Massey Ferguson Series Tractors 8210, 8220, 8220 Heavy Duty, 8220 Xtra, 8240, 8240 Xtra, 8245, 8245 Heavy Duty, 8250, 8250 Xtra, 8260, 8260 Xtra, 8270, 8270 Xtra, 8280, 8280 Xtra Repair Service Manual (3378177M1)

Complete service repair manual with Electrical Wiring Diagrams for Massey Ferguson Tractors 210, 8220, 8220 Heavy Duty, 8220 Xtra, 8240, 8240 Xtra, 8245, 8245 Heavy Duty, 8250, 8250 Xtra, 8260, 8260 Xtra, 8270, 8270 Xtra, 8280, 8280 Xtra, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Massey Ferguson 8200 Series Tractors workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,964 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

3378177M1 - Massey Ferguson 8200 Series Tractors Workshop Service Manual (8210, 8220, 8220 Heavy Duty, 8220 Xtra, 8240, 8240 Xtra, 8245, 8245 Heavy Duty, 8250, 8250 Xtra, 8260, 8260 Xtra, 8270, 8270 Xtra, 8280, 8280 Xtra).pdf

MAIN SECTIONS

CONTENTS...1

1 . INTRODUCTION...2

1 A01 Introduction...4

A . Reading the manual...5

B . General specifications...6

C. Safety instructions...22

D . Practical advice...23

E . Instructions for putting the tractor in service...26

F . Conversion tables...27

G . Locking compounds and sealants...35

H . Tightening torques...36

2 . SPLITTING THE TRACTOR...39

2 A01 Splitting the tractor between front frame / Engine...41

General...42

A . Preliminary operations...42

Fig. 2...43

Fig. 3...44

B . Disassembling (Fig. 4)...45

C . Reassembling...45

D . Final operations...45

E. Version with Carraro front axle...47

F. Service tools...51

2 B01 Splitting the tractor betwwen Engine / Gearbox...53

General...55

A . Preliminary operations...55

B . Disassembling (Fig. 4)...57

C . Reassembling...58

D . Final operations...62

E . Service tools...63

2 C01 Splitting the tractor between Gearbox / Intermediate housing...65

General...66

A . Preliminary operations...66

B . Disassembling (Fig. 2)...68

C . Reassembling...69

D . Final operations...70

E . Service tools...71

F . Heavy Duty Version...72

2 D01 Splitting the tractor between Intermediate housing / Centre housing...79

General...80

A . Preliminary operations...80

B . Disassembling...83

C . Reassembling...85

D . Final operations...87

2 E01 Separating PTO housing / Centre housing...89

A . Preliminary operations...90

B . Disassembling (Fig. 4)...91

C . Reassembling (Fig. 4)...91

D . Final operations...92

2 F01 Chassis reinforcements...93

A . General...95

Parts list...95

Fig. 1...95

Fig. 2...96

Fig. 3...96

B . Installing and adjusting the reinforcements (Heavy Duty gearbox) (Fig. 2 - 3)...97

2 G01 Rear wheels / Hubs...99

General...100

A . Presentation of the main assemblies and torque values...101

B . Changing track...109

C . Replacing a wheel stud...113

3 . ENGINE...115

3 A01 General...117

A . Introduction...119

B . Main characteristics...120

C . Viscostatic fan...124

3 B01 Flywheel and dampers...125

A . General...126

Parts list...128

Fig. 1...127

Fig. 2...128

B . Removing and refitting the damper (Figs 1 - 2)...126

C . Removing and refitting the fly-wheel and the bearing...129

D . Replacing the starter ring gear...130

E . Service tools...130

3 C01 Spacer...131

A . Removing and refitting the spacer...132

Fig. 4...133

B . Service tools...136

3 C02 Spacer - Power Shuttle...137

A . Removing and refitting the spacer...138

B . Service tool...142

4 . CLUTCH...143

4 A01 Pressure loaded clutch...145

General...146

Parts list...147

Fig. 1...147

Fig. 1A...148

Fig. 2...149

A . Removing and refitting the clos-ing plate and replacing lip seal (57) and O?ring (1) P...151

B . Removing and refitting the clutch...152

C . Adjusting the clutch...154

D . Disassembling and reassembling the clutch...155

E . Removing and refitting control valve (Fig. 11)...157

F . Service tools...157

5 . GEARBOX...159

5 A01 General - Operation...161

A . General...163

Parts list...164

Fig. 1...165

B . Operation...167

C . Specifications...171

Fig. 6...171

5 A02 General - Operation...173

A . General...174

Parts list...176

Fig. 1...177

B . Operation...179

C . Sp?cifications...181

D . Tightening torques...183

5 B01 Input unit with mechanical reverse shuttle...185

General...186

A . Removing and refitting the unit...186

B . Service tools...188

5 B02 Input unit with power shuttle...191

General...192

A. Preliminary operations...193

B . Removal...195

C . Refitting...196

D . Adjusting of the progressive sensor...196

E . Final operations...197

F . Service tools...197

5 B03 Dynashift...199

General...200

Theory of Operation...200

Parts list...201

Fig. 1...201

Fig. 2...202

A . Preliminary operations...207

B . Removing and disassembling the cover, housing, front clutch and brake...207

C . Removing and separating the planet pinion cage assembly...208

D . Disassembling the rear clutch and brake...208

E . Assembling the planet pinion cages...209

F . Reassembling the rear clutch and brake...209

G . Reassembling the cover, front clutch, brake and housing...210

H . Shimming the planet pinion cage...212

I . Assembling the input unit...213

J . Final operations...214

K . Service tools...214

5 B04 Dynashift...215

General...216

Parts list (Fig. 1 - 2)...217

Fig. 1...217

Fig. 2...218

Operating principle...216

A . Preliminary operations...223

B . Removing and disassembling the cover, front clutch casing and brake (Fig. 7 - 8)...223

Fig. 8...224

C . Removing and splitting the planet carrier unit...225

D . Disassembling the rear clutch and brake...226

E . Assembling the planet carriers...226

F. Refitting the rear clutch and brake...227

G . Refitting the cover, front clutch, brake and casing...228

H . Shimming the planet carriers...229

I . Assembling the input unit...231

J . Final operations...231

K . Service tools...232

5 B05 Mechanical reverse shuttle...233

General...234

Operation...234

Parts List...234

Fig. 1...235

Fig. 2...236

A . Preliminary operations...237

5 B06 Power Shuttle...243

General...245

Parts list...248

Fig. 2...249

Fig. 3...250

Fig. 4...251

A . Removing and refitting the front clutch...253

B . Disassembling and reassembling the front clutch...254

C . Shimming the front clutch...257

D . Disassembling and reassembling the rear clutch...258

E . Disassembling and reassembling the driving pinion - Shimming the shaft...262

F . Service tools...265

5 C01 Selector cover...267

General...268

Parts list...268

Fig. 1...269

Fig. 2...270

A . Operation...273

B . Removing and refitting the cover...275

C . Replacing the Hare/Tortoise pis-ton seals (Fig. 4)...278

D . Disassembling and reassembling the selector mechanisms...278

E . Installing and adjusting the gear linkage and reverse shuttle control cables (tractors with cab)...280

F . Version for tractors with platforms...284

Fig. 19...285

G . Adjusting the Hare/Tortoise range...288

H . Service tools...289

5 C02 Selector cover...291

General...292

Parts list...292

Fig. 1...293

Fig. 2...294

A . Operation...297

B . Removing and refitting the cover...299

C . Replacing Hare / Tortoise piston seals (Fig. 4)...301

D . Disassembling and reassembling the selector mechanisms...301

E . Fitting and adjusting the gear linkage...303

F . Adjusting the Hare / Tortoise range...305

G . Service tools...306

5 C03 Selector cover - Optimised Hare / Tortoise function...307

General...308

Parts list...308

Fig. 1...309

Fig. 2...310

A . Identification and functions of components - Hare / Tortoise function...313

B . Removing and refitting the cover...315

C . Replacing Hare / Tortoise piston seals (Fig. 4)...318

D . Disassembling and reassembling the selector mechanisms...318

E . Fitting and adjusting the gear linkage...321

F . Adjusting the Hare / Tortoise range...323

G . Service tools...324

5 D01 Selector rails...325

General...326

Parts list...327

Fig. 1...327

Fig. 2...328

A . Disassembling and reassembling selector rails and adjusting forks and gearbox selector...329

B . Disassembling and reassembling selector rail and adjusting input unit fork...331

5 D02 Selector rails...333

General...334

Parts list...335

Fig. 1...335

Fig. 2...336

A . Disassembling and reassembling selector rails and adjusting forks and gearbox selector...337

5 E01 Output shaft...339

General...341

Parts list...341

Fig. 1...342

Fig. 2...343

A . Preliminary operations...344

B . Removing and refitting the selec-tor rails and forks...344

C . Removing, refitting and shimming the shaft...344

Fig. 3...345

Fig. 4...346

Fig. 5...346

D . Final operations...347

5 F01 Mainshaft...349

General...350

Parts list...350

Fig. 1...351

Fig. 2...352

A . Preliminary operations...353

B . Disassembling and reassembling the shaft...353

C . Final operations...355

D . Shimming of the input pinion (Fig. 8)...356

E . Shimming the shaft...357

5 F02 Mainshaft...359

General...360

Parts list...360

Fig. 1...361

Fig. 2...362

A . Preliminary operations...363

B . Disassembling and reassembling the shaft...363

C . Final operations...365

D . Shimming the shaft...366

E . Service tools...367

5 G01 Layshaft...369

General...370

Parts list General...370

Fig. 1...371

Fig. 2...372

A . Preliminary operations...373

B . Removing and disassembling the shaft...373

C . Reassembling and refitting the shaft...374

D . Final operations...375

E . Shimming the pinions (Fig. 7)...376

F . Shimming the bearings...376

G . Service tools...378

5H01 General...379

A . General...380

B . Characteristics...380

C . Transmission (Figs. 2 to 7)...381

Parts list...381

Fig. 2...382

Fig. 3...383

Fig. 4...384

Fig. 5...385

Fig. 6...386

Fig. 7...387

D . Power transmission ? Description...390

E . Vibration damper and coupling shafts (Figs. 15 - 16)...396

Parts list...396

Fig. 15...397

Fig. 16...398

F . Service tools...399

5I01 Transmission hydraulic circuit...403

A . Characteristics - Transmission hydraulic circuit...405

B . General...406

C . Hydraulic circuit diagram...407

Parts list...407

Fig. 1...407

D . Oil filter (Fig. 2)...408

Fig. 2...408

E . Thermostatic valve (Fig. 4)...410

F . Pressure regulating-valve (Fig. 6)...412

G . Proportional solenoid valve (Fig. 7)...413

H . Pump and pressure circuit...414

I . Disassembling the pump...415

J . Pump reassembly...416

K . Clutch circuit...417

L . Lubricating circuit...418

5J01 Transmission - Repair...419

A . Disassembling the gearbox...420

B . Removing the front housing...421

C . Removing clutches and trans-mission shafts...422

D . Replacing the input shaft seal...424

E . Inspecting and repairing the hous-ing...425

F . Reassembling the gearbox...426

G . Overhauling a speed clutch train...428

Parts list...433

Fig. 38...432

Parts list...435

Fig. 39...434

Parts list...437

Fig. 40...436

H . Input shaft - 1 st stage shaft (Fig. 50)...441

I . Repairing the range clutch shaft...442

Parts list...447

Fig. 64...446

Parts list...449

Fig. 65...448

Parts list...451

Fig. 66...450

5 K01 Creeper unit...457

General...458

Operation (Fig. 2)...459

Parts list...460

Fig. 3...461

Fig. 4...462

A . Removing and remounting the unit...463

B . Disassembling, reassembling and adjusting the selector...465

C . Disassembling and reassembling the epicyclical reducer...468

D . Control adjustment...469

6 . REAR AXLE...471

6A01 Description...473

A . General...474

Parts list...474

Fig. 1...475

Fig. 2...476

B . Layout of the main components (Fig. 1 and 2)...474

6B01 Standard trumpets...477

General...478

Parts list...478

Fig. 1...479

Fig. 2...480

A . Removing and refitting the trumpet housing assembly...481

B . Removing and refitting the brake plate and crownwheel assembly...483

C . Removing and disassembling the planetary carrier...484

D . Reassembling and refitting the planetary carrier...485

E . Replacing the axle shaft bearings...486

F . Shimming the axle shaft bearings...488

G . Replacing a wheel stud on the axle flange...489

6B02 Trumpets with sealed compartment...491

General...492

Parts list...492

Fig. 1...493

Fig. 2...494

A . Removing and refitting the trumpet assembly...495

B . Removing and refitting the com-partment and crownwheel assem-bly...497

C . Replacing compartment seals...498

D . Removing and refitting the planetary carrier...499

E . Reassembling and refitting the planetary carrier...499

F . Replacing the axle shaft bearings...500

G . Shimming the axle shaft bearings...502

H . Service tools...504

6B03 Trumpets with composite drive unit...505

General...507

Parts list...508

Fig. 1...509

Fig. 2...510

Fig. 3...510

A . Removing and refitting the trum-pet assembly...511

B . Removal and refitting the spacer and crownwheel assembly...515

C . Replacing the spacer seals...516

D . Replacing the cassette seal...517

E . Removing and dissassembling of the planetary carrier...518

F . Reassembling and refitting the planetary carrier...519

G . Shimming the planetary gear...520

H . Replacing the axle shaft bearings...521

I . Shimming the axle shaft bearings...522

J . Service tools...524

6B04 Trumpets with double reduction...527

General...529

Parts list...530

Fig. 2...531

Fig. 3...532

A . Removing and refitting the trumpet assembly...533

B . Removing and refitting brake plate, crownwheels, spacer and epicyclic reducer gears (Fig. 12)...537

C . Replacing the cassette seal...540

D . Disassembling and reassembling the planetary gears...541

E . Replacing the axle shaft bearings...542

F . Shimming the axle shaft bearings...543

G . Service tools...545

6C01 Handbrake unit and control link...547

General...548

Operation...548

Parts list...548

Fig. 1...549

Fig. 2...550

A . Disassembling and reassembling the handbrake unit...551

B . Disassembling, reassembling and adjusting the controls...553

C . Disassembling, reassembling the lever and replacing the cable...555

6D01 Differential with standard bevel gear and hydromechanical lock...557

General...558

Parts list...559

Fig. 1...559

Fig. 2...559

Fig. 3...560

A . Removing and refitting the left-hand differential lock carrier, disas-sembling and reassembling the lock assembly...561

B . Removing and refitting the right-hand differential lock carrier...564

C . Removing and refitting the differ-ential unit assembly...565

D . Removing and refitting the plan-etary gears and sun gears and dis-assembling and reassembling the crownwheel...567

E . Adjusting and checking the back-lash...569

F . Shimming the differential unit...571

G . Removing and refitting the drive pinion...574

H . Removing and refitting the drive pinion...577

I . Service tools...581

6D02 Differential with standard bevel gear and multidisc lock...583

General...584

Parts list...585

Fig. 1...585

Fig. 2...585

Fig. 3...586

A . Removing and refitting the car-riers...587

B . Removal and refitting the diffe-rential unit assembly...589

C . Removing and refitting the multi-disc lock...592

D . Removing and refitting the plane-tary gears and sun gears and disassemblying and reassembling the crownwheel...594

E . Adjusting and checking the back-lash...596

F . Shimming the differential unit...598

G . Removing and refitting the drive pinion...600

H . Adjusting and shimming the drive pinion...603

I . Service tools...606

6D03 Differential with hypoid bevel gear and multidisc lock...607

General...608

Parts list...609

Fig. 1...609

Fig. 2...609

Fig. 3...610

A . Removing and refitting the car-riers...611

B . Removing and refitting the diffe-rential unit assembly...613

C . Removing and refitting the multi-disc lock...616

D . Removing and refitting the plane-tary gears and sun gears and disassembling and reassembling the crownwheel...617

E . Adjusting and checking the multi-disc...619

F . Shimming the differential unit...621

G . Removing and refitting the drive pinion...623

H . Adjusting the position and shim-ming the drive pinion...627

I . Service tools...631

6E01 Brake pistons and seals...633

General...634

Parts list...634

Fig. 1...635

Fig. 2...635

Fig. 3...636

Fig. 4...636

Fig. 5...637

A . Disassembly...638

B . Reassembly...640

C . Service tools...643

6F01 Park lock...645

General...646

Parts list...647

Fig. 1...647

Fig. 2...648

A . Unlocking the system and posi-tioning the special bolt...649

B . Removing and refitting the sleeve...650

C . Disassembling the control...651

D . Reassembling the control...652

6G01 Lift cylinder supports...653

General...655

Parts list...656

Fig. 2...657

Fig. 3...658

A . Cylinder attaching points...659

Parts list...659

Fig. 4...659

B . Preliminary operations...660

C . Removing and refitting the shaft (7)...661

D . Disassembling and reassembling the supports (2) (16)...662

E . Final operations...662

F . Service tools...663

6H01 Creeper...665

General...666

Parts list...667

Fig. 2...667

Fig. 3...667

Fig. 4...668

A . Removing and refitting the unit...669

B . Disassembling, reassembling and adjusting the selection mechanism...671

C . Disassembling and reassembling the epicyclical reducer gear (Fig. 7)...675

D . Adjusting the control...676

6I01 Brackets and automatic hook...677

General...678

Fig. 1...679

Fig. 2...680

Fig. 3...680

A . Identifying the brackets, yokes, swinging drawbars and automatic hook (Fig. 1)...678

B . Adjusting the rods and automatic hook control...680

C . Operating principle of the Dromone retractable hook...682

6J01 Rear hitch mechanism...685

A . General...686

Parts list...686

Fig. 1...687

Fig. 2...687

Fig. 3...687

Fig. 4...687

Fig. 5...687

Fig. 6...687

B . Description of the hitch mecha-nism...686

C . Disassembling and reassembling a lift cylinder...689

7 . POWER TAKE-OFF...691

7A01 Description of the Power Take-off...693

A . General...694

B . Overall views...696

7B01 Driving pinions - Bearings - Layshaft...699

General...700

Parts list...700

Fig. 1...701

Fig. 2...702

A . Removing and refitting the driving pinion, bearings and layshaft...703

B . Shimming...705

7C01 Removable shaft...707

General...708

Part list...708

Fig. 1...709

Fig. 2...710

A . Disassembling and reassembling pinions 540 - 1000 rpm or 750 - 1000 rpm...711

B . Disassembling and reassembling the front bearing block (1)...711

C . Disassembling and reassembling the bearings...712

D . Removing and refitting the shaft and replacing the oil seal...713

E . Shimming (Fig. 3 - 4)...714

F . Service Tools...715

7D01 Shiftable PTO shaft...717

General...718

Parts list...718

Fig. 1...719

Fig. 2...720

A . Disassembling and reassembling 540 - 1000 rpm or 750 - 1000 rpm pinions, fork and bearing (24)...721

B . Removing, refitting and disassembling, reassembling the rear bearing block, oil seal and shaft bearings...722

C . Shimming (Fig. 4 ? 5)...723

D . Long shaft version...723

E . Adjusting the control...724

F . Service tools...725

7E01 1000 rpm power take-off shaft...727

General...728

Parts list...728

Fig. 1...729

Fig. 2...730

A . Disassembling and reassem-blying 1000 rpm pinion and bearing (24)...731

B . Removing, refitting and disassembling, reassembling the rear bearing block, oil seal and shaft bearings...732

C . Shimming (Figs. 4 - 5)...733

D . Long shaft version...733

E . Service tools...734

7F01 Clutch and brake...735

A . General...737

Parts list...738

Fig. 2...739

Fig. 3...739

B . Removing and refitting the clutch...741

C . Disassembling and reassembling the clutch...743

D . Service tools...745

8 . FRONT AXLE...747

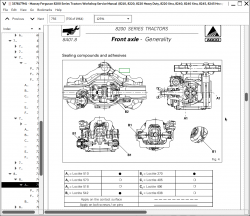

8A01 Generality - Carraro front axle...749

A. General description...750

Parts list...750

Fig. 1...751

B. Safety instructions...762

8B01 Dana final drive units...765

General...766

Parts list...766

Fig. 1...767

Fig. 2...767

Fig. 3...768

A . Layout of main components...769

B . Removing and disassembling the planetary carrier, sun gear and crownwheel...771

C . Reassembling and refitting the planetary carrier, crownwheel and sun gear...773

D . Disassembling and reassembling the wheel hub...774

E . Replacing a wheel stud...776

F . Disassembling, reassembling and shimming the swivel housing...776

G . Removing and refitting the universal drive shaft...779

H . Service tools...781

8 B02 ZF final drive units...783

General...784

Parts list...784

Fig. 1...785

A . Removing and refitting the pla-netary carrier, sun gear, crownwheel and wheel hub...787

B . Disassembling and reassembling the planetary carrier...789

C . Replacing the lip seal and wheel hub bearings...790

D . Adjusting the rotational torque of the wheel hub...791

E . Shimming the planetary carrier...792

F . Disassembling and reassembling the swivel housing...793

G . Replacing the seal and transmis-sion bushes...796

H . Removing and refitting - disassembling and reassembling the universal drive shaft...797

I . Replacing a wheel stud...798

J . Service tools...799

8B03 Carraro final drive units...801

General...802

A. Steering cylinder group disassembly...802

B. Epicyclic reduction gear disassembly...803

C. Wheel hub group disassembly...804

D. Axle beam group disassembly...808

E. Axle beam group assembly...809

F. Wheel hub group assembly...810

G. Epicyclic reduction gear assembly...815

H . Toe-in adjustement...816

J. Steering angle adjustment...818

K. Service tools...819

8C01 Dana differential...823

General...824

Parts list...824

Fig. 1...825

Fig. 2...825

Fig. 3...826

A . Splitting front axle / frame...827

B . Removing swivel housings, wheel hub and drive shafts...827

C . Removing the differential housing assembly...827

D . Disassembling the differential...828

E . Removing the differential lock (Fig. 7)...829

F . Removing the crownwheel and drive pinion...829

G . Refitting the drive pinion and crownwheel...831

H . Reassembling the differential lock...834

I . Piston leak test...836

J . Refitting swivel housings, wheel hub and drive shafts...836

K . Refitting swivel housings, wheel hub and drive shafts...836

L . Assembling front axle / frame...836

M . Service tools...837

8C02 ZF differential...839

General...840

Parts list...840

Fig. 1...841

A . Splitting front axle / frame...843

B . Removing the swivel housings...843

C . Removing the axle nose...843

D . Removing and refitting - disas-sembling and reassembling the dif-ferential housing and crownwheel...844

E . Shimming the differential hou-sing and adjusting the backlash...849

F . Removing and refitting the drive pinion, adjusting the bevel gear dis-tance and shimming the bearings...851

G . Refitting the axle nose...857

H . Refitting the swivel housings...857

I . Assembling front axle / frame...857

J . Service tools...858

8 C03 Carraro differential...861

General...862

A. Splitting front axle / frame...862

B. Removing swivel housings, wheel hub and drive shafts...862

C. Disassembling the differential support group...863

D. Pinion group disassembly...866

E. Differential group disassembly...868

F. Pinion group assembly...870

G. Differential group assembly...874

H. Differential carrier group assembly...876

I. Service tools...882

8 D01 2 WD front axle...887

General...888

Parts list...888

Fig. 1...889

Fig. 2...890

A . Removing and refitting the steering arm ball joint...891

B . Removing and refitting the hub, axle spindle and extending arm...891

C . Removing and refitting the stee-ring ram...893

D . Removing and refitting the front axle...894

E . Adjusting the wheel alignment...896

F . Adjusting the wheel track...896

G . Service tools...897

8 E01 Steering column...899

General...900

Parts list...900

Fig. 1...901

Fig. 2...902

Operation...900

A . Removing and refitting the stee-ring column...903

B . Disassembling and reassembling the control lever assembly...903

C . Removing and refitting the not-ched lever and rack...904

D . Removing and refitting the lock-ing mechanism...904

E . Replacing the shafts and bea-rings...905

F . Replacing the guide bushes (26) (27) (30)...905

8 F01 Bearings and transmission shafts (Dana front axles)...907

General...908

Parts list...908

Fig. 1...909

Fig. 2...910

Fig. 3...911

A . Removing and refitting the bea-rings...912

B . Replacing bushes and seal...915

C . 2 WD version...916

8 F02 Bearings and transmission shafts (ZF front axles)...917

General...918

Parts list...920

Fig. 1...919

Fig. 2...920

Fig. 3...921

A . Disassembling and reassembling 4WD transmission shafts and uni-versal joint spiders...922

B . Removing and refitting the bea-rings...924

C . Replacing bushes and seal...926

8 F03 Bearings and transmission shafts (Carraro front axle)...929

General...930

Parts list (Fig.2) ...930

Fig. 1...931

Parts list (Figs. 3 - 4)...932

Fig. 2...932

A . Disassembling and reassembling the 4WD transmission shafts and the universal joint spiders...934

B . Removing and refitting the front bearing support and front axle...936

C . Replacing the friction rings and seal...942

8G01 4 WD clutch...945

General...947

Part list...948

Fig. 1...949

Fig. 2...950

A . Preliminary operations...951

B . Removing, refitting the clutch assembly and shaft...951

C . Disassembling, reassembling and shimming the clutch...953

D . Shimming the shaft...955

E . Final operations...955

8G02 Carraro suspension...957

A. Arms unit disassembly...958

B. Arms unit assembly...961

C. Service tools...970

8I01 Carraro troubleshooting...975

Generality...976

A. Troubleshooting...978

B. Axle problem and diagnosis...980

9 . HYDRAULICS...982

9 A01 Description of the 110 l/min circuit...984

A . General...986

B . Principle...987

C . Centre housing lubricating circuit...987

D . Layout of components in AG 150 - AG 250 Full Powershift and Heavy Duty gearboxes...989

Parts list...989

Fig. 2...990

Fig. 3...991

Parts list...994

Fig. 6...995

Fig. 7...996

Fig. 7A...997

E . Diagrams...1003

Parts list...1003

9A02 Description of the 150 l/min circuit...1012

A . General...1013

B . Principle...1014

C . Centre housing lubricating circuit...1015

D . Layout of components in AG 150 and AG 250 Full Powershift gear-boxes...1016

Parts list...1016

Fig. 4...1017

Fig. 5...1018

E . Diagram...1021

Parts list...1021

Fig. 8...1022

9 B01 Priority blocks with trailer braking...1024

General...1025

A . Identification of ports (Figs. 2 to 4)...1028

B . Operation of spool valves...1029

9 C01 Priority blocks without trailer braking...1032

General...1033

A . Identification of ports (Fig. 2 to 4)...1034

Parts list...1034

Fig. 2...1034

Fig. 3...1035

Fig. 4...1036

B . Operation (Fig. 5)...1037

9 D01 Auxiliary spool valves...1040

General...1041

Operation (Fig. 5 to 7)...1043

A . Different types of spool valves...1046

Fig. 5...1046

Fig. 6-7...1047

Fig. 8...1048

B . Diagram...1049

C . Removing and refitting the spool valves...1050

9 D02 Bosch auxiliary spool valves...1054

General...1055

Operation (Fig. 2 - 3)...1057

A . Layout of components, designation of ports and parts...1057

B . Diagram...1060

C . Removing and refitting the unit - Splitting the spool valves...1061

D . Assembly procedure...1066

E . Assembling and adjusting the control cables (Fig. 19)...1067

9 D03 Electro-hydraulic spool valves...1070

General...1071

Parts list (Fig. 1)...1071

Fig. 1...1072

A . Layout of components and identification of channels and ports...1075

B . Diagram...1078

C . Spool valve assembly...1079

D . Assembly procedure...1082

E . Location of levers on the console and fitting, adjustment of a control cable...1083

9 E01 Lift control spool valve...1086

General...1087

A . Diagrams...1089

B . Removing and refitting the spool valve...1091

C . Neutral position...1093

D . Raise position...1094

E . Lower position...1095

9 F01 Hydrostatic steering...1096

General...1097

Parts list...1097

Fig. 1...1098

A . The principle of Load Sensing...1097

B . Layout of channels and ports (Fig. 3)...1100

C .Diagram...1102

D . Neutral position (engine running) (Fig. 5)...1103

E . Steering lock (engine running) (Fig. 6)...1105

F . Manual steering (engine stopped) (Fig. 7)...1107

G . Disassembling and reassembling the Orbitrol steering unit (Fig. 1)...1109

H . Removing, refitting and disassembling, reassembling the Dana and Carraro steering rams...1111

9 F02 Hydrostatic steering for 4WD front axles - APL5052...1116

General...1118

A . Principle of "Load Sensing"...1119

Parts list...1119

Fig. 1...1120

Fig. 2...1121

B . Neutral position (engine running) (Fig. 3)...1122

C . Wheel steering lock position (engine running) (Fig. 4)...1124

D . Manual steering (engine stopped) (Fig. 5)...1126

E . Disassembling and reassembling the distribution valve (Orbitrol) (Fig. 1 - 2)...1128

F . Removing and refitting ? Disassembling and reassembling a steering ram...1131

G . Layout of channels and ports...1133

9 G01 Right-hand cover 110 l/min Load Sensing...1134

General...1135

Parts list...1137

Fig. 3...1138

3A...1139

Fig. 4...1140

Fig. 5...1141

Fig. 5A...1142

A . Removing and refitting the cover...1146

B . Description and operation of the variable displacement pump...1150

C . Removing and refitting the pump...1153

D . Adjusting the engine speed sen-sor (Heavy Duty version)...1154

E . Removing and refitting ? Disassembly and reassembling the pump bearing...1155

9 G02 150 l/min right-hand cover...1160

General...1162

Parts list...1163

Fig. 9...1170

Fig. 10...1170

A . Removing and refitting the cover...1172

B . Description and operation of the variable displacement pump...1175

C . Removing and refitting the pump...1179

D . Disassembling, reassembling and shimming of the idler pinion...1181

E . Removing and refitting - Disassembling and reassembling the pump bearing block...1184

9 H01 Left-hand cover 110 l/min and 150 l/min Load Sensing...1188

General...1189

Parts list...1191

Fig. 3...1192

Fig. 4...1193

A . Removing and refitting the cover...1195

B . Removing and refitting the boos-ter pump...1197

C . Replacing the pump seals (Fig. 10)...1198

9 I01 Brake and clutch master cylinders circuit and bleeding...1200

General...1202

A . Servicing the master cylinders...1208

B . Brake master cylinders...1208

C . Master cylinder and servobrake assembly...1209

D . Adjusting the servobrake rod (Fig. 10)...1211

E . Adjusting the brake pedals (Fig. 11)...1211

F . Clutch master cylinder...1212

G . Adjusting the clutch pedal (Heavy Duty transmission version)...1213

H . Bleeding the main brake circuit...1214

I . Bleeding the trailer braking circuit...1216

J . Bleeding the clutch control...1217

9 I02 Brake and clutch master cylinders circuit and bleeding...1218

General...1219

A . Servicing the master cylinders and FTE valve...1223

B . Brake master cylinders...1223

Parts list (Fig. 8)...1223

Fig. 8...1224

C. FTE valve (Fig. 9)...1225

D . Adjusting the brake pedals (Fig. 12)...1227

E . Bleeding the main brake circuit...1228

9 J01 Clutch control valve...1231

General...1232

A . Operating phases of the clutch valve...1234

B . Disassembling and reassembling the valve (Fig. 10)...1239

C . Service tools...1241

9 K01 Power Shuttle control unit...1243

General...1244

A . Designation of pipes and components (Fig. 1)...1244

B . Removing and refitting the control unit (1) (Fig.1)...1246

C . Location of ports and identifying proportional solenoid valves...1248

9K02 Hydraulic control unit - Suspended front axle...1249

A. Technical Features...1250

Parts list (Fig. 1 - 2)...1250

Fig. 2...1251

B . Description of the hydraulic circuit...1252

C . Disassembly / Assembly of the hydraulic control unit...1255

D . Disassembly / Assembly of the steering cylinder...1257

9 L01 Dynashift control...1261

General...1262

A . Explanation of ratios...1266

B . Checking piston pressures...1268

9M01 Oil decontamination...1269

A . General...1270

B . Decontamination procedure...1271

C . Diagrams...1275

Parts list...1275

Fig. 3...1275

Parts list...1277

Fig. 4...1277

9 N01 Hydraulic tests...1279

A . General...1280

B . Testing the high pressure 110 l/ min circuit...1281

Fig. 10...1285

Fig. 11...1285

Fig. 13...1286

C . Testing the low pressure 110 l/min circuit...1287

D . Testing the high pressure 150 l/ min circuit...1294

E . Testing the low pressure 150 l/min circuit...1302

F . Low pressure hydraulic functions of the Full Powershift gearbox...1303

10 . ELECTRICAL EQUIPMENT...1313

10 A01 Electrical equipment...1315

A . General...1317

B . Dynashift - Cab accessories and engine equipment (Fig. 1 to 7)...1322

Fig. 1...1323

Parts list...1322

Identification of connectors...1322

Fig. 2...1325

Parts list...1324

Identification of connectors...1324

Fig. 3...1327

Parts list...1326

Identification of connectors...1326

Fig. 4...1329

Parts list...1328

Identification of connectors...1328

Fig. 5...1331

Parts list...1330

Identification of connectors...1330

Fig. 6...1333

Parts list...1332

Identification of connectors...1332

Fig. 7...1335

Parts list...1334

Identification of connectors...1334

C . Full Powershift ? Engine equipment (Fig. 8)...1336

Fig. 8...1337

Parts list...1336

equip-ment Colour codes Identification of connectors...1336

D . Full Powershift - Cab equipment (Fig. 9)...1338

Fig. 9...1339

Parts list...1338

Identification of connectors...1338

E . Lighting layout (except North America) (Fig. 10)...1340

Fig. 10...1341

Parts list...1340

Identification of connectors...1340

F . Direction indicator lamps (except North America) (Fig. 11)...1342

Fig. 11...1343

Parts list...1342

Identification of connectors...1342

G . Work lights and flashing beacons (except North America) (Fig. 12)...1344

Fig. 12...1345

Parts list...1344

Identification of connectors...1344

H . Dynashift - Full lighting system (North America) (Fig. 13) ...1346

Fig. 13...1347

Parts list...1346

Identification of connectors...1346

I . Full lighting system - Full Powershift (North America) (Fig. 14)...1348

Fig. 14...1349

Parts list...1348

Identification of connectors...1348

J . Dynashift ? Fuses (except North America) (Fig. 15)...1350

K . Full Powershift ? Fuses (except North America) (Fig. 16)...1351

L . Dynashift ? Fuses (North America) (Fig. 17)...1352

M . Full Powershift ? Fuses (North America) (Fig. 18)...1353

10 A02 Deutsch electrical equipment...1355

A . General...1357

B . Engine and cab equipment Autotronic 3 (Fig. 2 to 10)...1366

Parts list...1366

Fig. 2...1367

Parts list...1368

Fig. 3...1369

Parts list...1370

Fig. 4...1371

Parts list...1372

Fig. 5...1373

Parts list...1374

Fig. 6...1375

Parts list...1376

Fig. 7...1377

Parts list...1378

Fig. 8...1379

Parts list...1380

Fig. 9...1381

Parts list...1382

Fig. 10...1383

Parts list...1384

Fig. 11...1385

C . Engine and cab equipment...1384

Parts list...1386

Fig. 12...1387

Parts list...1388

Fig. 13...1389

Parts list...1390

Fig. 14...1391

Parts list...1392

Fig. 15...1393

Parts list...1394

Fig. 16...1395

Parts list...1396

Fig. 17...1397

Parts list...1398

Fig. 18...1399

Parts list...1400

Fig. 19...1401

Parts list...1402

Fig. 20...1403

D . Lighting equipment - Europe...1404

Parts list...1404

Fig. 21...1405

Parts list...1406

Fig. 22...1407

Parts list...1408

Fig. 23...1409

E . Lighting equipment - North...1410

Parts list...1410

Fig. 24...1411

Parts list...1412

Fig. 25...1413

Parts list...1414

Fig. 26...1415

F . Location of fuses - Dynashift (Europe) (Fig. 27)...1416

G . Location of fuses - Dynashift (North America) (Fig. 28)...1417

H . Location of fuses - Powershift (Europe) (Fig. 29)...1418

I . Location of fuses - Powershift (North America) (Fig. 30)...1419

11 . ELECTRONICS...1421

11 A01 Description...1423

A . General...1425

B . Flowchart of Autotronic 2 modes...1426

C . Flowchart of functions...1427

D . Diagrams...1432

11 A02 Checks without a tester...1435

A . Test procedure...1436

B . Analysis of possible faults...1440

11 A03 Description...1443

A . General...1444

B . Autotronic 3 status flowcharts...1444

C . Automatic responses of the Autotronic 3...1447

D . Operating principle of the Auto-matic Dynashift...1456

E . Calibration of throttle pedal potentiometer...1460

F . Power Shuttle principles...1461

G . Calibration of the Power Shuttle...1463

H . Power Shuttle error codes...1467

I . Disassembling, reassembling the Power Shuttle lever ...1471

J . Operation of the manoeuvring pedal...1473

K . Electrical diagram...1474

Parts list...1474

Fig. 8...1475

Parts list...1476

Fig. 9...1477

Parts list...1478

Fig. 10...1479

Parts list...1480

Fig. 11...1481

Parts list...1482

Fig. 12...1483

Parts list...1484

Fig. 13...1485

Parts list...1486

Fig. 14...1487

Parts list...1488

Fig. 15...1489

Parts list...1490

Fig. 16...1491

Parts list...1492

Fig. 17...1493

Parts list...1494

Fig. 18...1495

11 B01 Description and operation...1497

A . Description...1499

B . DCC dashboard...1501

C . Status of DCC switches...1510

D . Characteristics of DCC sensor input signals...1514

E . Transmission Controller (TC)...1517

F . Operation of solenoid valves and test procedures...1531

G . Input signals of TC sensors / swit-ches...1532

H . Operation of the manoeuvring pedal...1537

I . Operation of the armrest gear selector switch assembly...1538

J .Steering wheel gear shift lever...1539

K . Use of the Backup Harness...1541

L . Location of sensors...1542

11B02 Calibration...1547

A. General...1548

B . Level 0...1549

C . Level 1...1551

D . Level 2...1555

E . Level 3...1563

F . Adjust the shifting...1564

G . Diagnostic modes...1565

11B03 Error codes...1575

A . General...1576

B . List of TC and DCC error codes...1576

C . TC and DCC error codes analysis...1581

11 C01 Description of electronic linkage...1597

A . Description...1598

B . Console...1602

C . Diagram...1605

11 C02 Linkage auto-diagnostics...1613

A . Operation...1614

11 D01 Datatronic...1617

A . General...1618

B . Activating the basic data...1623

C . The "Working" key...1625

D . The "Implement Width" key...1626

F .The "Wheel Slip Control" key...1627

G . "Memory" keys...1628

H . Comparative mode...1632

I . Flowmeter fitting...1634

J . Diagram...1640

11 D02 Front Dual Control...1643

A . General...1644

B . Block diagram...1645

C . Description of the Adjustment screen EXT.TEMP...1648

D . Adjustments...1649

E . Use...1650

F . Error codes...1651

G . Assembly of the additional lever...1651

11 D03 Dual Control for Semi-mounted implement...1653

A . General...1654

B . Block diagram...1655

C . Description of the Adjustment screen EXT.TEMP...1658

D . Adjustments...1659

E . Use...1661

F . Error codes...1663

G . Assembly of the additional lever...1663

11 D04 TIC for semi-mounted implements...1665

A . General...1667

B . Block Diagram...1668

C . Description of the screen...1672

D . Settings...1673

E . Using...1676

F . Error codes...1676

G . Lever and electro-hydraulic spool valve assembly...1677

11 F01 Wintest ? General...1687

A . General - Description...1689

B . Installing Wintest on the PC?s hard drive...1690

C . Updating Wintest software...1691

D. Connections...1692

E . Accessing the Wintest main menu...1695

F . Wintest version...1699

11 F02 Autotronic 2 with Wintest...1701

A. Using Autotronic 2 with Wintest...1702

B. Programming and Setting parameters...1703

C. Setting parameters...1719

D . Tests and diagnostics...1731

11 F03 Autotronic 3 with Wintest...1747

A . General...1748

B . Using Autotronic 3 with Wintest ...1749

C . Programming...1750

D . Setting parameters...1753

E . Tests and diagnostics...1761

F . Manual calibration of the power shuttle...1778

G . List of error codes...1783

11 F04 TC and DCC with Wintest...1787

A . General...1788

B . Programming...1789

C . Setting parameters...1794

D . Adjusting the restarting speed...1802

E . Tests and diagnostics...1803

E . List of error codes...1822

11 F05 Electronic linkage with Wintest...1825

A. Using the Electronic linkage control with Wintest...1826

B. Tests and diagnostics...1827

C. Error codes...1831

D . Adjusting the position sensor...1834

E . Setting the parameters...1836

F . Dual Control/TIC...1843

11 F06 Datatronic 2 with Wintest...1847

A . Using the Datatronic 2 with Wintest...1848

B . Tests and diagnostics...1849

11 F07 Joystick with Wintest...1859

A . Using the Joystick...1860

B . Tests and diagnostics...1861

C . Joystick calibration...1864

D . Valve parameters...1866

11 F08 Autotronic 3 to Kit Autotronic...1871

A . Programming Autotronic 3...1872

B . Accessing the Wintest main menu...1876

C . Parameters...1877

11 F09 Kit Autotronic to Autotronic 3...1883

A . General...1884

B . Reprogramming Autotronic 3...1885

11G01 Carraro suspension...1889

General...1890

A. Suspension control system...1890

B . Disassembling and assembling of the sensor...1891

C. Electronic control unit (Fig.14)...1895

D. Service tools...1898

11H01 Description...1899

A . General...1901

B . Description of SMS components...1902

C . Operation and troubleshooting without a tester...1908

D . SMS error codes...1910

E . Disassembly, reassembly of the Joystick...1915

F . Replacement of ON / OFF or Memory switches...1915

G . Electrical diagram...1916

12 . CAB AND EQUIPMENT...1919

13 . ACCESSORIES...1920

14 . SERVICE TOOLS...1921

14 A01 Service tools...1923

Splitting the tractor...1924

Perkins engines...1925

Valmet engines...1930

Clutch...1941

Gearbox...1942

Rear axle...1945

Power take off...1947

Front axle...1948

Hydraulics...1954

Electricity - Electronics...1956

Cab and equipment...1963