YANMAR ViO35-6A Excavator Repair Service Manual (OBKB3-U00100 )

Complete service repair manual with Electrical Wiring Diagrams for YANMAR ViO35-6A Excavator, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

YANMAR ViO35-6A Excavator workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 686 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

OBKB3-U00100 - YANMAR ViO35-6A Excavator Service Manual.pdf

MAIN SECTIONS

TABLE OF CONTENTS

CHAPTER 1

GENERAL CAUTIONS FOR MAINTENANCE WORK

1-1 Correct Work ..1-1

1-2 Safety Precautions ..1-1

1-3 Preparations ..1-1

1-4 Cautions for Disassembly and Reassembly..1-1

1-5 Cautions for Removal and Installation of Hydraulic Equipment ..1-2

1-6 Cautions for Removal and Installation of Hydraulic Piping..1-2

1-7 Cautions for Handling Seals..1-3

1-8 Correct Installation of Hydraulic Hose ..1-3

1-9 Specifications of Hydraulic Hose..1-6

1-10 Air Release of Hydraulic Equipment..1-11

CHAPTER 2

TECHNICAL DATA

2-1 Specifications .. 2-1-1

2-2 Outline Drawing and Working Area .. 2-2-1

2-2-1 Canopy type .. 2-2-1

2-2-2 Cabin type .. 2-2-2

2-3 Weight List of Main Parts .. 2-3-1

2-4 Lifting Capacity List .. 2-4-1

CHAPTER 3

SERVICE STANDARDS

3-1 Machine Performance .. 3-1-1

3-2 Engine .. 3-2-1

3-3 Undercarriage .. 3-3-1

3-3-1 Rubber Track Specifications .. 3-3-1

3-3-2 Steel Track Specifications .. 3-3-2

3-3-3 Common Specifications of Steel & Rubber Tracks .. 3-3-3

3-4 Controls .. 3-4-1

3-5 Hydraulic Equipment .. 3-5-1

3-5-1 Hydraulic Cylinders .. 3-5-1

3-6 Implement .. 3-6-1

3-6-1 Front Attachments .. 3-6-1

3-6-2 Blade Moving Device.. 3-6-2

3-6-3 Bucket Teeth .. 3-6-2

3-7 List of Tightening Torque .. 3-7-1

3-7-1 Machine.. 3-7-1

3-7-2 Engine .. 3-7-4

3-7-3 Tightening Torque for General Bolts and Nuts.. 3-7-4CHAPTER 4

ENGINE

4-1 General .. 4-1-1

4-1-1 How to Read This Manual .. 4-1-1

4-1-2 Precautions for Service Work.. 4-1-3

4-1-3 Engine External Views .. 4-1-4

4-1-4 Structural Description .. 4-1-4

4-1-5 Exhaust Gas Emission Regulation .. 4-1-5

4-2 Troubleshooting .. 4-2-1

4-2-1 Quick Reference Table for Troubleshooting.. 4-2-1

4-2-2 Troubleshooting by Measuring Compression Pressure .. 4-2-4

4-3 Inspection and Adjustment ..4-1

4-3-1 Oil Inspection.. 4-3-1

4-3-2 Cooling Water Inspection .. 4-3-1

4-3-3 Inspecting Water Leak from Cooling Water System and Radiator .. 4-3-1

4-3-4 Fan Belt Tension Inspection and Adjustment.. 4-3-2

4-3-5 Adjusting the Valve Clearance .. 4-3-3

4-3-6 Inspecting the Fuel Injection Valve Injection Pressure and Spray Pattern.. 4-3-5

4-3-7 Fuel Injection Timing Adjustment / Fuel Injection Pump Inspection and Adjustment .. 4-3-9

4-3-8 Sensor Inspection.. 4-3-12

4-3-9 Battery Inspection.. 4-3-13

4-3-10 Adjusting Operation.. 4-3-15

4-3-11 Long Storage.. 4-3-16

4-3-12 Periodic Maintenance Schedule.. 4-3-17

4-4 Engine Body.. 4-4-1

4-4-1 Introduction.. 4-4-1

4-4-2 Cylinder Head.. 4-4-2

4-4-3 Gear Train and Camshaft.. 4-4-11

4-4-4 Cylinder Block .. 4-4-16

4-5 Lubrication System.. 4-5-1

4-5-1 Lubrication System Diagram .. 4-5-1

4-5-2 Trochoid Pump Components.. 4-5-1

4-5-3 Disassembly (Reverse the Procedure Below for Assembly) .. 4-5-1

4-5-4 Servicing Points.. 4-5-2

4-5-5 Parts Inspection and Measurement.. 4-5-2

4-6 Cooling System .. 4-6-1

4-6-1 Cooling Water System.. 4-6-1

4-6-2 Cooling Water Pump Components.. 4-6-1

4-6-3 Disassembly (Reverse the Procedure Below for Assembly) .. 4-6-2

4-6-4 Servicing Points.. 4-6-2

4-7 Fuel Injection Pump / Governor.. 4-7-1

4-7-1 Introduction.. 4-7-1

4-7-2 Fuel Injection Pump.. 4-7-1

4-8 Electrical Equipment .. 4-8-1

4-8-1 Starter Motor .. 4-8-1

4-8-2 Alternator.. 4-8-3

4-8-3 Air Heater .. 4-8-6CHAPTER 5

HYDRAULIC SYSTEM

5-1 Outline .. 5-1-1

5-1-1 Control Valve Operation .. 5-1-4

5-1-2 Additional Operation of Control Valve .. 5-1-6

5-2 Hydraulic Circuit Schematic .. 5-2-1

5-2-1 Quick Coupler.. 5-2-1

5-2-2 W/O Quick Coupler .. 5-2-2

5-3 Circuit Operation .. 5-3-1

5-3-1 Boom .. 5-3-1

5-3-2 Arm.. 5-3-3

5-3-3 Bucket .. 5-3-5

5-3-4 Swing.. 5-3-7

5-3-5 Boom Swing .. 5-3-9

5-3-6 Blade .. 5-3-11

5-3-7 Travel .. 5-3-13

5-3-8 Non-Deviation Travel (with Boom, Arm or Boom Swing Operation).. 5-3-15

5-3-9 Non-Deviation Travel (with Bucket Operation) .. 5-3-17

5-3-10 Simultaneous Operation of Boom Up and Arm Retract.. 5-3-19

5-3-11 Simultaneous Operation of Boom Up and Bucket.. 5-3-21

5-3-12 Simultaneous Operation of Boom Up and Swing .. 5-3-23

5-3-13 Simultaneous Operation of Arm and Bucket .. 5-3-25

5-3-14 Hydraulic P.T.O. .. 5-3-27

5-3-15 Quick Coupler.. 5-3-29

5-4 Pressure Adjustment .. 5-4-1

5-4-1 Relief Valves .. 5-4-1

5-4-2 Swing Brake Valve .. 5-4-3

5-4-3 Cut-Off Valve.. 5-4-4

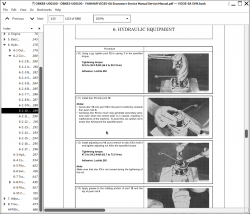

CHAPTER 6

HYDRAULIC EQUIPMENT

6-1 Hydraulic Pump .. 6-1-1

6-2 Control Valve.. 6-2-1

6-3 Pilot Valve .. 6-3-1

6-4 Swing Motor .. 6-4-1

6-5 Travel Motor .. 6-5-1

6-6 Blade Control Pilot Valve .. 6-6-1

6-7 Solenoid Valve for P.T.O. Operation .. 6-7-1

6-8 Pilot Check Valve (For Quick Coupler Circuit) .. 6-8-1CHAPTER 7

ADJUSTMENT AND REPAIR

7-1 Electric Equipment of Machine.. 7-1-1

7-1-1 Parts Layout of Electrical Equipment .. 7-1-1

7-1-2 Monitor and Alarm Systems .. 7-1-3

7-1-3 Wiring Diagram.. 7-1-6

7-1-4 Circuit Description of Engine Start and Stop, and Battery Charging .. 7-1-7

7-1-5 Removal and Reinstallation of Engine .. 7-1-9

7-1-6 Removal and Reassembly of Starter Motor .. 7-1-18

7-1-7 Removal and Reassembly of Drive Belts for Generator and Compressor .. 7-1-19

7-2 Undercarriage .. 7-2-1

7-2-1 Outline .. 7-2-1

7-2-2 Main Parts .. 7-2-1

7-2-3 Points of Reassembly (Rubber Track) .. 7-2-2

7-2-4 Points of Reassembly (Steel Track) .. 7-2-3

7-2-5 Removal and Reinstallation of Track.. 7-2-4

7-2-6 Removal and Reinstallation of Steel Track .. 7-2-5

7-2-7 Disassembly and Reassembly of Front Idler .. 7-2-8

7-2-8 Disassembly and Reassembly of Track Roller .. 7-2-10

7-2-9 Installation of Floating Seal .. 7-2-12

7-2-10 Drawings of Jigs .. 7-2-13

7-2-11 Disassembly and Reassembly of Carrier Roller.. 7-2-15

7-3 Controls .. 7-3-1

7-3-1 Control Train.. 7-3-1

7-3-2 Mechanical Control Linkage .. 7-3-2

7-3-3 Adjustment of Travel Levers.. 7-3-4

7-3-4 Adjustment of Boom Swing Pedal .. 7-3-5

7-3-5 Adjustment of Lock Lever.. 7-3-6

7-3-6 Adjustment Procedure of Travel Alarm Switch .. 7-3-7

7-3-7 Adjustment Procedure of P.T.O. Pedal .. 7-3-8

7-3-8 Adjustment Procedure of P.T.O. Pedal Lock.. 7-3-8

7-3-9 Adjustment of Accelerator Lever .. 7-3-9

7-4 Swing Bearing .. 7-4-1

7-5 Hydraulic Equipment .. 7-5-1

7-5-1 Removal and Reinstallation of Hydraulic Pump .. 7-5-1

7-5-2 Removal and Reinstallation of Control Valve .. 7-5-3

7-5-3 Removal and Reinstallation of Swing Motor.. 7-5-6

7-5-4 Removal and Reinstallation of Swivel Joint.. 7-5-9

7-5-5 Disassembly and Reassembly of Swivel Joint .. 7-5-13

7-5-6 Disassembly and Reassembly of Hydraulic Cylinders .. 7-5-16

7-5-7 Hydraulic Oil Tank .. 7-5-20

7-5-8 Piping Layout.. 7-5-26

7-6 Work Implements .. 7-6-1

7-6-1 Removal and Reinstallation of Work Implements.. 7-6-1

7-6-2 Quick Coupler.. 7-6-107-7 Cabin.. 7-7-1

7-7-1 Cabin .. 7-7-1

CHAPTER 8

Periodic Inspection and Servicing

8-1 List of Periodic Inspection and Servicing..8-1

CHAPTER 9

FUEL, LUBE OIL AND GREASE RECOMMENDED

9. Fuel, Lube Oil and Grease Recommended ..9-1

CHAPTER 10

TROUBLESHOOTING

10-1 Non-breakdowns .. 10-1-1

10-1-1 Natural Release of Bucket.. 10-1-1

10-1-2 Discontinuous Arm Movement .. 10-1-1

10-1-3 Drifting of Upperstructure on Quick Travel Operation .. 10-1-2

10-1-4 Thermal Shock of Travel Motor .. 10-1-3

10-1-5 Elongation of Boom Swing Cylinder on 70 degrees Swing .. 10-1-4

10-1-6 Telescopic Motion of Boom Swing Cylinder with Lock Lever Set to Lock Position .. 10-1-5

10-1-7 Time Lag on Travel Speed Switching.. 10-1-6

10-1-8 Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change.. 10-1-7

10-1-9 Operation of Quick Coupler Cylinder (for Quick Coupler Type) .. 10-1-8

10-2 Troubleshooting .. 10-2-1

10-2-1 Machine and Engine.. 10-2-1

10-2-2 Electrical Equipment on Panel .. 10-2-23

CHAPTER 11

REFERENCE DATA

11-1 Dimensions and Specifications for Attachment ..11-1

TABLE OF CONTENTS

COVER...1

FOREWORD...2

CONTENTS...3

1. General Cautions for Maintenance Work...9

1-1 Correct Work...9

1-2 Safety Precautions...9

1-3 Preparations...9

1-4 Cautions for Disassembly and Reassembly...9

1-5 Cautions for Removal and Installation of Hydraulic Equipment...10

1-6 Cautions for Removal and Installation of Hydraulic Piping...10

1-7 Cautions for Handling Seals...11

1-8 Correct Installation of Hydraulic Hose...11

1-9 Specifications of Hydraulic Hose...14

1-10 Air Release of Hydraulic Equipment...16

2. Technical Data...19

2-1 Specifications...19

2-2 Outline Drawing and Working Area...27

2-3 Weight List of Main Parts...31

2-4 Lifting Capacity List...32

2-5 Specifications for Attachment...34

2-6 Periodic Inspection and Servicing...35

2-7 Fuel, Lube Oil and Grease Recommended...37

2-8 Hydraulic Circuit Schematic...38

2-9 Wiring Diagram...39

3. Service Standards...46

3-1 Machine Performance...46

3-2 Engine...50

3-3 Undercarriage...55

3-3-1 Rubber Crawler Specifications...55

3-3-2 Steel Crawler Specifications...56

3-3-3 Common Specifications of Steel & Rubber Crawlers...57

3-4 Controls...58

3-5 Hydraulic Equipment...59

3-5-1 Hydraulic Cylinders...59

3-6 Implement...60

3-6-1 Front Attachments...60

3-6-2 Blade Moving Device...61

3-6-3 Bucket Teeth...61

3-7 List of Tightening Torque...62

3-7-1 Machine...62

3-7-2 Engine...67

3-7-3 Tightening Torque for General Bolts and Nuts...68

3-7-4 Hydraulic Fitting...69

3-8 Pressure Adjustment...70

3-8-1 Relief Valves...70

3-8-2 Swing Brake Valve...73

3-8-3 Cut-Off Valve...74

4. Engine...76

4-1 Engine...76

4-1-1 Safety Precautions...76

4-1-2 Introduction...96

4-1-3 Special Service Tools...97

4-1-4 Measuring Instruments...99

4-1-5 2-Valve Cylinder Head...101

4-1-6 Measuring and Adjusting Valve Clearance...116

4-1-7 Crankshaft and Camshaft Components...118

4-1-8 EGR System...145

4-2 Fuel System...151

4-2-1 Before You Begin Servicing...151

4-2-2 Introduction...156

4-2-3 Special Service Tools...159

4-2-4 Measuring Instruments...159

4-2-5 Fuel System Diagram...160

4-2-6 Fuel System Components...161

4-2-7 Fuel Injection Pump...163

4-2-8 Fuel Injectors...179

4-3 Cooling System...186

4-3-1 Before You Begin Servicing...186

4-3-2 Introduction...188

4-3-3 Cooling System Diagram...188

4-3-4 Engine Coolant Pump Components...189

4-3-5 Engine Coolant System Check...190

4-3-6 Engine Coolant Pump...190

4-4 Lubrication System...195

4-4-1 Before You Begin Servicing...195

4-4-2 Introduction...197

4-4-3 Lubrication System Diagram...197

4-4-4 Checking Engine Oil Pressure...198

4-4-5 Trochoid Oil Pump...198

4-5 Starter Motor...202

4-5-1 Before You Begin Servicing...202

4-5-2 Introduction...204

4-5-3 Starter Motor Specifications...204

4-5-4 Starter Motor Troubleshooting...205

4-5-5 Starter Motor Components...206

4-5-6 Starter Motor...207

4-6 Alternator...217

4-6-1 Before You Begin Servicing...217

4-6-2 Introduction...220

4-6-3 Alternator Specifications...220

4-6-4 Alternator Troubleshooting...221

4-6-5 Alternator Components...222

4-6-6 Alternator Wiring Diagram...223

4-6-7 Alternator Standard Output...224

4-6-8 Alternator...225

4-7 Electronic Control System...230

4-7-1 Engines available with the electronic control system...230

4-7-2 Before You Begin Servicing...230

4-7-3 Main Electronic Control Components and Features...233

4-8 Electric Wiring...235

4-8-1 Electric Wiring Precautions...235

4-9 Failure Diagnosis...236

4-9-1 Special Service Tools...236

4-9-2 Troubleshooting By Measuring Compression Pressure...237

5. Electric System...245

5-1 Electric Equipment of Machine...245

5-1-1 Parts Layout of Electrical Equipment...245

5-1-2 LCD Monitor and Alarm Systems...250

5-2 Electronic Control System...256

5-2-1 Start/Stop Control...256

5-2-2 Circuit Description of Engine Start, Stop and Battery Charging...257

5-3 Engine ECU (engine controller)...260

5-3-1 Engine ECU...260

5-3-2 Circuit Description of Auto Deceleration Mode...261

5-3-3 Circuit Description of Eco Mode...263

5-3-4 Engine Speed and Output Control...265

5-4 Hydraulic ECU (Controller)...266

5-5 Error Code List...268

6. Hydraulic System...276

6-1 Outline...276

6-1-1 Control Valve Operation...278

6-1-2 Additional Operation of Control Valve...279

6-2 Circuit Operation...280

6-2-1 Boom...280

6-2-2 Arm...281

6-2-3 Bucket...282

6-2-4 Swing...283

6-2-5 Boom Swing...284

6-2-6 Blade...285

6-2-7 Travel...286

6-2-8 Non-Deviation Travel (with Boom, Arm or Boom Swing Operation)...287

6-2-9 Non-Deviation Travel (with Bucket Operation)...288

6-2-10 Simultaneous Operation of Boom Up and Arm Retract...289

6-2-11 Simultaneous Operation of Boom Up and Bucket...290

6-2-12 Simultaneous Operation of Boom Up and Swing...291

6-2-13 Simultaneous Operation of Arm and Bucket...292

6-2-14 Hydraulic P.T.O...293

6-2-15 Quick Coupler (Quick coupler spec.)...294

6-2-16 Travel Alarm...295

6-2-17 Auto Deceleration...296

6-3 Hydraulic Pump...297

6-4 Control Valve...334

6-5 Pilot Valve...402

6-6 Swing Motor...416

6-7 Travel motor...447

6-8 Proportional solenoid valve...495

6-8-1 Proportional Solenoid Valve for P.T.O. (Without Air Conditioner spec.)...495

6-8-2 Proportional Solenoid Valve for P.T.O. and Engine Speed Sensing (Air Conditioner spec.)...501

6-9 Pilot Check Valve (For Quick Coupler Circuit)...507

6-10 2-way valve...515

7. Adjustment and Repair...518

7-1 Engine and Electric Equipment...518

7-1-1 Removal and Reinstallation of Engine...518

7-1-2 Removal and Reinstallation of Starter Motor...531

7-1-3 Removal and Reinstallation of Radiator and Oil Cooler...533

7-1-4 Removal and Reinstallation of Fan Belt and Compressor Driving Belt...538

7-1-5 Removal and Reinstallation of Engine ECU...541

7-1-6 Removal and Reinstallation of Hydraulic ECU (Air conditioner spec.)...543

7-2 Undercarriage...544

7-2-1 Outline...544

7-2-2 Main Parts...544

7-2-3 Points of Reassembly (Rubber Track)...545

7-2-4 Points of Reassembly (Steel Track)...546

7-2-5 Removal and Reinstallation of Crawler...548

7-2-6 Removal and Reinstallation of Travel Motor...550

7-2-7 Disassembly and Reassembly of Idler...552

7-2-8 Disassembly and Reassembly of Track Roller...555

7-2-9 Disassembly and Reassembly of Carrier Roller...558

7-2-10 Installation of Floating Seal...560

7-2-11 Drawings of Jigs...561

7-3 Controls...562

7-3-1 Mechanical Control Linkage...562

7-3-2 Adjustment of Travel Levers...564

7-3-3 Adjustment of Boom Swing Pedal...565

7-3-4 Adjustment of Blade Lever...565

7-3-5 Adjustment of Lock Lever...566

7-4 Swing Bearing...567

7-5 Hydraulic Equipment...569

7-5-1 Removal and Reinstallation of Hydraulic Pump...569

7-5-2 Removal and Reinstallation of Control Valve...571

7-5-3 Removal and Reinstallation of Pilot Valves (L and R)...575

7-5-4 Removal and Reinstallation of Swing Motor...577

7-5-5 Removal and Reinstallation of Swivel Joint...579

7-5-6 Disassembly and Reassembly of Swivel Joint...583

7-5-7 Disassembly and Reassembly of Hydraulic Cylinder...586

7-5-8 Removal and Reinstallation of Hydraulic Oil Tank...591

7-5-9 Piping Layout...600

7-6 Work Implements...607

7-6-1 Removal and Reinstallation of Work Implements...607

7-6-2 Quick Coupler...617

7-7 Cabin...620

7-7-1 Removal and Reinstallation of Cabin...620

7-7-2 Disassembly and Reassembly of Cabin...624

7-8 Air Conditioner...656

7-8-1 Removal and Reinstallation of Air Conditioner...656

8. Troubleshooting...673

8-1 Non-Breakdowns...673

8-1-1 Natural Release of Bucket...673

8-1-2 Discontinuous Arm Movement...673

8-1-3 Drifting of Upperstructure on Quick Travel Operation...674

8-1-4 Thermal Shock of Travel Motor...675

8-1-5 Elongation of Boom Swing Cylinder on 65 degrees Swing...676

8-1-6 Telescopic Motion of Boom Swing Cylinder with Lock Lever Set to Lock Position...677

8-1-7 Time Lag on Travel Speed Switching...678

8-1-8 Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change...679

8-1-9 Operation of Quick Coupler Cylinder (for Quick Coupler Type)...680

8-2 Quick Reference Table for Troubleshooting...681

APPENDIX ViO35-6A Wiring Diagram...686