Komatsu Hydraulic Excavators PC400LC-LM, PC400HD-LM Series Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC400LC-6LM, PC400HD-6LM, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC400LC-6LM, PC400HD-6LM workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,157 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM008000 - Hydraulic Excavator PC400LC-6LM, PC400HD-6LM Operation & Maintenance Manual.pdf

CEBM005302 - Hydraulic Excavator PC400LC-6LM, PC400HD-6LM Shop Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...13

SAFETY NOTICE...13

IMPORTANT SAFETY NOTICE...13

GENERAL PRECAUTIONS...13

PREPARATIONS FOR WORK...13

PRECAUTIONS DURING WORK...13

FOREWORD...15

GENERAL...15

HOW TO READ THE SHOP MANUAL...16

VOLUMES...16

DISTRIBUTION AND UPDATING...16

FILING METHOD...16

REVISED EDITION MARK...16

REVISIONS...16

SYMBOLS...16

HOISTING INSTRUCTIONS...17

HOISTING...17

WIRE ROPES...17

COATING MATERIALS...18

STANDARD TIGHTENING TORQUE...20

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS...20

TIGHTENING TORQUE OF HOSE NUTS...21

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS...21

TIGHTENING TORQUE FOR FLARED NUTS...21

ALTERNATIVE FASTENERS...22

BOLT IDENTIFICATION CHART...22

GRADE 5 AND 8 NON PHOSPHATE COATED HARDWARE...23

GRADE 8 PHOSPHATE COATED HARDWARE...24

STANDARD METRIC FASTENERS...24

HYDRAULIC TUBES AND FITTINGS...25

HOSE CLAMPS...25

SPLIT FLANGE CONNECTIONS...25

ELECTRIC WIRE CODE...26

CLASSIFICATION BY THICKNESS...26

CLASSIFICATION BY COLOR AND CODE...26

CONVERSION TABLES...27

METHOD OF USING THE CONVERSION TABLE...27

01 GENERAL...33

SPECIFICATION DRAWINGS...34

MACHINE...34

WORK EQUIPMENT...36

SPECIFICATIONS...38

WEIGHT TABLE...40

FUEL COOLANT AND LUBRICANTS...42

ENGINE OIL SPECIFICATIONS...43

NORMAL OPERATION...43

ARCTIC OPERATION...43

FINAL DRIVE OIL SPECIFICATIONS...44

COOLANT SPECIFICATIONS...45

10 STRUCTURE AND FUNCTION...51

PARTS RELATED TO ENGINE...52

RADIATOR, OIL COOLER...54

POWER TRAIN...55

FINAL DRIVE...56

SWING CIRCLE...57

SWING MACHINERY...58

TRACK FRAME, RECOIL SPRING...59

PC400LC-6LM...59

TRACK FRAME, RECOIL SPRING...60

PC400LC-6LM - Variable Gauge...60

TRACK FRAME, RECOIL SPRING...61

PC400HD-6LM...61

TRACK SHOE...62

HYDRAULIC PIPING DRAWING...63

HYDRAULIC CIRCUIT DIAGRAM...64

HYDRAULIC TANK, HYDRAULIC FILTER...65

HYDRAULIC PUMP...66

MAIN PUMP...67

TVC, LS VALVE...72

CONTROL VALVE...86

STANDARD AND 2 SERVICE VALVES...86

MAIN STRUCTURE OF 9 SPOOL VALVE (1/4)...87

MAIN STRUCTURE OF 9 SPOOL VALVE (2/4)...88

MAIN STRUCTURE OF 9 SPOOL VALVE (3/4)...89

MAIN STRUCTURE OF 9 SPOOL VALVE (4/4)...90

9 SPOOL VALVE - STD AND 2 SERVICE VALVES...92

8 SPOOL VALVE - STD AND 1 SERVICE VALVES...93

7 SPOOL VALVE - STD...94

SELF REDUCING PRESSURE VALVE...95

STRUCTURE...95

WHEN ENGINE IS STOPPED...97

AT NEUTRAL AND WHEN LOAD PRESSURE P2 IS LOW...98

WHEN LOAD PRESSURE P2 IS HIGH...98

WHEN THERE IS ABNORMAL HIGH PRESSURE...99

SUCTION SAFETY VALVE...100

FOR SERVICE VALVE...100

CLSS...101

OUTLINE OF CLSS...101

BASIC PRINCIPLE...102

CONTROL OF PUMP SWASH PLATE ANGLE...102

PRESSURE COMPENSATION...103

WHEN UNLOAD VALVE IS ACTUATED...107

CUT-OFF CONTROL ACTUATED...108

CUT-OFF CANCELED...108

INTRODUCTION OF LS PRESSURE...109

LS BYPASS VALVE...110

PRESSURE COMPENSATION VALVE...111

SHUTTLE VALVE INSIDE PRESSURE COMPENSATION VALVE...114

VARIABLE TYPE PRESSURE COMPENSATION VALVE (FOR SERVICE VALVE)...116

BOOM REGENERATION CIRCUIT...117

ARM REGENERATION CIRCUIT...119

MERGE FLOW DIVIDER VALVE...120

LS SELECT VALVE...122

2-STAGE SAFETY VALVE (INSTALLED TO BOOM CYLINDER HEAD)...123

WHEN ALL WORK EQUIPMENT IS AT NEUTRAL (10-75)...124

WHEN PUMP FLOW MERGED, BUCKET CURL OPERATED INDEPENDENTLY (10-76)...127

WHEN PUMP FLOW MERGED, BOOM RAISE OPERATED INDEPENDENTLY (10-79)...128

WHEN PUMP FLOW MERGED, ARM IN OPERATED INDEPENDENTLY (10-80)...131

WHEN PUMP FLOW MERGED, ARM OUT OPERATED INDEPENDENTLY (10-83)...132

WHEN PUMP DIVIDED, TRAVEL OPERATED INDEPENDENTLY (10-84)...135

WHEN PUMP FLOW MERGED, ARM IN + BOOM RAISE OPERATED SIMULTANEOUSLY (10-87)...136

WHEN PUMP FLOW MERGED, SWING + BOOM RAISE OPERATED SIMULTANEOUSLY (10-88)...139

WHEN PUMP FLOW DIVIDED, TRAVEL + BOOM RAISE OPERATED SIMULTANEOUSLY (10-91)...140

WHEN PUMP FLOW DIVIDED, TRAVEL + ARM IN OPERATED SIMULTANEOUSLY (10-92)...143

SWING MOTOR...144

KMF160ABE-3...144

SUCTION-SAFETY VALVE...146

SWING BRAKE...147

CENTER SWIVEL JOINT...148

TRAVEL MOTOR...149

OPERATION OF MOTOR...151

AT LOW SPEED...151

AT HIGH SPEED...152

OPERATION OF PARKING BRAKE...153

COUNTERBALANCE VALVE, CHECK VALVE...154

SAFETY VALVE...155

VALVE CONTROL...158

WORK EQUIPMENT PPC VALVE...159

OPERATION...161

TRAVEL PPC VALVE...163

OPERATION...165

SERVICE PPC VALVE...167

PPC SAFETY LOCK VALVE...169

PPC ACCUMULATOR...170

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE...171

PPC SHUTTLE VALVE...172

TRAVEL JUNCTION VALVE...175

STRAIGHT-TRAVEL SYSTEM...176

LS-EPC VALVE...178

FUNCTION...179

OPERATION...179

SOLENOID VALVE...181

WHEN SOLENOID IS DEACTIVATED...182

WHEN SOLENOID IS EXCITED...182

BOOM HOLDING VALVE...183

OPERATION...184

BOOM LEVER AT HOLD...184

AT BOOM LOWER...185

WORK EQUIPMENT...186

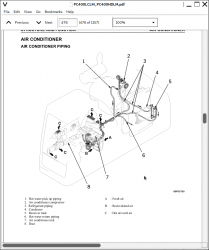

AIR CONDITIONER...187

AIR CONDITIONER PIPING...187

ACTUAL ELECTRICAL WIRING DIAGRAM...188

ENGINE CONTROL...194

OPERATION OF SYSTEM...195

COMPONENTS OF SYSTEM...196

ELECTRONIC CONTROL SYSTEM...200

CONTROL FUNCTION...200

PUMP AND ENGINE MUTUAL CONTROL SYSTEM...202

CONTROL METHOD IN EACH MODE...203

PUMP AND VALVE CONTROL FUNCTION...205

FUNCTION...205

LS CONTROL FUNCTION...205

CUT-OFF FUNCTION...206

CUT-OFF CANCEL FUNCTION...206

FINE CONTROL MODE FUNCTION...207

POWER MAX. FUNCTION, SWIFT SLOW-DOWN FUNCTION...208

FUNCTION...208

POWER MAX. FUNCTION...208

SWIFT SLOW-DOWN FUNCTION...208

AUTO DECELERATION SYSTEM...209

FUNCTION...209

OPERATION...210

AUTOMATIC WARMING-UP AND ENGINE OVERHEAT PREVENTION FUNCTION...211

FUNCTION...211

ENGINE AUTOMATIC WARMING-UP FUNCTION...212

ENGINE OVERHEAT PREVENTION FUNCTION...212

SWING CONTROL SYSTEM...213

FUNCTION...213

SWING LOCK, SWING HOLDING BRAKE FUNCTION...214

HYDRAULIC OIL QUICK WARM-UP FUNCTION WHEN SWING LOCK SWITCH IS ON...214

TRAVEL CONTROL SYSTEM...215

FUNCTION...215

PUMP CONTROL FUNCTION WHEN TRAVELING...216

TRAVEL SPEED SELECTION FUNCTION...216

ACTIVE MODE FUNCTION...217

FUNCTION...217

INCREASE IN ENGINE SPEED...218

2-STAGE BOOM LOWERING SPEED...218

2-STAGE STROKE FOR SWING SPOOL...218

COMPONENTS OF SYSTEM...219

ENGINE SPEED SENSOR...219

PPC HYDRAULIC SWITCH...219

PUMP PRESSURE SENSOR...220

TVC PROLIX RESISTOR...221

MACHINE MONITOR SYSTEM...222

MONITOR PANEL...223

OUTLINE...223

INPUT AND OUTPUT SIGNALS...223

MONITOR DISPLAY...224

CONTENT OF DISPLAY...225

OIL MAINTENANCE FUNCTION...226

ELAPSED TIME RESET...227

DEMO MODE...227

MODE SELECTION SWITCHES...228

SWITCH ACTUATION TABLE...228

SENSORS...229

ENGINE OIL LEVEL SENSOR...230

HYDRAULIC OIL LEVEL SENSOR...230

ENGINE OIL PRESSURE SENSOR (BOTH LO AND HI)...230

COOLANT TEMPERATURE SENSOR...230

FUEL LEVEL SENSOR...231

AIR CLEANER CLOGGING SENSOR...231

20 TESTING, ADJUSTING AND TROUBLESHOOTING...233

STANDARD VALUE TABLE...234

FOR ENGINE...234

FOR CHASSIS RELATED PARTS...235

FOR ELECTRICAL PARTS...240

SERVICE TOOLS TABLE...245

MEASURING ENGINE SPEED...246

MEASURING EXHAUST COLOR...247

MEASURING WITH HANDY SMOKE CHECKER H1...247

MEASURING WITH SMOKE METER H2...247

VALVE CLEARANCE...248

COMPRESSION PRESSURE...249

BLOW BY PRESSURE...250

FUEL INJECTION TIMING...251

ADJUSTING...252

ENGINE OIL PRESSURE...253

FAN BELT TENSION...254

A/C COMPRESSOR BELT...255

ENGINE SPEED SENSOR...256

BOOST PRESSURE...257

GOVERNOR MOTOR LEVER STROKE...258

WORK, SWING, AND TRAVEL CIRCUIT...259

TVC VALVE OUTPUT PRESSURE...262

LS VALVE OUTPUT AND DIFFERENTIAL PRESSURE...264

CONTROL CIRCUIT OIL PRESSURE...267

SOLENOID VALVE OUTPUT PRESSURE...268

PPC VALVE OUTPUT PRESSURE AND SHUTTLE VALVE...271

WORK EQUIPMENT, SWING PPC VALVE...273

TRAVEL DEVIATION...274

LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT...275

MEASURING OIL LEAKAGE...277

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT...280

TESTING CLEARANCE OF SWING CIRCLE BEARING...281

WEAR OF SPROCKET...282

TRACK SHOE TENSION...283

BLEEDING AIR...284

TROUBLESHOOTING GENERAL...287

POINTS TO REMEMBER WHEN TROUBLESHOOTING...289

SEQUENCE OF EVENTS IN TROUBLESHOOTING...291

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE...292

PRECAUTIONS WHEN HANDLING ELECTRIC EQUIPMENT...292

HANDLING CONTROL BOX...297

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT...298

CHECKS BEFORE TROUBLESHOOTING...300

JUDGEMENT OF POWER TRAIN...301

PRECAUTIONS WHEN TROUBLESHOOTING...302

SAFETY...302

METHODS FOR TROUBLESHOOTING...302

PRECAUTIONS WHEN REMOVING, INSTALLING, DISASSEMBLING OR ASSEMBLING PARTS DURING TROUBLESHOOTING...304

PREVENTING RECURRENCE OF TROUBLE...305

HYDRAULIC EQUIPMENT...305

OIL CHECKS...305

CLEANING FRAGMENTS OF DAMAGED PARTS...305

METHOD OF USING TROUBLESHOOTING CHARTS...306

CATEGORY OF TROUBLESHOOTING CODE NUMBER...306

METHOD OF USING TROUBLESHOOTING TABLE FOR EACH TROUBLESHOOTING MODE...306

METHOD OF USING MATRIX TROUBLESHOOTING TABLES...308

METHOD OF USING ENGINE RELATED CHARTS...310

TROUBLESHOOTING...315

CONNECTOR TYPES AND MOUNTING LOCATIONS...316

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...319

CONTROL MECHANISM FOR ELECTRICAL SYSTEM...329

MACHINE CONTROL FUNCTIONS...329

MONITORING PANEL...330

DISPLAY ON MACHINE MONITOR...330

RECORDING OF SERVICE CODES AND USER CODE DISPLAY FUNCTION...330

MACHINE DATA MONITORING FUNCTION...332

METHOD OF DISPLAYING MONITORING CODE...332

TABLE OF MACHINE MONITORING CODES...333

BIT PATTERN CHART...334

GOVERNOR MOTOR ADJUSTMENT MODE...336

TIME ADJUSTMENT MODE...336

WORKING MODE DEFAULT SETTING MODE...337

METHOD OF USING JUDGEMENT TABLE...338

WHEN USING JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER [GOVERNOR CONTROL SYSTEM] AND ENGINE REL....338

WHEN USING JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER [GOVERNOR CONTROL SYSTEM] AND HYDRAULIC ....339

METHOD OF USING TROUBLESHOOTING CHARTS...340

CATEGORY OF TROUBLESHOOTING CODE NUMBER...340

METHOD OF USING TROUBLESHOOTING TABLE FOR EACH TROUBLESHOOTING MODE...340

TROUBLESHOOTING CODE NUMBER AND PROBLEM...340

DISTINGUISHING CONDITIONS...340

METHOD OF FOLLOWING TROUBLESHOOTING CHART...340

GENERAL PRECAUTIONS...340

DETAILS OF TROUBLESHOOTING AND PROCEDURE...343

PROCEDURE FOR CHECKING MONITOR PANEL OUTPUT SIGNAL...345

CHECKING INPUT SIGNAL OF GOVERNOR, PUMP CONTROLLER...346

SERVICE CODE TABLE...348

TROUBLSHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N-MODE)...349

N-1 [E218] Communication abnormality...350

TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER, GOVERNOR CONTROL SYSTEM (E-MODE)...353

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM...354

ACTIONS TAKEN...355

JUDGEMENT TABLE...357

ELECTRICAL CIRCUIT DIAGRAM FOR MODE SYSTEM...358

E-1 Abnormality in governor, pump controller power source, controller LED is OFF...359

E-2 [E308] Abnormality in fuel control dial input value is displayed...360

E-3 [E317] Abnormality, disconnection in motor drive system is displayed...361

E-4 [E318] Abnormality, short circuit in motor drive system is displayed...362

E-5 [E306] Abnormality in feedback potentiometer system is displayed...363

E-6 [E315] Abnormality, short circuit in battery relay output system is displayed...364

E-7 [E316] Abnormality, step out in motor displayed...365

E-8 Engine does not start...366

E-9 Engine does not start...369

E-10 Lack of output, engine high idle speed too low...370

E-11 Engine does not stop...371

E-12 Faulty operation of battery relay system, engine does not stop...372

TROUBLESHOOTING OF ENGINE SYSTEM (S-MODE)...375

METHOD OF USING ENGINE RELATED CHARTS...376

S-1 Starting performance is poor (Starting always take time)...381

S-2 Engine does not start...382

S-3 Engine does not pick up smoothly (Follow-up is poor)...385

S-4 Engine stops during operation...386

S-5 Engine does not run smoothly (Hunting)...387

S-6 Engine lacks output (No power)...388

S-7 Exhaust gas is black (Incomplete Combustion)...389

S-8 Oil consumption is excessive (or exhaust gas is blue)...390

S-9 Oil becomes contaminated quickly...391

S-10 Fuel consumption is excessive...392

S-11 Oil in coolant, or coolant spurts back, or coolant level goes down...393

S-12 Oil pressure lamp lights up (Drop in oil pressure)...394

S-13 Oil level rises...395

S-14 Coolant Temperature becomes too high (Overheating)...396

S-15 Abnormal noise is made...397

S-16 Vibration is excessive...398

TROUBLESHOOTING OF GOVERNOR PUMP CONTROLLER, PUMP CONTROL SYSTEM (C-MODE)...399

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM...400

ACTIONS TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE...401

JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER (PUMP CONTROL SYSTEM) AND HYDRAULIC RELATED PARTS...405

ELECTRIC CIRCUIT DIAGRAM FOR C MODE...406

C-1 Abnormality in controller power source system, controller LED is OFF...408

C-2 [E232] Short circuit in front pump TVC solenoid system is displayed...409

C-3 [E233] Disconnection in front pump TVC solenoid system is displayed...410

C-4 [E236] Short circuit in rear pump TVC solenoid system is displayed...411

C-5 [E237] Disconnection in rear pump TVC solenoid system is displayed...412

C-6 [E207] Short circuit in LS select solenoid system is displayed...413

C-7 [E208] Disconnection in active mode, boom, solenoid system is displayed...415

C-8 [E203] Short circuit in swing brake solenoid system is displayed...416

C-9 [E213] Disconnection in swing brake solenoid system is displayed...417

C-10 [E204] Short circuit in pump merge divider solenoid system is displayed...418

C-11 [E214] Disconnection in pump merge divider solenoid system is displayed...419

C-12 [E206] Short circuit in travel speed solenoid system is displayed...420

C-13 [E216] Disconnection in travel speed selector solenoid system is displayed...421

C-14 [E217] Short circuit in active mode, swing, solenoid system is displayed...422

C-15 [E235] Disconnection in active mode, swing, solenoid system is displayed...423

C16 [E217] Model selection input error is displayed...424

C-17 [E222] Short circuit in LS-EPC solenoid system is displayed...426

C-18 [E224] Disconnection in LS-EPC solenoid system is displayed...427

C-19 [E224] Abnormality in front pump pressure sensor system is displayed...428

C-20 [E225] Abnormality in rear pump pressure sensor system is displayed...429

C-21 [E226] Abnormality in i pressure sensor power source system is displayed...430

C-22 [E227] Abnormality in engine speed sensor system is displayed...431

C-23 [E225] Abnormality in machine push up solenoid system, no service code displayed...432

a) If solenoid is not actuated, turned on, when machine push up switch is set to low pressure setting...432

b) If solenoid is not canceled, turned off, when machine push up switch is set to high pressure setting...433

TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER, INPUT SIGNAL SYSTEM (F-MODE)...435

ELECTRIC CIRCUIT DIAGRAM FOR F MODE...437

F-1 Bit pattern 20-[1] Swing oil pressure switch does not light up...438

F-2 Bit pattern 20-[2] Travel oil pressure switch does not light up...439

F-3 Bit pattern 20-[3] Boom LOWER oil pressure switch does not light up...440

F-4 Bit pattern 20-[4] Boom RAISE oil pressure switch does not light up...441

F-5 Bit pattern 20-[5] Arm IN oil pressure switch does not light up...442

F-6 Bit pattern 20-[6] Arm OUT oil pressure switch does not light up...443

F-7 Bit pattern 21-[1] Bucket CURL oil pressure switch does not light up...444

F-8 Bit pattern 21-[2] Bucket DUMP oil pressure switch does not light up...445

F-9 Bit pattern 21-[3] Swing lock oil pressure switch does not light up...446

F-10 Bit pattern 22-[5] Mode connection does not light up...447

F-11 Bit pattern 22-[6] Left knob switch does not light up...448

TROUBLESHOOTING OF MACHINE MECHANICAL MODE (H-MODE)...449

PUMP MERGE DIVIDER LOGIC...450

SOLENOID ACTUATION TABLE...450

TABLE OF FAILURE MODES AND CAUSES...451

H-1 Speeds of all work equipment swing, travel are slow or lack power...453

H-2 There is excessive drop in engine speed, or engine stalls...454

H-3 No work equipment, travel, swing movement...454

H-4 Abnormal noise generated around pump...455

H-5 Auto decel does not work when PPC shuttle valve is cause...455

H-6 Fine control ability is poor or response is poor...455

H-7 Boom is slow or lacks power...456

H-8 Arm is slow or lacks power...457

H-9 Bucket is slow or lacks power...458

H-10 Work Equipment; Boom, Arm, Bucket, Does Not Move, But Travel and Swing Are Normal...459

H-11 Excessive hydraulic drift, boom, arm, bucket ...459

1) Excessive hydraulic drift of boom...459

2) Excessive hydraulic drift of arm or bucket...459

H-12 Excessive time lag, engine at low idling...460

H-13 Other equipment moves when single circuit is relieved...460

H-14 In L/O, F3/O modes, work equipment speed is faster than specified speed...461

H-15 Malfunction of machine push up function...461

H-16 In compound operations, work equipment with larger load is slow...461

H-17 In swing plus boom RAISE, boom RAISE is slow...462

H-18 In swing plus arm, arm is slow...462

H-19 In swing plus travel, travel speed drops excessively...462

H-20 Travel deviation...463

H-21 Travel speed is slow...465

H-22 Steering does not turn easily or lacks power...466

H-23 Travel speed does not switch or is faster than specified speed...467

H-24 Travel does not move, one side only...467

H-25 Does not swing...468

H-26 Travel speed is slow...469

H-27 Excessive overrun when stopping swing...470

H-28 Excessive shock when stopping swing, one direction only...471

H-29 Excessive abnormal noise when stopping swing...471

H-30 Excessive hydraulic drift of swing...472

H-31 Swing speed is faster than specified swing speed...472

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M-MODE)...473

ACTIONS TAKEN BY MONITOR PANEL...475

ELECTRIC CIRCUIT DIAGRAM FOR M MODE...476

M-1 [E101] Abnormality in error data is displayed...477

[E102] Error in clock data is displayed...477

M-2 [E103] Short circuit in buzzer output or 24V wiring harness contact with buzzer harness is displayed...478

M-3 [E104] Air cleaner restriction detected is displayed...479

M-4 [E106] Drop in engine oil Hi pressure detected is displayed...479

M-5 [E108] Engine coolant temperature 105 C detected is displayed...479

M-6 When start switch is turned ON, no lamps on monitor panel light up for three seconds...480

M-7 When start switch is turned ON, monitor panel lamps all stay illuminated and do not go out...482

M-8 When start switch is turned ON, items illuminated on monitor panel are different from actual machine...482

M-9 When start switch is turned ON, engine stopped, basic check items flash...483

M-10 Preheating is not used, but on monitor panel lights up...486

M-11 When start switch is turned ON and engine is started, basic check items flash...487

M-12 When start switch is turned ON, engine speed, caution items, emergency items flash. Battery, engine oil pressure lamps d...489

M-13 When start switch is turned ON and engine is started, caution items, emergency items flash, when there is no abnormality...491

M-14 When start switch is turned ON, engine stopped, buzzer does not sound for one second, Caution ite....494

M-15 No abnormality is displayed on monitor panel but buzzer sounds...495

M-16 Night light on monitor panel does not light up, liquid crystal display is normal...496

M-17 Coolant temperature gauge does not rise...497

M-18 Coolant temperature gauge does not give any display, no gauge lamps light up during operation...498

M-19 Fuel level gauge always displays FULL...499

M-20 Fuel level gauge does not give display...500

M-21 Swing lock switch is turned ON, but on monitor panel does not light...501

M-22 Swing prolix switch is turned ON, but on monitor panel does not flash...502

M-23 Service meter does not advance while engine is running...503

M-24 When start switch is at OFF and time switch is pressed, time and service meter are not displayed...503

M-25 Faulty fuel level sensor system...504

M-26 Faulty coolant temperature sensor system...505

M-27 Faulty engine oil level sensor system...506

M-28 Faulty coolant level sensor system...507

M-29 Faulty hydraulic oil level sensor system...508

M-30 [E112, E113] Wiper does not work or switch is not being used, but wiper is actuated...509

M-31 [E114] Wiper does not work or switch is not being used, but washer motor is not actuated...513

30 DISASSEMBLY AND ASSEMBLY...515

METHOD OF USING MANUAL...516

SPECIAL TOOL LIST...521

SKETCHES OF SPECIAL TOOLS...526

STARTING MOTOR...534

REMOVAL...534

INSTALLATION...534

ALTERNATOR...535

REMOVAL...535

INSTALLATION...535

ENGINE OIL COOLER...536

REMOVAL...536

INSTALLATION...536

FUEL INJECTION PUMP...537

REMOVAL...537

INSTALLATION...538

WATER PUMP...539

REMOVAL...539

INSTALLATION...539

NOZZLE HOLDER...540

REMOVAL...540

INSTALLATION...540

TURBOCHARGER...541

REMOVAL...541

INSTALLATION...541

THERMOSTAT...542

REMOVAL...542

INSTALLATION...542

FRONT ENGINE SEAL...543

REMOVAL...543

INSTALLATION...543

REAR ENGINE SEAL...544

REMOVAL...544

INSTALLATION...545

CYLINDER HEAD...547

REMOVAL...547

INSTALLATION...551

GOVERNOR MOTOR...554

REMOVAL...554

INSTALLATION...554

AFTERCOOLER CORE...555

REMOVAL...555

INSTALLATION...555

OIL COOLER...556

REMOVAL...556

INSTALLATION...557

RADIATOR, OIL COOLER...558

REMOVAL...558

INSTALLATION...560

ENGINE, MAIN PUMP...561

REMOVAL...561

INSTALLATION...565

DAMPER...567

REMOVAL...567

INSTALLATION...567

FUEL TANK...568

REMOVAL...568

INSTALLATION...568

CENTER SWIVEL JOINT...569

REMOVAL...569

INSTALLATION...569

DISASSEMBLY...570

ASSEMBLY...570

FINAL DRIVE...571

REMOVAL...571

INSTALLATION...571

DISASSEMBLY...572

ASSEMBLY...576

TRAVEL MOTOR...582

DISASSEMBLY...582

ASSEMBLY...586

SPROCKET...595

REMOVAL...595

INSTALLATION...595

SWING MOTOR...596

REMOVAL...596

INSTALLATION...596

DISASSEMBLY...597

ASSEMBLY...599

SWING MACHINERY...606

REMOVAL...606

INSTALLATION...606

DISASSEMBLY...607

ASSEMBLY...610

REVOLVING FRAME...615

REMOVAL...615

INSTALLATION...616

SWING CIRCLE...617

REMOVAL...617

INSTALLATION...617

IDLER AND RECOIL SPRING...618

REMOVAL...618

INSTALLATION...618

IDLER...619

DISASSEMBLY...619

ASSEMBLY...620

RECOIL SPRING...623

DISASSEMBLY...623

ASSEMBLY...624

TRACK ROLLER...625

REMOVAL...625

INSTALLATION...625

DISASSEMBLY...626

ASSEMBLY...627

CARRIER ROLLER...630

REMOVAL...630

INSTALLATION...630

DISASSEMBLY...631

ASSEMBLY...632

TRACK CHAIN...635

REMOVAL...635

INSTALLATION...635

HYDRAULIC TANK...636

REMOVAL...636

INSTALLATION...637

MAIN PUMP...638

REMOVAL...638

INSTALLATION...639

DISASSEMBLY...640

PUMP ASSEMBLY...640

FRONT PUMP...640

REAR PUMP...645

ASSEMBLY...648

FRONT PUMP...648

REAR PUMP...655

MAIN PUMP OIL SEAL...666

REMOVAL...666

INSTALLATION...666

CONTROL VALVE...667

REMOVAL...667

INSTALLATION...669

DISASSEMBLY...670

(1/3)...670

(2/3)...671

(3/3)...672

ASSEMBLY...675

(1/3)...675

(2/3)...676

(3/3)...677

PUMP MERGE DIVIDER VALVE...681

DISASSEMBLY...681

ASSEMBLY...681

PRESSURE COMPENSATION VALVE...682

DISASSEMBLY...682

ASSEMBLY...682

FRONT PUMP SERVO VALVE...683

REMOVAL...683

INSTALLATION...683

REAR PUMP SERVO VALVE...684

REMOVAL...684

INSTALLATION...684

LS-EPC SOLENOID VALVE...685

REMOVAL...685

INSTALLATION...685

SOLENOID VALVE...686

REMOVAL...686

INSTALLATION...686

WORK EQUIPMENT PPC VALVE...687

REMOVAL...687

INSTALLATION...687

DISASSEMBLY...688

ASSEMBLY...688

TRAVEL PPC VALVE...689

REMOVAL...689

INSTALLATION...689

DISASSEMBLY...690

ASSEMBLY...690

PPC SHUTTLE VALVE...691

REMOVAL...691

INSTALLATION...692

DISASSEMBLY...692

ASSEMBLY...693

BOOM LOCK VALVE...694

REMOVAL...694

INSTALLATION...694

DISASSEMBLY...695

ASSEMBLY...695

BOOM CYLINDER...696

REMOVAL...696

INSTALLATION...696

ARM CYLINDER...698

REMOVAL...698

INSTALLATION...698

BUCKET CYLINDER...699

REMOVAL...699

INSTALLATION...699

HYDRAULIC CYLINDER...701

THREADED STYLE PISTON...701

DISASSEMBLY...701

ASSEMBLY...703

WORK EQUIPMENT...707

REMOVAL...707

INSTALLATION...708

BUCKET...709

REMOVAL...709

INSTALLATION...710

ARM...711

REMOVAL...711

INSTALLATION...712

BUCKET AND ARM...713

REMOVAL...713

INSTALLATION...714

BOOM...715

REMOVAL...715

INSTALLATION...716

OPERATOR?S CAB...717

REMOVAL...717

INSTALLATION...718

COUNTERWEIGHT...719

REMOVAL...719

INSTALLATION...719

COMPRESSOR...720

REMOVAL...720

INSTALLATION...720

CONDENSER...721

REMOVAL...721

INSTALLATION...721

RECEIVER TANK...722

REMOVAL...722

INSTALLATION...722

AIR CONDITIONER UNIT...723

REMOVAL...723

INSTALLATION...724

GOVERNOR, PUMP CONTROLLER...725

REMOVAL...725

INSTALLATION...725

MONITOR PANEL...726

REMOVAL...726

INSTALLATION...726

CONTROL STAND CASE...727

REMOVAL...727

TRAY...727

BOOT...727

UPPER CASE...728

INSTALLATION...728

40 MAINTENANCE STANDARD...729

ENGINE MOUNT...730

RADIATOR AND OIL COOLER MOUNT...731

SWING MACHINERY...735

SWING CIRCLE...736

FINAL DRIVE...737

TRACK FRAME AND RECOIL SPRING...738

IDLER...742

CARRIER ROLLER...744

TRACK ROLLER...745

TRACK SHOE...746

TRACK SHOE...748

HYDRAULIC PUMP...749

CONTROL VALVE...750

SELF REDUCING PRESSURE VALVE...757

SUCTION SAFETY VALVE...758

SWING MOTOR...759

TRAVEL MOTOR...760

WORK EQUIPMENT ? SWING PPC VALVE...761

TRAVEL PPC VALVE...762

SERVICE PPC VALVE...763

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE...764

LS-EPC VALVE...765

SOLENOID VALVE...766

CENTER SWIVEL JOINT...767

BOOM HOLDING VALVE...768

HYDRAULIC CYLINDER...770

BOOM, BUCKET CYLINDER - THREADED PISTON...770

ARM CYLINDER - THREADED PISTON...770

WORK EQUIPMENT...772

DIMENSIONS OF WORK EQUIPMENT...774

BUCKET...776

90 OTHERS...779

Foldout 20-203 Connector types and mounting location...781

Foldout 20-229 Details of troubleshooting and troubleshooting procedures...783

Foldout 20-353 Actions taken by controller when abnormality occurs and problems on machine...785

Foldout 20-354 Action taken by controller when abnormality occurs and problems on machine...787

Foldout 20-355 Judgement table for governor pump controller and engine related parts...789

Foldout 20-356 Electrical circuit diagram for E mode...791

Foldout 20-365 E-8 Engine does not start...793

Foldout 20-366 E-9a Engine speed is irregular...795

Foldout 20-367 E-9b There is hunting...797

Foldout 20-368 E-10 Lack of output, engine high idle speed is low...799

Foldout 20-369 E-11 Engine does not stop...801

Foldout 20-453 Actions taken by controller when abnormality occurs and problems on machine...803

Foldout 20-454 Actions taken by controller when abnormality occurs and problemss...805

Foldout 20-455 Actions taken by controller when abnormality occurs and problems on machine...807

Foldout 20-456 Actions taken by controller when abnromality occurs and problems on machine...809

Foldout 20-457 Judgement table for governor, pump controller (pump control system) and hydraulic related parts...811

Foldout 20-458 Electric circuit diagram for C mode...813

Foldout 20-461 C-2 [E232] Short circuit in front pump TVC solenoid is displayed...815

Foldout 20-462 C-3 [E233] Disconnection in front pump TVC solenoid system is displayed...817

Foldout 20-463 C-4 [E236] Short circuit in rear pump TVC solenoid system is displayed...819

Foldout 20-464 C-5 [E237] Disconnection in rar pump TVC solenid system is displayed...821

Foldout 20-467 C-7 [E208] Disconnection in active mode, boom, solenoid system is displayed...823

Foldout 20-468 C-8 [E203] Short circuit in swing brake solenoid system is displayed...825

Foldout 20-469 C-9 [E213] Disconnection in swing brake solenoid system is displayed...827

Foldout 20-471 C-11 [E214] Disconnection in pump merge divider solenoid system is displayed...829

Foldout 20-473 C-13 [E216] Disconnection in travel speed selector solenoid system is displayed...831

Foldout 20-475 C-15 [E235] Disconnection in active mode, swlin solenoid system is displayed...833

Foldout 20-503 Electric circuit diagram for F mode...835

Foldout 20-553 Table of failure modes and causes (1/2)...837

Foldout 20-554 Table of fialure modes and causes (2/2)...839

Foldout 20-555 H-1 Speed of all work equipment, swing, travel are slow or lack power...841

Foldout 20-557 H-4 Abnormal noise generated around pump...843

Foldout 20-557 H-5 Auto decel does not work when PPC shuttle valve is cause...843

Foldout 20-557 H-6 Fine control ability is poor or response is poor...843

Foldout 20-558 H-7 Boom is slow or lacks power...845

Foldout 20-559 H-8 Arm is slow or lacks power...847

Foldout 20-560 H-9 Bucket is slow or lacks power...849

Foldout 20-567 H-21 Travel speed is slow...851

Foldout 20-568 H-22 Steering does not turn easily or lacks power...853

Foldout 20-571 H-26 Travel speed is slow...855

Foldout 20-603 Actions taken by controller when abnormality occurs and problems on machine...857

Foldout 20-604 Electric circuit diagram for M mode...859

Foldout 20-637 M-30 Wiper does not work or switch is not being used, but wiper is actuated [include E112, E113]...861

Foldout 20-638 M-30 (continued)...863

Foldout 20-641 M-31 Wiper does not work or switch is not being used, but washer motor is actuated (include E114)...865