal and Reinstallation of Steel Track .. 7-2-5

7-2-7 Disassembly and Reassembly of Front Idler .. 7-2-8

7-2-8 Disassembly and Reassembly of Track Roller .. 7-2-10

7-2-9 Installation of Floating Seal .. 7-2-12

7-2-10 Drawings of Jigs .. 7-2-13

7-2-11 Disassembly and Reassembly of Carrier Roller.. 7-2-15

7-3 Controls .. 7-3-1

7-3-1 Control Train.. 7-3-1

7-3-2 Mechanical Control Linkage .. 7-3-2

7-3-3 Adjustment of Travel Levers.. 7-3-4

7-3-4 Adjustment of Boom Swing Pedal .. 7-3-5

7-3-5 Adjustment of Lock Lever.. 7-3-6

7-3-6 Adjustment Procedure of Travel Alarm Switch .. 7-3-7

7-3-7 Adjustment Procedure of P.T.O. Pedal .. 7-3-8

7-3-8 Adjustment Procedure of P.T.O. Pedal Lock.. 7-3-8

7-3-9 Adjustment of Accelerator Lever .. 7-3-9

7-4 Swing Bearing .. 7-4-1

7-5 Hydraulic Equipment .. 7-5-1

7-5-1 Removal and Reinstallation of Hydraulic Pump .. 7-5-1

7-5-2 Removal and Reinstallation of Control Valve .. 7-5-3

7-5-3 Removal and Reinstallation of Swing Motor.. 7-5-6

7-5-4 Removal and Reinstallation of Swivel Joint.. 7-5-9

7-5-5 Disassembly and Reassembly of Swivel Joint .. 7-5-13

7-5-6 Disassembly and Reassembly of Hydraulic Cylinders .. 7-5-16

7-5-7 Hydraulic Oil Tank .. 7-5-20

7-5-8 Piping Layout.. 7-5-26

7-6 Work Implements .. 7-6-1

7-6-1 Removal and Reinstallation of Work Implements.. 7-6-1

7-6-2 Quick Coupler.. 7-6-107-7 Cabin.. 7-7-1

7-7-1 Cabin .. 7-7-1

CHAPTER 8

Periodic Inspection and Servicing

8-1 List of Periodic Inspection and Servicing..8-1

CHAPTER 9

FUEL, LUBE OIL AND GREASE RECOMMENDED

9. Fuel, Lube Oil and Grease Recommended ..9-1

CHAPTER 10

TROUBLESHOOTING

10-1 Non-breakdowns .. 10-1-1

10-1-1 Natural Release of Bucket.. 10-1-1

10-1-2 Discontinuous Arm Movement .. 10-1-1

10-1-3 Drifting of Upperstructure on Quick Travel Operation .. 10-1-2

10-1-4 Thermal Shock of Travel Motor .. 10-1-3

10-1-5 Elongation of Boom Swing Cylinder on 70 degrees Swing .. 10-1-4

10-1-6 Telescopic Motion of Boom Swing Cylinder with Lock Lever Set to Lock Position .. 10-1-5

10-1-7 Time Lag on Travel Speed Switching.. 10-1-6

10-1-8 Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change.. 10-1-7

10-1-9 Operation of Quick Coupler Cylinder (for Quick Coupler Type) .. 10-1-8

10-2 Troubleshooting .. 10-2-1

10-2-1 Machine and Engine.. 10-2-1

10-2-2 Electrical Equipment on Panel .. 10-2-23

CHAPTER 11

REFERENCE DATA

11-1 Dimensions and Specifications for Attachment ..11-1

TABLE OF CONTENTS

SPINE TITLE...2

FOREWORD...3

CONTENTS...5

1. General Cautions for Maintenance Work...13

1-1 Correct Work...13

1-2 Safety Precautions...13

1-3 Preparations...13

1-4 Cautions for Disassembly and Reassembly...13

1-5 Cautions for Removal and Installation of Hydraulic Equipment...14

1-6 Cautions for Removal and Installation of Hydraulic Piping...14

1-7 Cautions for Handling Seals...15

1-8 Correct Installation of Hydraulic Hose...15

1-9 Specifications of Hydraulic Hose...18

1-10 Air Release of Hydraulic Equipment...23

2. Technical Data...27

2-1 Specifications...27

2-2 Outline Drawing and Working Area...40

2-2-1 Canopy type...40

2-2-2 Cabin type...41

2-3 Weight List of Main Parts...42

2-4 Lifting Capacity List...44

3. Service Standards...51

3-1 Machine Performance...51

3-2 Engine...55

3-3 Undercarriage...59

3-3-1 Rubber Track Specifications...59

3-3-2 Steel Track Specifications...60

3-3-3 Common Specifications of Steel & Rubber Tracks...61

3-4 Controls...62

3-5 Hydraulic Equipment...63

3-5-1 Hydraulic Cylinders...63

3-6 Implement...64

3-6-1 Front Attachments...64

3-6-2 Blade Moving Device...65

3-6-3 Bucket Teeth...65

3-7 List of Tightening Torque...66

3-7-1 Machine...66

3-7-2 Engine...69

3-7-3 Tightening Torque for General Bolts and Nuts...69

4. Engine...73

4-1 General...73

4-1-1 How to Read This Manual...73

4-1-2 Precautions for Service Work...75

4-1-3 Engine External Views...76

4-1-4 Structural Description...76

4-1-5 Exhaust Gas Emission Regulation...77

4-2 Troubleshooting...0

4-2-1 Quick Reference Table for Troubleshooting...81

4-2-2 Troubleshooting by Measuring Compression Pressure...85

4-3 Inspection and Adjustment...87

4-3-1 Oil Inspection...87

4-3-2 Cooling Water Inspection...87

4-3-3 Inspecting Water Leak from Cooling Water System and Radiator...87

4-3-4 Fan Belt Tension Inspection and Adjustment...88

4-3-5 Adjusting the Valve Clearance...89

4-3-6 Inspecting the Fuel Injection Valve Injection Pressure and Spray Pattern...91

4-3-7 Fuel Injection Timing Adjustment / Fuel Injection Pump Inspection and Adjustment...95

4-3-8 Sensor Inspection...98

4-3-9 Battery Inspection...99

4-3-10 Adjusting Operation...101

4-3-11 Long Storage...102

4-3-12 Periodic Maintenance Schedule...103

4-4 Engine Body...104

4-4-1 Introduction...104

4-4-2 Cylinder Head...105

4-4-3 Gear Train and Camshaft...114

4-4-4 Cylinder Block...119

4-5 Lubrication System...133

4-5-1 Lubrication System Diagram...133

4-5-2 Trochoid Pump Components...133

4-5-3 Disassembly (Reverse the Procedure Below for Assembly)...133

4-5-4 Servicing Points...134

4-5-5 Parts Inspection and Measurement...134

4-6 Cooling System...135

4-6-1 Cooling Water System...135

4-6-2 Cooling Water Pump Components...135

4-6-3 Disassembly (Reverse the Procedure Below for Assembly)...136

4-6-4 Servicing Points...136

4-7 Fuel Injection Pump / Governor...137

4-7-1 Introduction...137

4-7-2 Fuel Injection Pump...137

4-8 Electrical Equipment...141

4-8-1 Starter Motor...141

4-8-2 Alternator...143

4-8-3 Air Heater...146

5. Hydraulic System...149

5-1 Outline...149

5-1-1 Control Valve Operation...152

5-1-2 Additional Operation of Control Valve...154

5-2 Hydraulic Circuit Schematic...155

5-3 Circuit Operation...157

5-3-1 Boom...157

5-3-2 Arm...159

5-3-3 Bucket...161

5-3-4 Swing...163

5-3-5 Boom Swing...165

5-3-6 Blade...167

5-3-7 Travel...169

5-3-8 Non-Deviation Travel (with Boom, Arm orBoom Swing Operation)...171

5-3-9 Non-Deviation Travel (with Bucket Operation)...173

5-3-10 Simultaneous Operation of Boom Upand Arm Retract...175

5-3-11 Simultaneous Operation of Boom Upand Bucket...177

5-3-12 Simultaneous Operation of Boom Upand Swing...179

5-3-13 Simultaneous Operation of Arm andBucket...181

5-3-14 Hydraulic P.T.O...183

5-3-15 Quick Coupler...185

5-4 Pressure Adjustment...187

5-4-1 Relief Valves...187

5-4-2 Swing Brake Valve...189

5-4-3 Cut-Off Valve...190

6. Hydraulic Equipment...193

6-1 Hydraulic Pump...193

6-2 Control Valve...227

1. Outline...227

2. Operation...228

3. Operation of Directional Control Valves...230

4. Disassembly and Reassembly...253

5. Disassembly and Reassembly of Relief Valves...263

6. 2-way Valve...274

7. Service Standard...283

8. Troubleshooting...283

6-3 Pilot Valve...284

6-4 Swing Motor...294

6-5 Travel Motor...325

6-6 Blade Control Pilot Valve...370

6-7 Solenoid Valve for P.T.O. Operation...385

6-8 Pilot Check Valve (For Quick Coupler Circuit)...388

7. Adjustment and Repair...399

7-1 Electric Equipment of Machine...399

7-1-1 Parts Layout of Electrical Equipment...399

7-1-2 Monitor and Alarm Systems...401

7-1-5 Removal and Reinstallation of Engine...409

7-1-6 Removal and Reassembly of Starter Motor...418

7-1-7 Removal and Reassembly of Drive Belts for Generator and Compressor...419

7-2 Undercarriage...420

7-2-1 Outline...420

7-2-2 Main Parts...420

7-2-3 Points of Reassembly (Rubber Crawler)...421

7-2-4 Points of Reassembly (Steel Crawler)...422

7-2-5 Removal and Reinstallation of Crawler...423

7-2-6 Removal and Reinstallation of Steel Crawler...424

7-2-7 Disassembly and Reassembly of Front Idler...427

7-2-8 Disassembly and Reassembly of Track Roller...429

7-2-9 Installation of Floating Seal...431

7-2-10 Drawings of Jigs...432

7-2-11 Disassembly and Reassembly of Carrier Roller...434

7-3 Controls...436

7-3-1 Control Train...436

7-3-2 Mechanical Control Linkage...437

7-3-3 Adjustment of Travel Levers...439

7-3-4 Adjustment of Boom Swing Pedal...440

7-3-5 Adjustment of Lock Lever...441

7-3-6 Adjustment Procedure of Travel Alarm Switch...442

7-3-7 Adjustment Procedure of P.T.O. Pedal...443

7-3-8 Adjustment Procedure of P.T.O. Pedal Lock...443

7-3-9 Adjustment of Accelerator Lever...444

7-4 Swing Bearing...445

7-5 Hydraulic Equipment...447

7-5-1 Removal and Reinstallation of Hydraulic Pump...447

7-5-2 Removal and Reinstallation of Control Valve...449

7-5-3 Removal and Reinstallation of Swing Motor...452

7-5-4 Removal and Reinstallation of Swivel Joint...455

7-5-5 Disassembly and Reassembly of Swivel Joint...459

7-5-6 Disassembly and Reassembly of Hydraulic Cylinders...462

7-5-7 Hydraulic Oil Tank...466

7-5-8 Piping Layout...472

7-6 Work Implements...482

7-6-1 Removal and Reinstallation of Work Implements...482

7-6-2 Quick Coupler...491

7-7 Cabin...494

7-7-1 Cabin...494

8. Periodic Inspection and Servicing...513

8-1 List of Periodic Inspection and Servicing...513

9. Fuel, Lube Oil and Grease Recommended...517

10. Troubleshooting...521

10-1 Non-breakdowns...521

10-1-1 Natural Release of Bucket...521

10-1-2 Discontinuous Arm Movement...521

10-1-3 Drifting of Upperstructure on Quick Travel Operation...522

10-1-4 Thermal Shock of Travel Motor...523

10-1-5 Elongation of Boom Swing Cylinder on 70 degrees Swing...524

10-1-6 Telescopic Motion of Boom Swing Cylinder with Lock Lever Set to Lock Position...525

10-1-7 Time Lag on Travel Speed Switching...526

10-1-8 Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change...527

10-1-9 Operation of Quick Coupler Cylinder (for Quick Coupler Type)...528

10-2 Troubleshooting...529

10-2-1 Machine and Engine...529

10-2-2 Electrical Equipment on Panel...551

11. Reference Data...563

11-1 Dimensions and Specifications for Attachment...563