Komatsu Hydraulic Excavators PC650, PC650LC, PC650SE, PC710 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC650-1, PC650-3, PC650-5, PC650LC-3, PC650SE-3, PC710-5, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC650-1, PC650-3, PC650-5, PC650LC-3, PC650SE-3, PC710-5 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,573 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM0209A04 - Hydraulic Excavator PC650-1 Shop Manual.pdf

SEBM000607 - Hydraulic Excavator PC650-5, PC710-5 Shop Manual.pdf

SEBM02090307 - Hydraulic Excavator PC650-3, PC650LC-3, PC650SE-3 Shop Manual.pdf

SEAM000604 - Hydraulic Excavator PC650-5, PC650LC-5, PC650SE-5, PC710-5, PC710SE-5 Operation & Maintenance Manual.pdf

SEAM02090303 - Hydraulic Excavator PC650-3 Operation & Maintenance Manual.pdf

SEAM02090306 - Hydraulic Excavator PC650-3, PC650LC-3, PC650SE-3 Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

10 ENGINE...27

11 STRUCTURE AND FUNCTION...27

ENGINE RELATED PARTS...28

PTO (POWER TAKE-OFF)...29

PTO LUBRICATION SYSTEM...30

RADIATOR AND OIL COOLER...31

FUEL TANK AND PIPING...32

ENGINE CONTROL SYSTEM...33

AUTO-DECELERATION SYSTEM (IF EQUIPPED)...34

12 TESTING AND ADJUSTING...42

STANDARD FOR TESTING AND ADJUSTING...43

TESTING AND ADJUSTING TOOL LIST...43

ADJUSTING VALVE CLEARANCE...44

MEASURING COMPRESSION PRESSURE...45

ADJUSTING FUEL INJECTION TIMING...46

MEASURING EXHAUST GAS COLOR...47

MEASURING BLOW-BY PRESSURE...48

TESTING AND ADJUSTING FAN BELT TENSION...49

TESTING AND ADJUSTING ALTERNATOR BELT TENSION...49

ADJUSTING FUEL CONTROL LEVER...50

ADJUSTING AUTO-DECELERATION SYSTEM...53

13 DISASSEMBLY AND ASSEMBLY...54

STARTING MOTOR...55

REMOVAL...55

INSTALLATION...55

ALTERNATOR...55

REMOVAL...55

INSTALLATION...55

ENGINE OIL COOLER...55

REMOVAL...55

INSTALLATION...55

FUEL INJECTION PUMP...57

REMOVAL...57

INSTALLATION...57

WATER PUMP...57

REMOVAL...57

INSTALLATION...57

NOZZLE HOLDER...59

REMOVAL...59

INSTALLATION...59

TURBOCHARGER...59

REMOVAL...59

INSTALLATION...59

CYLINDER HEAD...61

REMOVAL...61

INSTALLATION...65

HYDRAULIC OIL COOLER...69

REMOVAL...69

INSTALLATION...69

RADIATOR...69

REMOVAL...69

INSTALLATION...69

ENGINE, PTO AND HYDRAULIC PUMP...71

REMOVAL...71

INSTALLATION...75

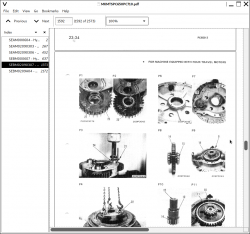

PTO...79

REMOVAL...79

INSTALLATION...79

DISASSEMBLY...81

ASSEMBLY...81

DECELERATOR CYLINDER (IF EQUIPPED)...85

REMOVAL...85

INSTALLATION...85

14 MAINTENANCE STANDARD...87

PTO...88

20 POWER TRAIN...89

21 STRUCTURE AND FUNCTION...89

POWER TRAIN ...90

TRAVEL AND BRAKE SYSTEM...92

1. OUTLINE...92

2. TRAVEL CONTROL CIRCUIT SCHEMATICS...94

3. TRAVEL CONTROL CIRCUIT...96

4. STRAIGHT-TRAVEL SYSTEM...98

5. CENTER SWIVEL JOINT...104

6. TRAVEL MOTOR (WITH PARKING BRAKE) ASSEMBLY...105

7. TRAVEL BRAKE VALVE...121

8. FINAL DRIVE...124

SWING SYSTEM...127

1. OUTLINE...127

2. SWING HYDRAULIC CIRCUIT SCHEMATICS...128

3. SWING HYDRAULIC CIRCUIT...129

4. SWING PUMP...130

5. SWING CONTROL VALVE...133

6. SWING MOTOR (WITH MECHANICAL BRAKE) AND SAFETY VALVE ASSEMBLY...137

7. SWING BRAKE (AUTOMATIC) AND SWING PARKING BRAKE (MANUAL)...143

8. FREE SWING SYSTEM...147

9. SWING MACHINERY...152

10. SWING CIRCLE...154

23 DISASSEMBLY AND ASSEMBLY...155

CENTER SWIVEL JOINT...156

REMOVAL...156

INSTALLATION...156

DISASSEMBLY...158

ASSEMBLY...158

TRAVEL MOTOR (WITH FOUR TRAVEL MOTORS)...160

REMOVAL...160

INSTALLATION...160

DISASSEMBLY...164

ASSEMBLY...170

TRAVEL BRAKE VALVE (WITH FOUR TRAVEL MOTORS)...160

REMOVAL...160

INSTALLATION...160

TRAVEL MOTOR (WITH TWO TRAVEL MOTORS)...162

REMOVAL...162

INSTALLATION...162

DISASSEMBLY...180

ASSEMBLY...193

FINAL DRIVE...209

REMOVAL (WITH FOUR TRAVEL MOTORS)...209

INSTALLATION (WITH FOUR TRAVEL MOTORS)...209

REMOVAL (WITH TWO TRAVEL MOTORS)...211

INSTALLATION (WITH TWO TRAVEL MOTORS)...211

DISASSEMBLY (WITH FOUR TRAVEL MOTORS)...213

ASSEMBLY (WITH FOUR TRAVEL MOTORS)...217

DISASSEMBLY (WITH TWO TRAVEL MOTORS)...225

ASSEMBLY (WITH TWO TRAVEL MOTORS)...229

SPROCKET...237

REMOVAL...237

INSTALLATION...237

SWING PUMP...239

REMOVAL...239

INSTALLATION...239

DISASSEMBLY...241

ASSEMBLY...245

CO?NC VALVE (FOR SWING PUMP)...255

REMOVAL...255

INSTALLATION...255

SERVO VALVE (FOR SWING PUMP)...255

REMOVAL...255

INSTALLATION...255

SWING CONTROL VALVE...255

REMOVAL...255

INSTALLATION...255

DISASSEMBLY...257

ASSEMBLY...257

MAIN RELIEF VALVE (FOR SWING CONTROL VALVE)...257

REMOVAL...257

INSTALLATION...257

SWING MOTOR...259

REMOVAL...259

INSTALLATION...259

DISASSEMBLY...261

ASSEMBLY...265

REVOLVING FRAME...269

REMOVAL...269

INSTALLATION...269

SWING CIRCLE...271

REMOVAL...271

INSTALLATION...271

SWING MACHINERY...273

REMOVAL...273

INSTALLATION...273

DISASSEMBLY...275

ASSEMBLY...279

24 MAINTENANCE STANDARD...283

TRAVEL MOTOR...284

TRAVEL SHUTTLE VALVE...285

STRAIGHT-TRAVEL VALVE...286

TRAVEL BRAKE VALVE...287

FINAL DRIVE...289

SWING CONTROL VALVE...293

JET SENSOR...295

SWING MOTOR...296

SWING SHADOW VALVE (IF EQUIPPED)...297

CONNECTION VALVE (IF EQUIPPED)...298

SWING MACHINERY...299

SWING CIRCLE...301

30 UNDERCARRIAGE...302

31 STRUCTURE AND FUNCTION...302

TRACK FRAME...303

IDLER CUSHION...305

IDLER...309

TRACK ROLLER...310

CARRIER ROLLER...311

TRACK SHOE...312

33 DISASSEMBLY AND ASSEMBLY...314

IDLER...315

REMOVAL...315

INSTALLATION...315

IDLER CUSHION...315

REMOVAL...315

INSTALLATION...315

DISASSEMBLY...317

ASSEMBLY...317

IDLER ADJUSTMENT CYLINDER...317

DISASSEMBLY...317

ASSEMBLY...317

TRACK ROLLER...319

REMOVAL...319

INSTALLATION...319

CARRIER ROLLER...319

REMOVAL...319

INSTALLATION...319

TRACK SHOE...321

REMOVAL...321

INSTALLATION...321

34 MAINTENANCE STANDARD...323

TRACK FRAME...324

TRACK SHOE...325

IDLER...327

TRACK ROLLER...329

CARRIER ROLLER...331

50 AIR SYSTEM...332

51 STRUCTURE AND FUNCTION...332

AIR PIPING...333

AIR CIRCUIT DIAGRAM...334

AIR GOVERNOR...335

AIR TANK...335

SAFETY VALVE...336

HORN VALVE...336

GREASE PUMP...337

60 HYDRAULIC SYSTEM...338

61 STRUCTURE AND FUNCTION...338

HYDRAULIC PIPING...339

HYDRAULIC CIRCUIT DIAGRAM...343

WORK EQUIPMENT CONTROL...347

ELECTRONIC AUTOMATIC WORK EQUIPMENT CONTROL SYSTEM (IF EQUIPPED)...363

HYDRAULIC TANK...372

MAIN PUMP...373

HYDRAULIC OIL FILTER...392

CHARGING AND PTO LUBRICATING PUMP...396

2-STAGE AND 3-STAGE MODE SELECTOR OLSS (OPEN CENTER LOAD SENSING SYSTEM)...397

HYDRAULIC CONTROL VALVE...415

PPC VALVE...422

PPC SHUTTLE VALVE...428

ACCUMULATOR...430

PILOT RELIEF VALVE...431

SAFETY LOCK VALVE...433

HYDRAULIC CYLINDER...435

WORK EQUIPMENT...442

62 TESTING AND ADJUSTING...444

TABLE OF JUDGEMENT STANDARD VALUE...445

TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE...454

TESTING AND ADJUSTING TOOL LIST...468

TESTING TRAVEL AND OPERATING FORCE...469

TESTING AND ADJUSTING MAIN RELIEF VALVE...470

TESTING CONTROL CIRCUIT PRESSURE...472

MEASURING DISCHARGE OF MAIN PISTON PUMP...475

CHECKING AND ADJUSTING TRAVEL MOTOR PERFORMANCE...476

MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTOR...479

TESTING OIL LEAKAGE FROM SWIVEL JOINT...480

BLEEDING AIR...482

CHARGING ACCUMULATOR WITH GAS...485

TESTING METHOD USING VISUAL AND FUNCTIONAL CHECK...487

ADJUSTMENT OF WORK EQUIPMENT POTENTIOMETER...488

ADJUSTMENT OF WORK EQUIPMENT CONTROL BOX...489

TROUBLESHOOTING...494

ELECTRICAL CIRCUIT DIAGRAM...495

POSITION OF CONNECTORS FOR TROUBLESHOOTING ...499

CONNECTION TABLE FOR CONNECTOR PINS...509

TROUBLESHOOTING PROCEDURE...513

CHECKS BEFORE TROUBLESHOOTING...514

E.H MODE TROUBLESHOOTING...517

ABNORMALITY JUDGEMENT CONDITIONS FOR SELF-TESTING DISPLAY...518

TROUBLESHOOTING (EXCEPT TROUBLESHOOTING FOR MACHINE MONITOR)...519

E-1 MACHINE DEVIATES EXCESSIVELY...523

a) SELF-TESTING DISPLAY SHOWS ABNORMALITY...524

b) IF CAUSE IS REMOVED WHEN SWITCHING TO PROLIX CIRCUIT (WHEN SELF-TESTING DISPLAY SHOWS NORMAL)...526

E-2 WORK EQUIPMENT, SWING, TRAVEL SPEEDS EXTREMELY SLOW, OR LACK OF POWER...527

a) SELF-TESTING DISPLAY SHOWS ABNORMALITY...527

b) IF CAUSE IS REMOVED WHEN SWITCHING TO PROLIX CIRCUIT (WHEN SELF-TESTING DISPLAY SHOWS NORMAL)...529

E-3 ENGINE STALLS DURING OPERATIONS, OR ENGINE SPEED DROPS...532

a) SELF-TESTING DISPLAY SHOWS ABNORMALITY...532

b) IF CAUSE IS REMOVED WHEN SWITCHING TO PROLIX CIRCUIT (WHEN SELF-TESTING DISPLAY SHOWS NORMAL)...534

E-4 NO CHANGE IN OUTPUT WHEN MODE SWITCH IS OPERATED...535

a) SELF-TESTING DISPLAY SHOWS ABNORMALITY...536

b) IF CAUSE IS REMOVED WHEN SWITCHING TO PROLIX CIRCUIT (WHEN SELF-TESTING DISPLAY SHOWS NORMAL)...536

E-5 AUTO-DECELERATION DOES NOT WORK...541

a) SELF-TESTING DISPLAY SHOWS ABNORMALITY...541

b) IF CAUSE IS REMOVED WHEN SWITCHING TO PROLIX CIRCUIT (WHEN SELF-TESTING DISPLAY SHOWS NORMAL)...545

E-6 SWING DOES NOT WORK...547

E-7 EXCESSIVE HYDRAULIC DRIFT OF SWING ...549

E-8 TRAVEL SPEED DOES NOT SWITCH...550

a) SPEED DOES NOT INCREASE WHEN PLACED IN HI (DOES NOT SWITCH TO HI)...550

b) SPEED DOES NOT DECREASE WHEN PLACED IN LO...550

H-1 MACHINE DEVIATES EXCESSIVELY (DEVIATES MORE THAN STANDARD WHEN ONLY TRAVEL SYSTEM IS USED, TRAVEL LEVER AT FULL POSITION)...556

H-2 EXCESSIVE DEVIATION IN TRAVEL DURING SIMULTANEOUS OPERATIONS...560

H-3 MACHINE DEVIATES EXCESSIVELY WHEN STARTING...562

H-4 CONTROL LEVERS ARE EXTREMELY HEAVY...564

a) IF TRAVEL LEVER IS HEAVY...564

b) IF WORK EQUIPMENT LEVERS ARE HEAVY...564

H-5 WORK EQUIPMENT, TRAVEL, AND SWING START SUDDENLY DURING FINE CONTROL OPERATIONS...565

H-6 SPEEDS FOR WORK EQUIPMENT, SWING, AND TRAVEL ARE ALL EXTREMELY SLOW, OR THERE IS NO POWER...566

a) MACHINE HARDLY MOVES...566

b) ABNORMALITY IN SOME PART (ABNORMALITY ON ONE SIDE)...568

H-7 ENGINE STALLS OR ENGINE SPEED DROPS DURING OPERATIONS...570

H-8 NO CHANGE IN OUTPUT WHEN MODE SELECTOR SWITCH IS OPERATED...571

H-9 AUTO-DECELERATION DOES NOT COME ON, OR DOES NOT GO OFF...572

H-10 ABNORMAL NOISE COMES FROM AROUND PUMP...572

H-11 SWING SPEED IS SLOW, OR OVERRUN WHEN STOPPING SWING IS EXCESSIVE...573

H-12 UPPER STRUCTURE DOES NOT SWING...575

H-13 EXCESSIVE HYDRAULIC DRIFT...577

H-16 EXCESSIVE TIME LAG FOR WORK EQUIPMENT...577

H-17 TRAVEL SPEED DOES NOT SWITCH...578

a) SPEED DOES NOT INCREASE EVEN WHEN SELECTOR SWITCH IS PLACED IN HI...578

b) SPEED DOES NOT DECREASE EVEN WHEN SELECTOR SWITCH IS PLACED IN LO...578

FAILURE MODE AND COMPONENTS...579

W.L MODE TROUBLESHOOTING ...580

ABNORMALITY JUDGEMENT CONDITIONS FOR SELF-TESTING DISPLAY...581

TROUBLESHOOTING...582

W-1 IN ARC DIGGING MODE, WORK EQUIPMENT CARRIES OUT HORIZONTAL DIGGING, OR THERE IS BUCKET ANGLE COMPENSATION...584

W-2 IN HORIZONTAL DIGGING MODE, WORK EQUIPMENT DOES NOT CARRY OUT HORIZONTAL DIGGING...585

a) SELF-TESTING DISPLAY DOES NOT SHOW ABNORMALITY...585

b) SELF-TESTING DISPLAY SHOWS ABNORMALITY...587

W-3 IN HORIZONTAL DIGGING MODE, THERE IS BUCKET ANGLE COMPENSATION...593

W-4 IN HORIZONTAL DIGGING + BUCKET ANGLE COMPENSATION MODE, WORK EQUIPMENT CARRIES OUT HORIZONTAL DIGGING, BUT THERE IS NO BUCKET ANGLE COMPENSATION...594

a) SELF-TESTING DISPLAY DOES NOT SHOW ABNORMALITY...594

b) SELF-TESTING DISPLAY SHOWS ABNORMALITY...596

W-5 IN HORIZONTAL DIGGING + BUCKET ANGLE COMPENSATION MODE, THERE IS BUCKET ANGLE COMPENSATION, BUT WORK EQUIPMENT DOES NOT CARRY OUT HORIZONTAL DIGGING...598

a) SELF-TESTING DISPLAY DOES NOT SHOW ABNORMALITY...598

b) SELF-TESTING DISPLAY SHOWS ABNORMALITY...598

W-6 IN HORIZONTAL DIGGING + BUCKET ANGLE COMPENSATION MODE, WORK EQUIPMENT DOES NOT CARRY OUT HORIZONTAL DIGGING, AND THERE IS NO BUCKET ANGLE COMPENSATION...600

a) SELF-TESTING DISPLAY DOES NOT SHOW ABNORMALITY...600

b) SELF-TESTING DISPLAY SHOWS ABNORMALITY...601

L-1 WORK EQUIPMENT DOES NOT CARRY OUT HORIZONTAL DIGGING OR BUCKET ANGLE COMPENSATION...607

63 DISASSEMBLY AND ASSEMBLY...608

CHARGING AND PTO LUBRICATION PUMP...609

REMOVAL AND INSTALLATION...609

NO.1 PUMP...611

REMOVAL AND INSTALLATION...611

NO.2 PUMP...613

REMOVAL AND INSTALLATION...613

MAIN PUMP...615

DISASSEMBLY...615

ASSEMBLY...619

SERVO VALVE (FOR NO.1 FRONT PUMP)...631

REMOVAL AND INSTALLATION...631

SERVO VALVE (FOR NO.1 REAR PUMP)...631

REMOVAL AND INSTALLATION...631

SERVO VALVE (FOR NO.2 FRONT PUMP)...631

REMOVAL AND INSTALLATION...631

SERVO VALVE (FOR NO.2 REAR PUMP)...631

REMOVAL AND INSTALLATION...631

CO?NC VALVE (FOR NO.1 FRONT PUMP)...633

REMOVAL AND INSTALLATION...633

CO?NC VALVE (FOR NO.1 REAR PUMP)...633

REMOVAL AND INSTALLATION...633

TVC VALVE...635

REMOVAL AND INSTALLATION...635

L.H.5-SPOOL CONTROL VALVE...637

REMOVAL...637

INSTALLATION...639

R.H.4-SPOOL CONTROL VALVE...643

REMOVAL ...643

INSTALLATION...645

CONTROL VALVE...649

DISASSEMBLY AND ASSEMBLY...649

MAIN RELIEF VALVE (FOR L.H.5-SPOOL,R.H.4-SPOOL VALVE)...651

REMOVAL AND INSTALLATION...651

PILOT RELIEF VALVE...651

REMOVAL AND INSTALLATION...651

PPC VALVE (FOR TRAVEL)...653

REMOVAL AND INSTALLATION...653

DISASSEMBLY AND ASSEMBLY...655

PPC VALVE (FOR WORK EQUIPMENT AND SWING)...655

DISASSEMBLY AND ASSEMBLY...655

BOOM CYLINDER (BACK HOE)...657

REMOVAL AND INSTALLATION...657

ARM CYLINDER (BACK HOE)...659

REMOVAL AND INSTALLATION...659

BUCKET CYLINDER (BACK HOE)...661

REMOVAL AND INSTALLATION...661

BOOM CYLINDER (LOADING SHOVEL)...663

REMOVAL AND INSTALLATION...663

ARM CYLINDER (LOADING SHOVEL)...665

REMOVAL AND INSTALLATION...665

BUCKET CYLINDER (LOADING SHOVEL)...667

REMOVAL AND INSTALLATION...667

BOTTOM DUMP CYLINDER (LOADING SHOVEL)...669

REMOVAL AND INSTALLATION...669

HYDRAULIC CYLINDER...671

DISASSEMBLY...671

ASSEMBLY...675

BUCKET (BACK HOE)...679

REMOVAL AND INSTALLATION...679

ARM (BACK HOE)...681

REMOVAL AND INSTALLATION...681

BOOM (BACK HOE)...683

REMOVAL AND INSTALLATION...683

BUCKET AND ARM (BACK HOE)...685

REMOVAL AND INSTALLATION...685

WORK EQUIPMENT (BACK HOE)...687

REMOVAL AND INSTALLATION...687

BUCKET (LOADING SHOVEL)...689

REMOVAL AND INSTALLATION...689

ARM (LOADING SHOVEL)...691

REMOVAL AND INSTALLATION...691

BOOM (LOADING SHOVEL)...693

REMOVAL AND INSTALLATION...693

WORK EQUIPMENT (LOADING SHOVEL)...695

REMOVAL AND INSTALLATION...695

POTENTIOMETER (LOADING SHOVEL)...697

DISASSEMBLY AND ASSEMBLY...697

COUNTERWEIGHT ...697

REMOVAL AND INSTALLATION...697

64 MAINTENANCE STANDARD...699

CHARGING AND PTO LUBRICATION PUMP...700

PILOT RELIEF VALVE...701

L.H. 5-SPOOL CONTROL VALVE...702

R.H. 4-SPOOL CONTROL VALVE...704

PPC VALVE...706

PPC SHUTTLE VALVE...707

HYDRAULIC CYLINDER...708

WORK EQUIPMENT...712

80 ELECTRIC AND ELECTRONIC SYSTEM...716

81 STRUCTURE AND FUNCTION...716

ELECTRICAL WIRING DIAGRAM...717

ELECTRICAL CIRCUIT DIAGRAM...719

ELECTRONIC COMPONENTS OF 3-STAGE MODE SELECTOR OLSS...723

ELECTRONIC COMPONENTS OF AUTOMATIC WORK EQUIPMENT CONTROL SYSTEM...728

EVMS...732

82 TESTING AND ADJUSTING...740

ELECTRICAL CIRCUIT DIAGRAM...741

POSITION OF CONNECTORS FOR TROUBLESHOOTING ...743

M MODE TROUBLESHOOTING...753

SERIAL NO: 10501-10599...755

M-1 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DISPLAY DOES NOT APPEAR...755

a) NO DISPLAY APPEARS ON MONITOR PANEL (GAUGES AND MONITOR ITEMS)...755

b) DISPLAY OF EITHER GAUGES OR MONITOR ITEMS DOES NOT APPEAR ON MONITOR PANEL...755

c) DISPLAY DOES NOT APPEAR ON PART OF MONITOR PANEL ASSEMBLY...756

M-2 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DOES NOT GO OUT...756

M-3 WHEN STARTING SWITCH IS TURNED ON (DO NOT START ENGINE), CHECK BEFORE STARTING ITEM FLASH OR PREHEATING ITEM LIGHTS UP...757

a) (COOLANT LEVEL) FLASHES...757

b) (ENGINE OIL LEVEL) FLASHES...757

c) (HYDRAULIC OIL LEVEL) FLASHES...758

d) (HEATER SIGNAL) FLASHES...758

M-4 WHEN STARTING SWITCH IS TURNED ON (ENGINE STARTED), CHECK BEFORE STARTING ITEMS FLASH...760

a) ALTERNATOR SYSTEM...760

b) ENGINE OIL PRESSURE SYSTEM...760

M-5 WHEN STARTING SWITCH IS TURNED ON, (DO NOT START ENGINE), CAUTION ITEMS FLASH...762

M-6 WHEN STARTING SWITCH IS ON (ENGINE STARTED), CAUTION ITEMS FLASH...763

a) (ENGINE OIL PRESSURE) FLASHES...763

b) (COOLANT LEVEL) FLASHES...763

c) (COOLANT TEMPERATURE GAUGE) FLASHES...764

d) (CHARGE LEVEL) FLASHES...764

e) (HYDRAULIC OIL FILTER) FLASHES...765

f) (HYDRAULIC OIL TEMPERATURE) FLASHES...766

M-7 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) FOR 2 SECONDS, OR WHEN CAUTION ITEMS ARE FLASHING, WARNING BUZZER DOES NOT SOUND...769

M-8 NO ABNORMAL DISPLAY ON MONITOR BUT WARNING BUZZER SOUNDS...771

M-9 MONITOR PANEL LAMPS DO NOT LIGHT UP (INDICATION ON MONITOR PANEL IS CORRECT)...772

a) NO LAMPS ON PANEL LIGHT UP...772

b) SOME LAMPS ON PANEL DO NOT LIGHT UP...773

M-10 WHEN ENGINE IS STARTED, SERVICE METER DOES NOT MOVE WHEN ENGINE IS STOPPED, SERVICE METER MOVES...775

a) SERVICE METER DOES NOT MOVE...775

b) SERVICE METER DOES NOT STOP MOVING ...776

M-11 ENGINE COOLANT TEMPERATURE IS HIGH, BUT LOWEST LEVEL DISPLAYED...777

M-12 ENGINE COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY...777

M-13 FUEL TANK IS NOT FULL BUT DISPLAY SHOWS FULL TANK...779

M-14 NO DISPLAY IS GIVEN FOR FUEL LEVEL...779

SERIAL NO: 10600 AND UP...781

M-1 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DISPLAY DOES NOT APPEAR...781

a) NO DISPLAY APPEARS ON MONITOR PANEL (GAUGE AND MONITOR ITEMS)...781

b) DISPLAY DOES NOT APPEAR ON PART OF MONITOR PANEL ASSEMBLY...781

M-2 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DOES NOT GO OUT...781

M-3 WHEN STARTING SWITCH IS TURNED ON (DO NOT START ENGINE), CHECK BEFORE STARTING ITEM FLASH OR PREHEATING ITEM LIGHTS UP (FLUID LEVEL OF CHECK BEFORE STARTING ITEMS ARE CORRECT)...782

a) (COOLANT LEVEL) FLASHES...782

b) (ENGINE OIL LEVEL) FLASHES...782

c) (HYDRAULIC OIL LEVEL) FLASHES...783

M-4 WHEN STARTING SWITCH IS TURNED ON (ENGINE STARTED), CHECK BEFORE STARTING ITEMS FLASH...785

a) ALTERNATOR SYSTEM...785

b) ENGINE OIL PRESSURE SYSTEM...785

M-5 WHEN STARTING SWITCH IS TURNED ON, (DO NOT START ENGINE), CAUTION ITEMS FLASH...787

M-6 WHEN STARTING SWITCH IS ON (ENGINE STARTED), CAUTION ITEMS FLASH...788

a) (ENGINE OIL PRESSURE) FLASHES...788

b) (COOLANT LEVEL) FLASHES...788

c) (COOLANT TEMPERATURE GAUGE) FLASHES...789

d) (CHARGE LEVEL) FLASHES...789

e) (HYDRAULIC OIL FILTER) FLASHES...790

f) (HYDRAULIC OIL TEMPERATURE) FLASHES...790

M-7 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) FOR 1 SECOND, OR WHEN CAUTION ITEMS ARE FLASHING, WARNING BUZZER DOES NOT SOUND...793

M-8 NO ABNORMAL DISPLAY ON MONITOR BUT WARNING BUZZER SOUNDS...793

M-9 MONITOR PANEL LAMPS DO NOT LIGHT UP (INDICATION ON MONITOR PANEL IS CORRECT)...795

M-10 WHEN ENGINE IS STARTED, SERVICE METER DOES NOT MOVE WHEN ENGINE IS STOPPED, SERVICE METER MOVES...796

a) SERVICE METER DOES NOT MOVE, WHEN ENGINE IS STARTED...796

b) SERVICE METER DOES NOT STOP MOVING, WHEN ENGINE IS STOPPED...796

M-11 ENGINE COOLANT TEMPERATURE IS HIGH, BUT LOWEST LEVEL DISPLAYED...798

M-12 ENGINE COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY...798

M-13 FUEL TANK IS NOT FULL BUT DISPLAY SHOWS FULL TANK...800

M-14 NO DISPLAY IS GIVEN FOR FUEL LEVEL...800