Komatsu Wheel Loader WA500L Series Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheel Loader WA500-1L, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheel Loader WA500-1L workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,361 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAMW25010 - Wheel Loader WA500-1L Operation & Maintenance Manual.pdf

CEBMW25010 - Wheel Loader WA500-1L Shop Manual.pdf

SEAMA4250101 - Wheel Loader WA500-1L Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

CONTENTS...5

10 ENGINE...19

12 TESTING AND ADJUSTING...19

STANDARD VALUE TABLE...20

TOOL LIST...22

VALVE CLEARANCE ...23

COMPRESSION PRESSURE ...25

FUEL INJECTION ...26

TESTING TIMING...26

ADJUSTING TIMING BY DELIVERY CHECK...27

BLOW-BY PRESSURE ...28

ALTERNATOR FAN BELT ...29

ENGINE FAN BELT ...29

EXHAUST GAS COLOR ...30

OIL PRESSURE ...32

OIL TEMPERATURE ...32

ACCELERATOR PEDAL ...33

OPERATING FORCE...33

ENGINE ...34

13 DISASSEMBLY AND ASSEMBLY...35

STARTING MOTOR ...37

REMOVAL...37

INSTALLATION...37

ALTERNATOR ...38

REMOVAL...38

INSTALLATION...38

OIL COOLER ...39

REMOVAL...39

INSTALLATION...39

FUEL INJECTION PUMP ...40

REMOVAL...40

INSTALLATION...40

WATER PUMP ...41

REMOVAL...41

INSTALLATION...41

NOZZLE HOLDER ...42

REMOVAL...42

INSTALLATION...42

TURBOCHARGER...43

REMOVAL...43

INSTALLATION...43

AIR COMPRESSOR ...44

REMOVAL...44

INSTALLATION...44

CYLINDER HEAD ...45

REMOVAL...45

INSTALLATION...50

RADIATOR ...56

REMOVAL...56

INSTALLATION...59

ENGINE...62

REMOVAL ...62

INSTALLATION...68

FUEL TANK ...75

REMOVAL...75

INSTALLATION...77

14 MAINTENANCE STANDARD ...79

ENGINE MOUNT ...80

20 POWER TRAIN ...81

21 STRUCTURE AND FUNCTION ...81

GENERAL ...83

HYDRAULIC CIRCUIT FOR POWER TRAIN ...86

HYDRAULIC DIAGRAM FOR POWER TRAIN ...87

DAMPER ...89

TORQUE CONVERTER AND TRANSMISSION PIPING ...91

RADIATOR AND OIL COOLER ...92

TORQUE CONVERTER AND PTO ...93

TORQUE CONVERTER OIL FILTER ...95

TRANSMISSION...96

TRANSMISSION foldout # 1...97

TRANSMISSION CONTROL VALVE...101

UPPER VALVE...102

LOWER VALVE...103

TRANSMISSION SOLENOID VALVE ...104

TRANSMISSION SOLENOID VALVE ...105

EMERGENCY MANUAL SPOOL ...107

FORWARD 1st ...108

PRIORITY VALVE ...110

MODULATING VALVE AND QUICK RETURN VALVE ...111

ACCUMULATOR VALVE ...114

PILOT REDUCING VALVE ...117

MAIN RELIEF VALVE ...119

REDUCING VALVE ...120

TORQUE CONVERTER RELIEF VALVE ...122

LUBRICATION BY-PASS VALVE ...124

TRANSMISSION PILOT OIL FILTER ...126

TRANSFER ...127

DRIVE SHAFT ...128

CENTER SUPPORT ...129

AXLES ...130

FRONT ...130

REAR ...131

DIFFERENTIAL ...132

FRONT ...132

REAR ...133

TORQUE PROPORTIONING DIFFERENTIAL...135

FINAL DRIVE ...136

AXLE MOUNT ...138

TIRE AND WHEEL ...140

22 TESTING AND ADJUSTING ...141

STANDARD VALUE TABLE ...143

TOOL LIST ...144

ENGINE STALL SPEED ...145

TORQUE CONVERTER STALL...145

HYDRAULIC STALL...146

FULL STALL...146

TORQUE CONVERTER AND TRANSMISSION OIL PRESSURE ...147

SHIFT LEVER ...149

EMERGENCY MANUAL SPOOL ...151

OPERATION...151

TIRE AND WHEEL ...153

TROUBLESHOOTING...154

PRECAUTIONS WHEN TROUBLESHOOTING ...155

METHOD OF READING TROUBLESHOOTING TABLES...157

PREVENTING RECURRENCE OF TROUBLE...159

JUDGEMENT ON POWER TRAIN...160

TROUBLESHOOTING TABLE...162

Machine does not move...162

Machine lacks power or speed...164

Excessive time lag when starting machine or shifting gear...166

Torque converter oil temperature too high...167

23 DISASSEMBLY AND ASSEMBLY ...169

DAMPER ...172

REMOVAL ...172

INSTALLATION ...176

DISASSEMBLY ...180

ASSEMBLY ...183

TORQUE CONVERTER CHARGING PUMP ...187

REMOVAL ...187

INSTALLATION ...187

TORQUE CONVERTER AND TRANSMISSION ...188

REMOVAL ...188

INSTALLATION ...196

TORQUE CONVERTER ASSEMBLY...206

DISASSEMBLY...206

PTO ASSEMBLY...208

Disassembly...208

ASSEMBLY...210

PTO ASSEMBLY...210

Assembly...210

TORQUE CONVERTER ASSEMBLY...212

ASSEMBLY...212

TRANSMISSION ASSEMBLY...215

DISASSEMBLY...215

ASSEMBLY...225

TRANSFER CASE ASSEMBLY...237

DISASSEMBLY...237

ASSEMBLY...242

TRANSMISSION CONTROL VALVE...248

REMOVAL...248

INSTALLATION...249

LOWER VALVE ASSEMBLY...250

DISASSEMBLY...251

ASSEMBLY...251

UPPER VALVE ASSEMBLY...252

DISASSEMBLY...253

ASSEMBLY...253

MAIN RELIEF VALVE ASSEMBLY...254

DISASSEMBLY...254

ASSEMBLY...254

CENTER SUPPORT...255

REMOVAL...255

INSTALLATION...256

DISASSEMBLY...257

ASSEMBLY...259

DRIVE SHAFT...261

DISASSEMBLY...261

ASSEMBLY...263

FRONT AXLE...265

REMOVAL...265

INSTALLATION...267

FRONT DIFFERENTIAL...269

REMOVAL...269

INSTALLATION...272

REAR AXLE...275

REMOVAL...275

INSTALLATION...279

REAR DIFFERENTIAL...283

REMOVAL...283

INSTALLATION...284

DIFFERENTIAL GEAR ASSEMBLY...286

DISASSEMBLY...286

FINE DISASSEMBLY OF PINION ASSEMBLY...288

FINE DISASSEMBLY OF DIFFERENTIAL GEAR CASE ASSEMBLY...289

ASSEMBLY...290

FINE ASSEMBLY OF DIFFERENTIAL GEAR ASSEMBLY...290

FINE ASSEMBLY OF PINION ASSEMBLY...291

ASSEMBLY OF DIFFERENTIAL ASSEMBLY...292

FINAL DRIVE...297

DISASSEMBLY...297

ASSEMBLY...300

24 MAINTENANCE STANDARD...305

TRANSMISSION MOUNT ...306

DAMPER ...307

TORQUE CONVERTER CHARGING PUMP ...308

TORQUE CONVERTER AND PTO ...309

TRANSMISSION ...310

TRANSMISSION CONTROL VALVE ...314

UPPER VALVE ...314

LOWER VALVE ...316

SOLENOID VALVE ...318

TRANSFER ...320

DIFFERENTIAL ...322

FINAL DRIVE ...326

DRIVE SHAFT ...327

CENTER SUPPORT ...328

AXLE MOUNT...330

40 STEERING SYSTEM...333

41 STRUCTURE AND FUNCTION...333

CENTER HINGE PIN ...334

STEERING PIPING ...335

STEERING CIRCUIT DIAGRAM ...336

STEERING COLUMN AND GEAR BOX ...337

STEERING LINKAGE ...338

STEERING CONTROL SYSTEM ...339

STEERING VALVE ...339

ROTOR SEAL ...341

STEERING RELIEF VALVE ...342

SAFETY VALVE (WITH SUCTION VALVE) ...343

OPERATION OF DEMAND SPOOL...345

OPERATION OF THE STEERING VALVE ...348

TWO-WAY RESTRICTOR VALVE ...351

42 TESTING AND ADJUSTING...353

STANDARD VALUE TABLE ...354

TOOL LIST ...354

STEERING WHEEL PLAY ...355

OPERATING FORCE OF STEERING WHEEL ...356

OPERATING TIME OF STEERING WHEEL ...357

STEERING OIL PRESSURE ...358

STEERING LINKAGE ...360

TROUBLESHOOTING TABLES...363

1. Steering wheel does not turn. ...364

2. Steering wheel is sluggish. ...365

3. Steering wheel moves unsteadily or is subject to large shock. ...366

4. Machine tends to turn naturally in one particular direction when traveling. ...366

5. Left and right turning radii are different. ...366

43 DISASSEMBLY AND ASSEMBLY...367

STEERING GEAR ...369

REMOVAL ...369

INSTALLATION...371

STEERING GEAR BOX ...372

DISASSEMBLY ...372

ASSEMBLY ...373

STEERING AND PPC PUMP ...376

REMOVAL ...376

INSTALLATION ...377

STEERING VALVE ...378

REMOVAL ...378

INSTALLATION ...380

DISASSEMBLY ...382

ASSEMBLY...383

STEERING CYLINDER...384

REMOVAL...384

INSTALLATION...386

DISASSEMBLY...388

ASSEMBLY...390

CENTER HINGE PIN ...393

REMOVAL ...393

INSTALLATION ...400

44 MAINTENANCE STANDARD...409

CENTER HINGE PIN...410

STEERING LINKAGE AND STEERING COLUMN ...412

STEERING GEAR BOX ...414

STEERING PUMP ...415

STEERING CYLINDER MOUNT ...416

STEERING VALVE ...418

50 BRAKE AND AIR SYSTEM...421

51 STRUCTURE AND FUNCTION...421

GENERAL ...422

AIR SYSTEM ...422

BRAKE CIRCUIT ...422

BRAKE AND AIR SCHEMATICS ...423

BRAKE AND AIR PIPING ...423

BRAKE AND AIR CIRCUIT DIAGRAM ...423

BRAKE AND AIR CIRCUIT SYSTEM ...423

AIR TANK ...424

WET TANK ...424

DRY TANK (UPPER) ...425

DRY TANK (LOWER) ...426

SAFETY VALVE ...427

BRAKE VALVE ...428

BRAKE ACTUATED ...429

OPERATING IN BALANCE ...430

BRAKE RELEASED ...431

AIR GOVERNOR ...432

TWO-WAY VALVE ...434

BRAKE CHAMBER...435

SLACK ADJUSTER ...437

CHECK VALVE ...440

BRAKE ...441

PARKING BRAKE ...443

PARKING BRAKE SOLENOID VALVE ...445

SPRING CYLINDER ...446

BRAKE CALIPER ...447

52 TESTING AND ADJUSTING...449

STANDARD VALUE TABLE ...451

TOOL LIST ...452

BRAKE PEDAL ...453

AIR PRESSURE ...454

BRAKE PERFORMANCE ...457

BRAKE OIL PRESSURE ...458

BRAKE DISC ...459

AIR BLEEDING FROM BRAKE LINE ...460

PARKING BRAKE ...461

PERFORMANCE...461

CHECKING AND ADJUSTING...462

TROUBLESHOOTING...465

TROUBLESHOOTING TABLE ...466

1. Air pressure does not rise at all. ...466

2. Air pressure does not rise to the specified range. ...467

3. Brake is ineffective or not very effective. ...468

4. Brake does not release, or drags. ...469

5. Parking brake does not release, or drags. (Applies to machine equipped with air park- ing brake.) ...470

53 DISASSEMBLY AND ASSEMBLY...471

BRAKE VALVE ...473

REMOVAL ...473

INSTALLATION...475

DISASSEMBLY...477

ASSEMBLY...479

BRAKE CHAMBER...481

REMOVAL ...481

INSTALLATION ...483

DISASSEMBLY ...482

ASSEMBLY...487

SLACK ADJUSTER ...490

REMOVAL ...490

INSTALLATION ...490

DISASSEMBLY ...491

ASSEMBLY ...492

BRAKE ASSEMBLY...493

REMOVAL ...493

INSTALLATION...495

DISASSEMBLY (FRONT OR REAR) ...499

ASSEMBLY (FRONT OR REAR) ...502

SPRING CYLINDER ...506

REMOVAL ...506

INSTALLATION...507

PARKING BRAKE ...508

REMOVAL ...508

INSTALLATION...511

PARKING BRAKE PAD ...514

REMOVAL ...514

INSTALLATION ...514

AIR GOVERNOR ...515

DISASSEMBLY ...515

ASSEMBLY ...516

54 MAINTENANCE STANDARD...517

BRAKE VALVE ...518

BRAKE CHAMBER ...520

SLACK ADJUSTER ...521

BRAKE ...522

PARKING BRAKE ...524

SPRING CYLINDER ...526

60 WORK EQUIPMENT SYSTEM...527

61 STRUCTURE AND FUNCTION...527

GENERAL ...529

HYDRAULIC PIPING ...530

HYDRAULIC CIRCUIT...530

SCHEMATICS...530

DIAGRAM ...530

HYDRAULIC TANK ...531

OIL FILTER By-pass VALVE ...532

BREATHER ...533

PROPORTIONAL PRESSURE CONTROL VALVE (PPC VALVE) ...534

OPERATION OF PPC VALVE ...536

PPC RELIEF VALVE ...540

MAIN CONTROL VALVE ...541

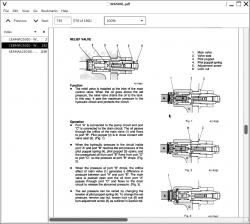

RELIEF VALVE...544

SAFETY VALVE (with suction valve)...545

SUCTION VALVE ...546

FLOAT SELECTOR VALVE AND UNLOADER VALVE...547

ACCUMULATOR ...549

OPERATION OF MAIN CONTROL VALVE ...550

LIFT AND DUMP SPOOLS AT ?HOLD? ...550

LIFT SPOOL AT ?RAISE?...551

LIFT SPOOL AT ?LOWER? ...552

LIFT SPOOL AT ?FLOAT ...553

DUMP SPOOL AT ?DUMP?...554

DUMP SPOOL AT ?TILT BACK?...555

BUCKET LINKAGE ...556

BUCKET ...558

BUCKET POSITIONER AND BOOM KICK-OUT ...559

Bucket positioner...560

Boom kick-out...560

WORK EQUIPMENT LEVER LINKAGE ...561

62 TESTING AND ADJUSTING...563

STANDARD VALUE TABLE ...565

TOOL LIST ...566

EMERGENCY MANUAL SPOOL...567

METHOD FOR OPERATION...567

OUTLINE...567

OPERATION...567

DUMP AND LIFT CONTROL LEVER ...569

MEASURING ...569

ADJUSTING ...570

HYDRAULIC CIRCUIT FLUSHING...572

PPC RELIEF VALVE ...575

MEASURING PRESSURE...575

ADJUSTING...577

WORK EQUIPMENT ...578

RELIEF VALVE...578

MEASURING TIME...580

HYDRAULIC DRIFT ...581

BUCKET POSITIONER ...582

BOOM KICK-OUT ...583

TROUBLESHOOTING ...584

TROUBLESHOOTING TABLE ...584

1. Lift arm does not rise. ...584

2. Lift arm moves slowly or does not have sufficient lifting power. ...585

3. Lift arm movement becomes slow after it reaches a certain height. ...586

4. Bucket cannot be held down with lift arm cylinder...586

5. Lift arm has large hydraulic drift...586

6. Lift arm movement is unsteady during work...586

7. Lift arm descends momentarily when control lever is shifted from ?Hold? to ?Raise?...586

8. Bucket does not tilt back. ...587

9. Bucket moves slowly or has insufficient tilt back power. ...588

10. Bucket movement becomes slow during tilt back...589

11. Bucket cannot be held down by the bucket cylinder. ...589

12. Bucket has large hydraulic drift. ...589

13. Bucket moves unsteadily when machine travels 10. Bucket movement becomes slow during tilt back. under load. (Main control valve in ?Hold?). Checks before troubleshooting Checks before troubleshooting ...589

14. Bucket dumps momentarily when control lever is shifted from ?Hold? to ?Tilt back?. Check before troubleshooting ...589

15. Control levers of lift arm and dump move stiffly and sluggishly. ...590

63 DISASSEMBLY AND ASSEMBLY...591

HYDRAULIC TANK ...593

REMOVAL ...593

INSTALLATION ...595

HYDRAULIC FILTER ...597

REMOVAL ...597

INSTALLATION ...597

WORK EQUIPMENT PUMP ...598

REMOVAL ...598

INSTALLATION ...600

SWITCH PUMP...601

REMOVAL...601

INSTALLATION...603

PPC VALVE ASSEMBLY ...604

REMOVAL ...604

INSTALLATION...606

DISASSEMBLY...608

ASSEMBLY...608

PPC RELIEF VALVE ASSEMBLY...609

DISASSEMBLY...609

ASSEMBLY...609

MAIN CONTROL VALVE ...610

REMOVAL ...610

INSTALLATION ...613

DISASSEMBLY ...613

ASSEMBLY ...622

DUMP CYLINDER ...625

REMOVAL ...625

INSTALLATION...627

LIFT CYLINDER...629

REMOVAL ...629

INSTALLATION ...631

LIFT AND DUMP CYLINDERS ...633

DISASSEMBLY ...633

ASSEMBLY ...635

WORK EQUIPMENT ...638

REMOVAL ...638

INSTALLATION ...642

COUNTERWEIGHT ...646

REMOVAL ...646

INSTALLATION ...646

64 MAINTENANCE STANDARD ...647

HYDRAULIC AND SWITCH PUMP ...648

HYDRAULIC PUMP SAR(3)-100 ...648

SWITCH PUMP SAR(3)-100 ...648

PPC PUMP ...649

SAR(1)-014 ...649

PPC VALVE ...650

MAIN CONTROL VALVE ...652

HYDRAULIC CYLINDERS ...654

STEERING CYLINDER ...654

LIFT CYLINDER ...654

DUMP CYLINDER ...655

BUCKET LINKAGE ...656

BUCKET ...660

BUCKET POSITIONER AND BOOM KICK-OUT ...662

80 ELECTRIC AND ELECTRONIC SYSTEM...665

81 STRUCTURE AND FUNCTION ...665

ELECTRICAL WIRING DIAGRAM ...667

ENGINE STARTING CIRCUIT ...668

ENGINE STOP CIRCUIT ...670

PREHEATING CIRCUIT ...671

PREHEATING AND AFTER-HEATING WITH HEATER SWITCH ...671

PREHEATING WITH STARTING SWITCH...672

AUTOMATIC PREHEATING...674

COMBINATION SWITCH ...677

TRANSMISSION CUT-OFF SWITCH ...678

TRANSMISSION CUT-OFF SELECTOR SWITCH...679

NEUTRALIZER RELAY ...680

KICK-DOWN SWITCH ...681

KICK-DOWN ELECTRIC CIRCUIT ...682

ELECTRICAL PARKING BRAKE CONTROL ...688

PARKING BRAKE VALVE...690

PARKING SAFETY RELAY...690

NEUTRALIZER RELAY...690

EMERGENCY BRAKE SWITCH...690

CONDITIONS ...691

1. STARTING SWITCH OFF...691

2. STARTING SWITCH ON ...692

2-1. When parking brake switch is turned ON before starting switch is turned ON. ...692

2-2. Parking brake switch turned OFF (released) before starting switch is turned ON. Electric ...693

3. PARKING BRAKE SWITCH TURNED OFF (Released) AFTER STARTING SWITCH IS TURNED ON...694

4. PARKING BRAKE SWITCH ON (operated)...695

5. WHEN AIR PRESSURE DROPS. (Emergency brake actuated) ...696

BUCKET POSITIONER AND BOOM KICK-OUT ...697

Bucket positioner...698

Boom kick-out...698

PROXIMITY SWITCH ...699

OPERATION ...699

Lift arm RAISE ...699

Kick-out ...701

BUCKET "TILT" ...702

Hold ...702

Tilt...703

Positioned ...704

ELECTRICAL CIRCUIT DIAGRAM FOR AIR GAUGE ...705

ELECTRICAL CIRCUIT DIAGRAM FOR INTERMITTENT WIPER ...706

ELECTRONIC VEHICLE MONITORING SYSTEM (EVMS) ...707

INDICATION ON MONITOR PANEL ...709

MONITOR WIRING HARNESS ...712

SENSORS ...713

ENGINE OIL LEVEL SENSOR ...713

BRAKE OIL LEVEL...714

COOLANT LEVEL...714

FUEL GAUGE...715

ENGINE OIL PRESSURE...716

PARKING BRAKE...717

AIR PRESSURE...718

TORQUE CONVERTER OILTEMPERATURE...719

COOLANT TEMPERATURE...719

ROTATIONAL SPEED...720

BRAKE LINE FAILURE...720

TRANSMISSION OIL FILTER CLOGGING SENSOR ...721

82 TESTING AND ADJUSTING ...723

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM ...726

MACHINE MONITOR (SPEEDOMETER MODULE) ...729

TROUBLESHOOTING...731

CHECKS BEFORE TROUBLESHOOTING ...732

JUDGEMENT ON POWER TRAIN...733

METHOD OF READING TROUBLESHOOTING TABLE ...734

METHOD OF USING YES-NO TROUBLESHOOTING FLOW CHART ...734

PRECAUTION WHEN HANDLING CONNECTOR ...736

CONNECTOR TERMINAL NUMBERS ...738

ELECTRICAL WIRING DIAGRAM ...744

ELECTRICAL CONNECTOR (CN) DIAGRAM ...744

VEHICLE MONITOR SYSTEM DIAGRAM ...744

ELECTRICAL CIRCUIT SYSTEM ...745

ENGINE STARTING AND STOP CIRCUIT SYSTEM...745

PARKING BRAKE SYSTEM...746

KICK-DOWN CIRCUIT SYSTEM...747

PREHEATING CIRCUIT SYSTEM...748

TROUBLESHOOTING CHART FOR ELECTRIC SYSTEM...749

POSITION OF CONNECTORS TROUBLESHOOTING ...751

TROUBLESHOOTING ...750

E-1 ENGINE DOES NOT START ...760

E-2 ENGINE DOES NOT STOP ...764

E-3 ENGINE STOPS WHEN TRAVELING...765

E-4 PARKING BRAKE DOES NOT WORK ...766

E-5 PARKING BRAKE IS APPLIED WHEN TRAVELING...768

E-6 PARKING BRAKE IS RELEASED WHEN STARTING ...770

E-7 SHIFT LEVER DOES NOT ENTER NEUTRAL...770

E-8 TRANSMISSION DOES NOT WORK NORMALLY...772

E-9 KICK-DOWN SWITCH DOES NOT WORK ...794

E-10 KICK-DOWN ONLY WORKS WHEN KICK-DOWN SWITCH IS ON ...797

E-11 KICK-DOWN OPERATION IS NOT CANCELED...798

E-12 KICK-DOWN WORKS BY MISTAKE WHEN TRAVELING IN F2...800

E-13 MACHINE DOES NOT TRAVEL WHEN KICK-DOWN SWITCH IS PRESSED...800

E-14 PREHEAT DISPLAY STAYS ON...802

E-15 PREHEAT DOSE NOT STOP...802

TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM ...803

POSITION OF CONNECTORS FOR TROUBLESHOOTING ...804

TROUBLESHOOTING ...816

M-1 (BRAKE OIL LEVEL) FLASHES WHEN ENGINE IS STOPPED...816

M-2 (ENGINE OIL LEVEL) FLASHES WHEN ENGINE IS STOPPED...817

M-3 (RADIATOR WATER LEVEL) FLASHES WHEN ENGINE IS STOPPED...818

M-4 (BATTERY CHARGE) FLASHES WHEN ENGINE IS RUNNING...818

M-5 (TRANSMISSION OIL FILTER CLOGGING) FLASHES WHEN ENGINE IS RUNNING...820

M-6 (FUEL LEVEL) FLASHES WHEN ENGINE IS RUNNING...821

M-7 (BRAKE LINE FAILURE) FLASHES WHEN ENGINE IS RUNNING...821

M-8 (ENGINE OIL PRESSURE) FLASHES WHEN ENGINE IS RUNNING...823

M-9 (RADIATOR WATER LEVEL) FLASHES WHEN ENGINE IS RUNNING...823

M-10 (DROP IN AIR PRESSURE) FLASHES WHEN ENGINE IS RUNNING...825

M-11 (ENGINE WATER TEMPERATURE) FLASHES WHEN ENGINE IS RUNNING...825

M-12 (TORQUE CONVERTER OIL TEMPERATURE) FLASHES WHEN ENGINE IS RUNNING...825

M-13 (PARKING BRAKE) LIGHTS UP ABNORMALLY OR DOES NOT LIGHT UP...827

M-14 (WORKING LAMP) LIGHTS UP ABNORMALLY, OR DOES NOT LIGHT UP...829

M-15 (PREHEATING) LIGHTS UP, OR DOES NOT LIGHT UP...831

M-16 (TRANSMISSION CUT-OFF) LIGHTS UP, DOES NOT LIGHT UP...833

M-17 TURN SIGNAL HI BEAM LIGHTS UP, OR DOES NOT LIGHT UP...835

M-18 TURN SIGNAL DOES NOT FLASH EVEN WHEN HAZARD SWITCH IS TURNED ON...840

M-19 SPEEDOMETER DISPLAY DOES NOT WORK NORMALLY...841

M-20 HOURMETER DISPLAY DOES NOT WORK NORMALLY...842

M-21 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DOES NOT WORK, OR ONLY PARTS WORKS...843

M-22 WHEN STARTING SWITCH IS TURNED ON, ALL MONITOR PANEL LIGHTS LIGHT UP, BUT DO NOT GO OUT...844

M-23 (BATTERY CHARGE) FLASHES OR (ENGINE OIL PRESSURE) FLASHES WHEN ENGINE IS STOPPED...845

M-24 NONE OF THE MACHINE MONITOR PANEL LIGHTING LIGHTS UP, OR PARTS OF IT DOES NOT LIGHT UP...847

M-25 WHEN THE STARTING SWITCH IS TURNED TO THE ON POSITION (ENGINE STOPPED), AND THE BUZZER DOES NOT SOUND FOR 1 SEC. WITH THE C...852

M-26 NO ABNORMALITY IS SHOWN ON THE MONITOR DISPLAY, BUT THE ALARM BUZZER SOUNDS...852

M-27 WHEN THE STARTING SWITCH IS TURNED TO THE ON POSITION (ENGINE STOPPED), AND THE WARNING LAMP DOES NOT LIGHT UP FOR 2 SEC. T...854

M-28 NO ABNORMALITY IS SHOWN ON THE MONITOR DISPLAY, BUT THE WARNING LAMP LIGHTS UP...855

M-29 ABNORMALITY IN THE FUEL GAUGE SYSTEM...856

M-30 ABNORMALITY IN THE AIR PRESSURE GAUGE SYSTEM...858

M-31 ABNORMALITY IN THE ENGINE WATER TEMPERATURE GAUGE SYSTEM...860

M-32 ABNORMALITY IN THE TORQUE CONVERTER OIL TEMPERATURE GAUGE SYSTEM...862

83 DISASSEMBLY AND ASSEMBLY ...865

MACHINE MONITOR ...866

REMOVAL ...866

INSTALLATION ...867

90 OTHERS...869

91 STRUCTURE AND FUNCTION ...869

GENERAL ...871

BASIC INFORMATION ON AIR CONDITIONERS ...871

UNITS RELATED TO REFRIGERATION ...871

Heat ...871

Temperature...871

Pressure...872

Humidity ...873

PRINCIPLE OF COOLING...874

Why do coolers cool?...874

Refrigerator using evaporation latent heat...874

Refrigeration method (Vapor compression)...874

Refrigerating cycle ...875

Heating cycle...877

REFRIGERANTS ...878

SAFETY PRECAUTIONS ...878

REFRIGERATOR OIL (LUBE OIL)...879

SPECIFICATIONS...880

PIPING DIAGRAM ...881

ELECTRIC WIRING DIAGRAM ...882

COMPRESSOR (CRANK TYPE) ...883

MAGNETIC CLUTCH ...886

CONDENSER ...887

RECEIVER W/SIGHT GLASS ...889

AIR CONDITIONER UNIT ...891

EXPANSION VALVE ...892

EVAPORATOR ...894

THERMOSTAT ...894

PRESSURE SWITCH ...895

HEATER ...897

BLOWER UNIT ...897

PIPING ...898

AIR CONTROL SYSTEM ...899

CONTROL PANEL ...900

BLOWER SWITCH...900

AIR CONDITIONER SWITCH...900

TEMPERATURE CONTROL LEVER...900

AIR SOURCE SELECTOR LEVER...900

92 TESTING AND ADJUSTING...901

SERVICE TOOLS ...903

GAUGE MANIFOLD ...903

GAS LEAK DETECTOR ...906

HALIDE TORCH LEAK DETECTOR...906

ELECTRIC LEAK TESTER...908

VALVE FOR SERVICE CANS ...909

MAINTENANCE PROCEDURE ...910

PRECAUTIONS WHEN REMOVING OR INSTALLING PIPING ...910

PROHIBITED WORK...910

OTHER PRECAUTIONS...910

BLEEDING AIR FROM REFRIGERATION CIRCUIT ...912

PURPOSE...912

CONNECTING GAUGE MANIFOLD...912

EVACUATION...913

AIR-TIGHTNESS CHECK...913

GAS-LEAK CHECK...913

EVACUATION (REPEATING)...914

CHARGINGTHE REFRIGERATION CIRCUIT WITH REFRIGERANT ...915

CHARGING FROM THE HIGH-PRESSURE SIDE...915

CHARGING FROM THE LOW PRESSURE SIDE (REPLENISHING THE REFRIGERATION CIRCUIT)...916

WHEN THE AMBIENT TEMPERATURE IS LOW...917

WHEN THE AMBIENT TEMPERATURE IS HIGH...917

REPLACING SERVICE CANS ...918

CHECKING THE AMOUNT OF REFRIGERANT ...918

REMOVAL OF GAUGE MANIFOLD ...920

DISCHARGING THE REFRIGERANT ...920

DAILY CHECKS ...921

CHECK REFRIGERANT LEVEL...921

CLEANING THE CONDENSER...921

CHECKING THE V-BELT...921

CHECKING OIL LEVEL ...922

PROCEDURE FOR CHECKING...922

PROCEDURE FOR CHECKING OIL LEVEL...922

ADDING AND REMOVING OIL...923

ADDING OIL BY EVACUATION...923

TROUBLESHOOTING...924

VISUAL AND ACOUSTICAL CHECKS ...924

DEFECTIVE COOLING ...925

TROUBLESHOOTING TABLES ...926

DEFECTIVE HEATING ...928

TROUBLESHOOTING USING GAUGE MANIFOLD ...929

PREPARATIONS BEFORE MEASURING...929

INSUFFICIENT REFRIGERANT...929

EXCESSIVE REFRIGERANT OR INSUFFICIENT 3. COOLING OF CONDENSER ...930

AIR INSIDE REFRIGERATION SYSTEM ...930

MOISTURE IN REFRIGERATING SYSTEM ...931

REFRIGERANT DOES NOT CIRCULATE ...932

FAILURE OF EXPANSION VALVE ...933

DEFECTIVE MOUNTING OF HEAT SENSING TUBE...933

DEFECTIVE COMPRESSION BY COMPRESSOR ...933

93 DISASSEMBLY AND ASSEMBLY ...935

SPECIAL TOOLS ...936

MAGNETIC CLUTCH ...937

DISASSEMBLY OF ...937

CHECKS BEFORE DISASSEMBLY...938

REMOVAL OF ROTOR AND STATOR...938

REMOVAL OF CENTER PIECE FROM ROTOR...939

REMOVAL OF BEARING FROM ROTOR...940

ASSEMBLY OF ...941

ASSEMBLY OF BEARING TO ROTOR...941

ASSEMBLY OF CENTER PIECE TO ROTOR...941

ASSEMBLY OF STATOR AND ROTOR TO COMPRESSOR...942

AIR CONDITIONER UNIT ...943

DISASSEMBLY OF ...943

CHECKS BEFORE DISASSEMBLY...943

REMOVAL OF CONTROL PANEL AND THERMOSTAT...947

REMOVAL OF UNIT COVER...949

REMOVAL OF WATER VALVE...949

REMOVAL OF EXPANSION VALVE...951

REMOVAL OF EVAPORATOR...953

REMOVAL OF HEATER CORE ...953

REMOVAL OF PRESSURE SWITCHES ...953

BLOWER UNIT ...954

DISASSEMBLY OF ...954

CHECKS BEFORE DISASSEMBLY...954

REMOVAL OF BLOWER RESISTOR...954

REMOVAL OF BLOWER MOTOR AND FAN...955

CONDENSER ...956

DISASSEMBLY OF ...956

CHECKS BEFORE DISASSEMBLY...956

REMOVAL OF CONDENSER, FAN MOTOR...957

REMOVAL OF PRESSURE SWITCH...958

REMOVAL OF RESISTOR ...958

97 GEAR PUMP...959

GENERAL...960

PRINCIPLE OF OPERATION ...961

PRESSURE LOADED TYPE GEAR PUMP ...964

FIXED SIDE PLATE TYPE GEAR PUMP...966

SA SERIES ...967

STRUCTURE ...967

TESTING AND ADJUSTING ...971

DISASSEMBLY ...974

ASSEMBLY ...978

MAINTENANCE STANDARD ...983

99 METRIC CONVERSIONS ...985