John Deere PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail Component Technical Manual (CTM255)

JComplete Component Technical Manual with Electrical Wiring Diagrams for John Deere PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm255 - PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail - (Worldwide Edition) Component Technical Manual.pdf

CTM255 (15FEB11) (ENGLISH) - John Deere PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System with Denso High Pressure Common Rail Component Technical Manual.pdf

ctm255 - PowerTechTM 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail - (Worldwide Edition) Component Technical Manual.epub

Total Pages: 1,216 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

ctm255 - PowerTech™ 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail -: (Worldwide Edition)

Component Technical Manual

John Deere PowerTech 8.1L Diesel Engines Level 9 Electronic Fuel System With Denso High Pressure Common Rail Component Technical Manual (CTM255)

Table of Contents

Foreword

Trademarks

Section 01: General

Group 000: Safety

Handle Fluids Safely—Avoid Fires

Handle Starting Fluid Safely

Service Cooling System Safely

Prevent Battery Explosions

Prepare for Emergencies

Handling Batteries Safely

Wait Before Opening High-Pressure Fuel System

Avoid High-Pressure Fluids

Wear Protective Clothing

Service Machines Safely

Protect Against Noise

Work In Ventilated Area

Work in Clean Area

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Illuminate Work Area Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Practice Safe Maintenance

Use Proper Tools

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Live With Safety

Group 001: Engine Identification

Engine Model Designation

Engine Serial Number Plate Information

Engine Option Code Label

Group 002: Fuels, Lubricants, and Coolant

Lubricants and Coolant

Diesel Fuel - Tier 1

Diesel Fuel - Tier 2

Diesel Fuel Additive Products

Handling and Storing Diesel Fuel

Bio-Diesel Fuel

Testing Diesel Fuel

Fuel Filters

Lubricity of Diesel Fuel

Section 02: Repair and Adjustments

Group 090: Electronic Fuel System Repair and Adjustments

Fuel System - General Information

Relieve Fuel System Pressure

Clean Primary Fuel Filter (Strainer) (—246269)

Remove and Install Fuel Filter Head (—246269)

Remove and Install Fuel Filter Heads (246270—)

Fuel Filter Assemblies (—246269)

Fuel Filter Assemblies (246270—)

Replace Final Fuel Filter Element (—246269)

Replacing Fuel Filter Elements (246270—)

Remove and Install High Pressure Fuel Pump Overflow Valve

Remove and Install Hand Primer

Remove High-Pressure Fuel Pump

Remove and Install High Pressure Common Rail

Remove and Install Flow Limiters

Remove and Install HPCR Pressure Relief Valve

Install High-Pressure Fuel Pump

Remove Electronic Injectors

Clean Electronic Injector Bore

Clean Electronic Injector Orifice

Clean Electronic Injector Body

Inspect Electronic Injector Body

Install Electronic Injectors

Clean Electronic injectors (In Engine)

Group 110: Electronic Engine Control Repair and Adjustment

Engine Control Unit (ECU)

Electronic Engine Control System and Sensors

Fuel Pump Sensors

Replace Coolant Temperature Sensor

Replace Fuel Temperature Sensor

Replace Crankshaft Position Sensor

Replace Manifold Air Temperature (MAT) Sensor

Replace Water in Fuel (WIF) Sensor

Remove and Install Oil Pressure Sensor

Remove and Install Fuel Rail Pressure Sensor

Connectors

Use Electrical Insulating Compound

Using High-Pressure Washer

Repair WEATHERPACK Connector

Remove Blade Terminals from Connector Body

Repair (Pull Type) METRI-PACK™ Connectors

Repair (Push Type) METRI-PACK™ Connectors

Repair DEUTSCH Connectors

Repair AMP Connector

Repair SUMITOMO™ Connectors

Repair YAZAKI™ Connectors

Section 03: Theory Of Operation

Group 130: Electronic Fuel System Operation

About This Group

Fuel System Operation

Primary Fuel Filter (Strainer) Operation (—246269)

Primary Fuel Filter Operation (246270—)

Fuel Transfer Pump Operation

Final Fuel Filter Operation (—246269)

Final Fuel Filter Operation (246270—)

High Pressure Fuel Pump Operation

High Pressure Common Rail (HPCR) Operation

Electronic Injector (EI) Operation

Group 140: Electronic Control System Operation

About This Group

Electronic Control System Terminology

Electronic Control System Operation

Electronic Control System Overview

Monitoring Engine Parameters

Measuring Temperature

Measuring Pressure

Measuring Engine Speed

Water In Fuel (WIF) Sensor

Throttle Descriptions

Digital Throttle Adjustments

Marine Throttles

Pump Control Valves (PCVs)

Electronic Injector (EI) Wiring Harness Connector

Engine Control Unit (ECU)

Controlled Area Network (CAN)

Pilot Injection Operation

Low-Idle Warmup

Intake Air Heater Operation

Charge Air Cooling Operation

Cruise Control Operation

Engine Derate and Shutdown Protection

Torque Curves

Governor Droop Modes

Engine Control Unit (ECU) Self-Diagnosis

Section 04: Diagnostics

Group 150: Observable Diagnostics and Tests

About This Group

E1 - Engine Cranks/Won't Start/Very Hard to Start (—246269)

E1--Engine Cranks/Wont'Start/Very Hard to Start (246270--)

E2 - Engine Misfires/Runs Irregularly

E3 - Engine Does Not Develop Full Power

E4 - Engine Emits Excessive White Exhaust Smoke

E5 - Engine Emits Excessive Black or Gray Exhaust Smoke

E6 - Engine Will Not Crank

E7 - Engine Idles Poorly

E8 - Abnormal Engine Noise

F1 - Fuel Supply System Check

F2 - Excessive Fuel Consumption

F3 - Fuel in Oil

F4 - Excessive Fuel Filter Replacement

ECU Does Not Communicate with Service ADVISOR

D1 - ECU Does Not Communicate with DST

D2 - Diagnostic Gauge (Earlier Model) Does Not Communicate With ECU

D2 - Diagnostic Gauge (Earlier Model) Does Not Communicate With ECU

D3 - Diagnostic Gauge (Later Model) Does Not Communicate With ECU

D3 - Diagnostic Gauge (Later Model) Does Not Communicate With ECU

A1 - Intake Air Heater Check

A1 - Intake Air Heater Check

Mechanical Compression Test

Check Fuel Supply Quality

Test for Air in Fuel

Check Fuel Supply Pressure

Check for Restricted Fuel Return Line

Bleed the Fuel System (—246269)

Restarting Engine That Has Run Out Of Fuel (—246269)

Bleed the Fuel System (246270—)

Electric Fuel Priming Pump

Bleed the Fuel System Using Electric Priming Pump (246270—)

Restarting Engine That Has Run Out of Fuel (246270—)

Check and Adjust High Pressure Fuel Pump Static Timing

Load Profile Information Test — Instructions

Electrical Concepts

Using a Digital Multimeter

Electrical Circuit Malfunctions

Troubleshooting Circuit Malfunctions

Primary CAN Diagnostic Procedure

Terminal Test

Diagnostic Test Box — Using

Group 160: Trouble Code Diagnostics and Tests

About This Group

Connecting to Diagnostic Scan Tool (DST)

Connecting to Service ADVISOR

Viewing Active DTCs on Diagnostic Gauge (Earlier Model)

Viewing Stored DTCs on Diagnostic Gauge (Earlier Model)

Clearing Stored DTCs on Diagnostic Gauge (Earlier Model)

Engine Configuration Parameters on Diagnostic Gauge (Earlier Model)

Viewing Active DTCs on Diagnostic Gauge (Later Model)

Viewing Stored DTCs on Diagnostic Gauge (Later Model)

Clearing Stored DTCs on Diagnostic Gauge (Later Model)

Data Parameters on Diagnostic Tools

Engine Test Instructions—Cylinder Misfire Test

Engine Test Instructions—Compression Test

Engine Test Instructions— Cylinder Cutout Test

Engine Test Instructions— Tractor Torque Curve Change Test

Engine Control Unit (ECU) — Donating this Engine’s ECU to be Used Elsewhere

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU — Cannot Communicate with Current ECU

Engine Control Unit (ECU) — Reprogramming Current ECU

Engine Control Unit (ECU) — Reprogramming Instructions

Diagnostic Trouble Codes (DTCs)

List of Diagnostic Trouble Codes (DTCs) on ECU

Diagnostic Procedure Overview

Intermittent Fault Diagnostics

T1 - Multi-state Throttle Input High

T2 - Multi-state Throttle Input Low

T3 - Analog Throttle (A) Input High

T4 - Analog Throttle (A) Input Low

T5 - Analog Throttle (B) Input High

T6 - Analog Throttle (B) Input Low

T7 - CAN Throttle Invalid

T8 - PWM Throttle Input High

T9 - PWM Throttle Input Low

T10 - PWM Throttle Abnormal Pulse Width

T11 - Excavator Throttle Reference Voltage High

T12 - Excavator Throttle Reference Voltage Low

T13 - Excavator Throttle Ground Voltage High

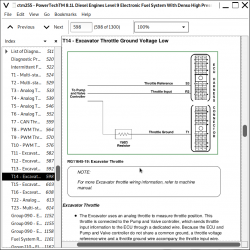

T14 - Excavator Throttle Ground Voltage Low

T15 - Excavator Throttle Input Voltage High

T16 - Excavator Throttle Input Voltage Low

T22 - Analog Throttle (A) Input Voltage Out of Range

T23 - Multi-state Throttle Input Voltage Out of Range

000028.03 - Throttle Voltage High

000028.04 - Throttle Voltage Low

000029.03 - Throttle Voltage High

000029.04 - Throttle Voltage Low

000029.14 - Throttle Voltage Out of Range

000084.09 - Vehicle Speed Invalid or Missing

000091.03 - Throttle Voltage High

000091.04 - Throttle Voltage Low

000091.08 - PWM Throttle Abnormal Pulse Width

000091.09 - Throttle Invalid

000091.14 - Throttle Voltage Out of Range

000094.03 - Fuel Rail Pressure Input Voltage High

000094.04 - Fuel Rail Pressure Input Voltage Low

000094.10 - Fuel Rail Pressure Loss Detected

000094.17 - Fuel Rail Pressure Not Developed

000097.00 - Water in Fuel Continuously Detected

000097.03 - Water in Fuel Input Voltage High

000097.04 - Water in Fuel Input Voltage Low

000097.16 - Water in Fuel Detected

000097.31 - Water in Fuel Detected

000100.01 - Engine Oil Pressure Extremely Low

000100.03 - Engine Oil Pressure Input Voltage High

000100.04 - Engine Oil Pressure Input Voltage Low

000100.16 - Engine Oil Pressure Above Normal

000100.18 - Engine Oil Pressure Moderately Low

000102.03 - Manifold Air Pressure Input Voltage High

000102.04 - Manifold Air Pressure Input Voltage Low

000105.03 - Manifold Air Temperature Input Voltage High

000105.04 - Manifold Air Temperature Input Voltage Low

000105.16 - Manifold Air Temperature Moderately High

000107.00 - Air Filter Restriction

000110.00 - Engine Coolant Temperature Extremely High

000110.03 - Engine Coolant Temperature Input Voltage High

000110.04 - Engine Coolant Temperature Input Voltage Low

000110.15 - Engine Coolant Temperature High Least Severe

000110.16 - Engine Coolant Temperature Moderately High

000110.31 - Engine Coolant Temperature High

000111.01 - Engine Coolant Level Low

000158.17 - ECU Power Down Error

000160.02 - Wheel Speed Input Noise

000171.03 - Ambient Air Temperature Input Voltage High

000171.04 - Ambient Air Temperature Input Voltage Low

000174.00 - Fuel Temperature High Most Severe

000174.03 - Fuel Temperature Input Voltage High

000174.04 - Fuel Temperature Input Voltage Low

000174.16 - Fuel Temperature High Moderately Severe

000189.00 - Engine Speed Derate

000190.00 - Engine Overspeed Extreme

000190.01 - Engine Overload Moderate

000190.16 - Engine Overspeed Moderate

000190.18 - Engine Overload Severe

000237.02 - Vehicle Identification Number Invalid

000237.13 - Vehicle Identification Option Code Invalid

000237.31 - Vehicle Model Number Invalid

000523.09 - Gear Selection Invalid

000596.31 - Cruise Control On/Off Inputs Shorted

000611.03 - Electronic Injector Wiring Shorted To Power Source

000611.04 - Electronic Injector Wiring Shorted To Ground

000620.03 - Sensor Supply 1 Voltage High

000620.04 - Sensor Supply 1 Voltage Low

000627.01 - Electronic Injector Supply Voltage Problem

000629.13 - ECU Error

000636.02 - Pump Position Sensor Input Noise

000636.08 - Pump Position Sensor Input Missing

000636.10 - Pump Position Sensor Input Pattern Error

000637.02 - Crankshaft Position Input Noise

000637.07 - Crankshaft Position/Pump Position Timing Moderately Out of Sync

000637.08 - Crankshaft Position Input Missing

000637.10 - Crankshaft Position Input Pattern Error

000639.13 - CAN Bus Error

000640.31 - Engine Shutdown - Vehicle Request

000644.02 - External Speed Command Input Erratic

000651.05 - Cylinder #1 EI Circuit Open

000651.06 - Cylinder #1 EI Circuit Shorted

000651.07 - Cylinder #1 EI Fuel Delivery Failure

000652.05 - Cylinder #2 EI Circuit Open

000652.06 - Cylinder #2 EI Circuit Shorted

000652.07 - Cylinder #2 EI Fuel Delivery Failure

000653.05 - Cylinder #3 EI Circuit Open

000653.06 - Cylinder #3 EI Circuit Shorted

000653.07 - Cylinder #3 EI Fuel Delivery Failure

000654.05 - Cylinder #4 EI Circuit Open

000654.06 - Cylinder #4 EI Circuit Shorted

000654.07 - Cylinder #4 EI Fuel Delivery Failure

000655.05 - Cylinder #5 EI Circuit Open

000655.06 - Cylinder #5 EI Circuit Shorted

000655.07 - Cylinder #5 EI Fuel Delivery Failure

000656.05 - Cylinder #6 EI Circuit Open

000656.06 - Cylinder #6 EI Circuit Shorted

000656.07 - Cylinder #6 EI Fuel Delivery Failure

000898.09 - Vehicle Speed or Torque Message Invalid

000970.31 - Engine Shutdown - Auxiliary Request

000971.31 - External Fuel Derate Switch Active

001069.09 - Tire Size Invalid

001069.31 - Tire Size Error

001079.03 - Sensor Supply 2 Voltage High

001079.04 - Sensor Supply 2 Voltage Low

001080.03 - Fuel Rail Pressure Sensor Supply Voltage High

001080.04 - Fuel Rail Pressure Sensor Supply Voltage Low

001109.31 - Engine Protection Shutdown Warning

001110.31 - Engine Protection Shutdown

001347.05 - Pump Control Valve #1 Error

001347.07 - Fuel Rail Pressure Incorrect

001347.10 - Pump Control Valve #1 Fuel Flow Not Detected

001348.05 - Pump Control Valve #2 Error

001348.10 - Pump Control Valve #2 Fuel Flow Not Detected

001568.02 - Torque Curve Selection Invalid

001568.09 - Torque Curve Selection Missing

001569.31 - Fuel Derate

001638.00 - Hydraulic Oil Temperature High Most Severe

001638.03 - Hydraulic Oil Temperature Sensor Above Normal

001638.04 - Hydraulic Oil Temperature Sensor Voltage Below Normal

001638.16 - Hydraulic Oil Temperature High

001639.01 - Fan Speed Input Missing

001639.16 - Fan Speed Higher Than Expected

001639.18 - Fan Speed Lower Than Expected

002005.09 - ACU Signal Missing

002049.09 - Cab Signal Missing

002071.09 - CCU Signal Missing

002580.03 - Brake Pressure Sensor Voltage Above Normal

002580.04 - Brake Pressure Sensor Voltage Below Normal

Section 05: Tools

Group 170: Electronic Fuel/Control System Repair Tools and Other Materials

Group 090 - Electronic Fuel System Repair and Adjustment Essential Tools

Fuel System Repair and Adjustment Other Materials

Group 110 - Electronic Engine Control Repair Tools

Control Repair and Adjustment Other Materials

Group 180: Diagnostic Service Tools

JDE81-4

JDG820

JDG886

JDG1705

JDG10460

JDG10461

JDG10466

JDG11233

JDG11263

JT01674A

JT05412

JT07306

JT07328

Section 06: Specifications

Group 200: Repair Specifications

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

General OEM Engine Specifications

Fuel System Component Torque Specifications

Engine Sensor Torque Specifications

Group 210: Diagnostic Specifications

Fuel System Diagnostic Specifications

Application Specifications

Articulated Dump Truck - Derate Specifications

Articulated Dump Trucks - Torque Curve Selection

Articulated Dump Trucks - Governor Mode Selection

Articulated Dump Trucks - ECU Terminal Identification

Cane Harvester - Derate Specifications

Cane Harvester - ECU Terminal Identification

Combines - Derate Specifications

Combines - Torque Curve Selection

Combines - Governor Mode Selection

Combines - ECU Terminal Identification

Crawler (Forestry) - Derate Specifications

Crawler (Forestry) - Torque Curve Selection

Crawler (Forestry) - Governor Mode Selection

Crawler (Forestry) - ECU Terminal Identification

Excavators - Derate Specifications

Excavators - Torque Curve Selection

Excavators - Governor Mode Selection

Excavators - ECU Terminal Identification

850/950 Feller Bunchers, Forwarders, and Harvesters (Forestry) - Derate Specifications

850/950 Feller Bunchers, Forwarders, and Harvesters (Forestry) - Torque Curve Selection

850/950 Feller Bunchers, Forwarders, and Harvesters (Forestry) - Governor Mode Selection

850/950 Feller Bunchers, Forwarders, and Harvesters (Forestry) - ECU Terminal Identification

Grader - Derate Specifications

Grader - Torque Curve Selection

Grader - Governor Mode Selection

Grader - ECU Terminal Identification

Loader - Derate Specifications

Loader - Torque Curve Selection

Loader - Governor Mode Selection

Loader - ECU Terminal Identification

OEM Engines - Derate Specifications

OEM Engines - Torque Curve Selection

OEM Engines - Governor Mode Selection With OC03040 Software or Later

OEM Engines - Governor Mode Selection With OC03036 Software or Earlier

OEM Engines - ECU Terminal Identification

OEM Engines - ECU Terminal Identification - Continued

Electronic Control System Wiring Diagram

6081 OEM Application Instrument Panel/Engine Start Components Electrical Wiring Diagram

6081 OEM Application Instrument Panel/Engine Start Components Electrical Wiring Diagram - Continued

Self-Propelled Forage Harvester - Derate Specifications

Self-Propelled Forage Harvester - Torque Curve Selection

Self-Propelled Forage Harvester - Governor Mode Selection

Self-Propelled Forage Harvester - ECU Terminal Identification

Skidders (Forestry) - Derate Specifications

Skidders (Forestry) - Torque Curve Selection

Skidders (Forestry) - Governor Mode Selection

Skidders (Forestry) - ECU Terminal Identification

Sprayer - Derate Specifications

Sprayer - Torque Curve Selection

Sprayer - Governor Mode Selection

Sprayer - ECU Terminal Identification

Tractors - 7010 Series - Derate Specifications

Tractors - 7010 Series - Torque Curve Selection

Tractors - 7010 Series - Governor Mode Selection

Tractors - 7010 Series - ECU Terminal Identification

Tractors - 7020 Series - Derate Specifications

Tractors - 7020 Series - Torque Curve Selection

Tractors - 7020 Series - Governor Mode Selection

Tractors - 7020 Series - ECU Terminal Identification

Tractors - 8020 Series - Derate Specifications

Tractors - 8020 Series - Torque Curve Selection

Tractors - 8020 Series - Governor Mode Selection

Tractors - 8020 Series - ECU Terminal Identification

Tractors - 9120 Series - Derate Specifications

Tractors - 9120 Series - Torque Curve Selection

Tractors - 9120 Series - Governor Mode Selection

Tractors - 9120 Series - ECU Terminal Identification

6.8 L and 8.1 L OEM Application Electronic Control System Wiring Diagram

8.1L Marine Application Electronic Control System Wiring Diagram

6.8 L & 8.1 L OEM Application Instrument Panel/Engine Start Components Electrical Wiring Diagram

6.8 L & 8.1 L OEM Application Instrument Panel/Engine Start Components Electrical Wiring Diagram - Continued