Komatsu Hydraulic Excavator PC400LC-LK, PC400HD-LK Series Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC400LC-6LK, PC400HD-6LK, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,123 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM002901 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Operation & Maintenance Manual.pdf

CEBM002502 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Shop Manual.pdf

MAIN SECTIONS

MAIN MENU....0

COVER....1

CONTENTS....2

FOREWORD....13

SAFETY....13

SAFETY NOTICE....13

IMPORTANT SAFETY NOTICE....13

GENERAL PRECAUTIONS....13

PREPARATIONS FOR WORK....13

PRECAUTIONS DURING WORK....13

GENERAL....15

HOW TO READ THE SHOP MANUAL....16

VOLUMES....16

DISTRIBUTION AND UPDATING....16

FILING METHOD....16

REVISED EDITION MARK....16

REVISIONS....16

SYMBOLS....16

HOISTING INSTRUCTIONS....17

HOISTING....17

WIRE ROPES....17

COATING MATERIALS....18

STANDARD TIGHTENING TORQUE....20

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS....20

TIGHTENING TORQUE OF HOSE NUTS....21

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS....21

TIGHTENING TORQUE FOR FLARED NUTS....21

ELECTRIC WIRE CODE....22

CLASSIFICATION BY THICKNESS....22

CLASSIFICATION BY COLOR AND CODE....22

CONVERSION TABLES....23

METHOD OF USING THE CONVERSION TABLE....23

01 GENERAL....29

SPECIFICATION DRAWINGS....30

MACHINE....30

WORK EQUIPMENT....32

SPECIFICATIONS....34

WEIGHT TABLE....36

FUEL COOLANT AND LUBRICANTS....38

10 STRUCTURE AND FUNCTION....39

PARTS RELATED TO ENGINE....43

ENGINE MOUNT TORQUES....45

RADIATOR, OIL COOLER....47

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (1/4)....48

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (2/4)....49

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (3/4)....50

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (4/4)....52

POWER TRAIN....53

FINAL DRIVE....55

FINAL DRIVE SPECIFICATIONS AND TORQUES....56

SWING CIRCLE....58

SWING CIRCLE SPECIFICATIONS AND TORQUES....59

SWING MACHINERY....61

SWING MACHINERY SPECIFICATIONS AND TORQUES....62

TRACK FRAME, RECOIL SPRING....64

PC400LC-6LK....64

TRACK FRAME, RECOIL SPRING TORQUES PC400LC-6LK....65

PC400LC-6LK - VARIABLE GAUGE....66

TRACK FRAME, RECOIL SPRING TORQUES PC400LC-6LK - VARIABLE GAUGE....67

PC400HD-6LK....68

TRACK FRAME, RECOIL SPRING TORQUES PC400HD-6LK....69

TRACK SHOE....71

TRACK SHOE SPECIFICATIONS....74

CARRIER ROLLER....75

IDLER....76

TRACK ROLLER....78

HYDRAULIC PIPING DRAWING....80

HYDRAULIC CIRCUIT DIAGRAM....82

HYDRAULIC TANK, HYDRAULIC FILTER....83

HYDRAULIC PUMP....84

HPV 160 + 160....84

HYDRAULIC PUMP TORQUES....87

TVC, LS VALVE....91

LS VALVE - OPERATION....94

TVC VALVE - OPERATION....98

HYDRAUIC CYLINDER....106

BOOM, BUCKET CYLINDER - THREADED PISTON....106

BOOM, BUCKET CYLINDER - CLAMPED PISTON....106

ARM CYLINDER - THREADED PISTON....106

ARM CYLINDER - CLAMPED PISTON....106

CONTROL VALVE....108

10 SPOOL VALVE - STD. AND 3 SERVICE VALVES....108

9 SPOOL VALVE - STD AND 2 SERVICE VALVES....114

8 SPOOL VALVE - STD AND 1 SERVICE VALVES....115

7 SPOOL VALVE - STD....116

CONTROL VALVE SPECIFICATIONS AND TORQUES....118

10 SPOOL VALVE....118

SELF REDUCING PRESSURE VALVE....124

SELF REDUCING PRESSURE VALVE SPECIFICATIONS....124

SUCTION SAFETY VALVE....130

FOR SERVICE....130

SUCTION SAFETY VALVE SPECIFICATIONS AND TORQUES....131

CLSS....132

OUTLINE OF CLSS....132

BASIC PRINCIPLE....133

CONTROL OF PUMP SWASH PLATE ANGLE....133

PRESSURE COMPENSATION....134

OPERATION FOR EACH FUNCTION OF CLSS....135

SYSTEM DIAGRAM....136

WHEN UNLOAD VALVE IS ACTUATED....137

OPERATION OF RELIEF VALVE....138

CUT-OFF CONTROL ACTUATED....138

CUT-OFF CANCELED....138

INTRODUCTION OF LS PRESSURE....139

LS BYPASS VALVE....140

PRESSURE COMPENSATION VALVE....141

SHUTTLE VALVE INSIDE PRESSURE COMPENSATION VALVE....144

VARIABLE TYPE PRESSURE COMPENSATION VALVE (FOR SERVICE VALVE)....146

VARIABLE PRESSURE COMPENSATION VALVE SPECIFICATIONS AND TORQUES....147

BOOM REGENERATION CIRCUIT....148

ARM REGENERATION CIRCUIT....150

MERGE FLOW DIVIDER VALVE....152

LS SELECT VALVE....154

2-STAGE SAFETY VALVE (INSTALLED TO BOOM CYLINDER HEAD)....155

OPERATION OF CLSS SYSTEM AS A WHOLE....156

WHEN ALL WORK EQUIPMENT IS AT NEUTRAL....156

WHEN PUMP FLOW MERGED, BUCKET CURL OPERATED INDEPENDENTLY....157

WHEN PUMP FLOW MERGED, BOOM RAISE OPERATED INDEPENDENTLY....157

WHEN PUMP FLOW MERGED, ARM IN OPERATED INDEPENDENTLY....157

WHEN PUMP FLOW MERGED, ARM OUT OPERATED INDEPENDENTLY....158

WHEN PUMP DIVIDED, TRAVEL OPERATED INDEPENDENTLY....158

WHEN PUMP FLOW MERGED, ARM IN + BOOM RAISE OPERATED SIMULTANEOUSLY....158

WHEN PUMP FLOW MERGED, SWING + BOOM RAISE OPERATED SIMULTANEOUSLY....159

WHEN PUMP FLOW DIVIDED, TRAVEL + BOOM RAISE OPERATED SIMULTANEOUSLY....159

WHEN PUMP FLOW DIVIDED, TRAVEL + ARM IN OPERATED SIMULTANEOUSLY....159

SWING MOTOR....160

SWING MOTOR SPECIFICATIONS AND TORQUES....162

SUCTION-SAFETY VALVE....163

SWING BRAKE....164

CENTER SWIVAL JOINT....165

CENTER SWIVEL JOINT SPECIFICATIONS....166

TRAVEL MOTOR....168

MOTOR OPERATION....172

AT LOW SPEED....172

AT HIGH SPEED....173

PARKING BRAKE OPERATION....174

BRAKE VALVE OPERATION....174

SAFETY VALVE....176

VALVE CONTROL....179

WORK EQUIPMENT PPC VALVE....180

OPERATION....182

AT NEUTRAL....182

DURING FINE CONTROL (NEUTRAL ? FINE CONTROL)....182

DURING FINE CONTROL (WHEN LEVER IS RETURNED)....183

AT FULL STROKE....183

WORK EQUIPMENT AND SWING PPC VALVE SPECIFICATIONS AND TORQUES....184

TRAVEL PPC VALVE....185

OPERATION....187

AT NEUTRAL....187

FINE CONTROL (NEUTRAL --> FINE CONTROL)....187

FINE CONTROL (CONTROL LEVER RETURNED)....188

AT FULL STROKE....188

TRAVEL PPC VALVE SPECIFICATIONS AND TORQUE....190

SERVICE PPC VALVE....192

SERVICE PPC VALVE SPECIFICATIONS AND TORQUES....194

PPC SAFETY LOCK VALVE....195

PPC ACCUMULATOR....196

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE....197

PPC SHUTTLE VALVE....198

TRAVEL JUNCTION VALVE....201

STRAIGHT-TRAVEL SYSTEM....202

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE SPECIFICATIONS AND TORQUES....204

LS-EPC VALVE....205

LS-EPC VALVE SPECIFICATIONS AND TORQUES....208

SOLENOID VALVE....209

SOLENOID VALVE TORQUES....211

BOOM HOLDING VALVE....212

BOOM HOLDING VALVE SPECIFICATIONS AND TORQUES....215

WORK EQUIPMENT....217

WORK EQUIPMENT SPECIFICATIONS....218

DIMENSIONS OF WORK EQUIPMENT....220

ARM....220

BUCKET....222

AIR CONDITIONER....225

A/C PIPING....225

A/C ELECTRICAL WIRING DIAGRAM....226

ENGINE CONTROL....230

OPERATION....231

STARTING ENGINE....231

ENGINE SPEED CONTROL....231

STOPPING ENGINE....231

COMPONENTS....232

FUEL CONTROL DIAL....232

GOVERNOR MOTOR....234

GOVERNOR, PUMP CONTROLLER....236

INPUT OUTPUT SIGNALS....237

ELECTRONIC CONTROL SYSTEM....239

CONTROL FUNCTION....239

TOTAL SYSTEM DIAGRAM....239

PUMP AND ENGINE CONTROL SYSTEM....240

PUMP AND VALVE CONTROL FUNCTION....243

CUT-OFF FUNCTION....244

CUT-OFF CANCEL FUNCTION....244

FINE CONTROL MODE FUNCTION....245

POWER MAX. FUNCTION, SWIFT SLOW-DOWN FUNCTION....246

AUTO DECELERATION SYSTEM....247

AUTOMATIC WARMING-UP AND ENGINE OVERHEAT PREVENTION FUNCTION....249

SWING CONTROL SYSTEM....252

TRAVEL CONTROL SYSTEM....254

ACTIVE MODE FUNCTION....256

INCREASE IN ENGINE SPEED....257

COMPONENTS OF SYSTEM....258

ENGINE SPEED SENSOR....258

PPC HYDRAULIC SWITCH....258

PUMP PRESSURE SENSOR....259

TVC PROLIX RESISTOR....260

MACHINE MONITOR SYSTEM....262

MONITOR PANEL....263

MONITOR DISPLAY....264

CONTENT OF DISPLAY....265

OIL MAINTENANCE FUNCTION....266

MODE SELECTION SWITCHES....268

SWITCH ACTUATION TABLE....268

SENSORS....269

20 TESTING, ADJUSTING AND TROUBLESHOOTING....273

STANDARD VALUE TABLES....275

ENGINE RELATED PARTS....275

CHASSIS RELATED PARTS....276

ELECTRICAL PARTS....281

TESTING AND ADJUSTING....287

SERVICE TOOLS....289

ENGINE....290

BLOW BY PRESSURE....290

BOOST PRESSURE....290

COMPRESSION PRESSURE....290

ENGINE OIL PRESSURE....290

ENGINE SPEED SENSOR....290

ENGINE SPEED (rpm)....290

EXHAUST COLOR....290

FUEL INJECTION TIMING....290

VALVE CLEARANCE....290

GOVERNOR MOTOR LEVER S TROKE....291

FAN BELT TENSION....292

A/C COMPRESSOR BELT....292

WORK EQUIPMENT, SWING, TRAVEL CIRCUIT....293

TVC VALVE OUTPUT PRESSURE....296

LS VALVE OUTPUT PRESSURE....298

LS DIFFERENTIAL PRESSURE....298

CONTROL CIRCUIT OIL PRESSURE....301

SOLENOID VALVE OUTPUT PRESSURE....302

PPC VALVE OUTPUT PRESSURE....305

PPC SHUTTLE VALVE....305

WORK EQUIPMENT, SWING PPC VALVE....307

WORK EQUIPMENT....309

HYDRAULIC DRIFT - LOCATIONS CAUSING....309

CYLINDER PACKING....309

BOOM LOCK VALVE....310

PPC VALVE....310

OIL LEAKAGE....311

WORK EQUIPMENT CYLINDER....311

SWING MOTOR....312

TRAVEL MOTOR....312

RELEASING REMAINING PRESSURE....313

TESTING CLEARANCE OF SWING CIRCLE BEARING....314

SPROCKET WEAR....315

TRACK SHOE TENSION....316

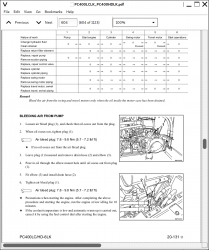

BLEEDING AIR....317

BLEEDING AIR FROM HYDRAULIC CYLINDERS....318

BLEEDING AIR FROM SWING MOTOR....318

BLEEDING AIR FROM TRAVEL MOTOR....318

TROUBLESHOOTING GENERAL....319

POINTS TO REMEMBER WHEN TROUBLESHOOTING....321

SEQUENCE OF EVENTS IN TROUBLESHOOTING....323

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE....324

POINTS TO REMEMBER WHEN HANDLING ELECTRIC EQUIPMENT....324

HANDLING WIRING HARNESSES AND CONNECTORS....324

REMOVING, INSTALLING, AND DRYING CONNECTORS AND WIRING HARNESSES....326

HANDLING CONTROL BOX....329

POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRIC CIRCUITS....330

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT....330

CHECKS BEFORE TROUBLESHOOTING....332

CONNECTOR TYPES AND MOUNTING LOCATIONS....333

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS....339

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM....349

EXPLANATION OF MACHINE CONTROL FUNCTIONS....349

DISPLAY METHOD AND SPECIAL FUNCTION OF MONITORING PANEL....350

DISPLAY ON MACHINE MONITOR....350

RECORDING OF SERVICE CODES AND USER CODE DISPLAY FUNCTION....350

METHOD OF DISPLAYING TROUBLE DATA....351

MACHINE DATA MONITORING FUNCTION....352

METHOD OF DISPLAYING MONITORING CODE....352

TABLE OF MACHINE MONITORING CODES....353

BIT PATTERN CHART....354

GOVERNOR MOTOR ADJUSTMENT MODE....356

TIME ADJUSTMENT MODE....356

WORKING MODE DEFAULT SETTING MODE....357

METHOD OF USING JUDGEMENT TABLE....358

METHOD OF USING TROUBLESHOOTING CHARTS....360

METHOD OF USING TROUBLESHOOTING TABLE FOR EACH TROUBLESHOOTING MODE....360

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE....364

PROCEDURE FOR CHECKING MONITOR PANEL OUTPUT SIGNAL....366

CHECKING INPUT SIGNAL OF GOVERNOR, PUMP CONTROLLER....367

PUMP CONTROL SYSTEM....367

GOVERNOR CONTROL SYSTEM....370

SERVICE CODE TABLE....371

TROUBLESHOOTING ELECTRICAL SYSTEM ON GOVERNOR PUMP CONTROLLER (C-MODE)....373

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....375

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....375

USER CODE MEMORY RETENTION FUNCTION....375

INFORMATION CONTAINED IN TESTING PROCEDURES....376

(C-1)....378

CONTROLLER POWER SOURCE (LED) IS OFF....378

(C-2)....380

SHORT IN FRONT PUMP (TVC) SOLENOID SYSTEM....380

(C-3)....382

OPEN IN FRONT PUMP (TVC) SOLENOID SYSTEM....382

(C-4)....384

SHORT IN REAR PUMP (TVC) SOLENOID SYSTEM....384

(C-5)....386

OPEN IN REAR PUMP (TVC) SOLENOID SYSTEM....386

(C-6)....388

SHORT IN (LS) SELECT SOLENOID SYSTEM....388

(C-7)....389

OPEN IN (LS) SELECT SOLENOID SYSTEM....389

(C-8)....390

SHORT IN SWING BRAKE SOLENOID SYSTEM....390

(C-9)....392

OPEN IN SWING BRAKE SOLENOID SYSTEM....392

(C-10)....394

SHORT IN PUMP MERGE DIVIDER SOLENOID SYSTEM....394

(C-11)....396

OPEN IN PUMP MERGE DIVIDER SOLENOID SYSTEM....396

(C-12)....398

SHORT IN TRAVEL SPEED SOLENOID SYSTEM....398

(C-13)....400

OPEN IN TRAVEL SPEED SOLENOID SYSTEM....400

(C-14)....402

SHORT IN ACTIVE MODE, SWING, SOLENOID SYSTEM....402

(C-15)....404

OPEN IN ACTIVE MODE, SWING, SOLENOID SYSTEM....404

(C-16)....406

ABNORMAL INPUT FOR MODEL CODE....406

(C-17)....408

SHORT IN (LS-EPC) SOLENOID SYSTEM....408

(C-18)....409

OPEN IN (LS-EPC) SOLENOID SYSTEM....409

(C-19)....410

ABNORMAL FRONT PUMP PRESSURE SENSOR SIGNAL....410

(C-20)....412

BINOMIAL REAR PUMP PRESSURE SENSOR SIGNAL....412

(C-21)....414

ABNORMAL PRESSURE SENSOR POWER SUPPLY....414

(C-22)....416

ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER....416

(C-23)....418

MACHINE PUSH-UP SOLENOID HAS NO RESPONSE....418

TROUBLESHOOTING ELECTRICAL SYSTEM ON GOVERNOR PUMP CONTROLLER (E-MODE)....421

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....423

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....423

USER CODE MEMORY RETENTION FUNCTION....423

INFORMATION CONTAINED IN TESTING PROCEDURES....424

(E-1)....426

CONTROLLER POWER SOURCE (LED) IS OFF....426

(E-2)....428

INCORRECT FUEL CONTROL DIAL VALUE DISPLAYED....428

(E-3)....430

OPEN IN MOTOR DRIVE SYSTEM....430

(E-4)....432

SHORT IN MOTOR DRIVE SYSTEM....432

(E-5)....434

INCORRECT FEEDBACK IN POTENTIOMETER DISPLAYED....434

(E-6)....436

SHORT IN BATTERY RELAY OUTPUT SYSTEM....436

(E-7)....438

ABNORMALITY IN STEP OUT MOTOR SYSTEM....438

(E-8)....440

ENGINE WILL NOT CRANK....440

(E-9)....442

ENGINE SPEED IRREGULAR....442

ENGINE SPEED IS HUNTING....444

(E-10)....446

ENGINE OUTPUT IS LOW....446

(E-11)....448

ENGINE WILL NOT SHUT DOWN....448

(E-12)....450

FAULTY OPERATION OF RELAY OUTPUT SYSTEM....450

TROUBLSHOOTING GOVERNOR, PUMP CONTROLLER, INPUT SIGNAL (F-MODE)....453

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....454

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....454

USER CODE MEMORY RETENTION FUNCTION....454

INFORMATION CONTAINED IN TESTING PROCEDURES....455

(F-1)....457

SWING OIL PRESSURE SWITCH DOES NOT LIGHT UP....457

(F-2)....458

TRAVEL OIL PRESSURE SWITCH DOES NOT LIGHT UP....458

(F-3)....459

BOOM (LOWER) PRESSURE SWITCH DOES NOT LIGHT UP....459

(F-4)....460

BOOM (RAISE) PRESSURE SWITCH DOES NOT LIGHT UP....460

(F-5)....461

ARM (IN) PRESSURE SWITCH DOES NOT LIGHT UP....461

(F-6)....462

ARM (OUT) PRESSURE SWITCH DOES NOT LIGHT UP....462

(F-7)....463

BUCKET (CURL) PRESSURE SWITCH DOES NOT LIGHT UP....463

(F-8)....464

BUCKET (DUMP) PRESSURE SWITCH DOES NOT LIGHT UP....464

(F-9)....465

SWING LOCK SWITCH DOES NOT LIGHT UP....465

(F-10)....466

MODE CONNECTION DOES NOT LIGHT UP....466

(F-11)....468

LEFT KNOB SWITCH DOES NOT LIGHT UP....468

TROUBLESHOOTING HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)....471

PUMP MERGE DIVIDER LOGIC....473

SOLENOID ACTUATION TABLE....473

TABLE OF FAILURE MODES AND CAUSES....474

H-1....478

SPEEDS OF ALL WORK EQUIPMENT, SWING, TRAVEL ARE SLOW OR LACK POWER....478

H-2....480

THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS....480

H-3....481

NO WORK EQUIPMENT, TRAVEL, SWING MOVEMENT....481

H-4....482

ABNORMAL NOISE GENERATED AROUND PUMP....482

H-5....483

AUTO DECELERATION DOES NOT WORK WHEN PPC SHUTTLE VALVE IS CAUSE....483

H-6....483

FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR....483

H-7....484

BOOM IS SLOW OR LACKS POWER....484

H-8....486

ARM IS SLOW OR LACKS POWER....486

H-9....488

BUCKET IS SLOW OR LACKS POWER....488

H-10....490

WORK EQUIPMENT; BOOM, ARM, BUCKET, DOES NOT MOVE, BUT TRAVEL AND SWING ARE NORMAL....490

H-11....490

EXCESSIVE HYDRAULIC DRIFT, BOOM, ARM, BUCKET....490

EXCESSIVE HYDRAULIC DRIFT OF BOOM....490

EXCESSIVE HYDRAULIC DRIFT OF ARM OR BUCKET....490

H-12....491

EXCESSIVE TIME LAG, ENGINE AT LOW IDLING....491

H-13....491

OTHER EQUIPMENT MOVES WHEN SINGLE CIRCUIT IS RELIEVED....491

H-14....492

IN L/O, F/O MODES, WORK EQUIPMENT SPEED IS FASTER THAN SPECIFIED SPEED....492

H-15....492

MALFUNCTION OF MACHINE PUSH UP FUNCTION....492

H-16....492

IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW....492

H-17....493

IN SWING PLUS BOOM RAISE, BOOM RAISE IS SLOW....493

IN ACTIVE MODE....493

IN OTHER MODE....493

H-18....493

IN SWING PLUS ARM, ARM IS SLOW....493

H-19....493

IN SWING PLUS TRAVEL, TRAVEL SPEED DROPS EXCESSIVELY....493

H-20....494

TRAVEL DEVIATION....494

WHEN THERE IS A DEVIATION IN NORMAL TRAVEL....494

EXCESSIVE DEVIATION WHEN STARTING....494

H-21....496

TRAVEL SPEED IS SLOW....496

H-22....498

STEERING DOES NOT TURN EASILY OR LACKS POWER....498

H-23....500

TRAVEL SPEED DOES NOT SWITCH OR IS FASTER THAN SPECIFIED SPEED....500

H-24....500

TRAVEL DOES NOT MOVE, ONE SIDE ONLY....500

H-25....501

DOES NOT SWING....501

DOES NOT SWING TO EITHER LEFT OR RIGHT....501

DOES NOT SWING IN ONE DIRECTION....501

H-26....502

SWING ACCELERATION IS POOR OR SWING SPEED IS SLOW....502

H-27....504

EXCESSIVE OVERRUN WHEN STOPPING SWING....504

ONE DIRECTION ONLY....504

BOTH DIRECTIONS....504

H-28....505

EXCESSIVE SHOCK WHEN STOPPING SWING, ONE DIRECTION ONLY....505

H-29....505

EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING....505

H-30....506

EXCESSIVE HYDRAULIC DRIFT OR SWING....506

WHEN SWING HOLDING BRAKE IS RELEASED....506

WHEN SWING HOLDING BRAKE IS APPLIED....506

H-31....507

SWING SPEED IS FASTER THAN SPECIFIED SWING SPEED....507

TROUBLESHOOTING MACHINE MONITOR SYSTEM (M-MODE)....509

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....511

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....511

USER CODE MEMORY RETENTION FUNCTION....511

INFORMATION CONTAINED IN TESTING PROCEDURES....512

(M-1)....514

ERROR IN DATA HISTORY....514

(M-2)....516

SHORT IN BUZZER OUTPUT DISPLAY....516

(M-3)....518

AIR CLEANER CLOG INDICATOR FAILURE....518

(M-4)....520

ABNORMAL ENGINE (HI) OIL PRESSURE....520

(M-5)....522

ENGINE COOLANT INDICATING OVERHEAT CONDITION....522

(M-6)....524

THREE SECOND DELAY ON MONITOR WHEN IGNITION KEY IS TURNED ?ON?....524

(M-7)....526

WHEN IGNITION SWITCH IS TURNED ?ON? ALL PANEL LAMPS STAY ILLUMINATED....526

(M-8)....526

WHEN IGNITION SWITCH IS TURNED ?ON? PANEL LIGHTS DO NOT MATCH THE MACHINE....526

(M-9)....528

ABNORMAL FLUID LEVEL INDICATIONS....528

ENGINE COOLANT LEVEL FLASHES....528

ENGINE OIL LEVEL FLASHES....530

HYDRAULIC OIL LEVEL FLASHES....531

(M-10)....532

PREHEATING INDICATION IS ?ON? WHEN SYSTEM IS OFF....532

(M-11)....534

WHEN ENGINE IS STARTED BASIC CHECK ITEMS FLASH....534

ALTERNATOR SYSTEM....534

ENGINE OIL PRESSURE....536

(M-12)....538

WHEN ENGINE IS STARTED CAUTION ITEMS FLASH....538

ALTERNATOR SYSTEM....538

ENGINE OIL PRESSURE....540

(M-13)....542

WHEN THE ENGINE IS STARTED CAUTION AND EMERGENCY ITEMS FLASH....542

ENGINE OIL PRESSURE FLASHES....542

COOLANT LEVEL FLASHES....542

BATTERY CHARGE INDICATOR FLASHES....542

COOLANT TEMPERATURE FLASHES....543

FUEL LEVEL FLASHES....544

AIR CLEANER CLOG INDICATOR FLASHES....545

(M-14)....546

WARNINGS FLASH BUT BUZZER IS DELAYED....546

(M-15)....548

BUZZER SOUNDS CONTINUOUSLY....548

(M-16)....550

NIGHT LIGHT ON MONITOR PANEL DOES NOT LIGHT-UP....550

(M-17)....552

ENGINE COOLANT TEMPERATURE DOES NOT RISE....552

(M-18)....554

ENGINE COOLANT TEMPERATURE GIVES NO DISPLAY....554

(M-19)....556

FUEL LEVEL GAUGE ALWAYS SHOWS ?FULL?....556

(M-20)....557

FUEL LEVEL GAUGE DOES NOT DISPLAY....557

(M-21)....558

SWING LOCK NOT INDICATED ON MONITOR WHEN ?ON?....558

(M-22)....560

SWING PROLOX NOT INDICATED ON MONITOR....560

(M-23)....562

SERVICE METER DOES NOT ADVANCE WHILE ENGINE IS RUNNING....562

(M-24)....563

WITH IGNITION SWITCH ?OFF?, WHEN THE TIME SWITCH IS PRESSED THE TIME AND SERVICE ARE NOT DISPLAYED....563

(M-25)....564

FAULTY FUEL LEVER SENSOR SYSTEM....564

(M-26)....565

COOLANT TEMPERATURE SENSOR SYSTEM....565

(M-27)....566

FAULTY ENGINE OIL LEVEL SENSOR SYSTEM....566

(M-28)....568

FAULTY ENGINE COOLANT LEVEL SENSOR SYSTEM....568

(M-29)....570

FAULTY HYDRAULIC OIL LEVEL SENSOR SYSTEM....570

(M-30)....572

WIPER DOES NOT WORK, OR REMAINS ?ON?....572

WIPER DOES NOT WORK....572

WIPER SWITCH IS IN THE "OFF" POSITION BUT WIPERS REMAIN ON....575

(M-13)....578

WASHER MOTOR WORKS WHEN SWITCH IS NOT BEING USED OR WASHER MOTOR DOES NOT WORK....578

TROUBLESHOOTING COMMUNICATION SYSTEM (N-MODE)....581

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....582

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....582

USER CODE MEMORY RETENTION FUNCTION....582

INFORMATION CONTAINED IN TESTING PROCEDURES....583

(N-1)....585

COMMUNICATION ABNORMALITY....585

30 DISASSEMBLY AND ASSEMBLY....587

METHOD OF USING MANUAL....589

PRECAUTIONS DURING OPERATION....590

PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK....590

PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK....591

PRECAUTIONS WHEN COMPLETING THE OPERATIONS....592

OTHER PRECAUTIONS....592

SPECIAL TOOL LIST....593

SKETCHES OF SPECIAL TOOLS....598

ENGINE....606

AFTERCOOLER....606

ALTERNATOR....606

CYLINDER HEAD....606

ENGINE OIL COOLER....606

ENGINE REAR SEAL....606

FUEL INJECTION PUMP....606

NOZZLE HOLDER....606

STARTING MOTOR....606

THERMOSTAT....606

TURBOCHARGER....606

WATER PUMP....606

GOVERNOR MOTOR....607

OIL COOLER....608

RADIATOR, OIL COOLER....610

ENGINE, MAIN HYDRAULIC PUMP....613

DAMPER....618

FUEL TANK....619

CENTER SWIVEL JOINT....620

FINAL DRIVE....622

TRAVEL MOTOR....633

SPROCKET....647

SWING MOTOR....648

SWING MACHINERY....658

REVOLVING FRAME....667

SWING CIRCLE....669

IDLER AND RECOIL SPRING....670

IDLER....671

RECOIL SPRING....675

TRACK ROLLER....677

CARRIER ROLLER....683

TRACK CHAIN....688

HYDRAULIC TANK....689

MAIN HYDRAULIC PUMP....691

DISASSEMBLY....693

PUMP ASSEMBLY....693

FRONT PUMP....693

REAR PUMP....698

ASSEMBLY....701

FRONT PUMP....701

REAR PUMP....709

MAIN PUMP OIL SEAL....720

CONTROL VALVE....721

PUMP MERGE DIVIDER VALVE....735

PRESSURE COMPENSATION VALVE....736

FRONT PUMP SERVO VALVE....737

REAR PUMP SERVO VALVE....738

LS-EPC SOLENOID VALVE....739

SOLENOID VALVE....740

WORK EQUIPMENT PPC VALVE....742

TRAVEL PPC VALVE....744

PPC SHUTTLE VALVE....747

BOOM LOCK VALVE....750

CYLINDER....752

BOOM....752

ARM....754

BUCKET....756

HYDRAULIC....758

BOLT ON TYPE PISTON....758

THREADED STYLE PISTON....762

WORK EQUIPMENT....768

BUCKET....770

ARM....772

BUCKET AND ARM....774

BOOM....776

OPERATORS CAB....778

COUNTERWEIGHT....780

AIR CONDITIONER....781

COMPRESSOR....781

CONDENSER....782

RECEIVER TANK....783

AIR CONDITIONER UNIT....784

GOVERNOR, PUMP CONTROLLER....786

MONITOR PANEL....787

CONTROL STAND CASE....788

90 OTHERS....791

ELECTRICAL....793

FOLDOUT 1 - CIRCUIT DIAGRAM SHEET 1 (Part 1 of 3)....793

FOLDOUT 2 - CIRCUIT DIAGRAM SHEET 1 (Part 2 of 3)....795

FOLDOUT 3 - CIRCUIT DIAGRAM SHEET 1 (Part 3 of 3)....797

FOLDOUT 4 - CIRCUIT DIAGRAM SHEET 2 (Part 1 of 2)....799

FOLDOUT 5 - CIRCUIT DIAGRAM SHEET 2 (Part 2 of 2)....801

FOLDOUT 6 - CIRCUIT DIAGRAM SHEET 3 (Part 1 of 1)....803

FOLDOUT 7 - ELECTRONIC CONTROL SYSTEM - TOTAL SYSTEM DIAGRAM....805

HYDRAULIC....807

FOLDOUT 8 - CIRCUIT DIAGRAM (Sheet 1 of 4)....807

FOLDOUT 9 - CIRCUIT DIAGRAM (Sheet 2 of 4)....809

FOLDOUT 10 - CIRCUIT DIAGRAM (Sheet 3 of 4)....811

FOLDOUT 11 - CIRCUIT DIAGRAM (Sheet 4 of 4)....813

CLSS OPERATION FOR EACH FUNCTION....815

FOLDOUT 12 - HYDRAULIC CIRCUIT DIAGRAM....815

FOLDOUT 13 - WHEN ALL WORK EQUIPMENT IS AT NEUTRAL....817

FOLDOUT 14 - WHEN PUMP FLOW MERGED, BUCKET CURL OPERATED INDEPENDENTLY....819

FOLDOUT 15 - WHEN PUMP FLOW MERGED, BOOM RAISE OPERATED INDEPENDENTLY....821

FOLDOUT 16 - WHEN PUMP FLOW MERGED, ARM IN OPERATED INDEPENDENTLY....823

FOLDOUT 17 - WHEN PUMP FLOW MERGED, ARM OUT OPERATED INDEPENDENTLY....825

FOLDOUT 18 - WHEN PUMP DIVIDED, TRAVEL OPERATED INDEPENDENTLY....827

FOLDOUT 19 - WHEN PUMP FLOW MERGED, ARM IN + BOOM RAISE OPERATED SIMULTANEOUSLY....829

FOLDOUT 20 - WHEN PUMP FLOW MERGED, SWING + BOOM RAISE OPERATED SIMULTANEOUSLY....831

FOLDOUT 21 - WHEN PUMP FLOW DIVIDED, TRAVEL + BOOM RAISE OPERATED SIMULTANEOUSLY....833

FOLDOUT 22 - WHEN PUMP FLOW DIVIDED, TRAVEL + ARM IN OPERATED SIMULTANEOUSLY....835S