Komatsu Forklift Series 4032 (FB13M-2R, FB15-2R, FB15M-2R, FB16-2R, FB16M-2R, FB18-2R, FB18M-2R, FB20-2R, FB20M-2R) Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Forklift Series 4032 (FB13M-2R, FB15-2R, FB15M-2R, FB16-2R, FB16M-2R, FB18-2R, FB18M-2R, FB20-2R, FB20M-2R), with technical information to maintain, diagnose, repair, and service like professional mechanics.

Komatsu Forklift Series 4032 (FB13M-2R, FB15-2R, FB15M-2R, FB16-2R, FB16M-2R, FB18-2R, FB18M-2R, FB20-2R, FB20M-2R) workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 378 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

40328042305 EN - Komatsu Forklift Series 4032 (FB13M-2R, FB15-2R, FB15M-2R, FB16-2R, FB16M-2R, FB18-2R, FB18M-2R, FB20-2R, FB20M-2R) Shop Manual.pdf

604.24.128 - Komatsu ELECTRONIC EQUIPMENT FORKLIFT TRUCKS FB 12M-1R, FB 15M-1R, FB 18M-1R, FB 15-1R FB18-1R, FB 18H-1R, FB 20H-1R, FB 20GH-1R, FB 22H-1R, FB 25-1R, FB 28-1R, FB 30-1R.pdf

FB13M(V)_30H.1E(ELE)-BE1 - Komatsu Forklift Truck Controller for Electric Lift Trucks (FB13MV_16MV-1E, FB16M_18M_20M-1E, FB16_18_20-1E, FB16H_20H_25H_30H-1E, FB16GH_20GH_25GH-1E) Shop Manual 1 of 2.pdf

FB13M(V)_30H.1E(ELE)-BE1 - Komatsu Forklift Truck Controller for Electric Lift Trucks (FB13MV_16MV-1E, FB16M_18M_20M-1E, FB16_18_20-1E, FB16H_20H_25H_30H-1E, FB16GH_20GH_25GH-1E) Shop Manual 2 of 2.pdf

Komatsu Forklift MJ-2E Series (FB13 • 15MJ-2E) Shop Manual.pdf

Komatsu Forklift Truck AM-3E_AM-2E Series Service Training Material.pdf

MAIN SECTIONS

40328042305...1

Header...3

Table of contents...3

00 General Information...11

Product information...11

Instruction and maintenance manual...11

General Forklift Description...11

Definition of travel direction...12

Overall dimensions for three-wheel truck...13

Three-wheel truck technical data...14

Overall dimensions for four-wheel truck...18

Four-wheel truck technical data...19

Three-wheel truck tyre characteristics...23

Four-wheel truck tyre characteristics...23

Fork lift truck capacities - Model 1300 kg 3 wheels - with vertical masts and forks = 1400 mm max...24

Fork lift truck capacities - Model 1500 kg 3 / 4 wheels - with vertical masts and forks = 1400 mm max...27

Fork lift truck capacities - Model 1600 kg 3 / 4 wheels - with vertical masts and forks = 1400 mm max...30

Fork lift truck capacities - Model 1800 kg 3 / 4 wheels - with vertical masts and forks = 1400 mm max...33

Fork lift truck capacities - Model 2000 kg 3 / 4 wheels - with vertical masts and forks = 1400 mm max...36

Alternative lift characteristics...39

Abbreviations key...40

Tyre inflation pressure...41

Lamps...41

Battery dimensions and weights...41

Internal accessibility...42

Safety features...43

Transporting the Forklift...45

Forklift towing...46

Loading and unloading the truck...47

Safety precautions...49

Description of safety symbols...49

Operations Preliminary to Maintenance...49

To avoid accidents...49

General safety Regulations...50

Safety Regulations Relative to Operating Materials...52

01 Service...55

Servicing...55

Preliminary operations before commissioning...55

Synoptic Table of Maintenance Operations...55

Supply Table...56

02 Diagnostics...57

Diagnostic software...57

Connection between the diagnostics PC and the forklift ...57

Software...58

Description of the menus in the WINPCCONSOLE software...59

Description of the PARAMETER menu ...63

Description of the TESTER menu...68

TESTER / Diagnostics Function...69

Parameters...72

Introduction...72

Parameters of the DUAL AC module...72

Parameters of the AC2 FLASH module...78

...80

...81

Parameters of the ECO DISPLAY module...81

Parameterisation of the drive function...85

Parameterisation of the steering function...86

Parameterisation of the electric braking function...87

Parameterisation of the battery state monitoring function...88

Parameterisation of the lifting function...88

Parameterisation of the hydraulically assisted steering function...89

Parameterisation of the tilt, side shift (SLI) and 4th lever functions...90

Alarms...91

State of the truck during an alarm situation...91

...91

...92

Alarms list...93

Analogue signals...108

Summary of signals from the analogue transducers...108

11 Traction motor...111

Asynchronous motors...111

Features of the asynchronous motors ...111

Checking the asynchronous motors ...113

Front axle motors...114

Traction motor technical data...114

Traction...114

Traction motor...116

Drive motor checks...118

Drive motor decomposition...120

Encoder...122

Replacing the traction encoder...122

Electrical connections of the traction motors...123

Temperature sensor KTY84...124

Insulation testing of traction motor...126

22 Transmission...127

Front axle...127

Front axle technical data...127

Removal of front axle with traction motors...130

Front axle reassembly...133

Reducer...134

Front axle reducer gearbox topography...134

Front axle reduction gear disassembly/reassembly...135

Removal / reassembly of the drive wheel reducer gearbox...136

Check reducer gearbox oil level...137

Reducer gearbox oil change...138

31 Truck...139

Counterweight...139

Counterweight removal...139

Counterweight reassembly...144

Covers...146

Cover topography...146

Side covers removal / reassembly...147

Battery cover removal / reassembly...148

Step plate removal / reassembly...150

Distributor cover removal / reassembly...152

Batteries...155

Battery removal...155

34 Driver's seat...157

Overhead guard...157

Removal of the overhead guard...157

Reassembly of the overhead guard...159

Fairings...160

Removal / reassembly of the steering column panelling...160

Removal / reassembly of the control panel panelling...161

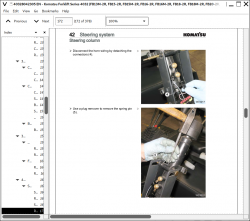

42 Steering system...165

Steering distributor...165

Steering distributor technical data...165

Removal / reassembly of the steering distributor...167

Steering distributor pressure switch technical data...169

Replacing the steering distributor pressure switch...170

Steering column...171

Removal / reassembly of the steering column...171

Fifth-wheel steering axle...175

Three-wheel truck rear axle technical data...175

Three-wheel truck axle removal...178

Three-wheel truck axle reassembly...181

Three-wheel axle disassembly...183

Three-wheel truck potentiometer technical data...187

Replacement of the three-wheel steering axle potentiometer...189

Four-wheel truck axle technical data...190

Four-wheel axle removal...191

Four-wheel truck axle reassembly...192

Four-wheel axle disassembly...194

Four-wheel truck potentiometer technical data...199

Replacing the four-wheel truck potentiometer...200

Lubricating the steering axle...205

46 Wheels and tyres...207

General information...207

Safety regulations for wheels and rims...207

General information for changing tyres...207

Tyrewear check...209

Wheel change...210

Wheel change...210

Wheel decomposition...213

Disassembly/assembly of tyres on rims with movable flange...213

Quick tyres assembly/disassembly...214

Tightening torques...216

Check wheel nut tightness (every 10 hours during run-in)...216

49 Braking system...217

Parking brake...217

Removal / reassembly of the parking brake lever...217

Parking brake control cable replacement...219

Replacing the parking brake microswitch...221

Parking brake adjustment...223

Service brake...224

Service brake pedal removal...224

Service brake pedal reassembly...225

Stop lights microswitch replacement...226

Replacing the service brake pedal potentiometer...226

Braking group...228

Removing / installing the brake group...228

50 Controls...233

Accelerator pedal...233

Accelerator pedal...233

Accelerator pedal potentiometer...233

56 Display elements...235

DISPLAY...235

Plate data...235

Connector...235

Multifunction panel...236

Setting the date and time...242

Speed reductions...246

Functionality of the display buttons...247

Data modification pushbutton functions...249

Multifunction panel removal / reassembly...250

Alarms...251

60 Electronic system...255

Software versions...255

Reference software versions...255

Electronic traction system...256

Characteristics of the electronic drive system...256

Plate data: traction...257

Connectors...257

Closing the general contactor...260

Thermal sensor operation...260

Hydraulic functions electronic system...261

Functions of the AC2 module...261

Plate data: pump...262

AC2 Connectors...262

Control of the general contactor...263

Lowering solenoid valve operation...264

Thermal sensor operation...264

Types of hours counters...265

Types of hour counters:...265

Hours counter management in case of electronic system replacement ...265

Resetting the machine hours...266

Electrical system components...267

Electronics panel technical data...267

Electronics panel removal / reassembly...267

Protection of the electrical system...272

Emergency pushbutton ...273

Replacing the emergency stop button...273

Assembly / disassembly of the lights switch (option)...274

Lamp replacement (if applicable)...276

Work light replacement procedure (optional)...277

Contactors...278

Location of Fuses...279

Changing a fuse...280

DC/DC Converter ...281

Buzzer...282

Fans...282

Encoder description...282

71 Hydraulic components...285

Hydraulic circuit...285

Layout of hydraulic parts...285

Hydraulic system assembly diagram...286

Pump motor...289

Pump motor technical data...289

Pump motor removal...290

Pump motor reassembly...294

Replacing the pump...295

Replacing the pump motor encoder ...297

Replacing the pump motor temperature sensor...298

Oil tank...299

Hydraulic oil tank...299

Oil tank removal / reassembly...300

Check hydraulic tank oil level...303

Hydraulic distributor...305

Hydraulic distributor technical data...305

Hydraulic distributor removal / reassembly...306

Replacing the hydraulic distributor probe...309

Valves...310

Safety valve (load lowering block) (VBDC)...310

Safety valve layout...311

Tilt cylinders...317

Tilt cylinders...317

Tilt cylinder removal / reassembly...317

Air bleeding of the tilt cylinders...320

80 Lifts...321

Lifts...321

Technical data for service...321

Lift typologies...322

Simplex Lift...325

Duplex Lift...329

Triplex Lift...334

Load chain locking device...340

Fork carriage retaining device...340

Assembly of the mast / carriage support rollers...340

Check...342

Disassembly of the Simplex lift cylinder...343

Disassembly of the side cylinders of the Duplex lift...344

Disassembly of the side cylinders of the Triplex lift...346

Duplex / Triplex central cylinder...348

Limit stop dampers...350

Disassembly of the fork carriage...351

Tilt cylinder...352

Lift disconnection...354

Lift reassembly...357

Air bleeding of the lift cylinders...358

Lift cylinders...360

Annex...369

A Diagrams...371

Wiring diagrams...371

Electrical circuit diagram 40328020002...371

Electrical connection diagram 40328020001...373

Hydraulic diagrams...375

Hydraulic diagram 40328082502...375