Komatsu Telescopic Handlers WH609, WH613, WH713, WH714, WH714H, WH716 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Telescopic Handlers WH609, WH613, WH713, WH714, WH714H, WH716, WH609-E0, WH613-E0, WH713-E0, WH714H-E0, WH716-E0, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Telescopic Handlers WH609-1, WH613-1, WH713-1, WH714-1, WH714H-1, WH716-1, WH609-1E0, WH613-1E0, WH713-1E0, WH714H-1E0, WH716-1E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,261 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEAM005900 - Telescopic Handler WH609-1, WH613-1, WH713-1, WH714-1, WH714H-1, WH716-1 Operation & Maintenance Manual.pdf

WEBM005700 - Telescopic Handler WH609-1, WH613-1, WH713-1, WH714-1, WH714H-1, WH716-1 Shop Manual.pdf

WEBM008500 - WH609-1E0, WH613-1E0, WH713-1E0, WH714H-1E0, WH716-1E0 Telescopic Handler Shop Manual.pdf

MAIN SECTIONS

CONTENTS...3

REVISED PAGES...5

k SAFETY...7

FOREWORD...9

HOW TO READ THE SHOP MANUAL...10

HOISTING INSTRUCTIONS...11

STANDARD TIGHTENING TORQUE...12

COATING MATERIALS...14

ELECTRIC...15

WEIGHT TABLE...16

TABLE OF OIL AND COOLANT QUANTITIES...17

CONVERSION TABLE...19

10 STRUCTURE AND FUNCTION...27

ENGINE-TRANSMISSION COUPLING...28

POWER TRAIN...29

TRANSMISSION...31

FRONT AXLE...57

REAR AXLE...61

BRAKE PUMPS...65

STEERING SYSTEM (4WS)...66

STEERING UNIT...70

HYDRAULIC DIAGRAM...71

HYDRAULIC PUMP...72

CONTROL VALVE...76

PPC VALVE...77

SOLENOID VALVES...80

SAFETY VALVES...86

CYLINDERS...93

AIR CONDITIONING SYSTEM...100

CLIMATE CONTROL SYSTEM OPERATION...101

20 TESTING AND ADJUSTMENTS...103

STANDARD SPECIFICATIONS...105

INTRODUCTION...135

VALVE LASH ADJUSTMENT...137

CHECKING ENGINE SPEED...138

TENSIONING THE AIR CONDITIONER COMPRESSOR BELT...141

ADJUSTING ACCELERATOR CABLE LENGTH...142

ADJUSTING BRAKE PEDAL TRAVEL AND POSITIONING THE STOP LAMP MICROSWITCHES...143

ADJUSTING THE PARKING BRAKES...145

BLEEDING AIR FROM CIRCUITS...147

PREPARING THE MACHINE READY FOR HYDRAULIC PRESSURE CHECK AND CALIBRATION...149

CHECKING AND CALIBRATING WORK EQUIPMENT HYDRAULIC PRESSURES...150

CALIBRATING THE PRESSURE OF THE STEERING SYSTEM...156

INSPECTING THE OPERATION OF THE UNLOADING VALVE...157

CHECKING AND CALIBRATING THE DR VALVE (PUMP FLOW VARIATION)...158

CHECKING THE DYNAMIC PUMP DP VALUE...159

CHECKING PUMP FLOW...160

BRAKE SYSTEM CHECKS...161

TRANSMISSION (POWER SHIFT) CHECKS...164

TRANSMISSION ASSEMBLY PRESSURE CHECKS...166

CHECKING THE SPEED OF THE TRANSMISSION SHAFTS RESPONSIBLE FOR TRANSLATION (CARDAN SHAFTS)...169

LEVEL CALIBRATION...170

CHECKING LOAD CELL CALIBRATION...171

CALIBRATING THE OVERTURN PREVENTION SYSTEM (STANDARD)...172

CALIBRATING THE OVERTURN PREVENTION (ASM) CONTROL UNIT...177

CHECKING LED CALIBRATION (version with ASM)...179

CHECKING SLIDING PADS CLEARANCE...180

CHECKING BOOM SIDE ALIGNMENT...182

BOOM CHAINS...184

CHAIN TENSIONING...186

CHECKING FOR BLOW-BY...191

ANALYSIS OF THE CAUSES RESPONSIBLE FOR HYDRAULIC DRIFT...194

EQUALIZING STABILIZER SPEED...203

AIR CONDITIONING SYSTEM MAINTENANCE...204

CHECKING THE A/C SYSTEM?S OPERATING TEMPERATURE...205

30 REMOVAL AND INSTALLATION...207

HOW TO READ THE MANUAL...211

PRECAUTIONS TO BE TAKEN WHEN WORKING...212

SPECIAL TOOLS...213

ENGINE HOOD...221

Removal...221

Installation...222

RADIATOR HOOD...223

Removal...223

Installation...223

AIR FILTER...224

Removal...224

Installation...224

TURBOCOMPRESSOR...225

Removal...225

Installation...226

EXHAUST PIPE...227

Removal...227

. 1st Length...227

. 2nd Length...227

Installation...228

BELT, FAN...229

Removal...229

Installation...230

RADIATOR-EXCHANGER ASSEMBLY...231

Removal...231

Installation...233

INTERCOOLER...234

Removal...234

Installation...236

MUFFLER...237

Removal...237

Installation...237

BATTERY - BATTERY TRAY...238

Removal...238

. Battery...238

. Battery tray...238

Installation...239

CYLINDER HEAD...240

Removal...240

Installation...241

INJECTORS...242

Removal...242

Installation...242

INJECTION PUMP...243

Removal...243

Installation...243

HYDRAULIC PUMP...244

Removal...244

Installation...245

COMPLETE ENGINE- SHIFT ASSEMBLY...246

Removal...246

Installation...255

ENGINE-TRANSMISSION...256

Detachment...256

Joining...257

CONTROL VALVE ASSEMBLY...258

Removal...258

Installation...261

BRACKET CONTROL, EQUIPMENT LOCK, AND FRAME LEVELLING SOLENOID VALVES...262

Removal...262

Installation...262

AIR CONDITIONER COMPRESSOR (only if equipped)...263

Removal...263

Installation...264

COMPRESSOR BELT...265

Removal...265

Installation...267

SERVO-CONTROL FEED VALVE...268

Removal...268

Installation...268

STEERING SELECTION SOLENOID VALVE ASSEMBLY...269

Removal...269

Installation...269

FRONT AXLE...270

Preparation...270

. Machine with outriggers...270

. Machine without outriggers...270

Removal...270

Installation...272

REAR AXLE...273

Preparation...273

. Machine with outriggers...273

. Machine without outriggers...273

Removal...273

Installation...275

TELESCOPIC BOOM...276

Removal...276

Installation...279

LIFT AND OFFSET CYLINDERS...283

Removal...283

Installation...284

INTERMEDIATE AND TOP BOOM...285

Removal...285

Installation...289

EXTENSION CYLINDER...290

Removal...290

Installation...291

BOOM SLIDING PADS...292

Replacement...292

1. Lower sliding pads for intermediate and top booms...292

2. Upper sliding pads for intermediate boom...293

3. Side sliding pads for intermediate and top boom...294

4. Upper sliding pads for top boom...294

5. Rear upper sliding pads for intermediate boom...296

6. Rear upper sliding pads for top boom...297

7. Rear lower sliding pads for intermediate and top boom...298

EXTENSION AND RETRACTION CHAINS (Versions with 3-section boom)...301

Removal...301

Installation...303

CHAIN RETURN PULLEY PINS AND BUSHINGS...304

RETRACTION CHAIN PULLEY...304

Removal...304

Installation...305

EXTENSION CHAIN PULLEYS...306

Removal...306

Installation...307

LOAD CELL...308

Installation...308

CONTROL UNIT...311

Removal...311

Installation...311

BALLAST...312

Removal...312

Installation...312

ENGINE LINE CENTRE...313

Removal...313

Installation...313

ACCELERATOR CABLE...314

Removal...314

Installation...315

SHIFT-REVERSING GEAR LEVER ASSEMBLY...316

Removal...316

Installation...316

STEERING COLUMN SWITCH UNIT - DIPSWITCH...317

Removal...317

Installation...317

STEERING UNIT...318

Removal...318

Installation...320

Disassembly...321

. Removing the seals...323

. Removing the wiper ring...323

Assembly...324

. Installing the inner seal (15)...324

. Installing the control valve...324

. Completing the installation procedure...325

STEERING COLUMN...328

Removal...328

Installation...328

BRAKE PUMPS...329

Removal...329

Installation...330

PPC VALVE...331

Removal...331

Installation...332

LEVEL...333

Removal...333

Installation...333

WIPER MOTORS...334

Removal...334

. Front wiper motor...334

. Rear wiper motor...335

. Upper wiper motor...336

Installation...336

PARKING BRAKE CABLE...337

Removal...337

Installation...338

DASH / INSTRUMENT PANEL...339

Removal...339

Installation...339

CONTROL PANEL...340

Removal...340

Installation...340

FUSE AND RELAY CENTRE...341

Removal...341

Installation...341

PROPELLER SHAFT...342

Removal...342

. Front cardan shaft...342

. Rear cardan shaft...342

Installation...343

FUEL TANK...344

Removal...344

Installation...345

HYDRAULIC OIL TANK...346

Removal...346

Installation...347

FRAME LEVELLING CYLINDER...348

Removal...348

Installation...348

FRAME SWING LOCKING ROD (WH609 and WH613 only)...349

Removal...349

Installation...349

AXLE LOCKING CYLINDER...350

Removal...350

Installation...350

STABILIZER CYLINDERS (If equipped)...351

Removal...351

Installation...352

EQUIPMENT HOLDER...354

Removal...354

Installation...355

EQUIPMENT MOTION CYLINDER...356

Removal...356

Installation...357

CYLINDERS...358

Disassembly...358

Assembly...359

EQUIPMENT QUICK-LOCK ASSEMBLY...363

Removal...363

Installation...363

AIR CONDITIONER FANS...364

Removal...364

Installation...364

AIR CONDITIONER CONDENSER ASSEMBLY...365

Removal...365

Installation...366

DEHUMIDIFYING FILTER...367

Removal...367

Installation...368

AIR CONDITIONING SYSTEM PRESSURE SWITCH...369

Removal...369

Installation...369

CAB...370

Removal...370

Installation...374

TRANSMISSION...375

TRANSMISSION ASSEMBLY...375

Disassembly...375

Assembly...386

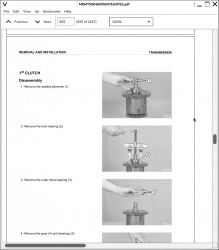

1st CLUTCH...387

Disassembly...387

Assembly...390

2nd CLUTCH...391

Disassembly...391

Assembly...395

4th CLUTCH...396

Disassembly...396

Assembly...399

3rd CLUTCH...400

Disassembly...400

Assembly...403

REVERSE CLUTCH...404

Disassembly...404

Assembly...406

FORWARD CLUTCH...408

Disassembly...408

Assembly...411

PRESSURE REGULATOR VALVE...412

Disassembly...412

Assembly...412

MODULATED VALVE...413

Disassembly...413

Assembly...414

SPACER PLATE...417

Disassembly...417

Assembly...421

CONVERTER HOUSING...422

Disassembly...422

Assembly...424

DROP BOX ASSEMBLY...425

Disassembly...425

. Complete drop box assembly...425

. Input shaft...427

Assembly...427

. Input shaft...427

. Complete drop box assembly...427

AXLES...436

Disassembly...436

. Planetary reduction...436

. Steering case...440

. Cardan shaft...443

. Brakes...445

. Parking brake assembly (front axle)...447

. Removal of steering cylinder...449

. Disassembly of steering cylinder...451

. Differential...452

. Bevel pinion...457

Assembly...460

. Bevel pinion...460

. Differential...468

. Steering cylinder...474

. Steering cylinder...477

. Convergency adjustment...480

. Parking brake assembly (front axle)...480

. Brakes...482

. Cardan shaft...485

. Steering case...486

. Planetary reduction...488

!!! new_index = 1

!!! num_start = 1

!!! num_style = Arabic

1.1 FOREWORD.....3

1.2 INFORMATION ON SAFETY.....4

1.3 INTRODUCTION.....6

1.3.1 INTENDED USES.....6

1.3.2 IMPROPER OR UNAUTHORIZED USE.....6

1.3.3 MAIN CHARACTERISTICS.....7

1.3.4 RUNNING-IN.....7

1.4 PRODUCT IDENTIFICATION.....9

1.4.1 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN).....9

1.4.2 MACHINE IDENTIFICATION PLATE.....10

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE.....11

1.4.4 FRONT AXLE SERIAL NUMBER.....11

1.4.5 REAR AXLE SERIAL NUMBER.....12

1.4.6 TRANSMISSION SERIAL NUMBER.....12

1.4.7 CAB SERIAL NUMBER.....12

1.4.8 SERIAL NUMBERS AND DEALER?S ADDRESS.....13

TABLE OF CONTENTS.....14

2.1 SAFETY, NOISE AND VIBRATION PLATES.....22

2.1.1 POSITION OF THE SAFETY PLATES.....22

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS.....26

2.1.3 POSITION OF THE NOISE PLATES.....34

2.2 GENERAL PRECAUTIONS.....35

2.2.1 GENERAL SAFETY RULES.....35

2.2.2 SAFETY DEVICES AND GUARDS.....35

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS.....35

2.2.4 UNAUTHORIZED MODIFICATIONS.....36

2.2.5 LEAVING THE OPERATOR?S SEAT.....36

2.2.6 GETTING ON AND OFF THE MACHINE.....37

2.2.7 CHECKING THE REAR-VIEW MIRRORS.....37

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL.....38

2.2.9 PREVENTING BURNS.....38

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER.....39

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT.....39

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT.....40

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE.....40

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT.....40

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING WORK.....41

2.3.1 SAFETY ON THE WORKSITE.....41

2.3.2 FIRE PREVENTION.....41

2.3.3 PRECAUTIONS CONCERNING THE DRIVING POSITION.....41

2.3.4 ROOM VENTILATION.....42

2.3.5 PRECAUTIONS CONCERNING THE LIGHTS.....42

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS- CHECKING THE WINDSHIELD WIPER BLADES.....42

2.4 PRECAUTIONS TO BE TAKEN DURING WORK.....43

2.4.1 WHEN STARTING THE ENGINE.....43

2.4.2 RULES FOR TRAVELLING ON ROADS.....43

2.4.3 CHECKS FOR TRAVELLING IN REVERSE.....44

2.4.4 MOVING THE MACHINE.....44

2.4.5 MOVING ON SLOPES.....45

2.4.6 WORKING ON SLOPES.....46

2.4.7 UNAUTHORIZED OPERATIONS.....46

2.4.8 WORKING IN WINDY WEATHER CONDITIONS.....47

2.4.9 MAIN OPERATING MODES.....48

2.4.9.1 LOADING THE MATERIAL.....48

2.4.9.2 UNLOADING THE MATERIAL.....50

2.4.10 PREVENTING ELECTROCUTION.....52

2.4.11 VISIBILITY.....52

2.4.12 WORKING ON ICY OR SNOW-COVERED SURFACES.....52

2.4.13 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT.....53

2.4.14 WORKING ON LOOSE GROUND.....53

2.4.15 PARKING THE MACHINE.....54

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES.....55

2.5.1 LOADING AND UNLOADING THE MACHINE.....55

2.5.2 THE ROUTE.....55

2.6 BATTERY.....56

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES.....56

2.6.2 STARTING WITH BOOSTER CABLES.....56

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY.....57

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE.....58

2.8.1 WARNING PLATES.....58

2.8.2 TOOLS.....58

2.8.3 PERSONNEL.....58

2.8.4 EQUIPMENT.....59

2.8.5 WORKING UNDER THE MACHINE.....59

2.8.6 KEEPING THE MACHINE CLEAN.....59

2.8.7 USE OF THE ENGINE DURING MAINTENANCE.....60

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY.....60

2.8.9 RULES TO BE FOLLOWED WHEN REFUELLING OR ADDING OIL.....60

2.8.10 CHECKING THE COOLANT LEVEL IN THE RADIATOR.....61

2.8.11 USING LAMPS.....61

2.8.12 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR.....61

2.8.13 PRECAUTIONS CONCERNING THE STARTER.....62

2.8.14 PRECAUTIONS CONCERNING THE GEAR LEVER.....62

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES AND FUEL PIPES.....63

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH- PRESSURE SYSTEMS.....63

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES.....63

2.8.18 COOLING FAN AND FAN BELT.....64

2.8.19 WASTE MATERIALS.....64

2.8.20 PRECAUTIONS CONCERNING TECHNOPOLYMERS AND ELASTOMERS.....64

2.8.21 PRECAUTIONS TO BE TAKEN WHEN INFLATING TYRES.....65

2.8.22 PRECAUTIONS TO BE TAKEN WHEN USING SYNTHETIC BIODEGRADABLE OIL TYPE ?HEES?.....65

3.1 GENERAL VIEWS.....68

3.1.1 RIGHT SIDE VIEW.....68

3.1.2 LEFT SIDE VIEW.....68

3.1.3 CAB INSIDE GENERAL VIEW.....69

3.2 INSTRUMENTS AND CONTROLS.....70

3.2.1 INSTRUMENTS.....70

3.2.2 WARNING LIGHTS.....72

3.2.3 SWITCHES AND PUSH BUTTONS.....77

3.2.4 ELECTRIC ACCESSORIES.....84

3.2.5 MACHINE CONTROLS.....85

3.3 LIFTING LOADS.....107

3.3.1 READING THE LOAD CHARTS.....107

3.3.1.1 DESCRIPTION OF THE LOAD CHARTS.....107

3.3.1.2 USING THE CHARTS.....109

3.4 FUSES AND RELAYS.....114

3.4.1 CENTRAL UNIT FUSES AND RELAYS.....114

3.4.1.1 CENTRAL UNIT FUSES.....115

3.4.1.2 CENTRAL UNIT RELAYS.....117

3.4.2 ENGINE LINE FUSES AND RELAYS.....118

3.4.2.1 ENGINE LINE FUSES.....118

3.4.2.2 ENGINE LINE RELAYS.....119

3.5 GUARDS, CAB AND DRIVER?S SEAT.....120

3.5.1 ENGINE HOOD.....120

3.5.2 CAB.....121

3.5.3 EMERGENCY EXIT.....122

3.5.4 VENTILATION AND HEATING.....123

3.5.5 AIR CONDITIONER (optional).....125

3.5.6 SEAT.....126

3.5.6.1 STANDARD SEAT.....126

3.5.6.2 OPTIONAL SEAT.....127

3.5.7 STEERING WHEEL.....128

3.5.8 SAFETY BELT.....128

3.5.9 WINDOW SHADE.....129

3.5.10 TECHNICAL DOCUMENTATION.....129

3.5.11 FIRE EXTINGUISHER.....130

3.6 USE OF THE MACHINE.....131

3.6.1 CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE.....131

3.6.1.1 VISUAL CHECKS.....131

3.6.1.2 DAILY CHECKS.....131

3.6.1.3 OPERATIONAL CHECKS.....132

3.6.2 STARTING THE ENGINE.....133

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES.....133

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES.....134

3.6.3 WARMING THE ENGINE.....135

3.6.4 HEATING THE HYDRAULIC OIL.....135

3.6.5 HOW TO MOVE THE MACHINE.....136

3.6.5.1 MOVING ON SLOPES.....137

3.6.5.2 MAXIMUM IMMERSION DEPTH.....138

3.7 PARKING THE MACHINE.....139

3.7.1 PARKING ON LEVEL GROUND.....139

3.7.2 PARKING ON SLOPES.....140

3.8 STOPPING THE ENGINE.....141

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES.....142

3.9.1 LOADING AND UNLOADING THE MACHINE.....142

3.9.2 TRANSPORT.....143

3.9.3 LIFTING THE MACHINE.....143

3.10 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON AND IN COLD PLACES.....144

3.10.1 FUEL AND LUBRICANTS.....144

3.10.2 ENGINE COOLANT.....144

3.10.3 BATTERY.....144

3.10.4 OTHER PRECAUTIONS.....145

3.10.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK.....145

3.11 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON.....146

3.12 EQUIPMENT.....147

3.12.1 INSTALLING EQUIPMENT WITH HYDRAULIC QUICK COUPLING.....147

3.12.2 INSTALLING EQUIPMENT WITH MANUAL COUPLING.....149

3.12.3 INSTALLING EQUIPMENT REQUIRING HYDRAULIC POWER (4X1 BUCKET - FORKS - ROUND BALE GRIPPERS, ETC.).....149

3.12.4 ORGANIZING THE WORK AREA.....150

3.12.5 OPERATING THE EQUIPMENT.....150

3.12.6 OPERATING THE MACHINE FITTED WITH FORKS.....151

3.12.6.1 FORKING A LOAD.....151

3.12.6.2 TRANSPORTING THE LOAD.....153

3.12.6.3 STACKING THE LOAD.....153

3.12.7 PREPARING THE MACHINE FOR TRAVELLING ON ROADS.....155

3.12.8 USING THE MACHINE AS A LOADER.....156

3.12.8.1 ORGANIZING THE WORK AREA.....156

3.12.8.2 LOADING HEAPED AND LEVEL MATERIAL.....156

3.13 LONG PERIODS OF INACTIVITY.....158

3.13.1 PREPARING THE MACHINE FOR A LONG PERIOD OF INACTIVITY.....158

3.13.2 PREPARING THE ENGINE FOR A LONG PERIOD OF INACTIVITY.....159

3.13.3 MAINTENANCE DURING A PERIOD OF INACTIVITY.....159

3.13.4 RESTARTING THE ENGINE.....160

3.13.5 AFTER A LONG PERIOD OF INACTIVITY.....160

3.14 OPERATIONS IN CASE OF FAILURE.....161

3.14.1 IF THE ENGINE BREAKS DOWN WITH BOOM LOADED, LIFTED AND EXTENDED.....161

3.14.2 REMOVING THE MACHINE IN CASE OF FAILURE.....162

3.14.3 IF THE FUEL HAS RUN OUT.....162

3.14.4 IF THE ENGINE FAILS TO START BECAUSE THE BATTERY HAS RUN DOWN.....163

3.14.4.1 STARTING WITH BOOSTER CABLES.....164

3.14.5 OTHER TROUBLES.....165

3.14.5.1 ELECTRIC CIRCUIT.....165

3.14.5.2 HYDRAULIC SYSTEM.....165

3.14.5.3 BRAKING SYSTEM.....166

3.14.5.4 CONVERTER.....166

3.14.5.5 ENGINE.....167

4.1 GUIDE TO MAINTENANCE.....170

4.2 MAINTENANCE NOTES.....172

4.2.1 NOTES REGARDING THE ENGINE.....172

4.2.1.1 ENGINE OIL.....172

4.2.1.2 COOLANT.....172

4.2.1.3 FUEL.....173

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM.....173

4.2.3 NOTES REGARDING THE ELECTRIC SYSTEM.....174

4.2.4 NOTES REGARDING LUBRICATION.....174

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING.....175

4.3 FUEL, COOLANT AND LUBRICANTS.....176

LUBRICATION WITH GREASE.....176

4.3.1 HOMOLOGATED SYNTHETIC BIODEGRADABLE LUBRICANTS ?HEES?.....178

4.4 DRIVING TORQUES FOR SCREWS AND NUTS.....179

4.4.1 STANDARD DRIVING TORQUES.....179

4.4.2 SPECIFIC DRIVING TORQUES.....179

4.5 LUBRICATION.....180

4.5.1 LUBRICATION DIAGRAM (2-SECTION BOOM).....180

4.5.2 LUBRICATION DIAGRAM (3-SECTION BOOM).....181

4.6 PERIODICAL CHANGE OF THE SAFETY-RELATED COMPONENTS.....182

4.6.1 CRITICAL PARTS FOR SAFETY.....183

4.6.1.1 FUEL SUPPLY SYSTEM.....183

4.6.1.2 DELIVERY HYDRAULIC SYSTEM.....184

4.6.1.3 CONTROL VALVE HYDRAULIC SYSTEM.....185

4.6.1.4 BOOM HYDRAULIC SYSTEM.....186

4.7 MAINTENANCE PLAN.....187

4.7.1 WHEN REQUIRED.....191

4.7.1.a CHECKING THE BATTERY ELECTROLYTE LEVEL - INSPECTING TERMINALS AND CABLES.....191

4.7.1.b CHECKING, CLEANING OR CHANGING THE ENGINE AIR CLEANERS.....192

4.7.1.c CHECKING AND CLEANING THE CAB AIR FILTER.....194

4.7.1.d FUSES AND RELAYS - CHECK AND CHANGE.....195

4.7.1.e CHECKING THE WINDSHIELD WASHER FLUID LEVEL.....195

4.7.1.f CHECKING THE WINDSHIELD WIPER BLADES.....196

4.7.1.g LUBRICATING THE CAB DOOR AND ENGINE HOOD HINGES.....196

4.7.1.h LUBRICATING THE FORK SUPPORT ROD.....196

4.7.1.i CHECKING THE FUEL LEVEL.....196

4.7.1.j TOPPING UP THE BRAKING SYSTEM OIL RESERVOIR.....197

4.7.2 MAINTENANCE EVERY 10 HOURS OF OPERATION OR EVERY DAY.....198

4.7.2.a VARIOUS CHECKS.....198

4.7.2.b CHECKING THE ACOUSTIC ALARMS, WARNING LIGHTS AND INSTRUMENTS.....198

4.7.2.c CHECKING THE ENGINE COOLANT LEVEL.....199

4.7.2.d CHECKING THE RADIATOR FLUID LEVEL.....199

4.7.2.e CHECKING THE ENGINE OIL LEVEL.....200

4.7.2.f CHECKING THE TYRE PRESSURE.....200

4.7.2.g CHECKING THE SERVICE BRAKES.....201

4.7.2.h CHECKING AND ADJUSTING THE PARKING BRAKE.....201

4.7.3 MAINTENANCE EVERY 50 HOURS OF OPERATION OR EVERY 2 WEEKS.....202

4.7.3.a LUBRICATING THE ARTICULATED JOINTS AND THE PADS.....202

4.7.3.b LUBRICATING THE CHAIN GEAR SHAFTS (Only for 3-section boom version).....204

4.7.3.c DRAINING THE WATER SEPARATOR.....204

4.7.3.d LUBRICATING BOOM.....205

4.7.4 MAINTENANCE EVERY 100 HOURS OF OPERATION.....206

4.7.4.a LUBRICATING THE DRIVE SHAFTS.....206

4.7.4.b LUBRICATING THE FRONT AND REAR AXLE SWING JOINT.....207

4.7.4.c LUBRICATING THE WHEEL HUB JOINTS.....207

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION.....208

4.7.6 MAINTENANCE EVERY 250 HOURS OF OPERATION OR EVERY 3 MONTHS.....208

4.7.6.a LUBRICATING THE ARTICULATED JOINTS.....208

4.7.6.b LUBRICATING THE BOOM INNER HOSES, ROLLERS AND GUARD.....209

4.7.6.c CHECKING THE AXLE OIL LEVEL (FRONT AND REAR AXLE).....210

4.7.6.d CHECKING THE TRANSMISSION OIL LEVEL.....211

4.7.6.e CLEANING THE OUTSIDE OF THE RADIATOR AND OF THE HEAT EXCHANGER.....212

4.7.6.f CHECKING THE ALTERNATOR-FAN BELT.....212

4.7.6.g CHECKING AND ADJUSTING THE A/C COMPRESSOR BELT TENSION (Optional).....213

4.7.6.h CHECKING THE ADJUSTMENT OF THE PARKING BRAKE.....214

4.7.6.i CHECKING THE ELECTROLYTE LEVEL.....214

4.7.7 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which synthetic biodegradable oil HEES is used).....215

4.7.8 MAINTENANCE EVERY 500 HOURS OF OPERATION OR EVERY 6 MONTHS.....216

4.7.8.a CHANGING THE FUEL FILTER.....216

4.7.8.b DRAINING THE FUEL TANK.....217

4.7.8.c CHECKING THE HYDRAULIC OIL LEVEL.....217

4.7.8.d CHANGING THE HYDRAULIC OIL DRAIN FILTER.....218

4.7.8.e DRAINING CONDENSATE FROM THE OIL TANK (Only for machines in which synthetic biodegradable oil HEES is used).....219

4.7.8.f CHANGING THE ENGINE OIL.....220

4.7.8.g CHANGING THE ENGINE OIL FILTER.....221

4.7.8.h CHECKING THE CHAINS FOR OXIDATION (Only for the 3-section boom version).....222

4.7.8.i CHECKING AND TIGHTENING THE BOOM CHAINS (Only for the 3-section boom version).....223

4.7.8.j CHECKING THE LENGTH OF THE CHAINS (Only for the 3-section boom version).....228

4.7.8.k LUBRICATING THE EXTENSION CHAINS (Only for the 3-section boom version).....229

4.7.8.l CHECKING THE CLEARANCE OF THE CHAIN DRIVING GEAR BUSHINGS (Only for the 3-section boom version).....230

4.7.8.m CHECKING THE SLIDING BLOCK CLEARANCE.....230

4.7.8.n CHECKING THE WHEEL NUT DRIVING TORQUE.....230

4.7.9 MAINTENANCE EVERY 1000 HOURS OF OPERATION OR EVERY YEAR.....231

4.7.9.a CHANGING THE FRONT AND REAR AXLE OIL.....231

4.7.9.b CHANGING THE HYDRAULIC TRANSMISSION OIL.....232

4.7.9.c CHANGING THE HYDRAULIC TRANSMISSION FILTER.....233

4.7.9.d CHECKING THE ENGINE COOLANT LEVEL AND TOPPING UP.....233

4.7.10 MAINTENANCE EVERY 2000 HOURS OF OPERATION OR EVERY 2 YEARS.....234

4.7.10.a CHECKING THE ALTERNATOR AND THE STARTER.....234

4.7.10.b CHANGING THE ALTERNATOR BELT.....234

4.7.10.c CHANGING THE COOLANT.....234

4.7.10.d CHANGING THE BRAKING SYSTEM OIL.....235

4.7.10.e CHANGING THE HYDRAULIC OIL AND CLEANING THE INTAKE FILTER.....237

4.7.11 MAINTENANCE EVERY 3 YEARS.....238

4.7.11.a CHANGING THE SAFETY BELT.....238

4.7.12 MAINTENANCE EVERY 3000 HOURS OF OPERATION OR EVERY 3 YEARS.....238

4.7.12.a CHANGING THE ENGINE THERMOSTATIC VALVE.....238

4.7.12.b CHECKING THE ENGINE ANTIVIBRATION AND RETAINING SCREWS.....238

4.7.12.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE AND THE INJECTION TIMING ADVANCE.....238

5.1 TECHNICAL DATA.....240

5.1.1 DIMENSIONS WITH FORKS.....240

5.1.2 TECHNICAL CHARACTERISTICS.....242

5.1.2.1 TECHNICAL CHARACTERISTICS WH609 (Aspirated engine).....242

5.1.2.2 TECHNICAL CHARACTERISTICS WH609 (Turbo engine).....243

5.1.2.3 TECHNICAL CHARACTERISTICS WH613 (Aspirated engine).....244

5.1.2.4 TECHNICAL CHARACTERISTICS WH613 (Turbo engine).....245

5.1.2.5 TECHNICAL CHARACTERISTICS WH713.....246

5.1.2.6 TECHNICAL CHARACTERISTICS WH714.....247

5.1.2.7 TECHNICAL CHARACTERISTICS WH714H.....248

5.1.2.8 TECHNICAL CHARACTERISTICS WH716.....249

5.1.3 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED.....250

5.1.4 LOAD DISTRIBUTION ON THE AXLES.....250

5.1.5 OPERATING PERFORMANCE.....251

5.1.5.1 OPERATING PERFORMANCE WITH FORKS (ON WHEELS).....251

5.1.5.2 OPERATING PERFORMANCE WITH FORKS (ON STABILIZERS).....252