Komatsu Log Loader Road Builder PC240LL-10 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Log Loader Road Builder PC240LL-10, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Log Loader Road Builder PC240LL-10 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 345 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM028500 - Log Loader Road Builder PC240LL-10 Shop Manual.pdf

MAIN SECTIONS

CEBM028500 PC240LL-10 S/N A20601 & Up...1

CONTENTS...2

00 - FOREWORD ...3

SAFETY...3

Safety Notice...3

Important Safety Notice...3

General Precautions...3

Preparations For Work...4

Precautions During Work...4

GENERAL...7

HOW TO READ THE SHOP MANUAL...8

Volumes...8

Distribution And Updating...8

Filing Method...8

Revised Edition Mark...8

Revisions...8

Symbols...8

HOISTING INSTRUCTIONS...9

Hoisting...9

Making Signs...9

Precautions...9

Precautions for Sling Work...9

Precautions for Using Mobile Crane...10

Precautions for Using Overhead Hoist Crane...10

Selecting Wire Ropes...11

HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS...12

Points to Remember When Handling Electric Equipment...12

Points to Remember When Handling Hydraulic Equipment...23

PUSH PULL COUPLER...25

Type 1...25

Disconnection...25

Connection...25

Type 2...26

Disconnection...26

Connection...26

Type 3...27

Disconnection...27

Connection...27

EXPLANATION OF MAINTENANCE STANDARD TERMS...28

HANDLING OF FUEL SYSTEM DEVICES...29

HANDLING OF INTAKE SYSTEM PARTS...30

STANDARD TIGHTENING TORQUE...31

Bolts And Nuts...31

Tightening Torque Of Hose Nuts...32

Tightening Torque Of Split Flange Bolts...32

Tightening Torque For Flared Nuts...32

Tightening Torques for Split Flanged Bolts...33

Tightening Torques For O-ring Boss Piping Joints...33

Table Of Tightening Torques For O-ring Boss Plugs...33

Tightening Torque For Hoses (Taper Seal Type And Face Seal Type)...34

Tightening Torque For Face Seal Joints...34

For 102, 107, and 114 Engine Series (Bolts and Nuts)...34

For 102, 107, and 114 Engine Series (Eye Joints)...35

For 102, 107, and 114 Engine Series (Taper Screws)...35

ELECTRIC WIRE CODE...36

Classification By Thickness...36

Classification By Color And Code...36

How To Read Electric Wire Code...37

PRECAUTIONS FOR OPERATIONS...40

Precautions when Carrying Out Removal Work...40

Precautions when Carrying Out Installation Work...41

Precautions when Completing the Operation...42

CONVERSION TABLES...43

Method Of Using The Conversion Table...43

COATING MATERIALS...49

LIST OF ABBREVIATIONS...52

List of Abbreviations Used in the Shop Manual...52

List of Abbreviations Used in the Circuit Diagrams...56

01 - GENERAL...57

SPECIFICATIONS...58

Dimension Drawings...58

Road Builder...58

Log Loader...58

Dimensions...59

Working Ranges...61

Road Builder...61

Log Loader...62

Engine...63

Undercarriage...63

Hydraulic System...64

Road Builder...64

Log Loader...65

WEIGHT TABLE...66

FUEL, COOLANT AND LUBRICANTS...68

Lubrication Chart...70

10 - STRUCTURE AND FUNCTION...71

ENGINE AND COOLING SYSTEM...74

Engine Related Parts...74

Radiator, Oil Cooler, Aftercooler, and Fuel Cooler...76

POWER TRAIN...78

Power Train...78

Swing Machinery...80

Swing Circle...82

Final Drive...84

UNDERCARRIAGE AND FRAME...86

Track Frame and Idler Cushion...86

HYDRAULIC SYSTEM...88

Hydraulic Equipment Layout...88

Valve Control...90

Hydraulic Tank...92

Oil Filler Cap...93

CLSS...94

Structure of CLSS...94

Basic Principle...95

Main Pump...98

Operation...102

LS Valve...104

PC Valve...110

LS(PC)-EPC Valve...117

Control Valve...120

Functions and Operation by Valve...132

Hydraulic Circuit Diagram and Name of Valves...132

Unload Valve...135

Introduction of LS Pressure...136

LS By-Pass Plug...137

Pressure Compensation Valve...138

Shuttle Valve In Pressure Compensation Valve...141

Boom Regeneration Circuit...143

Arm Regeneration Circuit...145

Merge-Divider Valve...147

LS Selector Valve...150

Self-Pressure Reducing Valve...151

Travel Junction Valve...154

Travel PPC Shuttle Valve...157

Boom Hydraulic Drift Prevention Valve...159

Arm Hydraulic Drift Prevention Valve (Road Builder)...162

Arm Drift Prevention Valve (Log Loader)...165

Operation...166

Suction Safety Valve For Drift Prevention Valve...168

Arm Quick Return Valve...169

Variable Back Pressure Valve...171

Main Relief Valve...173

Swing Motor...174

Swing Holding Brake...176

Relief Valve...178

Swing 2-Stage Relief Valve...180

Swing Motor Reverse Prevention Valve...181

Travel Motor...184

Operation of Travel Motor...187

Operation of Parking Brake...189

Brake Valve...190

Counterbalance Valve...191

Suction Safety Valve...192

PPC Valve...196

Work Equipment and Swing PPC Valve...196

Travel PPC Valve...201

Solenoid Valve...206

Attachment Solenoid Valve...209

Center Swivel Joint...211

Accumulator...213

PPC Accumulator...213

WORK EQUIPMENT...214

Road Builder...214

Log Loader...215

Work Equipment Shim...216

Bucket Play Adjustment Shim (Road Builder)...216

CAB AND ITS ATTACHMENTS...217

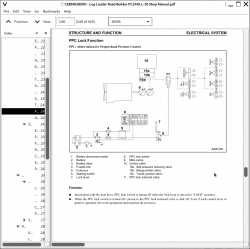

ELECTRICAL SYSTEM...219

Electrical Control System...219

Machine Control System Diagram...219

Engine Control Function...221

Engine and Pump Combined Control Function...223

Pump and Valve Control Function...229

One-Touch Power Maximizing Function...231

Auto-Deceleration Function...233

Engine Automatic Warm-Up Function...235

Overheat Prevention Function...237

Turbocharger Protection Function...238

Swing Control Function...239

Quick Warm-Up Function...243

Swing 2-Stage Relief Function...243

Travel Control Function...244

PPC Lock Function...246

Attachment Flow Control Function...247

System Component Part...249

Engine Controller...249

Pump Controller...253

Fuel Control Dial...256

Resister for PC-EPC valve...257

CAN Terminating Resistor...258

Engine Oil Pressure Switch...259

PPC Oil Pressure Switch...260

MACHINE MONITOR SYSTEM...261

Machine Monitor...263

Input and Output Signals...264

Display...266

Gauges...268

Caution Monitor...270

Pilot Monitor...273

Switches...275

Guidance ICON and Function Switch...277

Operator Mode Function...280

Service Mode Function...282

KOMTRAX SYSTEM...283

KOMTRAX terminal...284

Input and Output Signals...285

SENSORS...287

Ambient Pressure Sensor...287

Charge (Boost) Pressure and Temperature Sensor...288

Coolant Temperature Sensor...289

Ne (Crankshaft) Speed Sensor...289

Bkup (Camshaft) Speed Sensor...290

Common Rail Pressure Sensor...290

Exhaust Manifold Pressure Sensor...291

EGR Orifice Temperature Sensor...291

EGR Valve Lift Sensor...292

Turbo Speed Sensor...293

KVGT Position Sensor...294

Mass Air Flow and Temperature Sensor...295

KDPF Differential Pressure and Outlet Pressure Sensor...295

KDOC Inlet Temperature Sensor...296

KDOC Outlet Temperature Sensor...296

KDPF Outlet Temperature Sensor...297

Crankcase Pressure Sensor...297

Engine Oil Level Sensor...298

Fuel Level Sensor...299

Coolant Level Sensor...300

Hydraulic Oil Temperature Sensor...300

Front Pump Oil Pressure Sensor...301

Rear Pump Oil Pressure Sensor...302

PPC Oil Pressure Sensor...303

Air Cleaner Clogging Sensor...304

Front Pump Swash Plate Sensor...305

Rear Pump Swash Plate Sensor...307

Water-In-Fuel Sensor...309

20 - STANDARD VALUE TABLES...311

STANDARD SERVICE VALUE TABLES...312

Standard Value Table for Engine Related Parts...312

Standard Value Table for Chassis Related Parts...314

Engine Speed...314

Control Valve Spool Stroke...314

Control Lever Stroke...315

Operating Effort of Control Lever and Pedal...315

Hydraulic Pressure...316

Swing...317

Travel...318

Work Equipment...319

Performance in Combined Operation...321

Pump Swash Plate Sensor...321

Hydraulic Pump...322

Posture of Machine for Measuring Performance and Measurement Procedure...323

Control Valve: Spool Stroke...323

Swing 1: Overrun When Stopping Swing, Time Taken to Start Swing, Time Taken to Swing...323

Swing 2: Hydraulic Drift of Swing...323

Travel 1: Travel Speed, Idle Running (Without Load)...324

Travel 2: Travel Speed (Actual Run), Travel Deviation...324

Travel 3: Travel Deviation...325

Travel 4: Hydraulic Drift of Travel...325

Work Equipment 1: Hydraulic Drift of Work Equipment...326

Work Equipment 2: Boom Speed...326

Work Equipment 3: Arm Speed...326

Work Equipment 4: Bucket Speed/Heel Speed...327

Work Equipment 5: Boom Time Lag...327

Work Equipment 6: Arm Time Lag...328

Work Equipment 7: Bucket Time Lag...328

90 - DIAGRAMS AND SCHEMATICS...329

HYDRAULIC SYSTEM...331

Symbols in Hydraulic Circuit Diagrams...331

Hydraulic Circuit Diagram (1/2)...332

Hydraulic Circuit Diagram (2/2)...333

ELECTRICAL SYSTEM...334

Symbols in Electrical Circuit Diagrams...334

Air Conditioner Electrical Circuit...335

Electrical Control System Diagram...336

Electrical Diagram (1/5)...337

Electrical Diagram (2/5)...338

Electrical Diagram (3/5)...339

Electrical Diagram (4/5)...340

Electrical Diagram (5/5)...341

Electrical Circuit Diagram - Log Loader Unique...342

Connector List and Stereogram...343

Chassis...343

Operator's Compartment...344

Engine Compartment...345