Komatsu Wheel Loader WA800L avance Repair Service Manual + Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheel Loader WA800L-3 avance, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheel Loader WA800L-3 avance workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 803 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM035603 - Wheel Loader WA800L-3 avance Shop Manual.pdf

TEN00007-02 - Wheel Loader WA800L-3 avance Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...28

GENERAL ASSEMBLY DRAWING...29

SPECIFICATIONS...30

WEIGHT TABLE...33

LIST OF LUBRICANT AND WATER...35

10 STRUCTURE AND FUNCTION...43

POWER TRAIN...44

POWER TRAIN SYSTEM...45

ENGINE CONTROL...46

RADIATOR AND COOLER...47

DAMPER...49

TORQUE CONVERTER AND TRNSMISSION PIPING...50

TRANSMISSION HYDRAULIC SYSTEM DIAGRAM...51

TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM...52

TORQUE CONVERTER...53

TRANSMISSION...58

TRANSFER...66

TRANSMISSION CONTROL VALVE...67

TORQUE CONVERTER OIL COOLER...83

DRIVE SHAFT...84

CENTER SUPPORT...85

AXLE...86

DIFFERENTIAL...88

FINAL DRIVE...91

CENTER HINGE PIN...92

AXLE MOUNT...93

TIRE AND WHEEL...95

STEERING PIPING...96

JOYSTICK STEERING LINKAGE...97

STEERING PUMP...98

SWITCH PUMP...100

STEERING DEMAND VALVE...102

EPC VALVE...113

ROTARY VALVE...114

TWO-WAY RESTRICTOR VALVE...116

DIVERTER VALVE...117

BRAKE PIPING...121

BRAKE CIRCUIT DIAGRAM...122

BRAKE VALVE...124

CHARGE VALVE...129

ACCUMULATOR (FOR BRAKE)...133

SLACK ADJUSTER...134

BRAKE...137

PARKING BRAKE...138

SPRING CYLINDER...140

PARKING BRAKE SOLENOID VALVE...141

HYDRAULIC PIPING...142

WORK EQUIPMENT LEVER LINKAGE...145

HYDRAULIC TANK...146

MAIN PISTON PUMP...149

ES VALVE (ENGINE SENSING VALVE)...157

SERVO VALVE...159

PPC VALVE (PROPORTIONAL PRESSURE VALVE)...162

PPC RELIEF VALVE...166

ACCUMULATOR (FOR PPC VALVE)...167

MAIN CONTROL VALVE...168

LUBRICATION OF WORK EQUIPMENT...181

WORK EQUIPMENT LINKAGE...184

BUCKET POSITIONER AND BOOM KICK-OUT...186

OPERATION OF PROXIMITY SWITCH...188

CAB AND ROPS CANOPY...192

AIR CONDITIONER...193

MACHINE MONITOR SYSTEM...197

MAIN MONITOR...198

MAINTENANCE MONITOR...202

ENGINE STARTING CIRCUIT...205

ENGINE STOP CIRCUIT...208

PREHEATING CIRCUIT...209

ELECTRICAL TRANSMISSION CONTROL...210

KICK-DOWN, HOLD SWITCH...211

AUTOMATIC TRANSMISSION (ATM) SYTEM...212

AJSS (ADVANCED JOYSTICK STEERING SYSTEM)...222

ELECTRIC PARKING BRAKE CONTROL...227

20 TESTING AND ADJUSTING...236

STANDARD VALUE TABLE FOR ENGINE...237

STANDARD VALUE TABLE FOR CHASSIS...238

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...242

TESTING AND ADJUSTING...252

TABLE OF TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING...253

MEASURING ENGINE SPEED...255

MEASURING EXHAUST GAS COLOR...256

ADJUSTING VALVE CLEARANCE...257

MEASURING COMPRESSION PRESSURE...257

MEASURING BLOW-BY PRESSURE...257

TESTING AND ADJUSTING FUEL INJECTION TIMING...257

MEASURING ENGINE OIL PRESSURE...257

MEASURING EXHAUST TEMPERATURE...257

MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)...257

TESTING AND ADJUSTING ALTERNATOR BELT TENSION...258

TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR...259

MEASURING ACCELERATOR PEDAL ...260

TESTING AND ADJUSTING TORQUE CONVERTER AND TRANSMISSION OIL PRESSURE...261

PROCEDURE FOR OPERATING EMERGENCY STEERING SPOOL WHEN TRANSMISSION VALVE FAILS...263

TESTING AND ADJUSTING STEERING OIL PRESSURE ...265

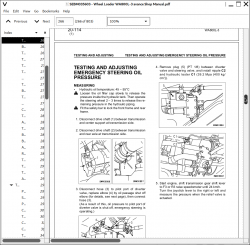

TESTING AND ADJUSTING EMERGENCY STEERING OIL PRESSURE ...266

BLEEDING AIR FROM STEERING CIRCUIT...268

TESTING AND ADJUSTING STEERING STOPPER BOLT...269

TESTING AND ADJUSTING STEERING LEVER ANGLE SENSOR AND FRAME ANGLE SENSOR...270

TESTING WHEEL BRAKE PERFORMANCE...271

TESTING WHEEL BRAKE OIL PRESSURE DROP...272

MEASURING WEAR OF WHEEL BRAKE DISC...274

TESTING AND ADJUSTING ACCUMULATOR CHARGE CUT-IN AND CUT-OUT PRESSURE...275

BLEEDING AIR FROM WHEEL BRAKE CIRCUIT...277

TESTING PARKING BRAKE PERFORMANCE...278

MEASURING PARKING RAKE SOLENOID OUTPUT PRESSURE...279

CHECKING AND ADJUSTING PARKING BRAKE PAD...280

TESTING AND ADJUSTING PPC PRESSURE...282

ADJUSTING PPC VALVE LINKAGE...283

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE...284

BLEEDING AIR FROM PISTON PUMP...286

BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT...287

ADJUSTING WORK EQUIPMENT LEVER LINKAGE...288

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT...289

TESTING AND ADJUSTING BUCKET PROXIMITY SWITCH...290

TESTING AND ADJUSTING BOOM PROXIMITY SWITCH...290

TESTING PROXIMITY ACTUATION PILOT LAMP...291

ADJUSTING SPEEDOMETER MODULE OF MAIN MONITOR...292

TROUBLESHOOTING...293

POINTS TO REMEMBER WHEN TROUBLESHOOTING...294

SEQUENCE OF EVENTS IN TROUBLESHOOTING...295

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...296

CHECKS BEFORE TROUBLESHOOTING...304

TYPES AND LOCATIONS OF CONNECTORS...305

CONNECTOR LOCATION STEREOGRAM...311

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...317

T-BRANCH BOX AND T-BRANCH TABLE...342

EXPLANATION OF FUNCTIONS OF ELECTRIC CONTROL MECHANISM...344

METHOD OF DISPLAYING ACTION CODE AND FAILURE CODE...348

CHART OF ACTION CODES AND FAILURE CODES, AND RE-ENACTION...350

TRANSMISSION CONTROLLER LED DISPLAY...352

METHOD OF USING JUDGEMENT TABLE...353

METHOD OF USING TROUBLESHOOTING CHARTS...354

METHOD OF USING MATRIX TROUBLESHOOTING TABLES...356

TROUBLESHOOTING OF ENGINE (S MODE)...358

METHOD OF USING TROUBLESHOOTING CHARTS...359

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)...363

S-2 ENGINE DOES NOT START...364

(1) ENGINE DOES NOT TURN...364

(2) ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED) (INCLUDING CASES WITH V-TYPE ENGINE WHERE THERE IS NO FUEL INJECTION FOR THE BANK ON ONE SIDE)...365

(3) EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)...366

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)...367

S-4 ENGINE STOPS DURING OPERATIONS (FOR V TYPE ENGINE, INCLUDING CASES WHERE ONE BANK STOPS)...368

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)...369

S-6 ENGINE LACKS OUTPUT (NO POWER) (WITH V-TYPE ENGINE, FOR CASES WHERE THERE IS INJECTION FOR ONLY ONE BANK, GO TO TROUBLESHOOTING S-2-(2) OR S-4.)...370

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)...371

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)...372

S-9 OIL BECOMES CONTAMINATED QUICKLY...373

S-10 FUEL CONSUMPTION IS EXCESSIVE...374

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN...375

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)...376

S-13 OIL LEVEL RISES...377

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)...378

S-15 ABNORMAL NOISE IS MADE...379

S-16 VIBRATION IS EXCESSIVE...380

TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (T MODE)...381

JUDGEMENT TABLE FOR TRANSMISSION CONTROL SYSTEM RELATED PARTS...382

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE...383

ELECTRICAL CIRCUIT DIAGRAM FOR TRANSMISSION CONTROL SYSTEM...387

T-1 FAILURE CODE [10] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN BACKUP LAMP RELAY) IS DISPLAYED...389

T-2 FAILURE CODE [12] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN F SOLENOID) IS DISPLAYED...390

T-3 FAILURE CODE [13] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN R SOLENOID) IS DISPLAYED...391

T-4 FAILURE CODE [14] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 1ST SOLENOID) IS DISPLAYED...392

T-5 FAILURE CODE [15] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 2ND SOLENOID) IS DISPLAYED...393

T-6 FAILURE CODE [16] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 3RD SOLENOID) IS DISPLAYED...394

T-7 FAILURE CODE [20] (SHORT CIRCUIT OR DISCONNECTION IN JOYSTICK LEVER SWITCH SYSTEM) IS DISPLAYED...395

T-8 FAILURE CODE [21] (SHORT CIRCUIT OR DISCONNECTION IN JOYSTICK SHIFT-UP/SHIFT-DOWN SWITCH SYSTEM) IS DISPLAYED...396

T-9 FAILURE CODE [22] (DISCONNECTION IN TRAVEL SPEED SENSOR) IS DISPLAYED...397

T-10 FAILURE CODE [23] (SHORT CIRCUIT, DISCONNECTION IN ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED...398

T-11 KICKDOWN SWITCH SIGNAL SYSTEM AND HOLD SWITCH SIGNAL SYSTEM...399

T-12 TRANSMISSION CUT-OFF SIGNAL SYSTEM...400

T-13 NEUTRALIZER SIGNAL SYSTEM...401

T-14 BUZZER SIGNAL SYSTEM...402

T-15 NETWORK SYSTEM...403

T-16 TRANSMISSION CONTROLLER POWER SOURCE SYSTEM...404

T-17 SHORT CIRCUIT IN TRAVEL SPEED SENSOR SYSTEM...405

T-18 ABNORMALITY IN MACHINE SELECTION WIRING HARNESS...406

TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE)...407

TROUBLE DATA DISPLAY...409

ELECTRICAL CIRCUIT DIAGRAM FOR MAIN MONITOR SYSTEM...411

M-1 MAIN MONITOR DOES NOT WORK...413

M-2 WHEN STARTING SWITCH IS TURNED ON (WITHIN 3 SECONDS) AND ENGINE S STARTED IMMEDIATELY, ALL LAMPS STAY LIGHTED UP...414

M-3 SPEEDOMETER DISPLAY DOES NOT WORK PROPERLY...415

M-4 ABNORMALITY IN SHIFT INDICATOR...416

a) DISPLAYS N EVEN WHEN DIRECTIONAL SWITCH IS AT F...416

b) DISPLAYS N EVEN WHEN DIRECTIONAL SWITCH IS AT R...416

c) DOES NOT DISPLAY N EVEN WHEN DIRECTIONAL SWITCH IS AT N (DISPLAY 1ST-3RD)...416

M-5 TURN SIGNAL DISPLAY DOES NOT LIGHT UP...418

a) L.H. TURN SIGNAL DISPLAY DOES NOT LIGHT UP...418

b) R.H. TURN SIGNAL DISPLAY DOES NOT LIGHT UP...418

M-6 ABNORMALITY IN PARKING DISPLAY...420

a) PARKING LAMP DISPLAY DOES NOT LIGHT UP...420

b) PARKING LAMP DISPLAY STAYS LIGHTED UP...420

M-7 NIGHT LIGHTING DOES NOT LIGHT UP...421

M-8 ABNORMALITY IN FRONT WORKING LAMP...423

a) NEITHER MONITOR DISPLAY NOR FRONT WORKING LAMP LIGHT UP...423

b) WORKING LAMP LIGHTS UP BUT MONITOR DISPLAY DOES NOT LIGHT UP...423

c) MONITOR DISPLAY LIGHTS UP BUT FRONT WORKING LAMP DOES NOT LIGHT UP...423

M-9 ABNORMALITY IN REAR WORKING LAMP...425

a) NEITHER MONITOR DISPLAY NOR REAR WORKING LAMP LIGHT UP...425

b) REAR WORKING LAMP LIGHTS UP BUT MONITOR DISPLAY DOES NOT LIGHT UP...425

c) MONITOR DISPLAY LIGHTS UP BUT REAR WORKING LAMP DOES NOT LIGHT UP...425

M-10 ABNORMALITY IN TRANSMISSION CUT-OFF...427

a) WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS PRESSED, CUT-OFF FUNCTION IS NOT SWITCHED AND DISPLAY DOES NOT CHANGE...427

b) WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS OFF, MONITOR DISPLAY GOES OUT BUT CUT-OFF FUNCTION IS ACTUATED WHEN PEDAL IS DEPRESSED...427

c) WHEN MONITOR DISPLAY IS TURNED OFF (TRANSMISSION CUT-OFF SWITCH TURNED OFF), CUT-OFF FUNCTION IS ALWAYS ACTUATED...427

d) CUT-OFF FUNCTION IS ALWAYS ACTUATED REGARDLESS OF MONITOR DISPLAY (TRANSMISSION CUT-OFF SWITCH ON OR OFF)...427

e) MONITOR DISPLAY LIGHTS UP (TRANSMISSION CUT-OFF SWITCH TURNED ON), BUT CUT-OFF FUNCTION IS NOT ACTUATED...428

M-11 ABNORMALITY IN LOW IDLE SELECTION...429

a) WHEN MONITOR SWITCH (LOW IDLE SELECTOR SWITCH) IS TURNED ON, THE LOW IDLE SPEED DOES NOT RISE AND DISPLAY DOES NOT CHANGE...429

b) WHEN MONITOR SWITCH (LOW IDLE SELECTOR SWITCH) IS TURNED ON, THE MONITOR LIGHTS UP BUT THE LOW IDLE SPEED DOES NOT RISE...429

c) WHEN MONITOR SWITCH (LOW IDLE SELECTOR SWITCH) IS TURNED OFF, THE MONITOR GOES OFF BUT THE LOW IDLE SPEED DOES NOT LOWER...430

M-12 ABNORMALITY IN EMERGENCY STEERING NORMAL DISPLAY...431

M-13 ABNORMALITY IN EMERGENCY STEERING ACTUATION DISPLAY...432

a) EMERGENCY STEERING ACTUATION DISPLAY DOES NOT LIGHT UP...432

b) EMERGENCY STEERING ACTUATION DISPLAY STAYS LIGHTED UP...432

M-14 ABNORMALITY IN PARKING BRAKE DRAGGING WARNING...433

a) WHEN PARKING BRAKE IS APPLIED, BUZZER SOUNDS (INTERMITTENTLY) AND CAUTION LAMP FLASHES EVEN WHEN DIRECTIONAL SWITCH IS AT N...433

b) WHEN PARKING BRAKE IS APPLIED, BUZZER DOES NOT SOUND AND CAUTION LAMP DOES NOT LIGHT UP EVEN WHEN DIRECTIONAL SWITCH IS AT POSITION OTHER THAN N...433

M-15 WHEN PARKING BRAKE DRAGGING WARNING IS GIVEN, BUZZER AND CAUTION LAMP ARE ACTUATED CONTINUOUSLY, OR THEY ARE NOT ACTUATED...434

a) ACTUATED CONTINUOUSLY...434

b) NOT ACTUATED...434

M-16 ABNORMALITY IN BUZZER...435

a) BUZZER DOES NOT SOUND WHEN STARTING SWITCH IS AT ON (FOR 3 SECONDS) (DURING SELF-CHECK)...435

b) BUZZER ALWAYS SOUNDS...435

M-17 CONDITION OF MONITOR SWITCHES IS NOT STORED IN MEMORY...436

M-18 ABNORMALITY IN FAILURE DISPLAY MODE...437

a) DOES NOT ENTER FAILURE DISPLAY MODE...437

b) COUNT FOR TIME ELAPSED SINCE FAILURE IN FAILURE DISPLAY MODE DOES NOT ADVANCE...437

M-19 BUZZER IS NOT MADE TO SOUND BY TRANSMISSION & JOYSTICK STEERING CONTROLLER...438

M-20 ABNORMALITY IN AUTO-GREASING SYSTEM...439

a) FORCED GREASING CANNOT BE CARRIED OUT...439

b) MONITOR DISPLAY FLASHES RAPIDLY (2 TIMES/SEC)...439

c) WHEN NO MORE GREASE REMAINS, MONITOR DISPLAY FLASHES RAPIDLY (2 TIMES/SEC)...439

d) MONITOR DISPLAY FLASHES SLOWLY (1 TIME/SEC) CONFIRM THAT GREASE IS NOT EMPTY...440

e) MONITOR DISPLAY GOES OUT...440

M-21 FAILURE CODE IS NOT SENT TO MAIN MONITOR (ABNORMALITY IN NETWORK)...441

TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (K MODE)...442

ELECTRICAL CIRCUIT DIAGRAM FOR MAINTENANCE MONITOR SYSTEM...443

K-1 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR DO NOT LIGHT UP FOR 3 SECONDS, MAINTENANCE MONITOR DOSE NOT WORK...445

a) NO LAMPS ON MAINTENANCE MONITOR LIGHT UP...445

b) SOME LAMPS DO NOT LIGHT UP...445

K-2 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR LIGHT UP BUT DO NOT GO OUT (EVEN AFTER 3 SECONDS)...446

K-3 WHEN ENGINE IS STARTED IMMEDIATELY AFTER STARTING SWITCH IS TURNED ON (WITHIN 3 SECONDS), NO LAMPS ON MAINTENANCE MONITOR GO OUT...447

K-4 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH...449

a) ENGINE OIL LEVEL DISPLAY FLASHES...449

b) ENGINE WATER LEVEL DISPLAY FLASHES...450

K-5 WHEN STARTING SWITCH IS TURNED ON (ENGINE STARTED), CAUTION ITEMS FLASH...451

a) ENGINE OIL PRESSURE DISPLAY FLASHES...451

b) BATTERY CHARGE LEVEL DISPLAY FLASHES...452

c) BRAKE OIL PRESSURE DISPLAY FLASHES (CHECK THAT THE BRAKE OIL PRESSURE IS CORRECT.)...453

d) AIR CLEANER (R.H.) CLOGGING DISPLAY FLASHES (CHECK THAT THE AIR CLEANER (R.H.) IS NOT CLOGGED.)...455

e) AIR CLEANER (L.H.) CLOGGING DISPLAY FLASHES (CHECK THAT THE AIR CLEANER (L.H.) IS NOT CLOGGED.)...456

f) TRANSMISSION OIL FILTER DISPLAY FLASHES (THE TRANSMISSION OIL FILTER MUST NOT BE CLOGGED.)...457

K-6 CAUTION ITEMS ARE FLASHING BUT BUZZER DOES NOT SOUND...458

K-7 THERE IS NO ABNORMALITY IN MONITOR DISPLAY BUT CAUTION BUZZER SOUNDS...459

K-8 CAUTION ITEMS ARE FLASHING BUT NEITHER CHECK LAMP NOR CAUTION LAMP FLASHES...460

a) CHECK LAMP...460

b) CAUTION LAMP...460

K-9 THERE IS NO ABNORMALITY IN MAINTENANCE MONITOR DISPLAY BUT CHECK LAMP OR CAUTION LAMP LIGHTS UP...461

a) CHECK LAMP...461

b) CAUTION LAMP...461

K-10 ONLY NIGHT LIGHTING OF MAINTENANCE MONITOR DOES NOT LIGHT UP WHEN LIGHTING SWITCH IS TURNED ON...462

K-11 NIGHT LIGHTING LIGHTS UP EVEN WHEN LIGHTING SWITCH IS TURNED OFF...463

K-12 SERVICE METER DOES NOT WORK...464

K-13 SERVICE METER IS RUNNING EVEN WHEN ENGINE IS STOPPED...464

K-14 ABNORMALITY IN GAUGE DISPLAY...466

a) ABNORMALITY IN FUEL GAUGE...466

b) ABNORMALITY IN ENGINE WATER TEMPERATURE GAUGE...467

c) ABNORMALITY IN TORQUE CONVERTER OIL TEMPERATURE GAUGE...468

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...469

ELECTRICAL CIRCUIT DIAGRAM FOR POWER SUPPLY, ENGINE STARTING, ENGINE STOPPING AND PREHEATING...470

ELECTRICAL CIRCUIT DIAGRAM FOR PARKING BRAKE...472

ELECTRICAL CIRCUIT DIAGRAM FOR BOOM KICK-OUT AND BUCKET POSITIONER...473

E-1 ENGINE DOES NOT START...474

a) STARTING MOTOR DOES NOT TURN...474

b) STARTING MOTOR TURNS...478

E-2 ENGINE DOES NOT...479

E-3 ABNORMALITY IN PREHEATING SYSTEM...482

a) DOES NOT CARRY OUT PREHEATING...482

b) ONLY MONITOR DISPLAY LIGHTS UP...482

c) MONITOR DISPLAY DOES NOT LIGHT UP WHEN PREHEATING IS COMPLETED...483

d) MONITOR DISPLAY KEEPS LIGHTING UP WHEN PREHEATING IS NOT COMPLETED...483

E-4 PARKING BRAKE DOES NOT HAVE EFFECT...485

a) PARKING BRAKE HAS NO EFFECT WHEN PARKING BRAKE SWITCH IS TURNED ON...485

b) PARKING BRAKE HAS NO EFFECT WHEN BRAKE PRESSURE (ACCUMULATOR PRESSURE) DROPS (DOES NOT WORK AS EMERGENCY BRAKE)...485

E-5 PARKING BRAKE IS APPLIED WHEN MACHINE IS TRAVELING...486

E-6 PARKING BRAKE IS RELEASED WHEN STARTING SWITCH IS TURNED ON...488

E-7 TRANSMISSION DOES NOT CHANGE TO NEUTRAL WHEN PARKING BRAKE IS APPLIED (BUT PARKING BRAKE WORKS NORMALLY)...488

E-8 KICK-DOWN SWITCH DOES NOT WORK...490

a) KICK-DOWN SWITCH DOES NOT WORK EVEN THOUGH GEAR SHIFT WORKS NORMALLY...490

b) KICK-DOWN CANNOT BE CANCELED...491

E-9 BOOM KICK-OUT DOES NOT WORK...492

E-10 ABNORMALITY IN BUCKET POSITIONER FUNCTION...495

E-11 ABNORMALITY IN LIGHTING UP OF FRONT WORKING LAMP...498

E-12 ABNORMALITY IN LIGHTING UP OF REAR WORKING LAMP...498

E-13 ABNORMALITY IN TRANSMISSION CUT-OFF...498

E-14 ABNORMALITY IN LOW IDLING SELECTION...498

E-15 ABNORMALITY IN PARKING BRAKE DRAGGING WARNING...498

E-16 ABNORMALITY IN BUZZER...498

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...499

H-1 MACHINE DOES NOT MOVE...500

H-2 MACHINE LACKS POWER OR SPEED (EVERY SPEED RANGE)...501

H-3 EXCESSIVE TIME LAG WHEN STARTING MACHINE OR SHIFTING GEAR...502

H-4 TORQUE CONVERTER OIL TEMPERATURE IS HIGH...503

H-5 STEERING DOES NOT TURN...504

H-6 TURNING, RESPONSE OF STEERING IS POOR...505

H-7 JOYSTICK LEVER IS HEAVY...506

H-8 STEERING WHEEL SHAKES OR JERKS...507

H-9 MINIMUM TURNING RADII TO RIGHT AND LEFT ARE DIFFERENT...508

H-10 WHEEL BRAKES DO NOT WORK OR BRAKING EFFECT IS POOR...509

H-11 WHEEL BRAKES ARE NOT RELEASED OR BRAKES DRAG...510

H-12 BOOM DOES NOT RISE...511

H-13 BOOM MOVES SLOWLY OR DOES NOT HAVE SUFFICIENT LIFTING POWER...512

H-14 WHEN RAISING BOOM, BECOMES SLOW AT CERTAIN HEIGHT...513

H-15 BOOM CYLINDER CANNOT HOLD DOWN BUCKET...513

H-16 BOOM HAS LARGE AMOUNT OF HYDRAULIC DRIFT...513

H-17 BOOM FLUCTUATES WHILE WORKING...514

H-18 BOOM DROPS MOMENTARILY WHEN LEVER IS OPERATED FROM HOLD TO RAISE...514

H-19 BUCKET DOES NOT TILT BACK...515

H-20 BUCKET MOVES SLOWLY OR HAS INSUFFICIENT TILT BACK POWER...516

H-21 BUCKET MOVEMENT BECOMES SLOW DURING TILT BACK...517

H-22 BUCKET CYLINDER CANNOT HOLD DOWN BUCKET...517

H-23 BUCKET HAS LARGE AMOUNT OF HYDRAULIC DRIFT...517

H-24 BUCKET FLUCTUATES WHILE TRAVELING UNDER LOAD (WORK EQUIPMENT VALVE "HOLD")...518

H-25 BUCKET DUMPS MOMENTARILY WHEN LEVER IS OPERATED FROM HOLD TO TILT...518

H-26 BOOM AND BUCKET LEVERS DO NOT MOVE SMOOTHLY...519

TROUBLESHOOTING OF AJSS (ADVANCED JOYSTICK STEERING SYSTEM) CONTROL SYSTEM (A MODE)...520

JUDGEMENT TABLE FOR AJSS CONTROL SYSTEM...521

OPERATIONS OF CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY...522

ELECTRIC CIRCUIT DIAGRAM FOR AJSS CONTROL...526

A-1 FAILURE CODE [56] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN CAUTION BUZZER RELAY SYSTEM) IS DISPLAYED...528

A-2 FAILURE CODE [57] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING LEVER ANGLE SENSOR SYSTEM) IS DISPLAYED...529

A-3 FAILURE CODE [58] (DEVIATION OF STEERING LEVER ANGLE SENSOR AND FRAME ANGLE SENSOR SIGNALS) IS DISPLAYED...530

A-4 FAILURE CODE [59] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN FRAME ANGLE SENSOR SYSTEM) IS DISPLAYED...531

A-5 FAILURE CODE [60] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING LEVER LOCK PRESSURE SWITCH SYSTEM) IS DISPLAYED...532

A-6 FAILURE CODE [62] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING NEUTRAL INTERLOCK RELAY SYSTEM) IS DISPLAYED...533

A-7 FAILURE CODE [63] (DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND, OR SHORT CIRCUIT WITH POWER SOURCE IN STEERING MAIN PRESSURE CONTROL EPC SOLENOID SYSTEM) IS DISPLAYED...534

A-8 STEERING SPEEDS IN BOTH DIRECTIONS ARE DIFFERENT...535

A-9 ABNORMALITY IN CONSOLE SWITCH (ADJUSTMENT OF STEERING LEVER ANGLE SENSOR AND FRAME ANGLE SENSOR IS IMPOSSIBLE)...536

A-10 ABNORMALITY IN POWER SOURCE AND VOLTAGE...537

30 DISASSEMBLY AND ASSEMBLY...538

METHOD OF USING MANUAL...540

PRECAUTIONS WHEN CARRYING OUT OPERATION...542

SPECIAL TOOL LIST...544

SKETCHES OF SPECIAL TOOLS...550

ENGINE RELATED PARTS...558

STARTING MOTOR...558

ALTERNATOR...558

ENGINE OIL COOLER...558

FUEL INJECTION PUMP FOR LEFT BANK...558

FUEL INJECTION PUMP FOR RIGHT BANK...558

WATER PUMP...558

NOZZELE HODLER...558

TURBOCHARGER...558

ENGINE FRONT SEAL...558

ENGINE REAR SEAL...558

CYLINDER HEAD...558

REMOVAL AND INSTALLATION OF RADIATOR...559

REMOVAL AND INSTALLATION OF ENGINE...562

REMOVAL AND INSTALLATION OF DAMPER ...567

DISASSEMBLY AND ASSEMBLY OF DAMPER...568

REMOVAL AND INSTALLATION OF TORQUE CONVERTER AND TRANSMISSION ASSEMBLY...572

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER...579

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER VALVE...586

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION...587

REMOVAL AND INSTALLATION OF TRANSMISSION VALVE...611

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION VALVE...612

DISASSEMBLY AND ASSEMBLY OF TRANSFER...616

DISASSEMBLY AND ASSEMBLY OF PTO...628

REMOVAL AND INSTALLATION OF CENTER SUPPORT...633

DISASSEMBLY AND ASSEMBLY OF CENTER SUPPORT...635

DISASSEMBLY AND ASSEMBLY OF DRIVE SHAFT...639

REMOVAL AND INSTALLATION OF FRONT AXLE...642

REMOVAL AND INSTALLATION OF REAR AXLE...644

REMOVAL AND INSTALLATION OF DIFFERENTIAL...649

DISASSEMBLY AND ASSEMBLY OF DIFFERENTIAL...651

DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE...659

REMOVAL AND INSTALLATION OF ROTARY VALVE...664

REMOVAL AND INSTALLATION OF EMERGENCY STEERING PUMP...665

REMOVAL AND INSTALLATION OF DIVERTER VALVE...666

DISASSEMBLY AND ASSEMBLY OF DIVERTER VALVE...667

REMOVAL AND INSTALLATION OF ACCUMULATOR CHARGE VALVE...669

DISASSEMBLY AND ASSEMBLY OF ACCUMULATOR CHARGE VALVE...670

REMOVAL AND INSTALLATION OF STEERING CYLINDER...672

REMOVAL AND INSTALLATION OF STEERING VALVE...674

REMOVAL AND INSTALLATION OF BRAKE VALVE...676

REMOVAL AND INSTALLATION OF SLACK ADJUSTER...677

DISASSEMBLY AND ASSEMBLY OF SLACK ADJUSTER...678

REMOVAL AND INSTALLATION OF BRAKE...680

DISASSEMBLY AND ASSEMBLY OF BRAKE...681

REMOVAL AND INSTALLATION OF PARKING BRAKE CALIPERS...685

DISASSEMBLY AND ASSEMBLY OF PARKING BRAKE CALIPERS...686

REMOVAL AND INSTALLATION OF PARKING BRAKE PAD...688

REMOVAL AND INSTALLATION OF PARKING BRAKE SPRING CYLINDER...689

REMOVAL AND INSTALLATION OF BRAKE OIL TANK...690

REMOVAL AND INSTALLATION OF HYDRAULIC PUMP...691

REMOVAL AND INSTALLATION OF HYDRAULIC TANK AND FILTER CASE ASSEMBLY...693

REMOVAL AND INSTALLATION OF PPC VALVE...695

DISASSEMBLY AND ASSEMBLY OF PPC VALVE...697

REMOVAL AND INSTALLATION OF WORK EQUIPMENT CONTROL VALVE ASSEMBLY...698

DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT CONTROL VALVE...700

REMOVAL AND INSTALLATION OF CAB...703

REMOVAL AND INSTALLATION OF FLOOR FRAME...705

REMOVAL AND INSTALLATION OF CENTER HINGE PIN...708

REMOVAL AND INSTALLATION OF WORK EQUIPMENT...715

REPLACEMENT OF BOOM FRONT END BUSH...720

REMOVAL AND INSTALLATION OF BUCKET CYLINDER...721

REMOVAL AND INSTALLATION OF LIFT CYLINDER...722

DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER...724

REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT...728

REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR...730

REMOVAL AND INSTALLATION OF RECEIVER TANK...731

REMOVAL AND INSTALLATION OF AIR CONDITIONER CONDENSER...732

REMOVAL AND INSTALLATION OF TRANSMISSION AND JOYSTICK STEERING CONTROLLER...733

REMOVAL AND INSTALLATION OF MAIN MONITOR...734

REMOVAL AND INSTALLATION OF FUEL TANK...736

REMOVAL AND INSTALLATION OF COUNTERWEIGHT...738

40 MAINTENANCE STANDARD...739

ENGINE MOUNT...740

TRANSMISSION MOUNT...741

DAMPER...742

TORQUE CONVERTER CHARGING, PPC AND BRAKE PUMP...744

TORQUE CONVERTER...746

TORQUE CONVERTER REGULATOR VALVE...747

TRANSMISSION (1/2)...748

TRANSMISSION (2/2)...750

TRANSFER...751

TRANSMISSION CONTROL VALVE...752

DRIVE SHAFT...757

CENTER SUPPORT...758

DIFFERENTIAL (1/2)...759

DIFFERENTIAL (2/2)...760

FINAL DRIVE...762

AXLE MOUNT...764

CENTER HINGE PIN...766

STEERING DEMAND VALVE...768

DIVERTER VALVE...770

STEERING CYLINDER MOUNT...771

EMERGENCY STEERING PUMP...772

BRAKE VALVE...773

SLACK ADJUSTER...776

BRAKE...777

PARKING BRAKE...779

PPC VALVE...781

PPC RELIEF VALVE...783

CONTROL PUMP...784

STEERING PUMP...785

SWITCH PUMP...786

MAIN PISTON PUMP...787

MAIN CONTROL VALVE...788

HYDRAULIC CYLINDER...790

WORK EQUIPMENT LINKAGE...791

BUCKET POSITIONER AND BOOM KICK-OUT...793

ROPS CANOPY...794

90 OTHERS...795

HYDRAULIC CIRCUIT DIAGRAM...796

ELECTRICAL CIRCUIT DIAGRAM (1/5)...797

ELECTRICAL CIRCUIT DIAGRAM (2/5)...798

ELECTRICAL CIRCUIT DIAGRAM (3/5)...799

ELECTRICAL CIRCUIT DIAGRAM (4/5)...800

ELECTRICAL CIRCUIT DIAGRAM (5/5)...801

ELECTRICAL CIRCUIT DIAGRAM (ENGINE SHUT-DOWN)...802

ELECTRICAL CIRCUIT DIAGRAM (AUTO-GREASING)...803

COVER.....1

FOREWORD.....2

FOREWORD.....3

SAFETY INFORMATION.....6

INTRODUCTION.....8

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE.....8

VISIBILITY FROM OPERATOR'S SEAT.....9

NECESSARY INFORMATION.....10

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE.....10

ENGINE SERIAL NO. PLATE AND POSITION.....10

POSITION OF SERVICE METER.....11

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....11

CONTENTS.....12

SAFETY.....15

SAFETY.....16

SAFETY LABELS.....18

LOCATION OF SAFETY LABELS.....18

GENERAL PRECAUTIONS.....24

SAFETY RULES.....24

IF ABNORMALITIES ARE FOUND.....24

CLOTHING AND PERSONAL PROTECTIVE ITEMS.....24

FIRE EXTINGUISHER AND FIRST AID KIT.....24

SAFETY FEATURES.....24

KEEP MACHINE CLEAN.....25

INSIDE OPERATOR'S COMPARTMENT.....25

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR'S SEAT.....26

HANDRAILS AND STEPS.....27

MOUNTING AND DISMOUNTING.....27

NO PEOPLE ON ATTACHMENTS.....27

DO NOT GET CAUGHT IN ARTICULATED PORTION.....28

PREVENTION OF BURNS.....28

FIRE PREVENTION.....29

ACTION IF FIRE OCCURS.....30

WINDOW WASHER LIQUID.....30

PRECAUTIONS WHEN USING ROPS (ROLL OVER PROTECTIVE STRUCTURE).....30

PRECAUTIONS FOR ATTACHMENTS, OPTIONS.....30

UNAUTHORIZED MODIFICATION.....30

SAFETY AT WORKSITE.....31

WORKING ON LOOSE GROUND.....31

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES.....32

ENSURE GOOD VISIBILITY.....32

PRECAUTIONS RELATED TO VENTILATION EXHAUST GAS.....33

CHECKING SIGNALMAN'S SIGNALS AND SIGNS.....33

EMERGENCY EXIT FROM OPERATOR'S CAB.....33

BE CAREFUL ABOUT ASBESTOS DUST.....33

PRECAUTIONS FOR OPERATION.....34

STARTING ENGINE.....34

CHECKS BEFORE STARTING ENGINE.....34

PRECAUTIONS WHEN STARTING.....34

PRECAUTIONS IN COLD AREAS.....35

OPERATION.....36

CHECKS BEFORE OPERATION.....36

PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE.....36

PRECAUTIONS WHEN TRAVELING.....37

TRAVELING ON SLOPES.....38

PROHIBITED OPERATIONS.....39

PRECAUTIONS WHEN OPERATING.....40

METHODS OF USING BRAKE.....40

OPERATE CAREFULLY ON SNOW.....41

PARKING MACHINE .....42

TRANSPORTATION.....44

LOADING AND UNLOADING.....44

SHIPPING.....44

BATTERY.....45

BATTERY HAZARD PREVENTION.....45

STARTING WITH BOOSTER CABLES.....46

TOWING.....47

PRECAUTIONS FOR MAINTENANCE.....48

WARNING TAG .....48

KEEP WORK PLACE CLEAN AND TIDY.....48

APPOINT LEADER WHEN WORKING WITH OTHERS.....48

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE.....49

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING.....51

PROPER TOOLS.....52

WORK EQUIPMENT SUPPORT.....52

ACCUMULATOR.....52

PERSONNEL.....52

ATTACHMENTS .....53

NOISE.....53

PRECAUTIONS WHEN USING HAMMER.....53

REPAIR WELDING .....53

REMOVING BATTERY TERMINAL .....53

PRECAUTIONS WITH HIGH-PRESSURE OIL.....54

HANDLING HIGH-PRESSURE HOSES.....54

WASTE MATERIALS .....54

MAINTENANCE OF AIR CONDITIONER.....54

COMPRESSED AIR.....55

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS .....55

PRECAUTIONS WITH TIRES.....56

HANDLING TIRES.....56

PRECAUTIONS WHEN STORING TIRES.....56

OPERATION.....57

GENERAL VIEW.....58

GENERAL VIEW OF MACHINE.....58

GENERAL VIEW OF CONTROLS AND GAUGES.....59

EXPLANATION OF COMPONENTS.....61

MACHINE MONITOR.....61

SWITCHES.....74

CONTROL LEVERS, PEDALS.....85

MAIN MONITOR TILT LEVER.....89

CAP WITH LOCK.....90

SAFETY BAR.....91

TOWING PIN.....91

ENGINE SHUT-DOWN SWITCH.....91

FUEL STOP LEVER.....92

GREASE PUMP.....92

BACKUP ALARM.....92

CAB DOOR OPEN LOCK.....92

TOOL BOX.....93

FUSE.....94

SLOW BLOW FUSE.....95

LUNCH BOX TRAY.....96

POWER OUTLET.....96

AM/FM RADIO-CASSETTE STEREO.....97

AIR CONDITIONER.....105

PRECAUTIONS WHEN HANDLING ACCUMULATOR.....110

OPERATION.....112

CHECK BEFORE STARTING ENGINE, ADJUST.....112

STARTING ENGINE.....129

OPERATIONS AND CHECKS AFTER STARTING ENGINE.....132

STOPPING ENGINE.....134

CHECK AFTER STOPPING ENGINE.....134

MOVING THE MACHINE (DIRECTIONAL, SPEED), STOPPING THE MACHINE.....135

TURNING.....143

OPERATION OF WORK EQUIPMENT.....144

WORK POSSIBLE USING WHEEL LOADER.....146

PRECAUTIONS FOR OPERATION.....152

ADJUSTING WORK EQUIPMENT POSTURE.....154

REMOVAL AND INSTALLATION OF THE BUCKET.....156

PARKING MACHINE.....159

CHECKS AFTER COMPLETION OF OPERATION.....161

LOCKING.....161

HANDLING THE TIRES.....162

OPERATING AUTO-GREASING SYSTEM.....164

TRANSPORTATION.....177

TRANSPORTATION PROCEDURE.....177

LOADING, UNLOADING WORK.....177

METHOD OF SECURING MACHINE.....177

METHOD OF LIFTING MACHINE.....179

COLD WEATHER OPERATION.....183

PRECAUTIONS FOR LOW TEMPERATURE.....183

PRECAUTIONS AFTER COMPLETION OF WORK.....185

AFTER COLD WEATHER.....186

WARMING-UP OPERATION FOR STEERING HYDRAULIC CIRCUIT IN COLD WEATHER.....186

LONG-TERM STORAGE.....187

BEFORE STORAGE.....187

DURING STORAGE.....187

AFTER STORAGE.....187

TROUBLESHOOTING.....188

WHEN MACHINE RUNS OUT OF FUEL.....188

METHOD OF TOWING MACHINE.....189

IF BATTERY IS DISCHARGED.....193

OTHER TROUBLE.....197

MAINTENANCE.....202

GUIDES TO MAINTENANCE.....203

OUTLINES OF SERVICE.....205

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC.....205

OUTLINE OF ELECTRIC SYSTEM.....208

WEAR PARTS.....209

WEAR PARTS LIST.....209

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.....210

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS.....210

FUEL, OIL AND COOLANT SPECIFICATIONS.....212

ENGINE OIL SPECIFICATIONS.....212

TRANSMISSION, CONVERTER, TRANSFER CASE, COOLER, SERVICE BRAKES AND HYDRAULIC SYSTEM OIL SPECIFICATIONS.....213

DRIVE AXLE OIL SPECIFICATIONS.....213

DIESEL FUEL SPECIFICATIONS.....213

COOLANT SPECIFICATIONS.....214

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....220

TORQUE LIST.....220

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....221

MAINTENANCE SCHEDULE CHART.....223

MAINTENANCE SCHEDULE CHART.....223

SERVICE PROCEDURE.....225

INITIAL 250 HOURS SERVICE.....225

WHEN REQUIRED.....226

CHECK, CLEAN, OR REPLACE AIR CLEANER ELEMENT.....226

CLEAN INSIDE OF COOLING SYSTEM.....228

CHECK TRANSMISSION OIL LEVEL, ADD OIL.....230

CHECK AXLE OIL LEVEL, ADD OIL.....232

CLEAN AXLE CASE BREATHER.....232

CLEAN AIR CONDITIONER CONDENSER.....233

CHECK WINDOW WASHING FLUID LEVEL, ADD FLUID.....233

CLEAN RADIATOR FINS.....234

CHECK ELECTRICAL INTAKE AIR HEATER.....234

REPLACE BUCKET TEETH.....235

LUBRICATE WORK EQUIPMENT CONTROL VALVE LINKAGE (2 PLACES).....238

CHECK AIR CONDITIONER.....238

BLEEDING AIR FROM BRAKE HYDRAULIC CIRCUIT.....239

BLEEDING AIR FROM PPC CIRCUIT.....239

REPLACE SLOW BLOW FUSE.....240

BLEEDING AIR FROM HYDRAULIC TANK.....241

REPLACE FAN BELT.....242

SELECTION AND INSPECTION OF TIRES.....244

DRAIN WATER FROM WATER SEPARATOR.....246

CHECK BEFORE STARTING.....247

EVERY 50 HOURS SERVICE.....248

DRAIN WATER, SEDIMENT FROM FUEL TANK.....248

EVERY 100 HOURS SERVICE.....249

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL.....249

CLEAN ELEMENT IN AIR CONDITIONER FRESH AIR FILTER.....250

EVERY 250 HOURS SERVICE.....251

CHECK BATTERY ELECTROLYTE LEVEL.....251

CHECK PARKING BRAKE.....252

CHECK ALTERNATOR BELT TENSION, ADJUST.....253

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST.....254

CHECK FOR LOOSE WHEEL HUB NUTS, TIGHTEN.....255

CLEAN ELEMENT IN AIR CONDITIONER RECIRCULATION FILTER.....255

EVERY 500 HOURS SERVICE.....256

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE.....256

REPLACE FUEL FILTER CARTRIDGE.....258

REPLACE TRANSMISSION OIL FILTER ELEMENT.....260

LUBRICATE CENTER DRIVE SHAFT.....261

CHECK FAN BELT FOR WEAR .....261

EVERY 1000 HOURS SERVICE.....262

CHANGE OIL IN TRANSMISSION CASE, CLEAN STRAINER.....262

CLEAN TRANSMISSION CASE BREATHER.....264

LUBRICATING.....264

CHECK TIGHTENING PARTS OF TURBOCHARGER.....265

CLEAN FUEL STRAINER.....265

TIGHTEN ROPS CANOPY.....265

REPLACE CORROSION RESISTOR CARTRIDGE.....266

EVERY 2000 HOURS SERVICE.....267

CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC FILTER ELEMENT.....267

CLEAN HYDRAULIC TANK STRAINER.....270

REPLACE HYDRAULIC TANK BREATHER ELEMENT.....271

CHANGE AXLE OIL.....272

REPLACE FILTER ELEMENT IN BRAKE OIL TANK.....274

REPLACE BRAKE OIL TANK BREATHER.....275

REPLACE ELEMENT IN AIR CONDITIONER RECIRCULATION AIR FILTER, FRESH AIR FILTER.....275

CLEAN PPC CIRCUIT STRAINER.....275

CHECK ALTERNATOR, STARTING MOTOR.....275

CHECK ENGINE VALVE CLEARANCE, ADJUST.....276

CHECK BRAKE DISC WEAR.....276

CLEAN AND CHECK TURBOCHARGER.....276

CHECK PLAY OF TURBOCHARGER ROTOR.....276

CHECK ACCUMULATOR FUNCTION.....277

CHECK ACCUMULATOR GAS PRESSURE.....277

LUBRICATE ENGINE FRONT TRUNNION.....277

EVERY 4000 HOURS SERVICE.....278

CHECK WATER PUMP.....278

CHECK VIBRATION DAMPER.....278

CHECK FAN PULLEY AND TENSION PULLEY.....278

SPECIFICATIONS.....279

SPECIFICATIONS.....280

INDEX.....281