Komatsu Motor Graders GD750A Repair Service Manual + Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Motor Graders GD750A, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Motor Graders GD750A workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

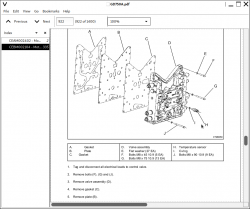

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,401 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM002402 - Komatsu Motor Grader GD750A-1 Operation & Maintenance Manual.pdf

CEBM002104 - Komatsu Motor Grader GD750A-1 Shop Manual.pdf

MAIN SECTIONS

TABLE OF CONTENTS

01 GENERAL... . . 01-1

10 STRUCTURE AND FUNCTION.. . . .10-1

20 TESTING AND ADJUSTMENT. . . . . 20-1

30 DISASSEMBLY AND ASSEMBLY. . . . . 30-1

40 MAINTENANCE STANDARD.. . . 40-1

MAIN MENU.0

COVER PAGE.1

1. FORWARD.5

2. SAFETY INFORMATION.6

3. INTRODUCTION.7

3.1 INTENDED USE.7

3.2 FEATURES.7

3.3 BREAKING IN THE MACHINE.7

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.8

4.1 P.I.N. NUMBER LOCATIONS.8

4.2 ENGINE SERIAL NO. PLATE POSITION.9

4.3 TRANSMISSION SERIAL NO. PLATE POSITION.9

4.4 REAR AXLE SERIAL NO. PLATE POSITION.9

4.5 CAB ROPS/FOBS SERIAL NO. PLATE POSITION.10

4.6 GENERAL PART NO. PLATE.10

4.7 TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.11

5. TABLE OF CONTENTS.12

SAFETY.20

6. GENERAL PRECAUTIONS.21

7. PRECAUTIONS DURING OPERATION.27

7.1 BEFORE STARTING ENGINE.27

7.2 OPERATING MACHINE.29

7.3 TRANSPORTATION.35

7.4 BATTERY.36

7.5 TOWING.39

7.6 TIRES.40

8. PRECAUTIONS FOR MAINTENANCE.42

8.1 BEFORE CARRYING OUT MAINTENANCE.42

8.2 DURING MAINTENANCE.46

9. POSITON FOR ATTACHING SAFETY LABELS.52

9.1 POSITION FOR ATTACHING SAFETY LABELS.52

OPERATION.62

10. GENERAL VIEW.63

10.1 GENERAL VIEW OF MACHINE.63

10.2 UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS.64

11. EXPLANATION OF COMPONENTS.65

11.1 STEERING CONSOLE CONTROLS AND GAUGES.65

11.2 RIGHT SIDE CONSOLE.73

11.3 MISCELLANEOUS CONTROLS.75

11.4 HEATER/AIR CONDITIONING CONTROLS.78

11.4.1 METHOD OF OPERATION.81

11.4.2 PRECAUTIONS WHEN USING AIR CONDITIONER.82

11.4.3 HANDLING DURING SEASON.82

11.4.4 HANDLING DURING OFF-SEASON.82

11.5 MISCELLANEOUS GAUGES AND VALVE.83

11.6 ACCESS COVERS, HOOD SIDES AND DOORS.84

11.7 CONTROL LEVERS AND PEDALS.87

11.8 CAP WITH LOCK.96

11.8.1 METHOD OF OPENING CAP WITH LOCK.96

11.8.2 METHOD OF CLOSING CAP WITH LOCK.96

11.9 ARTICULATE LOCK PIN.96

11.10 PARKING BRAKE.97

11.11 BACKUP ALARM.97

11.12 CIRCUIT BREAKERS.97

12. MACHINE OPERATION.99

12.1 WALK AROUND CHECK.99

12.2 TOWING.102

12.3 CHECKS BEFORE STARTING.103

12.3.1 CHECK COOLANT LEVEL, ADD COOLANT.104

12.3.2 CHECK MONITOR PANEL.104

12.3.3 CHECK FUEL LEVEL, ADD FUEL.105

12.3.4 CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL.105

12.3.5 CHECK ELECTRIC WIRING.106

12.3.6 DRAIN WATER AND SEDIMENT IN FUEL TANK.106

12.3.7 CHECK VOLTMETER.107

12.3.8 CHECK FOR SEDIMENT AND WATER IN THE WATER SEPARATOR.107

12.3.9 CHECK LAMPS FOR SWITCHING, DIRT AND DAMAGE.107

12.3.10 CHECK REAR VIEW MIRROR FOR POSITIONING, DIRT AND DAMAGE.107

12.3.11 CHECK HORN AND BACKUP ALARM.107

12.3.12 DO THE INTRUMENTS FUNCTION NORMALLY.107

12.3.13 CHECK THE SEAT BELT FOR NORMAL FUNCTION.107

12.3.14 CHECK THE DOOR LOCKS FOR NORMAL FUNCTION.107

12.3.15 CHECK THE WINDSHIELD WIPER, WINDOW WASHER AND DEFROSTER FOR NORMAL FUNCTION. CHECK FOR SUFFICIENT WASHER FLUID LEVE.108

12.3.16 CHECK FOR MISSING GUARDS, OR PROTECTIVE EQUIPMENT. DO NOT OPERATE UNIT IF ANY ARE MISSING.108

12.3.17 GENERAL SAFETY.108

12.4 REMOVAL OF ARTICULATION PIN.108

12.5 ENTERING OPERATOR'S CAB.108

12.6 ADJUSTMENTS BEFORE OPERATION.109

12.6.1 ADJUST OPERATOR'S SEAT.109

12.6.2 SEAT BELT.110

12.6.3 ADJUSTING POSITION OF STEERING WHEEL AND GAUGE PANEL.111

12.6.4 ADJUSTING MIRRORS.111

12.7 OPERATIONS AND CHECKS BEFORE STARTING ENGINE.112

12.8 STARTING ENGINE.114

12.8.1 NORMAL STARTING.114

12.8.2 STARTING IN COLD WEATHER: USING ETHER INJECTOR (OPTIONAL).115

12.8.3 STARTING PROCEDURES AFTER EXTENDED SHUTDOWN OR OIL CHANGE.117

12.8.4 STARTING PROCEDURES AFTER CHANGING FUEL FILTERS.117

12.8.5 STARTING PROCEDURES AFTER RUNNING OUT OF FUEL.118

12.9 OPERATIONS AND CHECKS AFTER STARTING ENGINE.119

12.9.1 ENGINE WARM UP.119

12.9.2 WHILE WARMING UP - ENGINE RUNNING ABOVE IDLE.119

12.9.3 COLD WEATHER START UP.120

12.9.4 HYDRAULIC SYSTEM COLD WEATHER START UP.120

12.10 TRAVELING POSTURE FOR MACHINE.121

12.11 MOVING MACHINE.122

12.12 SHIFTING GEARS.123

12.12.1 ACCELERATION.123

12.12.2 DECELERATION.123

12.13 SHIFTING BETWEEN FORWARD AND REVERSE.124

12.14 STOPPING MACHINE.125

12.15 TURNING MACHINE.126

12.15.1 LEANING OPERATION.126

12.15.2 ARTICULATING OPERATION.127

12.16 OPERATING WORK EQUIPMENT.128

12.16.1 OPERATING BLADE.128

12.16.2 OPERATING DRAWBAR SIDE SHIFT.131

12.16.3 OPERATING RIPPER.132

12.16.4 PROPULSION ANGLE OF BLADE.132

12.16.5 RH & LH 90 DEGREE BLADE SUSPENSION.133

12.17 WORK APPLICATION.135

12.17.1 LEVELING GROUND TO RIGHT.135

12.17.2 LEVELING GROUND TO LEFT.136

12.17.3 DIGGING RIGHT V-DITCHES.137

12.17.4 DIGGING LEFT V-DITCHES.139

12.18 RIGHT DITCH FINISHING.141

12.19 LEFT DITCH FINISHING.142

12.20 FINISHING RIGHT ROAD SHOULDER.143

12.21 FINISHING LEFT ROAD SHOULDER.143

12.22 CONSTRUCTING ROAD - METHOD OF MAKING V-DITCH.144

12.23 FLAT-BOTTOM DITCH.148

12.24 CONSTRUCTING ROAD - METHOD FOR MAKING FLAT BOTTOM DITCH.150

12.25 FINISHING WITH GRADER FOR DITCHES WHERE WET ROAD SHOULDER IS LOOSE.153

12.26 LEVELING 3:1 SLOPE FACE.153

12.27 BANK CUTTING METHOD - RIGHT SIDE.153

12.28 EXTREME SIDE REACH.157

12.29 RIPPER OPERATIONS - WITH FRAME STRAIGHT.158

12.30 PRECAUTIONS FOR OPERATION.159

12.30.1 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS.159

12.30.2 PRECAUTIONS WHEN USING ARTICULATED STEERING.159

12.30.3 PRECAUTIONS WHEN TRAVELING ON ROADS.160

12.30.4 CAUTIONS IN OPERATION OF WORK EQUIPMENT.160

12.31 ADJUSTING WORK EQUIPMENT POSTURE.160

12.31.1 BLADE PROTRUSION.160

12.32 PARKING MACHINE.161

12.33 CHECK AFTER FINISHING WORK.162

12.34 STOPPING ENGINE.162

12.35 CHECK AFTER STOPPING ENGINE.163

12.36 LOCKING.163

12.37 TIRES.164

12.37.1 PRECAUTIONS WHEN HANDLING TIRES.164

12.37.2 DIRECTION OF TIRE TREADS.164

12.37.3 TIRE MATCHING.164

12.38 BLADE ACCUMULATOR.165

12.38.1 OPERATION.165

12.38.2 FEATURES.166

12.39 HANDLING BLADE FLOAT.166

12.39.1 OPERATION.166

12.39.2 FEATURES.167

13. TRANSPORTATION.168

13.1 GENERAL.170

13.1.1 TRUCK.170

13.1.2 RAILROAD FLATCAR.170

13.1.3 DRIVING.170

13.2 MOVING A DISABLED MACHINE.171

13.3 METHODS OF TOWING.171

13.3.1 METHOD ONE.172

13.3.2 METHOD TWO.173

13.3.3 METHOD THREE.173

14. OPERATION UNDER UNUSUAL CONDITIONS.175

14.1 OPERATION IN EXTREME COLD.175

14.1.1 COLD WEATHER STARTING AID (OPTIONAL).176

14.1.2 ENGINE BLOCK HEATER (OPTIONAL).177

14.2 BATTERY.177

14.2.1 CHARGING.178

14.2.2 AFTER CHARGING.179

14.3 AFTER COLD WEATHER.179

14.4 OPERATION IN EXTREME HEAT.179

14.5 OPERATION IN DUSTY OR SANDY AREAS.180

14.6 OPERATION IN RAINY OR HUMID CONDITIONS.181

14.7 OPERATION IN SALT WATER AREAS.181

14.8 OPERATION AT HIGH ALTITUDES.182

15. MACHINE STORAGE.183

15.1 PREPARING FOR STORAGE.183

15.2 SERVICING MACHINE DURING STORAGE.186

15.2.1 ONE-MONTH REPETITIVE SERVICE PERIOD.186

15.2.2 SIX MONTH REPETITIVE SERVICE PERIOD.186

15.3 PREPARING FOR OPERATION.187

15.4 ROLLOVER PROTECTIVE STRUCTURE.188

15.5 THEFT DETERRENT PRACTICES.189

15.5.1 ACTION TO DISCOURAGE THEFT AND VANDALISM.189

15.5.2 ACTIONS TO AID IN RECOVERY OF STOLEN MACHINES.189

16. TROUBLESHOOTING.191

16.1 ETHER STARTING.191

16.1.1 FLUID CYLINDER.191

16.1.2 ATOMIZERS.191

16.1.3 TUBING.191

16.1.4 ELECTRIC VALVE.192

16.1.5 REASSEMBLY.192

16.2 AFTER RUNNING OUT OF FUEL.192

16.3 WHEN LEANING PIPING IS DAMAGED.193

16.3.1 HOW TO USE LEANING STOPPER.193

16.4 IF BATTERY IS DISCHARGED.194

16.4.1 STARTING ENGINE WITH BOOSTER CABLE.195

16.5 OTHER TROUBLE.197

16.5.1 ELECTRICAL SYSTEM.197

16.5.2 CHASSIS.198

16.5.3 ENGINE.201

16.5.4 INSTRUMENT PANEL.203

16.5.5 FAULT CODES EXPLANATION.206

16.5.6 SHIFT LEVER ERROR CODES.219

MAINTENANCE.220

17. GUIDES TO MAINTENANCE.221

18. OUTLINES OF SERVICE.224

18.1 OUTLINE OF OIL, FUEL, COOLANT.224

18.1.1 OIL.224

18.1.2 FUEL.225

18.1.3 COOLANT.225

18.1.4 GREASE.226

18.1.5 STORING OIL AND FUEL.226

18.1.6 FILTERS.226

18.2 RELATING TO ELECTRIC SYSTEM.227

18.2.1 BATTERIES.228

18.2.2 BATTERY - GENERAL MAINTENANCE.229

18.2.3 CLEANING THE BATTERIES.230

18.2.4 CONVENTIONAL ANTIMONY (LEAD-ACID) BATTERY.230

18.2.5 LOW MAINTENANCE BATTERY.230

18.2.6 MAINTENANCE FREE BATTERY.230

18.2.7 BATTERY CHARGING.230

19. WEAR PARTS LIST.237

20. FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.239

20.1 PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS.239

20.2 ENGINE OIL SPECIFICATIONS.241

20.2.1 NORMAL OPERATION.241

20.2.2 ARCTIC OPERATION.242

20.3 TRANSMISSION, TORQUE CONVERTER AND OIL COOLER, TANDEM DRIVE CASES.242

20.4 HYDRAULIC SYSTEM OIL SPECIFICATIONS.242

20.5 REAR DRIVE AXLE AND CIRCLE DRIVE BRAKE HOUSING OIL SPECIFICATIONS.242

20.6 DIESEL FUEL SPECIFICATIONS.242

20.7 COOLANT SPECIFICATIONS.243

20.7.1 GENERAL.243

20.7.2 ANTIFREEZE.244

20.7.3 SUPPLEMENTAL COOLANT ADDITIVES.245

20.8 CIRCLE DRIVE GEAR CASE OIL SPECIFICATIONS (HDTF).250

21 STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.251

21.1 INTRODUCTION OF NECESSARY TOOLS.251

21.2 TORQUE VALUES FOR STANDARD METRIC FASTENERS.252

21.3 TORQUE VALUES FOR STANDARD ENGLISH FASTENERS.253

21.3.1 TYPE 1, 5 AND 8 NON-PHOSPHATE COATED HARDWARE.253

21.3.2 TYPE 8 PHOSPHATE COATED HARDWARE.254

21.3.3 TORQUE VALUES FOR HOSE CLAMPS.255

21.3.4 TORQUE VALUES FOR SPLIT FLANGE CONNECTIONS.255

21.3.5 O-RING FACE SEAL FITTING TORQUE.256

22. PERIODIC REPLACEMENT OF CRITICAL PARTS.257

23. MAINTENANCE SCHEDULE CHART.258

23.1 MAINTENANCE SCHEDULE CHART.258

24. SERVICE PROCEDURES.263

24.1 PERIODIC SERVICE CHART.264

24.2 WHEN REQUIRED.265

24.2.1 ETHER STARTING AID.265

24.2.2 CIRCUIT BREAKERS.265

24.2.3 REVERSE AND REPLACE THE END BITS AND CUTTING EDGES.265

24.2.4 REPLACING RIPPER TOOTH.266

24.2.5 MOLDBOARD SLIDE.267

24.2.6 CHECK CIRCLE GUIDE CLEARANCE, ADJUST.267

24.2.7 MOLDBOARD ACCUMULATOR (IF EQUIPPED).271

24.2.8 WIPER BLADES.271

24.2.9 CIRCLE SLIP CLUTCH, LEVEL AND FILL PLUGS.271

24.2.10 CIRCLE REVERSE GEAR CASE - WET TYPE BRAKE ADJUSTING.272

24.2.11 INCHING PEDAL - INSPECTING.272

24.2.12 TRANSMISSION CLUTCH - CALIBRATION.273

24.2.13 TORQUE CONVERTER LOCK UP - CHECK.273

24.3 CHECK BEFORE STARTING ENGINE.274

24.4 EVERY SHIFT/10 HOURS SERVICE.275

24.4.1 BRAKES - CHECK.275

24.4.2 WARNING LIGHT - CHECK.275

24.4.3 GAUGES - CHECK.275

24.4.4 BACKUP ALARM - CHECK.275

24.4.5 OPERATIONAL LIGHTS - CHECK.275

24.4.6 RADIATOR COOLANT LEVEL - CHECK.276

24.4.7 RADIATOR DEBRIS - CHECK.277

24.4.8 FUEL/WATER SEPARATOR - DRAIN.277

24.4.9 FUEL TANK FUEL/WATER TRAP - DRAIN.277

24.4.10 FUEL TANK - CHECK.278

24.4.11 ENGINE AIR CLEANER - CHECK.278

24.4.12 TRANSMISSION OIL LEVEL TRANSMISSION DIPSTICK.281

24.4.13 HYDRAULIC OIL TANK LEVEL HYDRAULIC OIL TANK SIGHT GAGE.282

24.4.14 BLADE SLIDE RAILS.282

24.4.15 ENGINE OIL DIPSTICK & FILL CAP.283

24.4.16 CIRCLE TEETH.283

24.4.17 CIRCLE TOP & BOTTOM.283

24.4.18 ENGINE FAN BLADE.284

24.5 EVERY 50 MAN HOURS/WEEKLY SERVICE.285

24.5.1 AXLE AND FRONT STEERING LINKAGE.285

24.5.2 STEERING LINKAGE & CYLINDER PINS.285

24.5.3 THE ROD & LEANING WHEEL ROD CYLINDER.286

24.5.4 DRAWBAR BALL JOINT.286

24.5.5 ARTICULATION BEARINGS.287

24.5.6 RIPPER LINKAGE.287

24.5.7 CIRCLE REVERSE CASE OIL LEVEL.288

24.5.8 CAB AIR FILTERS (IF EQUIPPED).288

24.5.9 TIRES.288

24.5.10 TANDEM CASES, BREATHER.289

24.5.11 TANDEM CASES, FILL PLUG.289

24.5.12 TANDEM CASES, OIL LEVEL PLUG.289

24.5.13 HYDRAULIC OIL FILTER.289

24.5.14 TRANSMISSION FILTER.290

24.5.15 BATTERY.291

24.5.16 MACHINE.291

24.6 100 HOURS INITIAL SERVICE.292

24.6.1 LOCK/UNLOCK AXLE FILTER.292

24.6.2 REAR AXLE, SUCTION SCREEN.292

24.6.3 REAR AXLE DIFFERENTIAL.292

24.7 EVERY 250 HOURS/MONTHLY SERVICE.293

24.7.1 AIR INTAKE HOSES & CLAMPS.293

24.7.2 COOLANT SYSTEM HOSES & CLAMPS.293

24.7.3 REAR AXLE, OIL LEVEL.293

24.7.4 ENGINE OIL & FILTER CHANGE.294

24.7.5 COOLANT CORROSION RESISTER CARTRIDGE.295

24.7.6 CIRCLE REVERSE CASE BREATHER.295

24.7.7 CONTROL LEVER LINKAGES.295

24.7.8 CONTROL VALVE LINKAGES.296

24.7.9 BRAKE ACCUMULATOR GAS PRESSURE.296

24.7.10 BANK CONTROL GUIDE.296

24.7.11 RIPPER CYLINDERS (IF EQUIPPED).296

24.7.12 LIFT CYLINDER CAP.297

24.7.13 LIFT CYLINDER TRUNNIONS.297

24.7.14 LIFT CYLINDER TRUNNION SHAFTS.297

24.7.15 CIRCLE SIDE SHIFT CYLINDER.297

24.7.16 BLADE PITCH CYLINDER.298

24.7.17 ARTICULATION CYLINDERS.298

24.7.18 WHEEL HUB BOLTS.298

24.7.19 WHEEL BRAKE.299

24.7.20 AIR CONDITIONER BELT.300

24.8 EVERY 500 HOUR/THREE MONTHS SERVICE.301

24.8.1 COOLANT PROTECTION.301

24.8.2 FUEL FILTER.301

24.8.3 PARKING BRAKE.303

24.8.4 FUEL TANK, FILTER SCREEN (STRAINER).303

24.8.5 TRANSMISSION FILTER.303

24.8.6 WHEEL BRAKE.303

24.8.7 BLADE ACCUMULATORS.303

24.9 EVERY 1000 HOURS/SIX MONTHS SERVICE.304

24.9.1 DRAWBAR, FRONT BALL JOINT.304

24.9.2 ROPS MOUNT BOLTS.304

24.9.3 HYDRAULIC OIL FILTER.304

24.9.4 TRANSMISSION OIL.304

24.9.5 DRIVE SHAFT.305

24.9.6 LOCK/UNLOCK AXLE FILTER.305

24.9.7 FRONT WHEEL BEARING.306

24.9.8 TOE-IN.306

24.9.9 ENGINE DRIVE & ALTERNATOR BELTS.308

24.9.10 FAN BELT.309

24.9.11 ALTERNATOR BELT.310

24.9.12 AIR CONDITIONER BELT.310

24.10 EVERY 1500 HOURS SERVICE.311

24.10.1 ENGINE VALVES AND INJECTORS.311

24.10.2 TURBOCHARGER MOUNTING NUTS.311

24.10.3 ENGINE MOUNT BOLTS.311

24.10.4 WATER PUMP.311

24.10.5 ENGINE.311

24.11 EVERY 2000 HOUR/ONE YEAR SERVICE.312

24.11.1 TANDEM DRIVE CASE.312

24.11.2 HYDRAULIC TANK RETURN FILTER AND SUCTION STRAINER.313

24.11.3 HYDRAULIC TANK.314

24.11.4 HYDRAULIC TANK FILTER BREATHER CAP.317

24.11.5 REAR AXLE.317

24.11.6 CIRCLE DRIVE.317

24.11.7 FRONT WHEEL BEARING.317

24.11.8 LOCK/UNLOCK OF SUCTION SCREEN.318

24.11.19 VALVES & INJECTORS.318

24.11.10 CAB PRESSURIZER FILTER.319

24.11.11 ACCUMULATORS.319

24.11.12 BATTERIES.319

24.12 EVERY 4000 HOURS/TWO YEAR SERVICE.320

24.12.1 RADIATOR COOLANT.320

24.12.2 REFRIGERANT (GAS) IN AIR CONDITIONER CHECKING LEVEL.324

24.13 EVERY 6000 HOURS/THREE YEAR SERVICE.326

24.13.1 INJECTORS.326

24.13.2 FUEL PUMP.326

24.13.3 TURBOCHARGER.326

24.13.4 FAN HUB.326

24.13.5 IDLER PULLEY.326

24.13.6 VIBRATION DAMPER.326

SPECIFICATIONS.328

25. GD750A-1.329

25.1 WEIGHT.330

25.2 TRANSMISSION AND TORQUE CONVERTER PERFORMANCE.330

25.3 LIQUID CAPACITIES.330

25.4 ENGINE.331

25.5 HYDRAULIC.331

25.6 CIRCLE.331

25.7 DRAWBAR.332

25.8 MOLDBOARD.332

25.9 BLADE RANGE.332

25.10 FRONT AXLE.332

25.11 AXLE REAR.333

25.12 STEERING.333

25.13 TANDEM DRIVE.333

25.14 WHEELS, FRONT AND REAR.333

25.15 BRAKES.333

25.16 OPERATOR'S COMPARTMENT.333