Komatsu Wheel Loader WA500LK Series avance plus Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheel Loader WA500-3LK avance plus, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheel Loader WA500-3LK avance plus workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,441 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM008101 - Wheel Loader WA500-3LK avance plus Operation & Maintenance Manual.pdf

CEBM005403 - Wheel Loader WA500-3LK avance plus Shop Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...15

SAFETY NOTICE...15

IMPORTANT SAFETY NOTICE...15

GENERAL PRECAUTIONS...15

PREPARATIONS FOR WORK...15

PRECAUTIONS DURING WORK...15

GENERAL...17

HOW TO READ THE SHOP MANUAL...18

VOLUMES...18

DISTRIBUTION AND UPDATING...18

FILING METHOD...18

REVISED EDITION MARK...18

REVISIONS...18

SYMBOLS...18

HOISTING INSTRUCTIONS...19

HOISTING...19

WIRE ROPES...19

PUSH-PULL TYPE COUPLER...20

COATING MATERIALS...23

STANDARD TIGHTENING TORQUE...25

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS...25

TIGHTENING TORQUE OF HOSE NUTS...26

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS...26

TIGHTENING TORQUE FOR FLARED NUTS...26

ELECTRIC WIRE CODE...27

CLASSIFICATION BY THICKNESS...27

CLASSIFICATION BY COLOR AND CODE...27

CONVERSION TABLES...28

METHOD OF USING THE CONVERSION TABLE...28

01 GENERAL...35

DIMENSIONS...36

SPECIFICATIONS...38

WEIGHT TABLE...41

FUEL, COOLANT AND LUBRICATNTS...42

ENGINE OIL...43

NORMAL OPERATION...43

ARCTIC OPERATION...45

TRANSMISSION, HYDRAULIC SYSTEM, BRAKE SYSTEM OIL...45

AXLE OIL...45

GREASE...46

DIESEL FUEL...46

COOLANT SPECIFICATIONS...47

GENERAL...47

WATER...47

ANTIFREEZE...47

SUPPLEMENTAL COOLANT ADDITIVES...49

10 STRUCTURE AND FUNCTION...51

GENERAL...55

RADIATOR AND OIL COOLER...58

DAMPER...60

TORQUE CONVERTER AND TRANSMISSION PIPING...62

HYDRAULIC CIRCUIT FOR POWER TRAIN...64

HYDRAULIC CIRCUIT DIAGRAM FOR POWER TRAIN...65

TORQUE CONVERTER AND PTO...66

TRANSMISSION...68

TRANSMISSION CUTAWAY...70

OPERATION OF CLUTCH...72

FORWARD 1ST...73

FORWARD 2ND...74

FORWARD 3RD...75

FORWARD 4TH...76

REVERSE 1ST...77

TRANMISSION CONTROL VALVE...78

ECMV (ELECTRONIC CONTROL MODULATION VALVE)...80

OUTLINE OF ECMV...82

ECMV AND PROPORTIONAL SOLENOID...82

ECMV AND FILL SWITCH...82

ACTUATION OF ECMV...83

MAIN RELIEF, TORQUE CONVERTER RELIEF VALVE...86

MAIN RELIEF VALVE...87

TORQUE CONVERTER RELIEF VALVE...87

LUBRICATING RELIEF VALVE...88

TORQUE CONVERTER OIL FILTER...89

PILOT FILTER...90

TRANSFER...91

DRIVE SHAFT...92

CENTER SUPPORT...93

AXLE...94

FRONT...94

REAR...95

DIFFERENTIAL...96

NORMAL - (STANDARD)...96

FRONT...96

REAR...97

LIMITED SLIP (OPTION)...99

FRONT...99

REAR...99

FINAL DRIVE...104

AXLE MOUNT...106

CENTER HINGE PIN...108

TIRE AND WHEEL...109

STEERING PIPING...110

STEERING COLUMN...111

STEERING VALVE...112

DEMAND VALVE OPERATION...113

STEERING SPOOL AT NEUTRAL...113

STEERING SPOOL OPERATED - ENGINE AT LOW SPEED...114

STEERING SPOOL OPERATED - ENGINE AT HIGH SPEED...115

FLOW AMP...116

FLOW AMP OPERATION...116

STEERING VALVE OPERATION...119

STEERING RELIEF VALVE...122

RELIEF VALVE OPERATION...123

SAFETY VALVE (WITH SUCTION)...124

ORBIT-ROLL VALVE...126

STOP VALVE...130

DIVERTER VALVE...131

BRAKE...134

BRAKE PIPING...134

BRAKE CIRCUIT DIAGRAM...136

BRAKE VALVE...138

RIGHT BRAKE VALVE...138

LEFT BRAKE VALVE...139

CHARGE VALVE...144

ACCUMULATOR (FOR BRAKE)...148

SLACK ADJUSTER...149

BRAKE...151

PARKING BRAKE...153

PARKING BRAKE CONTROL...153

PARKING BRAKE...154

PARKING BRAKE SOLENOID VALVE...155

PARKING BRAKE EMERGENCY RELEASE SOLENOID VALVE...156

HYDRAULIC...157

HYDRAULIC PIPING...157

HYDRAULIC CIRCUIT DIAGRAM...159

MACHINES WITH STANDARD SPECIFICATIONS...159

WORK EQUIPMENT LEVER LINKAGE...162

HYDRAULIC TANK...163

OIL FILTER BY-PASS VALVE...164

BREATHER...164

ACCUMULATOR (FOR PPC VALVE)...165

PPC VALVE...166

FOR BUCKET / BOOM...166

FOR OPTIONAL ATTACHMENT...168

PPC VALVE NEUTRAL POSITION...170

PPC VALVE POSITIONS FUNCTIONS...171

PPC RELIEF VALVE...173

CUT-OFF VALVE...174

ECSS CONTROL VALVE...176

MAIN CONTROL VALVE...178

2-SPOOL...178

3-SPOOL...180

RELIEF VALVE...183

SAFETY VALVE (WITH SUCTION)...184

FLOAT SELECTOR VALVE AND UNLOAD VALVE...186

BOOM AND DUMP SPOOLS AT HOLD POSITION...187

BOOM SPOOL AT RAISE POSITION...188

BOOM SPOOL AT LOWER POSITION...189

BOOM SPOOL AT FLOAT POSITION...190

BUCKET SPOOL AT DUMP POSITION...191

BUCKET SPOOL AT TILT POSITION...192

WORK EQUIPMENT...194

WORK EQUIPMENT LINKAGE...194

BUCKET...196

BUCKET POSITIONER AND BOOM KICK-OUT...198

BUCKET POSITIONER...199

BOOM KICK-OUT...199

PROXIMITY SWITCH...200

CAB...205

ROPS CANOPY...206

AIR CONDITIONER...207

AIR CONDITIONER PIPING...207

AIR CONDITIONING (GENERAL)...208

BASIC INFORMATION ON AIR CONDITIONERS...208

HEAT...208

TEMPERATURE...209

PRESSURE...210

HUMIDITY...211

PRINCIPLE OF COOLING...211

REFRIGERANTS...216

FREON-TYPE GASES...216

SAFETY PRECAUTIONS...216

REFRIGERATOR OIL (LUBE OIL)...217

AIR CONDITONING CONDENSER...218

AIR CONDITIONER COMPRESSOR...221

RECEIVER WITH SIGHT GLASS (LIQUID TANK)...222

AIR CONDITIONER UNIT...224

MONITOR SYSTEMS...225

MACHINE MONITOR SYSTEM...225

MAIN MONITOR...226

MAIN MONITOR DISPLAY FUCTION...227

MAIN MONITOR SWITCH FUNCTION...228

TROUBLE DATA DISPLAY MODE...229

MAINTENANCE MONITOR...230

MAINTENANCE MONITOR DISPLAY FUNCTION...231

MAINTENANCE MONITOR SWITCH FUNCTION...232

ALL-RANGE ELECTRONIC CONTROL AUTOMATIC TRANSMISSION SYSTEM...233

SYSTEM STRUCTURE DIAGRAM...234

FUNCTION...235

TRANSMISSION CONTROLLER POWER SOURCE...240

INPUT SIGNALS...240

OUTPUT SIGNALS...242

LED DISPLAY...243

JOYSTICK TRANSMISSION SYSTEM...245

REMOTE POSITION, JOYSTICK STEERING CONTROLLER...246

ECSS SYSTEM...247

TRANSMISSION CONTROLLER...252

CONNECTOR SIGNALS...253

SENSORS...254

SPEEDOMETER SENSOR...254

ENGINE SPEED SENSOR...255

ENGINE OIL PRESSURE SENSOR...255

RADIATOR WATER LEVEL SENSOR...256

ENGINE OIL LEVEL SENSOR...256

FUEL LEVEL SENSOR...257

ENGINE WATER TEMPERATURE SENSOR...258

TORQUE CONVERTER OIL TEMPERATURE SENSOR...258

ELECTRICAL...259

ENGINE STARTING CIRCUIT...259

ENGINE STOP CIRCUIT...260

PREHEATING CIRCUIT...261

ELECTRICAL TRANSMISSION CONTROL...263

COMBINATION SWITCH...264

KICK-DOWN / HOLD SWITCH...266

KICK-DOWN SWITCH...266

HOLD SWITCH...266

KICK-DOWN ELECTRICAL CIRCUIT DIAGRAMS...267

NORMAL OPERATION...267

WHEN KICK-DOWN SWITCH IS OPERATED...268

KICK-DOWN SWITCH OPERATION CANCELED...269

ELECTRIC PARKING BRAKE CONTROL...271

PARKING BRAKE EMERGENCY RELEASE SWITCH...273

EMERGENCY BRAKE SWITCH...273

PARKING SAFETY RELAY...274

NEUTRALIZER RELAY...274

ELECTRICAL DIAGRAM...283

ECSS WIRING DIAGRAM - FOLDOUT 10-225-1...283

JOYSTICK STEERING WIRING DIAGRAM - FOLDOUT 10-225-2...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-3, (Sheet 1) (Part 1 of 5)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-4, (Sheet 1) (Part 2 of 5)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-5, (Sheet 1) (Part 3 of 5)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-6, (Sheet 1) (Part 4 of 5)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-7, (Sheet 1) (Part 5 of 5)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-8, (Sheet 2) (Part 1 of 4)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-9, (Sheet 2) (Part 2 of 4)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-10, (Sheet 2) (Part 3 of 4)...283

ELECTRICAL CIRCUIT DIAGRAM - FOLDOUT 10-225-11, (Sheet 2) (Part 4 of 4)...283

ENGINE FLOOR HARNESS DIAGRAM - FOLDOUT 10-225-12...283

CAB ELECTRICAL DIAGRAM - FOLDOUT 10-225-13...283

ENGINE HARNESS DIAGRAM...284

ENGINE - FRAME - FLOOR HARNESS DIAGRAM...285

A. The standard values in tables are those established for a new machine and are given as referen...289

B. Permissible values shown in the tables are estimations based on the results of test performed ...289

C. These standard values do not form a basis for judging claims...289

20 TESTING, ADJUSTING AND TROUBLESHOOTING...287

STANDARD VALUE TABLE FOR ENGINE - IN CHASSIS...291

STANDARD VALUE TABLE FOR CHASSIS...292

SKETCHES OF SPECIAL TOOLS...313

ENGINE...314

COMPONETS...314

BLEEDING AIR FROM FUEL SYSTEM (REFER TO ENGINE SHOP MANUAL)...314

BLOW-BY PRESSURE (REFER TO ENGINE SHOP MANUAL)...314

COMPRESSION PRESSURE (REFER TO ENGINE SHOP MANUAL)...314

EXHAUST TEMPERATURE (REFER TO ENGINE SHOP MANUAL)...314

FUEL PRESSURE (REFER TO ENGINE SHOP MANUAL)...314

HANDLING EQUIPMENT IN FUEL CIRCUIT (REFER TO ENGINE SHOP MANUAL)...314

INTAKE AIR PRESSURE (BOOST PRESSURE) (REFER TO ENGINE SHOP MANUAL)...314

LEAKAGE IN FUEL SYSTEM (REFER TO ENGINE SHOP MANUAL)...314

OIL PRESSURE (REFER TO ENGINE SHOP MANUAL)...314

PERFORMANCE TEST STANDARDS (REFER TO ENGINE SHOP MANUAL)...314

RELEASING REMAINING PRESSURE IN FUEL SYSTEM (REFER TO ENGINE SHOP MANUAL)...314

RUN-IN STANDARD (REFER TO ENGINE SHOP MANUAL)...314

SPEED SENSOR (REFER TO ENGINE SHOP MANUAL)...314

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING (REFER TO ENGINE SHOP MANUAL)...314

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) (REFER TO ENGINE SHOP MANUAL)...314

TROUBLESHOOTING OF ENGINE SYSTEM (S MODE) (REFER TO ENGINE SHOP MANUAL)...314

VALVE CLEARANCE (REFER TO ENGINE SHOP MANUAL)...314

HANDLING ENGINE CONTROLLER HIGH VOLTAGE CIRCUIT...315

REDUCED CYLINDER MODE...316

ALTERNATOR BELT TENSION...319

FAN BELT TENSION...320

AIR CONDITIONER BELT...321

TORQUE CONVERTER STALL SPEEDS...322

SHIFT LEVERS...323

OPERATING FORCE OF SPEED LEVER...323

TRAVEL OF SPEED LEVER...323

ACCELERATOR PEDAL...324

OPERATING FORCE...324

OPERATING ANGLE...325

TORQUE CONVERTER AND TRANSMISSION...326

OIL PRESSURE...326

HYDRAULIC CIRCUIT FLUSHING...329

TRANSMISSION VALVE FAILS - MOVING MACHINE...331

STEERING WHEEL...333

MEASURING PLAY...333

MEASURING OPERATING FORCE...333

MEASURING OPERATING TIME...334

STEERING OIL PRESSURE...335

MEASURING...335

ADJUSTING...336

STEERING STOP VALVE...337

TESTING...337

ADJUSTING...337

BRAKE PEDAL...338

OPERATING FORCE...338

TRAVEL...338

PEDAL PLAY...338

BRAKE PERFORMANCE...339

TESTING BRAKE OIL PRESSURE...340

BRAKE DISC WEAR...341

PARKING BRAKE...342

OIL PRESSURE...343

DISC WEAR...345

MANUAL RELEASE METHOD...346

PPC VALVE...347

OIL PRESSURE...347

MEASURING...347

ADJUSTING...348

ADJUSTING LINKAGE...349

ACCUMULATOR...350

CHARGE PRESSURE...350

MEASURING...350

ADJUSTING...350

WORK EQUIPMENT...351

HYDRAULIC PRESSURE...351

ADJUSTING...352

CUT-OFF VALVE...353

TESTING FUNCTION...353

PROCEDURE...353

LEVER LINKAGE...355

ADJUSTING...355

BUCKET POSITIONER...356

TESTING...356

ADJUSTING...356

BOOM KICK-OUT POSITIONER...357

TESTING...357

ADJUSTING...357

TRANSMISSION CONTROLLER...359

INITIAL TEACHING METHOD...359

MAIN MONITOR...361

ADJUSTMENT PROCEDURE...361

BLEEDING AIR...363

RELEASING REMAINING HYDRAULIC OIL PRESSURE...364

ADJUSTING JOYSTICK LEVER POTENTIOMETER...365

ADJUSTING JOYSTICK LEVER NEUTRAL DETECTION SWITCH...367

TROUBLESHOOTING GENERAL...369

POINTS TO REMEMBER WHEN TROUBLEHSOOTING...371

SEQUENCE OF EVENTS IN TROUBLESHOOTING...373

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE...374

PRECAUTIONS WHEN HANDLING ELECTRIC EQUIPMENT...374

HANDLING CONTROL BOX...379

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT...380

CHECKS BEFORE TROUBLESHOOTING...382

JUDGEMENT OF POWER TRAIN...383

PRECAUTIONS WHEN TROUBLESHOOTING...384

SAFETY...384

METHODS FOR TROUBLESHOOTING...384

PRECAUTIONS WHEN REMOVING, INSTALLING, DISASSEMBLING OR ASSEMBLING PARTS DURING TROUBLESHOOTING...386

PREVENTING RECURRENCE OF TROUBLE...387

HYDRAULIC EQUIPMENT...387

OIL CHECKS...387

CLEANING FRAGMENTS OF DAMAGED PARTS...387

METHOD OF USING TROUBLESHOOTING CHARTS...388

CATEGORY OF TROUBLESHOOTING CODE NUMBER...388

METHOD OF USING TROUBLESHOOTING TABLE FOR EACH TROUBLESHOOTING MODE...388

METHOD OF USING MATRIX TROUBLESHOOTING TABLES...390

METHOD OF USING ENGINE RELATED CHARTS...392

TROUBLESHOOTING CONNECTORS...397

CONNECTOR ARRANGEMENT DIAGRAM...399

CONNECTOR NUMBERS, TYPES AND PINS...400

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...409

TROUBLESHOOTING EXPLANATION OF FUNCTION OF ECM (ELECTRIC CONTROL MECHANISM)...421

EXPLANATION OF FUNCTIONS OF ECM (ELECTRIC CONTROL MECHANISM)...422

TRANSMISSION CONTROL SYSTEM...422

MAIN MONITOR SYSTEM...426

MAINTENANCE MONITOR SYSTEM...430

ECSS (ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM) CONTROL SYSTEM...434

JOYSTICK STEERING CONTROL SYSTEM...438

METHOD OF DISPLAYING ACTION AND FAILURE CODE...441

CONTROLLERS AND FAILURE CODES...443

RELATIONSHIP OF ELECTRONIC CONTROL SYSTEM...446

MAIN MONITOR FAILURE DISPLAY...446

TRANSMISSION CONTROLLER LED DISPLAY...449

ERROR CODE DISPLAYS...450

TROUBLESHOOTING OF ECSS (D MODE)...453

JUDGEMENT TABLE FOR CONTROLLER ELECTRICAL SYSTEM...454

D-1 ECSS DOES NOT WORK...456

A. ERROR CODE (D0) IS DISPLAYED...456

B. NO ABNORMALITY DISPLAY IS GIVEN...458

1. DOES NOT WORK AT ALL...458

D-2 ECSS CANNOT BE CANCELLED...459

TROUBLESHOOTING OF CHASSIS ELECTRICAL SYSTEM (E MODE)...461

E-1 ENGINE DOES NOT START...462

A. STARTING MOTOR DOES NOT TURN...462

B. STARTING MOTOR TURNS...466

E-2 ENGINE DOES NOT STOP...470

E-3 ENGINE STOPS WHEN MACHINE IS TRAVELING...472

E-5 PARKING BRAKE DOES NOT HAVE EFFECT...474

A. PARKING BRAKE HAS NOT EFFECT WHEN PARKING BRAKE SWITCH IS TURNED ON (ACTUATED)...474

B. PARKING BRAKE HAS NO EFFECT WHEN BRAKE PRESSURE DROPS (DOES NOT WORK AS EMERGENCY BRAKE)...474

E-6 PARKING BRAKE IS APPLIED WHEN MACHINE IS TRAVELING...476

E-7 PARKING BRAKE IS RELEASED WHEN STARTING SWITCH IS TURNED ON...480

E-8 TRANSMISSION DOES NOT CHANGE TO NEUTRAL WHEN PARKING BRAKE IS APPLIED (BUT PARKING BRAKE WORKS NORMALLY)...482

E-9 KICK-DOWN SWITCH DOE NOT WORK (SHIFT WORKS CORRECTLY DURING NORMAL GEAR SHIFT OPERATIONS)...484

A. KICK-DOWN SWITCH DOES NOT WORK (SHIFT WORKS CORRECTLY DURING NORMAL GEAR SHIFT OPERATIONS)...484

B. KICK-DOWN IS NOT CANCELLED...484

E-10 BOOM KICK-OUT CANNOT BE USED...486

E-11 ABNORMALITY IN BUCKET POSITIONER FUNCTION...490

E-12 ABNORMALITY IN LIGHTING UP OF FRONT WORKING LAMP...493

E-13 ABNORMALITY IN LIGHTING UP OF REAR WORKING LAMP...493

E-14 ABNORMALITY IN TRANMISSION CUT-OFF...493

E-15 ABNORMALITY IN PAKING BRAKE DRAGGING WARNING...493

E-16 ABNORMALITY IN BUZZER...493

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)...495

POWER TRAIN...496

H-1 MACHINE DOES NOT START...496

H-2 TRAVEL SPEED IS SLOW, THRUSTING POWER IS WEAK, LACKS POWER ON SLOPES, DOES NOT SHIFT GEAR...500

H-3 EXCESSIVE SHOCK WHEN STARTING MACHINE OR SHIFTING GEAR...505

H-4 EXCESSIVE TIME LAG WHEN STARTING MACHINE OR SHIFTING GEAR...508

H-5 TORQUE CONVERTER OIL TEMPERATURE IS HIGH...511

STEERING SYSTEM...512

H-6 STEERING WHEEL DOES NOT TURN...512

H-7 STEERING DOES NOT TURN (MACHINE WITH JOYSTICK)...513

H-8 TURNING, RESPONSE OF STEERING IS POOR...514

H-9 TURNING, RESPONSE OF STEERING IS POOR (MACHINE WITH JOYSTICK)...515

H-10 STEERING IS HEAVY...516

H-11 JOYSTICK STEERING IS HEAVY (MACHINES EQUIPPED WITH JOYSTICK)...517

H-12 STEERING WHEEL SHAKES OR JERKS...518

H-13 STEERING SHAKES OR THERE IS EXCESSIVE SHOCK (MACHINE WITH JOYSTICK)...519

H-14 TURNING RADIUS IS DIFFERENT BETWEEN LEFT AND RIGHT AT MAXIMUM STEERING...520

BRAKE SYSTEM...522

H-15 WHEEL BRAKES DO NOT WORK OR BRAKING EFFECT IS POOR...522

H-16 WHEEL BRAKES ARE NOT RELEASED OR BRAKES DRAG...524

H-17 PARKING BRAKE DOES NOT WORK OR BRAKING EFFECT IS POOR...525

H-18 PARKING BRAKE IS NOT RELEASED OR BRAKE DRAGS (INCLUDING EMERGENCY RELEASE SYSTEM)...526

WORK EQUIPMENT...527

H-19 NEITHER BOOM NOR BUCKET MOVE...527

H-20 BOTH BOOM AND BUCKET ARE SLOW OR LACK POWER...528

H-21 BOOM DOES NOT MOVE...529

H-22 NOT USED...529

H-23 BOOM IS SLOW OR BOOM LACKS POWER...530

H-24 NOT USED...530

H-25 BOOM CANNOT BE SET TO FLOAT OR CANNOT BE RELEASED FROM FLOAT...531

H-26 BOOM DROPS MOMENTARILY WHEN CONTROL LEVER IS OPERATED FROM HOLD TO RAISE...532

H-27 NOT USED...532

H-28 EXCESSIVE HYDRAULIC DRIFT OF BOOM...533

H-29 BUCKET DOES NOT MOVE...534

H-30 BUCKET IS SLOW OR LACKS POWER...535

H-31 EXCESSIVE HYDRAULIC DRIFT OF BUCKET...536

H-32 ECSS DOES NOT WORK, AND THERE IS PITCHING AND BOUNCING [MACHINES WITH ECSS]...537

TROUBLESHOOTING OF JOYSTICK STEERING CONTROLLER SYSTEM (J MODE)...539

JUDGEMENT TABLE FOR JOYSTICK CONTROLLER SYSTEM RELATED PARTS...541

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCUR...542

JOYSTICK CONTROLLER SYSTEM...542

J-1 FAILURE CODE [56] (SHORT CIRCUIT, DISCONNECTION IN CAUTION RELAY OUTPUT) IS DISPLAYED...546

J-2 FAILURE CODE [57] (SHORT CIRCUIT IN STEERING RIGHT SOLENOID (DETECTED WHEN OUTPUT)) IS DISPLAYED...547

J-3 FAILURE CODE [58] (SHORT CIRCUIT IN STEERING LEFT SOLENOID (DETECTED WHEN OUTPUT)) IS DISPLAYED...548

J-4 FAILURE CODE [59] (SHORT CIRCUIT IN STEERING RIGHT SOLENOID (HOT END) IS DISPLAYED...549

J-5 FAILURE CODE [60] (SHORT CIRCUIT IN STEERING LEFT SOLENOID (HOT END) IS DISPLAYED...550

J-6 FAILURE CODE [61] (SHORT CIRCUIT, DISCONNECTION IN STEERING SOLENOID CUT RELAY OUTPUT) IS DIS...551

J-7 FAILURE CODE [62] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK STEERING NEUTRAL SIGNAL) IS DISPL...552

J-8 FAILURE CODE [63] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK STEERING LEVER POTENTIOMETER SYST...553

J-9 ABNORMALITY IN POWER SOURCE, VOLTAGE...554

J-10 ABNORMALITY IN JOYSTICK STEERING ON-OFF SIGNAL SYSTEM...555

J-11 DISCONNECTION IN STEERING RIGHT SOLENOID...556

J-12 DISCONNECTION IN STEERING LEFT SOLENOID...557

TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (K-MODE)...559

K-1 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR DO NOT LIGHT UP FOR 3 SEC...561

A. NO LAMPS ON MAINTENANCE MONITOR LIGHT UP...561

B. SOME LAMPS DO NOT LIGHT UP...561

K-2 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR LIGHT UP BUT DO NOT GO OU...562

K-3 WHEN ENGINE IS STARTED IMMEDIATELY AFTER STARTING SWITCH IS TURNED ON (WITHIN 3 SECONDS), NO ...563

K-4 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH...564

A. ENGINE OIL LEVEL DISPLAY FLASHES...564

B. ENGINE WATER LEVEL DISPLAY FLASHES...565

K-5 WHEN STARTING SWITCH IS TURNED ON (ENGINE STARTED), CAUTION ITEMS FLASH...566

A. ENGINE OIL PRESSURE DISPLAY FLASHES...566

B. BATTERY CHARGE LEVEL DISPLAY FLASHES...567

C. BRAKE OIL PRESSURE DISPLAY FLASHES...568

D. AIR CLEANER DISPLAY FLASHES...569

K-6 CAUTION ITEMS ARE FLASHING BUT CAUTION BUZZER DOES NOT SOUND...570

K-7 THERE IS NO ABNORMALITY IN MONITOR DISPLAY BUT CAUTION BUZZER SOUNDS...571

K-8 CAUTION ITEMS ARE FLASHING BUT WARNING LAMP (CHECK LAMP, CAUTION LAMP) DOES NOT FLASH...572

A. CHECK LAMP...572

B. CAUTION LAMP...572

K-9 THERE IS NO ABNORMALITY IN MAINTENANCE MONITOR DISPLAY BUT WARNING LAMP (CHECK LAMP, CAUTION ...573

A. CHECK LAMP...573

B. CAUTION LAMP...573

K-10 NIGHT LIGHTING DOES NOT LIGHT UP WHEN LAMP SWITCH IS TURNED ON...574

K-11 NIGHT LIGHTING LIGHTS UP EVEN WHEN LAMP SWITCH IS OFF...575

K-12 SERVICE METER DOES NOT WORK...576

K-13 SERVICE METER IS RUNNING EVEN WHEN ENGINE IS STOPPED...577

K-14 ABNORMALITY IN GAUGE ITEMS...578

A. ABNORMALITY IN FUEL GAUGE...578

B) ABNORMALITY IN ENGINE COOLANT TEMPERATURE GAUGE...579

C) ABNORMALITY IN TORQUE CONVERTER OIL TEMPERATURE GAUGE...580

TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE)...581

M-1 MAIN MONITOR DOES NOT WORK...583

M-2 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED IMMEDIATELY, ALL LAMPS STAY LIGHTED UP...584

M-3 SPEEDOMETER DISPLAY DOES NOT WORK PROPERLY...585

M-4 ABNORMALITY IN SHIFT INDICATOR...586

A. DISPLAYS N EVEN WHEN DIRECTIONAL LEVER IS AT F...586

B. DISPLAYS N EVEN WHEN DIRECTIONAL LEVER IS AT R...586

C. DOES NOT DISPLAY N EVEN WHEN DIRECTIONAL LEVER IS AT N, AND DISPLAYS R WHEN DIRECTIONAL LEVER ...586

D. DOES NOT DISPLAY N EVEN WHEN DIRECTIONAL LEVER IS AT N, AND DISPLAY F WHEN DIRECTIONAL LEVER I...587

E. DOES NOT DISPLAY 1ST - 4TH...587

M-5 HIGH BEAM DOES NOT LIGHT UP...588

M-6 TURN SIGNAL DISPLAY DOES NOT LIGHT UP...589

A. LH TURN SIGNAL DISPLAY DOES NOT LIGHT UP...589

B. RH TURN SIGNAL DISPLAY DOES NOT LIGHT UP...589

M-7 ABNORMALITY IN PARKING DISPLAY...590

A. PARKING LAMP DISPLAY DOES NOT LIGHT UP...590

B. PARKING LAMP DISPLAY STAYS LIT UP...590

M-8 NOT USED...591

M-9 NIGHT LIGHTING DOES NOT LIGHT UP...592

M-10 ABNORMALITY IN FRONT WORKING LAMP...594

A. NEITHER MONITOR DISPLAY NOR FRONT WORKING LAMP LIGHT UP...594

B. WORKING LAMP LIGHTS UP, BUT MONITOR DISPLAY DOES NOT LIGHT UP...594

C. MONITOR DISPLAY LIGHTS UP, BUT WORKING LAMP DOES NOT LIGHT UP...594

M-11 ABNORMALITY IN REAR WORKING LAMP...596

A. NEITHER MONITOR DISPLAY NOR REAR WORKING LAMP LIGHT UP...596

B. WORKING LAMP LIGHTS UP, BUT MONITOR DISPLAY DOES NOT LIGHT UP...596

C. MONITOR DISPLAY LIGHTS UP, BUT WORKING LAMP DOES NOT LIGHT UP...596

M-12 ABNORMALITY IN TRANSMISSION CUT-OFF...598

A. WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS PRESSED, CUT-OFF FUNCTION IS NOT SWITCHED...598

B. WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS OFF, MONITOR DISPLAY GOES OUT, BUT CUT-OF...598

C. WHEN MONITOR DISPLAY IS TURNED OFF (TRANSMISSION CUT-OFF SWITCH TURNED OFF), CUT-OFF FUNCTION ...598

D. CUT-OFF FUNCTION IS ALWAYS ACTUATED REGARDLESS OF MONITOR DISPLAY (TRANSMISSION CUT-OFF SWITCH...598

E. MONITOR DISPLAY LIGHTS UP (TRANSMISSION CUT-OFF SWITCH TURN ON), BUT CUT-OFF FUNCTION IS NOT A...599

M-13 ABNORMALITY IN PARKING BRAKE DRAGGING WARNING...600

A. WHEN PARKING BRAKE IS APPLIED, BUZZER SOUNDS (INTERMITTENTLY) AND CAUTION LAMP FLASHES WEVEN W...600

B. WHEN PARKING BRAKE IS APPLIED, BUZZER DOES NOT SOUND AND CAUTION LAMP DOES NOT LIGHT UP EVEN W...600

M-14 WHEN PARKING BRAKE DRAGGING WARNING IS GIVEN, BUZZER AND CAUTION LAMP ARE ACTUATED CONTINUOU...602

A. ACTUATED CONTINOUSLY...602

B. NOT ACTUATED...602

M-15 ABNORMALITY IN BUZZER...603

A. BUZZER DOES NOT SOUND WHEN STARTING SWITCH IS AT ON (FOR 3 SECONDS) (DURING SELF-CHECK)...603

B. BUZZER ALWAYS SOUNDS...603

M-16 CONDITION OF MONITOR SWITCHES IS NOT STORED IN MEMORY...604

M-17 ABNORMALITY IN FAILURE DISPLAY MODE...605

A. DOES NOT ENTER FAILURE DISPLAY MODE...605

B. COUNT FOR TIME ELAPSED SINCE FAILURE IN FAILURE DISPLAY MODE DOES NOT ADVANCE...605

M-18 BUZZER IS NOT MADE TO SOUND BY TRANSMISSION CONTROLLER...606

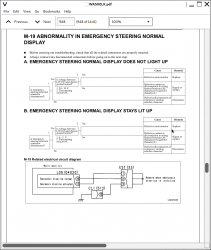

M-19 ABNORMALITY IN EMERGENCY STEERING NORMAL DISPLAY...607

A. EMERGENCY STEERING NORMAL DISPLAY DOES NOT LIGHT UP...607

B. EMERGENCY STEERING NORMAL DISPLAY STAYS LIT UP...607

M-20 ABNORMALITY IN EMERGENCY STEERING ACTUATION DISPLAY...608

A. EMERGENCY STEERING ACTUATION DISPLAY DOES NOT LIGHT UP...608

B. EMERGENCY STEERING DISPLAY STAYS LIT UP...608

M-21 NOT USED...609

M-22 ABNORMALITY IN ECSS SYSTEM...705

A. DISPLAY DOES NOT CHANGE WHEN SWITCH IS PRESSED...610

B. MONITOR DISPLAY LIGHTS UP, BUT ECSS FUNCTION DOES NOT WORK...610

M-23 FAILURE CODE IS NOT SENT TO MAIN MONITOR (ABNORMALITY IN NETWORK)...718

TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (T MODE)...613

JUDGEMENT TABLE FOR TRANSMISSION CONTROLLER SYSTEM RELATED PARTS...616

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE...618

T-1 FAILURE CODE [10] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN BACK-UP L...624

T-2 FAILURE CODE [12] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN F SOLENOI...626

T-3 FAILURE CODE [13] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN R SOLENOI...628

T-4 FAILURE CODE [14] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 1ST SOLEN...630

T-5 FAILURE CODE [15] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 2ND SOLEN...632

T-6 FAILURE CODE [16] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 3RD SOLEN...634

T-7 FAILURE CODE [17] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 4TH SOLEN...636

T-8 FAILURE CODE [19] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK DIRECTIONAL SWITCH SYSTEM) IS DIS...638

T-9 FAILURE CODE [20] (SHORT CIRCUIT, DISCONNECTION IN DIRECTIONAL SWITCH SYSTEM) IS DISPLAYED...640

T-10 FAILURE CODE [21] (SHORT CIRCUIT, DISCONNECTION IN RANGE SWITCH SYSTEM) IS DISPLAYED...644

T-11 FAILURE CODE [22] (DISCONNECTION IN TRAVEL SPEED SENSOR SYSTEM) IS DISPLAYED...648

T-12 FAILURE CODE [23] (SHORT CIRCUIT, DISCONNECTION IN ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED...650

T-13 FAILURE CODE [24] (SHORT CIRCUIT, DISCONNECTION IN EEP ROM) IS DISPLAYED...652

T-14 FAILURE CODE [25] (SHORT CIRCUIT IN TRANSMISSION OIL TEMPERATURE SYSTEM) IS DISPLAYED...653

T-15 FAILURE CODE [26] (SHORT CIRCUIT IN F ECMV FILL SWITCH SYSTEM) IS DISPLAYED...654

T-16 FAILURE CODE [27] (SHORT CIRCUIT IN R ECMV FILL SWITCH SYSTEM) IS DISPLAYED...655

T-17 FAILURE CODE [28] (SHORT CIRCUIT IN 1ST ECMV FILL SWITCH SYSTEM) IS DISPLAYED...656

T-18 FAILURE CODE [29] (SHORT CIRCUIT IN 2ND ECMV FILL SWITCH SYSTEM) IS DISPLAYED...657

T-19 FAILURE CODE [30] (SHORT CIRCUIT IN 3RD ECMV FILL SWITCH SYSTEM) IS DISPLAYED...658

T-20 FAILURE CODE [31] (SHORT CIRCUIT IN 4TH ECMV FILL SWITCH SYSTEM) IS DISPLAYED...659

T-21 FAILURE CODE [32] (SHORT CIRCUIT IN F OR R ECMV FILL SWITCH SYSTEM) IS DISPLAYED...660

T-22 FAILURE CODE [33] (SHORT CIRCUIT IN 1ST, 2ND, 3RD, OR 4TH ECMV FILL SWITCH SYSTEM) IS DISPLAYED...662

T-23 HOLD SWITCH SYSTEM...665

T-24 KICK-DOWN SWITCH SYSTEM...666

T-25 TRANSMISSION CUT-OFF SIGNAL SYSTEM...667

T-26 NEUTRALIZER RELAY SIGNAL SYSTEM...668

T-27 BUZZER SIGNAL SYSTEM...669

T-28 NETWORK SYSTEM...670

T-29 TRANSMISSION CONTROLLER POWER SOURCE SYSTEM...671

T-30 SHORT CIRCUIT IN TRAVEL SPEED SENSOR SYSTEM...672

T-31 DISCONNECTION IN TRANSMISSION OIL TEMPERATURE SENSOR SYSTEM...673

T-32 DISCONNECTION IN F ECMV FILL SWITCH SYSTEM...674

T-33 DISCONNECTION IN R ECMV FILL SWITCH SYSTEM...675

T-34 DISCONNECTION IN 1ST ECMV FILL SWITCH SYSTEM...676

T-35 DISCONNECTION IN 2ND ECMV FILL SWITCH SYSTEM...677

T-36 DISCONNECTION IN 3RD ECMV FILL SWITCH SYSTEM...678

T-37 DISCONNECTION IN 4TH ECMV FILL SWITCH SYSTEM...679

TROUBLESHOOTING AIR CONDITIONING (DENSO)...681

AIR CONDITIONER / HEATER (DENSO)...682

VISUAL AND AUDIBLE INSPECTION...682

TROUBLESHOOTING WITH MANIFOLD GAUGE (REFRIGERATION CYCLE)...683

NORMAL CONDITIONS...683

INSUFFICIENT REFRIGERANT...683

REFRIGERANT FAILS TO CIRCULATE (SYSTEM CLOGGED)...684

MOISTURE IN SYSTEM...684

COMPRESSOR FAILURE...684

EXCESSIVE REFRIGERANT OR INSUFFICIENT CONDENSER COOLING...685

AIR IN THE SYSTEM...685

EXPANSION VALVE OPENS TOO FAR...685

TROUBLESHOOTING THE ELECTRICAL CIRCUIT...686

BLOWER TROUBLESHOOTING...686

ELECTRICAL CIRCUIT CHECKS...688

HEATER RELAY...688

BLOWER SWITCH...688

COOLER CIRCUIT TROUBLESHOOTING...690

AIR CONDITIONER SWITCH...690

MAGNETIC CLUTCH RELAY...690

CONDENSER FAN OPERATION CIRCUIT...691

ERROR MESSAGE TABLES...694

A. PROBLEM - EO ERROR MESSAGE DISPLAY ON THE CONTROLLER...694

B. PROBLEM - E1 ERROR MESSAGE DISPLAY ON THE CONTROLLER...694

C. FALSE E1 ERROR MESSAGE / COLD WEATHER CHARGING PROBLEMS...695

D. PROBLEM - NO HEAT...695

E. PROBLEM - NO DISPLAY, THE BLOWER FAN WILL NOT TURN OFF, WHEN THE POWER IS TURNED ON...695

F. PROBLEM - COMPRESSOR CLUTCH WILL NOT ENGAGE, UNLESS DEFROST BUTTON IS PUSHED...696

WIRING DIAGRAM...698

WIRE CHART...699

INSPECTION AREAS...700

30 DISASSEMBLY AND ASSEMBLY...701

METHOD OF USING MANUAL...705

PRECAUTIONS DURING OPERATION...706

PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK...706

PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK...707

PRECAUTIONS WHEN COMPLETING THE OPERATIONS...708

OTHER PRECAUTIONS...708

SPECIAL TOOL LIST...709

SKETCHES OF SPECIAL TOOLS...713

ENGINE...716

COMPONENTS...716

ALTERNATOR (REFER TO THE ENGINE SHOP MANUAL)...716

CYLINDER HEAD (REFER TO THE ENGINE SHOP MANUAL)...716

ENGINE FRONT SEAL (REFER TO THE ENGINE SHOP MANUAL)...716

ENGINE OIL COOLER (REFER TO THE ENGINE SHOP MANUAL)...716

ENGINE REAR SEAL (REFER TO THE ENGINE SHOP MANUAL)...716

FUEL INJECTION PUMP (REFER TO THE ENGINE SHOP MANUAL)...716

NOZZLE HOLDER (REFER TO THE ENGINE SHOP MANUAL)...716

STARTING MOTOR (REFER TO THE ENGINE SHOP MANUAL)...716

THERMOSTAT (REFER TO THE ENGINE SHOP MANUAL)...716

TURBOCHARGER (REFER TO THE ENGINE SHOP MANUAL)...716

WATER PUMP (REFER TO THE ENGINE SHOP MANUAL)...716

REMOVAL...716

INSTALLATION...720

RADIATOR...722

REMOVAL...722

INSTALLATION...723

DAMPER...724

REMOVAL...724

INSTALLATION...725

DISASSEMBLY...726

ASSEMBLY...729

TORQUE CONVERTER AND TRANSMISSION...734

REMOVAL...734

INSTALLATION...737

DISCONNECTION...738

CONNECTION...738

TORQUE CONVERTER...739

DISASSEMBLY...739

ASSEMBLY...743

TRANSMISSION...750

DISASSEMBLY...750

ASSEMBLY...767

TRANSFER...784

DISASSEMBLY...784

ASSEMBLY...788

PARKING BRAKE...793

DISASSEMBLY...793

ASSEMBLY...796

TRANSMISSION CONTROL VALVE (ECMV)...800

REMOVAL...800

INSTALLATION...800

CENTER SUPPORT...801

REMOVAL...801

INSTALLATION...802

DISASSEMBLY...803

ASSEMBLY...805

DRIVE SHAFT...808

DISASSEMBLY...808

ASSEMBLY...811

FRONT AXLE...814

REMOVAL...814

INSTALLATION...815

REAR AXLE...816

REMOVAL...816

INSTALLATION...820

DIFFERENTIAL...822

REMOVAL (FRONT)...822

INSTALLATION (FRONT)...824

REMOVAL (REAR)...825

INSTALLATION (REAR)...826

DISASSEMBLY DIFFERENTIAL GEAR ASSEMBLY...827

FINE DISASSEMBLY OF PINION ASSEMBLY...829

FINE DISASSEMBLY OF DIFFERENTIAL GEAR CASE ASSEMBLY...830

FINE ASSEMBLY OF DIFFERENTIAL GEAR CASE ASSEMBLY...831

FINE ASSEMBLY OF PINION ASSEMBLY...832

ASSEMBLY OF DIFFERENTIAL GEAR ASSEMBLY...833

DISSASSEMBLY OF LIMITED SLIP DIFFERENTIAL ASSEMBLY...839

FINE DISASSEMBLY OF PINION ASSEMBLY...841

FINE DISASSEMBLY OF DIFFERENTIAL GEAR CASE ASSEMBLY...842

ASSEMBLY OF LIMITED SLIP DIFFERENTIAL ASSEMBLY...843

FINE ASSEMBLY OF PINION ASSEMBLY...845

ASSEMBLY OF DIFFERENTIAL ASSEMBLY...846

DISASSEMBLY OF FINAL DRIVE ASSEMBLY...853

ASSEMBLY OF FINAL DRIVE ASSEMBLY...856

STEERING ORBITAL VALVE...860

REMOVAL...860

INSTALLATION...860

DISASSEMBLY...861

ENSURE A CLEAN WORKING ENVIRONMENT...861

PREPARATORY WORK...861

ASSEMBLY...866

STEERING CYLINDER...874

REMOVAL...874

INSTALLATION...875

DISASSEMBLY...876

ASSEMBLY...878

STEERING VALVE...880

REMOVAL...880

INSTALLATION...882

BRAKE VALVE...884

REMOVAL...884

INSTALLATION...885

SLACK ADJUSTER...886

REMOVAL...886

INSTALLATION...886

DISASSEMBLY...887

ASSEMBLY...888

BRAKE ASSEMBLY (FRONT AND REAR)...889

REMOVAL...889

INSTALLATION...889

DISASSEMBLY...890

ASSEMBLY...893

HYDRAULIC PUMP...898

REMOVAL...898

INSTALLATION...899

HYDRAULIC TANK...900

REMOVAL...900

INSTALLATION...901

HYDRAULIC FILTER...902

REMOVAL...902

INSTALLATION...902

PPC VALVE...903

REMOVAL...903

INSTALLATION...903

DISASSEMBLY...904

ASSEMBLY...904

MAIN CONTROL VALVE...905

REMOVAL...905

INSTALLATION...907

DISASSEMBLY...908

ASSEMBLY...912

BUCKET CYLINDER...915

REMOVAL...915

INSTALLATION...916

DISASSEMBLY...917

ASSEMBLY...919

BOOM CYLINDER...922

REMOVAL...922

INSTALLATION...923

DISASSEMBLY...924

ASSEMBLY...926

CENTER HINGE PIN...929

REMOVAL...929

INSTALLATION...935

WORK EQUIPMENT...938

REMOVAL...938

INSTALLATION...942

BULKHEAD...944

REMOVAL...944

INSTALLATION...945

ENGINE HOOD...946

REMOVAL...946

INSTALLATION...948

CAB...950

REMOVAL...950

INSTALLATION...952

FLOOR FRAME...953

REMOVAL...953

INSTALLATION...955

COUNTERWEIGHT...956

REMOVAL...956

INSTALLATION...956

FUEL TANK...958

REMOVAL...958

INSTALLATION...959

AIR CONDITIONER UNIT...960

REMOVAL...960

INSTALLATION...961

CONDENSER...962

REMOVAL...962

INSTALLATION...962

RECEIVER TANK...963

REMOVAL...963

INSTALLATION...963

COMPRESSOR ASSEMBLY...964

REMOVAL...964

INSTALLATION...965

MAIN MONITOR...966

REMOVAL...966

INSTALLING...967

40 MAINTENANCE STANDARD...969

ENGINE MOUNT...971

TRANSMISSION MOUNT...972

TORQUE CONVERTER CHARGING PUMP...974

DAMPER...976

TORQUE CONVERTER AND PTO...978

TRANSMISSION...980

TRANSFER...984

MAIN RELIEF, TORQUE CONVERTER RELIEF VALVE...986

LUBRICATION RELIEF VALVE...987

DRIVE SHAFT...988

CENTER SUPPORT...990

DIFFERENTIAL, NORMAL - (STANDARD)...992

DIFFERENTIAL, LIMITED SLIP...996

FINAL DRIVE...998

AXLE MOUNT...1000

CENTER HINGE PIN...1002

STEERING COLUMN...1006

STEERING PUMP...1008

STEERING VALVE...1009

STEERING CYLINDER MOUNT...1010

BRAKE VALVE...1012

RIGHT...1012

LEFT...1014

SLACK ADJUSTER...1016

BRAKE...1018

PARKING BRAKE...1020

HYDRAULIC PUMP...1021

SAR(4)-160...1021

SWITCH, PPC PUMP...1022

SAR(3)-63 + SAR(1)-28...1022

PPC VALVE...1023

FOR BUCKET AND BOOM...1023

FOR AUXILIARY ATTACHMENT...1024

CUT-OFF VALVE...1025

MAIN CONTROL VALVE...1026

2 SPOOL VALVE...1026

3-SPOOL...1028

HYDRAULIC CYLINDERS...1030

BUCKET LINKAGE...1032

BUCKET...1034

BUCKET POSITIONER AND BOOM KICK-OUT...1035

ROPS CAB...1036

90 OTHERS...1037

ELECTRICAL DIAGRAMS...1039

ECSS WIRING DIAGRAM...1039

JOYSTICK STEERING WIRING DIAGRAM...1041

ELECTRICAL CIRCUIT DIAGRAM (SHEET 1) (PART 1 OF 5)...1043

ELECTRICAL CIRCUIT DIAGRAM (SHEET 1) (PART 2 OF 5)...1045

ELECTRICAL CIRCUIT DIAGRAM (SHEET 1) (PART 3 OF 5)...1047

ELECTRICAL CIRCUIT DIAGRAM (SHEET 1) (PART 4 OF 5)...1049

ELECTRICAL CIRCUIT DIAGRAM (SHEET 1) (PART 5 OF 5)...1051

ELECTRICAL CIRCUIT DIAGRAM (SHEET 2) (PART 1 OF 4)...1053

ELECTRICAL CIRCUIT DIAGRAM (SHEET 2) (PART 2 OF 4)...1055

ELECTRICAL CIRCUIT DIAGRAM (SHEET 2) (PART 3 OF 4)...1057

ELECTRICAL CIRCUIT DIAGRAM (SHEET 2) (PART 4 OF 4)...1059

ENGINE FLOOR HARNESS DIAGRAM...1061

CAB ELECTRICAL DIAGRAM...1063

CONNECTOR ARRANGEMENT DIAGRAM (SHEET 1) (PART 1 OF 5)...1065

CONNECTOR ARRANGEMENT DIAGRAM (SHEET 1) (PART 2 OF 5)...1067

CONNECTOR ARRANGEMENT DIAGRAM (SHEET 1) (PART 3 OF 5)...1069

CONNECTOR ARRANGEMENT DIAGRAM (SHEET 1) (PART 4 OF 5)...1071

CONNECTOR ARRANGEMENT DIAGRAM (SHEET 1) (PART 5 OF 5)...1073

3D CONNECTOR ARRANGEMENT DIAGRAM (SHEET 2) (PART 1 OF 2)...1075

3D CONNECTOR ARRANGEMENT DIAGRAM (SHEET 2) (PART 2 OF 2)...1077

PARKING BRAKE CONTROL DIAGRAM...1079

HYDRAULIC...1081

CIRCUIT DIAGRAM...1081

JOYSTICK STEERING LINE ASSEMBLY DIAGRAM (PART 1 OF 3)...1083

JOYSTICK STEERING LINE ASSEMBLY DIAGRAM (PART 2 OF 3)...1085

JOYSTICK STEERING LINE ASSEMBLY DIAGRAM (PART 3 OF 3)...1087

STEERING LINE ASSEMBLY DIAGRAM (PART 1 OF 3)...1089

STEERING LINE ASSEMBLY DIAGRAM (PART 2 OF 3)...1091

STEERING LINE ASSEMBLY DIAGRAM (PART 3 OF 3)...1093

HYDRAULIC LINE ASSEMBLY (PART 1 OF 3)...1095

HYDRAULIC LINE ASSEMBLY (PART 2 OF 3)...1097

HYDRAULIC LINE ASSEMBLY (PART 3 OF 3)...1099

COVER....1

INTRODUCTION....3

FOREWORD....4

SAFETY INFORMATION....5

APPROVED AND NON-APPROVED USES....6

Approved Functions....6

Non-Approved Functions....6

VISIBILITY STANDARD....7

Visibility in Immediate Area....7

12-M Radius Visibility....7

PRODUCT IDENTIFICATION....8

Directions of Machine....8

Machine Serial Number....9

Engine Serial Number, EPA Regulations....9

Service Meter Location....10

SERIAL NUMBERS AND DEALER INFORMATION....11

Model: WA500-3LK....11

TABLE OF CONTENTS....13

SAFETY....25

SAFETY AND WARNING DECALS....26

Location of the Safety Decals....26

Safety Labels....27

Additional Safety Decals....32

GENERAL SAFETY RULES AND PRECAUTIONS....34

General Safety Rules....34

Unauthorized Modifications....34

General Safety at Job Site....35

Working on Loose Ground....35

Safety Features....35

Personal Protective Equipment....36

Fire and Explosion Prevention....36

Fire Caused by Fuel or Oil....36

Fire Caused by Accumulation of Flammable Material....37

Fire Coming from Electrical Wiring....37

Fire Coming from Hydraulic Line....37

Windshield Washer Fluid....37

Action if Fire Occurs....37

Fire Extinguisher and First Aid Kit....38

Mounting and Dismounting....39

Inside Operator?s Compartment....40

Precautions When Standing Up from Operator?s Seat....40

Precautions When Using ROPS....41

Emergency Escape from Operator?s Cab....41

Leaving Operator?s Compartment....42

Asbestos Hazard Alert....43

Crush or Pinch-Point Dangers....43

Precautions for Ventilation Exhaust Gas....43

PRECAUTIONS BEFORE STARTING OPERATIONS....44

Pre-Operational Checks....44

Ensure Good Visibility....44

Confirmation of Marks....44

Precaution for Warning Tag....45

Checks Before Starting Engine, Adjustments....46

Precautions When Starting....47

Work Site Hazards....47

Avoiding Dangerous Situations....48

Working Clearances....49

Working Near High Voltage Cables....50

RULES FOR ROAD TRAVEL....51

Traveling in Reverse....51

Working on Loose or Unstable Ground....52

Operating on Snow or Frozen Surfaces....52

Travel on Slopes....53

Parking the Machine....55

PRECAUTIONS DURING MAINTENANCE OPERATIONS....56

Warning Tags....56

Equipment Storage....56

Working Under the Machine....57

Using Drop Lamps....57

Keeping the Machine Clean....57

Running the Machine During Maintenance....58

Rules for Refueling the Machine....59

Cooling System Precautions....59

Battery Precautions....59

Battery Hazard Prevention....60

Using Jumper Cables....61

Starting the Machine....61

High-Pressure Hoses....62

Safe Handling of High-Pressure Hoses....62

Precautions for High-Pressure Fuel....62

High-Temperature Areas....63

Disposal of Waste Materials....63

Inflating Tires....64

Accumulator....64

Critical Parts....64

High Voltage....65

Maintenance of Air Conditioner....65

OPERATION....67

GENERAL VIEW....68

General View of Machine....68

Controls and Gauges....69

Main Monitor....70

Maintenance Monitor....71

EXPLANATION OF COMPONENTS....72

Machine Monitor System....72

Warning Display....74

Central Check Lamp (CHECK)....75

Central Caution Lamp (CAUTION)....75

Engine Water Level Caution Pilot Lamp....76

Engine Oil Level Caution Pilot Lamp....76

Brake Oil Pressure Caution Pilot Lamp....77

Engine Oil Pressure Caution Pilot Lamp....77

Battery Charge Caution Pilot Lamp....77

Air Cleaner Clogging Caution Pilot Lamp....78

Emergency Steering Pilot Lamp (if equipped)....78

Front Axle Oil Temperature Warning Lamp (if equipped)....78

Meter Display Portion....79

Parking Brake Pilot Lamp....80

Engine Preheating Pilot Lamp....80

Front Working Lamp Pilot Lamp....80

Rear Working Lamp Pilot Lamp....80

Transmission Cutoff Pilot Lamp....81

Turn Signal Pilot Lamp....81

High Beam Pilot Lamp....81

Transmission Auto-Shift/Manual Selector Pilot Lamp....81

Fuel Gauge....82

Engine Water Temperature Gauge....82

Torque Converter Oil Temperature Gauge....82

Service Meter....83

Speedometer....83

Transmission Shift Indicator....83

Switches....84

Starting Switch....85

Transmission Cutoff Switch....85

Front Working Lamp Switch....86

Rear Working Lamp Switch....86

Transmission Auto-Shift/Manual Selector Switch....86

Lamp Switch....87

Turn Signal Lever....87

Dimmer Switch....87

Horn Button....87

Hazard Lamp Switch....88

Kickdown Switch....88

Front Wiper Switch....88

Rear Wiper Switch....89

Cigarette Lighter (if equipped)....89

Room Lamp Switch....89

Parking Brake Switch....90

Power Window Switch....90

Hold Switch....91

Control Levers, Pedals....92

Gearshift Lever....93

Directional Lever....94

Gearshift Lever Stopper....95

Safety Lock Lever (for Work Equipment Lever)....95

Bucket Control Lever....96

Lift Arm Control Lever....96

Brake Pedals....97

Accelerator Pedal....97

SECURITY LOCKS AND SAFETY FEATURES....98

Steering Column Tilt Lever....98

Cap with Lock....98

Opening the Cap....98

Locking the Cap....99

Safety Bar....99

Towing Pin....100

Backup Alarm....100

MACHINE FEATURES....101

Cab Door....101

Emergency Escape Right Door....101

Left Cab Door, Opening Lock....103

Left Cab Door, Opening Knob....104

Left Cab Window (Open, Lock, Cancel Knob)....104

Cab Wiper....105

Grease Pump....105

Dust Indicator....105

ELECTRICAL....106

Fuses....106

Fuse Capacity and Circuits....106

Slow-Blow Fuses....107

Power Outlet....107

WORK OPERATIONS....108

Walk-Around Check....108

Precautions Before Starting Work Operations....108

Check Before Starting Engine....111

Check Machine Monitor....111

Check Dust Indicator....111

Check Coolant Level, Add Coolant....112

Check Oil Level in Engine Oil Pan, Add Oil....113

Check Fuel Level, Add Fuel....114

Check Electric Wiring....115

Check Inflation Pressure of Tires....115

Check Parking Brake....115

Check Brake Pedal....115

Check Waterproof/Fireproof Dividing Walls....116

Adjust Seat....117

Adjust Seat Belt....118

Adjust Wrist Rest Height....119

Adjust Rearview Mirrors....119

Final Checks Before Starting Engine....120

Starting Engine....122

Normal Starting....122

Automatic Warming-Up Operation....124

Operations and Checks After Starting Engine....125

Breaking in the Machine....125

Checks After Starting Engine....125

Normal Operation....127

Stopping Engine....128

Check After Stopping Engine....128

Moving the Machine (Directional, Speed), Stopping the Machine....129

Moving the Machine....129

Changing Gear Speed....132

Changing Direction....133

Stopping the Machine....134

Turning....135

Operation of Work Equipment....136

Lift Arm Operation....136

Bucket Operation....137

Work Possible Using Wheel Loader....138

Digging Operations....138

Loading Piled Soil or Blasted Rock....138

Digging and Loading on Level Ground....140

Leveling Operations....141

Pushing Operations....141

Load-and-Carry Operations....141

Loading Operations....142

Cross-Drive Loading....142

V-Shape Loading....142

Preparations for Loading, Gathering Rocks....143

Approaching Facing....143

Digging....144

Traveling in Reverse After Excavation....146

Approaching Dump Truck....147

Loading Dump Truck....147

Reversing Away From Dump Truck....148

Precautions....150

When Piling Up Loads....150

When Handling Blasted Rock....150

During Cutting Face Operations....154

When Switching Between Forward and Reverse....154

When Turning When Tires Are Stationary....154

Permissible Water Depth....155

When Wheel Brake Does Not Work....155

When Driving Up or Down Slopes....155

When Driving the Machine....156

Adjusting Work Equipment....157

Adjusting Boom Kickout....157

Adjusting Bucket Positioner....158

Bucket Level Indicator....158

Removing the Bucket....159

Installing the Bucket....160

Parking the Machine....162

Checks After Completion of Operation....164

Before Stopping Engine....164

After Stopping Engine....164

Locking the Machine....164

HANDLING TIRES....165

Precautions When Handling Tires....165

Tire Pressure....166

Precautions for Using Load-and-Carry Method....167

Precautions when Storing Tires....167

TRANSPORTATION....168

Transportation Procedure....168

Loading and Unloading Trailers....168

Loading Machine....168

Securing Machine....169

Unloading Machine....170

LIFTING MACHINE....171

Lifting Position Marks....172

Lifting Procedure....173

COLD WEATHER OPERATION....175

Precautions for Low Temperature....175

Fuel and Lubricants....175

Coolant....175

Battery....176

Warming-Up Operation for Steering Hydraulic Circuit....177

Precautions After Completion of Work....177

When Cold Weather Ends....177

LONG-TERM STORAGE....178

Before Storage....178

During Storage....178

After Storage....179

TROUBLESHOOTING....180

When Machine Runs Out of Fuel....180

Bleeding Air from Fuel Line....180

Towing the Machine....182

When Engine Can Be Used....183

When Engine Cannot Be Used....183

Releasing Parking Brake....184

Emergency Travel Operation....185

If Battery is Discharged....186

Precautions....186

Removing the Battery....186

Installing the Battery....186

Precautions for Charging Battery....187

Starting Engine With Booster Cable....188

Precautions When Connecting or Disconnecting Booster Cable....188

Connecting Booster Cable....188

Starting Engine....189

Disconnecting Booster Cable....189

Other Troubleshooting....191

Electrical System....191

Chassis....192

Engine....194

Relationship of Electronic Control System....196

Transmission Control System....202

ECSS Control System....203

Joystick Control System....203

Electronic Governor Control System....204

MAINTENANCE....205

GUIDES TO MAINTENANCE....206

Check Service Meter....206

Komatsu Genuine Replacement Parts....206

Komatsu Genuine Oils....206

Always Use Clean Washer Fluid....206

Always Use Clean Oil and Grease....206

Checking for Foreign Materials in Drained Oil and On Filters....206

Fuel Strainer....206

Welding Instructions....207

Do Not Drop Things Inside Machine....207

Dusty Work Sites....207

Avoid Mixing Oil....207

Locking Inspection Covers....207

Bleeding Air from Hydraulic Circuit....207

Precautions When Installing Hydraulic Hoses....208

Checks After Inspection and Maintenance....208

OUTLINES OF SERVICE....209

Handling Oil, Fuel, Coolant, and Performing Oil Clinic....209

Oil....209

Fuel....210

Coolant and Water for Dilution....210

Grease....211

Performing KOWA (Komatsu Oil Wear Analysis)....212

KOWA Analysis Items....212

Oil Sampling....212

Storing Oil and Fuel....213

Filters....213

Outline of Electric System....213

WEAR PARTS....214

Wear Parts List....214

RECOMMENDED FUEL, COOLANT, AND LUBRICANTS....215

Fuel, Coolant, and Lubricant Ambient Temperature Chart....216

Recommended Brands, Other Than Komatsu Genuine Oil....217

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS....218

PERIODIC REPLACEMENT OF SAFETY-CRITICAL PARTS....220

MAINTENANCE SCHEDULE CHART....222

SERVICE PROCEDURE....224

Initial 10 Hours Service....224

Initial 250 Hours Service....224

When Required....225

Check, Clean, Replace Air Cleaner Element....225

Clean Inside of Cooling System....228

Check Transmission Oil Level, Add Oil....232

Check Axle Oil Level, Add Oil....234

Clean Axle Case Breather....235

Clean Air Conditioner Condenser....236

Check Window Washing Fluid Level, Add Fluid....236

Clean Radiator Fins and Oil Cooler Fins....237

Check Electrical Intake Air Heater....237

Replace Bucket Teeth (if equipped)....238

Replace Bucket Tooth with Segment Edge....240

Turn, Replace Bolt-On Cutting Edge....241

Lubricate Work Equipment Control Valve Linkage....241

Check Air Conditioner....242

Replace Slow-Blow Fuse....243

Select Tires....244

Check Tire Pressure....245

Check Before Starting....246

Every 50 Hours Service....247

Drain Water, Sediment from Fuel Tank....247

Every 100 Hours Service....248

Lubricate Rear Axle Pivot Pin....248

Clean Element in Air Conditioner Fresh Air Filter....248

Check Oil Level in Hydraulic Tank, Add Oil....249

Every 250 Hours Service....250

Check Battery Electrolyte Level....250

Check Parking Brake....252

Check Alternator Belt Tension, Adjust....252

Check Air Conditioner Compressor Belt Tension, Adjust....253

Check for Loose Wheel Hub Nuts, Tighten....253

Clean Element in Air Conditioner Recirculation Filter....254

Lubricating....254

Every 500 Hours Service....257

Change Oil in Engine Oil Pan, Replace Engine Oil Filter Cartridge....257

Replace Fuel Filter Cartridge....259

Replace Transmission Oil Filter Element....261

Lubricate Center Drive Shaft Spline....262

Check Fan Belt for Wear....262

Every 1000 Hours Service....263

Change Oil in Transmission Case, Clean Strainer....263

Clean Transmission Case Breather....264

Lubricating....264

Check Tightening Parts of Turbocharger....266

Replace Corrosion Resistor Cartridge....266

Clean Radiator Subtank Breather....267

Clean Fuel Strainer....267

Wash Fuel Tank Breather....267

Tighten ROPS Canopy....268

Every 2000 Hours Service....269

Change Oil in Hydraulic Tank, Replace Hydraulic Tank Filter Element....269

Replace Hydraulic Tank Breather Element....271

Change Axle Oil....272

Replace Element in Air Conditioner Recirculation Air Filter, Fresh Air Filter....273

Clean PPC Circuit Strainer....273

Clean Engine Breather Element....274

Check Alternator, Starting Motor....274

Check Engine Valve Clearance, Adjust....274

Check Brake Disc Wear....274

Clean and Check Turbocharger....274

Check Play of Turbocharger Rotor....274

Check Accumulator Function....275

Check Accumulator Gas Pressure....275

Check Injector....275

Every 4000 Hours Service....276

Check Water Pump....276

Check Vibration Damper....276

Check Fan Pulley and Tension Pulley....276

Check Air Conditioner Compressor, Adjust....276

Replace Injector....276

Check for Loose Engine High-Pressure Piping Clamps, Hardening of Rubber....277

Check for Missing Fuel Spray Prevention Caps, Hardening of Rubber....278

Every 8000 Hours Service....279

Replace High-Pressure Piping Clamps....279

Replace Fuel Spray Prevention Caps....279

SPECIFICATIONS....281

SPECIFICATIONS....282

OPTIONS, ATTACHMENTS....285

BUCKET AND TIRES....286

TIRE CHAINS....287

ELECTRONIC-CONTROLLED SUSPENSION SYSTEM....289

Operating ECSS....289

Precautions When Using ECSS Switch....289

Removal of ECSS Piping....289

Precautions When Handling Accumulator....290

AUTO-GREASING SYSTEM....291

Method of Operation....291

Starting Auto-Greasing....291

Lubrication Controller Display....292

Lubrication Controller Display Table....293

Setting the Greasing Time....294

Setting Greasing Time in Cold Areas....294

Procedure for Setting Greasing Time....295

Checking Amount of Grease....296

Replacing Grease Cartridge....296

Precautions When Handling Auto-Greasing System....297

Troubleshooting Auto-Greasing System....298

REMOTE POSITIONER....299

General Locations....299

Operating Remote Positioner....300

Adjusting Remote Positioner....300

Setting Remote Positioner Stop Position....301

Adjusting Sensor....301

JOYSTICK STEERING SYSTEM....302

Structure and Function....302

Components....304

Joystick Steering Lever....305

Kickdown Switch....306

Hold Switch....306

Steering with Joystick Lever or Steering Wheel....307

Precautions for Steering with Joystick....308

Operating the Joystick Steering System....309

Getting In and Out of Operator?s Cab....311

Adjustments....312

Adjusting Console....312

Adjusting Height of Armrest....312

Sliding the Console....312

Adjusting Air-Suspension Seat....313

CAR RADIO....315

Components....315

Power Switch/Volume....316

Tone Control Knob....316

Display....316

Clock Button/Displaying Frequency....316

AST....317

Preset Button....317

SEEK....317

Band Selector Switch....317

Tuning Switch....318

Method of Operation....318

Listening to Radio....318

Automatic Tuning....318

Manual Tuning....318

Setting Preset Buttons....319

Automatic Memory....319

Automatic Switching of Monaural/Stereo Reception....320

Adjusting Time....320

Precautions When Using....320

AM/FM RADIO CASSETTE STEREO SOUND SYSTEM....322

Sound System Components....324

Power Switch/Volume....324

Auto-Store/Preset Scan Button....324

Bass Control Knob....324

Treble Control Knob....325

Loudness Button....325

Time/Radio Display Selector Button....325

Tape Eject Button....326

Cassette Door....326

Fast-Forward, Rewind Buttons....326

Preset Buttons....326

Metal Tape Button....327

Manual Tuning Buttons....327

Seek Tuning Buttons....327

Band Selector Button....327

Method of Operation....328

Setting Preset Buttons....328

Using Auto-Preset....328

Using Manual Preset....328

Listening to Radio....329

Listening to Cassette Tape....329

Reversing the Tape....330

Precautions When Using....330

Handling Cassette Tape....330

AIR CONDITIONER....331

Control Panel....331

Fan Switch....332

Air Conditioner Switch....332

Mode Selector Switch....332

FRESH/RECIRC Selector Switch....332

Temperature Control Switch....333

Method of Operation....334

When Not Using the Air Conditioner Regularly....335

Precautions When Using Air Conditioner....335

Inspection and Maintenance....335

Cool Box....336

BRAKE COOLING SYSTEM....337

When Required....337

Check Axle Oil Level, Add Oil....337

Clean Axle Case Breather....338

Clean Brake Cooling Oil Cooler Fins....338

Every 2000 Hours Service....339

Replace Axle Oil and Brake Cooling Oil Filter Cartridge....339