John Deere 3029, 4039, 4045, 6059, 6068 Engines Component Technical Manual (CTM3274)

Complete service repair manual with Electrical Wiring Diagrams for John Deere 3029, 4039, 4045, 6059, 6068 Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere 3029, 4039, 4045, 6059, 6068 Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm3274 - John Deere 3029, 4039, 4045, 6059, 6068 engines (saran) ( -499999cd) Component Technical Manual.pdf

ctm3274 - John Deere 3029, 4039, 4045, 6059, 6068 engines (saran) ( -499999cd) Component Technical Manual.epub

Total Pages: 603 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

Engine Application Chart

|

3000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

3100.............. |

CD3029DRT65 |

(189846 - ) |

|

3110.............. |

CD3029DRT65 |

|

|

3200/3200X.............. |

CD4039DRT35 |

(181345 - ) |

|

3210/3210X.............. |

CD4039DRT35 |

|

|

3300/3300X.............. |

CD4045DRT35 |

(182145 - ) |

|

3310/3310X.............. |

CD4045DRT35 |

|

|

3400/3400X.............. |

CD4039TRT35 |

(181775 - ) |

|

3410/3410X.............. |

CD4039TRT35 |

|

|

4000-SERIES TELESCOPIC HANDLERS |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

4400.............. |

CD4039TF005 |

(237697 - ) |

|

4500.............. |

CD4039TF005 |

|

|

5000-SERIES TRACTORS (Agritalia-built) |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

5300/5300N.............. |

CD3029DAT01 |

(315424 - ) |

|

5400/5400N.............. |

CD3029TAT02 |

(289398 - ) |

|

5500/5500N.............. |

CD4039TAT01 |

(346168 - ) |

|

5000-SERIES TRACTORS (Augusta-built) |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

5400N.............. |

CD3029TLV01 |

|

|

5500N.............. |

CD4039TLV01 |

(201353 - ) |

|

5000-SERIES TRACTORS (For India) |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

5300.............. |

CD3029DPY01 |

(383283 - ) |

|

6000-SERIES TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

6100 (Direct fan drive).............. |

CD4045DL001 |

(101582 - ) |

|

6100 (Viscous fan drive).............. |

CD4045DL002 |

(101582 - ) |

|

6200 (Direct fan drive).............. |

CD4039TL001 |

(101625 - ) |

|

6200 (Viscous fan drive).............. |

CD4039TL004 |

(101625 - ) |

|

6300 (Direct fan drive).............. |

CD4039TL003 |

(101649 - ) |

|

6300 (Viscous fan drive).............. |

CD4039TL006 |

(101649 - ) |

|

6400 (Direct fan drive).............. |

CD4045TL001 |

(101682 - ) |

|

6400 (Viscous fan drive).............. |

CD4045TL003 |

(101682 - ) |

|

6506 (Viscous fan drive).............. |

CD6068DL001 |

(214852 - ) |

|

6600 (Viscous fan drive).............. |

CD6059TL001 |

(128886 - ) |

|

6800 (Viscous fan drive).............. |

CD6068TL001 |

(124505 - ) |

|

6900 (Viscous fan drive).............. |

CD6068TL002 |

(186326 - ) |

|

WATERLOO TRACTORS |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

7600.............. |

T06068TRW01 |

|

|

ZWEIBRÜCKEN COMBINES |

ENGINE MODEL |

SERIAL NUMBER |

|---|---|---|

|

2054.............. |

6068HZ001 |

(116452 - ) |

|

2254.............. |

6068HZ001 |

|

|

ENGINES FOR CHINESE COMBINES |

SERIAL NUMBER |

|---|---|

|

CD6059TYC01.............. |

(367019 - ) |

|

CD6059TYC02.............. |

(363170 - ) |

|

ENGINES FOR GOLDONI TRACTORS |

SERIAL NUMBER |

|---|---|

|

CD3029DFG21.............. |

(287123 - ) |

|

CD3029DFG22.............. |

(287325 - ) |

|

CD3029TFG21.............. |

(287526 - ) |

|

SARAN OEM ENGINES |

SERIAL NUMBER |

SARAN OEM ENGINES |

SERIAL NUMBER |

|---|---|---|---|

|

CD3029DF |

CD3029TF |

||

|

CD3029DF001 |

CD3029TF001 |

||

|

CD3029DF005 |

(162670 - ) |

CD3029TF002 |

(170797 - ) |

|

CD3029DF031 |

CD3029TF031 |

||

|

CD3029DF032 |

CD3029TF032 |

(176015 - ) |

|

|

CD3029DF033 |

(177875 - ) |

CD3029TF033 |

(177880 - ) |

|

CD3029DF034 |

CD3029TF120 |

||

|

CD3029DF120 |

CD3029TF121 |

||

|

CD3029DF121 |

CD3029TF123 |

(354029 - ) |

|

|

CD3029DF122 |

(263024 - ) |

CD3029TF160 |

|

|

CD3029DF123 |

(312932 - ) |

CD3029TF161 |

(288419 - ) |

|

CD3029DF124 |

(340207 - ) |

CD3029TF162 |

|

|

CD3029DF128 |

CD3029TF163 |

(342829 - ) |

|

|

CD3029DF160 |

|||

|

CD3029DF161 |

(288417 - ) |

||

|

CD3029DF162 |

|||

|

CD3029DF163 |

|||

|

CD3029DF164 |

|||

|

CD3029DF165 |

|||

|

CD4039DF |

CD4039TF |

||

|

CD4039DF001 |

CD4039TF001 |

||

|

CD4039DF002 |

CD4039TF002 |

||

|

CD4039DF004 |

(152613 - ) |

CD4039TF003 |

(169516 - ) |

|

CD4039DF005 |

(165009 - ) |

CD4039TF004 |

(152616 - ) |

|

CD4039DF006 |

(340212 - ) |

CD4039TF005 |

|

|

CD4039DF007 |

(378895 - ) |

CD4039TF006 |

(339780 - ) |

|

CD4039DF008 |

CD4039TF007 |

(379066 - ) |

|

|

CD4039DF031 |

CD4039TF008 |

||

|

CD4039DF032 |

CD4039TF031 |

||

|

CD4039TF032 |

(166826 - ) |

||

|

CD4045DF001 |

CD4045TF001 |

||

|

CD4045DF031 |

CD4045TF002 |

(170081 - ) |

|

|

CD4045TF003 |

(342250 - ) |

||

|

CD4045TF008 |

|||

|

CD4045TF031 |

|||

|

CD6059DF |

CD6059TF |

||

|

CD6059DF001 |

CD6059TF001 |

||

|

CD6059DF002 |

CD6059TF002 |

(158390 - ) |

|

|

CD6059DF003 |

CD6059TF003 |

(158394 - ) |

|

|

CD6059TF004 |

|||

|

CD6059TF005 |

(166159 - ) |

||

|

CD6059TF006 |

(166960 - ) |

||

|

CD6059TF008 |

(341217 - ) |

||

|

CD6068DF001 |

CD6068TF001 |

||

|

CD6068TF002 |

(187378 - ) |

||

|

CD6068TF003 |

|||

|

CD6068TF004 |

(344260 - ) |

||

|

CD6068TF008 |

|||

|

CD6068TF009 |

ctm3274 - 3029, 4039, 4045, 6059, 6068 engines (saran) ( -499999cd)

Component Technical Manual

Table of Contents

Foreword

Engine Identification Views

Section MISC: Engine Application Chart

Group : Engine Application Chart

Engine Application Chart

Section : Safety

Group 00: Safety

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Wear Protective Clothing

Service Machines Safely

Work in Ventilated Area

Work in Clean Area

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Illuminate Work Area Safely

Use Proper Lifting Equipment

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Live With Safety

Group 01: General Information

Engine Identification

Engine Plate Information (Earlier Design)

Engine Plate Information (Later Design)

Repower Engine Plate

OEM Engine Option Code Label

Engine References

Basic Engine Specifications (3029 - 4039 & 6059)

Basic Engine Specifications (4045 & 6068)

Diesel Fuel

Diesel Engine Oil

Diesel Engine Coolant

Metric Bolt and Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values

Group 02: Engine Mounting

Engine Repair Stand

Safety Precautions

Engine Lifting Procedure

Clean Engine

Disconnect Turbocharger Oil Inlet Line

Group 03: Engine Rebuild Guide

Engine Disassembly Sequence

Sealant Application Guidelines

Engine Assembly Sequence

Group 05: Cylinder Head and Valves

Special or Essential Tools

Specifications

Torques for Hardware

Cylinder Head - Exploded View

Check Valve Lift

Removing Cylinder Head

Cleaning Injection Nozzle Bores

Valve Actuating Parts

Remove Valves and Valve Springs

Checking Cylinder Head Flatness

Cleaning Valve Seats

Cleaning Valve Guides

Measure Valve Guides

Lapping Valve Seats

Check Valve Recess

Remove Valve Seat Inserts

Valve Seat Insert Installation

Check Valves

Grind Valves

Check Valve Spring Tension

Inspect Valve Rotators

Install Valves

Install Cylinder Head

Torque Turn Tightening Method

Checking Rocker Arm Shaft

Install Rocker Arm Assembly

Valve Clearance

Valve Adjustment Sequence

Install Rocker Arm Cover

Final Work

Group 10: Cyl. Block, Liners, Pistons & Rods

Special or Essential Tools

Specifications

Torques for Hardware

Exploded View

Piston and Connecting Rod Removal

Cylinder Liner Bore Measure

Cylinder Liner Removal

Cylinder Liner Deglazing

Cylinder Block Cleaning

Checking Piston Cooling Jets

Cam Follower Bore Measure

Camshaft Bore Measure

Camshaft Bushing Replacement Tool

Remove Camshaft Bushing

Installing Camshaft Bushing

Crankshaft Bore Measure

Crankshaft Bearing Cap Replacement

Cylinder Block Top Desk Flatness

Balancer Shaft Bore Measure

Balancer Shaft Bushing Replacement

Oversize Balancer Shaft Bushing Installation

Cylinder Liner Protrusion Measure

Liner Packing Installation

Liner O-Ring Installation

Cylinder Liner Installation

Connecting Rod Bearing Measure

Rod Bearing Clearance

Connecting Rod Bushing

Connecting Rod Bushing Replacement (Straight Pin-End Conrod Except Small Pin)

Connecting Rod Bushing Replacement (Tapered Pin-End Conrod)

Measure Piston Pin

Piston Cleaning

Measure Piston Pin Bore

Piston Top Ring Groove

Second and Third Piston Ring Grooves

Piston Head and Skirt Checking

Piston Ring Identification

Install Piston Rings

Piston Rings Staggering

Piston/Liner Set Information

Piston and Connecting Rod Assembly

Piston and Connecting Rod Installation

Torque-Turn Method

Piston Protrusion Measure

Final Verifications

Complete Final Assembly

Group 15: Crankshaft, Main Bearings and Flywheel

Special or Essential Tools

Self-Manufactured Tool Puller for Crankshaft Pulley w/o Threaded Holes

Specifications

Torques for Hardware

Vibration Damper Checking (Engine Without Front PTO)

Pulley or Vibration Damper Removal

Pulley or Vibration Damper Installation

Vibration Damper or Pulley Checking (Engine With Front PTO)

Vibration Damper or Pulley Removal (Engine With Front PTO)

Vibration Damper or Pulley Installation (Engine With Front PTO)

Install Vibration Damper or Pulley (Engine With Crankshaft-Gear-Driven Aux. Drive)

Flywheel Removal

Flywheel Ring Gear Replacement

Ball Bearing Installation

Flywheel Installation

Crankshaft Wear Sleeve Removal

Flywheel Housing Replacement

Oil Seal/Wear Sleeve Installation

Crankshaft End Play Measure

Crankshaft Removal

Crankshaft Identification

Crankshaft Inspection

Journal OD Check

Main Bearing Clearance

Determine Crankshaft Main Bearing Clearance Using PLASTIGAGEPLASTIGAGE is a trademark of DANA Corp.

Crankshaft Regrinding

Crankshaft Regrinding Guidelines

Micro-Finishing Specifications

Crankshaft Gear Replacement

Main Bearing Inserts Installation

2-Piece Thrust Bearing Installation

5/6-Piece Thrust Bearing Installation Standard thrust washer sets for service contain now 4 thrust washers instead of 3 currently installed by the factory and previously included in service sets.

Crankshaft Installation

Group 20: Camshaft, Balancer Shafts and Timing Gear Train

Special or Essential Tools

Self-Manufactured Tool Template for Front Plate Replacement

Specifications

Auxiliary Gear Drive Specifications (37 kW)

Torques for Hardware

Timing Gear Backlash Measure

Camshaft End Play Measure

Removing Camshaft

Camshaft Journal Measure

Measure Height of Cam Lobe

Camshaft Gear Replacement

Tachometer Pick-Up Pin Removal

Fuel Supply Pump Rear Cam Installation

Install Camshaft

Cam Follower Checking

Balancer Shaft Identification (4-Cylinder Engines)

Balancer Shaft End Play Measure

Balancer Shaft Removal

Balancer Shaft Journal Measure

Balancer Shaft Gear Replacement

Install Balancer Shafts

Idler Gear End Play Measure

Remove Front Plate

Idler Gear Bushing and Shaft Measure

Idler Gear Bushing Replacement

Remove Idler Shaft

Spring Pin Installation (If Equipped)

Upper Idler Shaft Installation

Lower Idler Shaft Installation

Front Plate Gasket

Front Plate Installation

Upper Timing Gear Train Installation

Lower Timing Gear Train Installation

Auxiliary Drive Gear Installation (37 kW)

Oil Deflector Installation

Timing Gear Cover Identification

Install Composite Material Timing Gear Cover

Install Aluminum Timing Gear Cover

Installation of Timing Gear Cover for 37 kW Auxiliary Drive

Install Crankshaft Front Oil Seal

Install Wear Ring

Install Auxiliary Equipment Driven by Camshaft Gear (19 kW Aux. Drive)

Crankshaft-Gear-Driven Auxiliary Drive (37 kW)

Auxiliary Drive Gear Removal (37 kW)

Ball Bearing and Dowel Installation

Auxiliary Gear and Shaft Installation (37 kW)

Output Shaft Cover Installation

Group 25: Lubrication System

Special or Essential Tools

Specifications

Specifications - Machine Model

Torques for Hardware

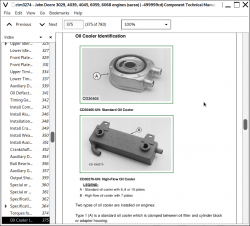

Oil Cooler Identification

Standard Oil Cooler Removal

Standard Oil Cooler Adapter Replacement

Standard Oil Cooler/Oil Filter Brackets Replacement

Replace Oil Filter Adapter On Engine With Remote Oil Filter

High-Flow Oil Cooler Removal

Oil Cooler Distributor Base Removal

Oil Cooler Distributor Base Repair

High-Flow Oil Cooler/Distributor Base Installation

Oil Pressure Regulating Valve Removal

Oil Pressure Regulating Valve Seat Replacement

Oil Pressure Regulating Valve Installation

Dipstick Guide Replacement

Oil By-Pass Valve Replacement

Oil Suction Screen Replacement (On Standard Oil Pump)

Oil Suction Screen Replacement (On High-Flow Oil Pump)

Oil Pump Identification

Standard Oil Pump Removal

Gear Axial Clearance (Standard Oil Pump)

Gear Radial Clearance (Standard Oil Pump)

Standard Oil Pump Specifications

Standard Oil Pump Installation

High-Flow Oil Pump Removal

Gear Axial Clearance (High-Flow Oil Pump)

Gear Radial Clearance (High-Flow Oil Pump)

High-Flow Oil Pump Specifications

High-Flow Oil Pump Installation

Oil Pan Installation

Group 30: Cooling System

Special or Essential Tools

Specifications

Torques for Hardware

Water Pump - Exploded View

Water Pump Identification

Water Pump Removal

Disassemble Water Pump (Standard Model)

Water Pump Bearing Shaft Installation

Water Pump Seal Installation

Water Pump Impeller Installation

Install Pulley or Hub

Install Water Pump

Water Pump With Rotating Assembly - Exploded View

Rotating Assembly Removal

Disassembling Rotating Assembly

Reassembling Rotating Assembly

Rotating Assembly Installation

Thermostat Test and Replacement

Cooling System Deaeration

Check Fan/Alternator Belt Tension

Install Fan

Install Engine Fan Pulley on 2054 and 2254 Combines (With CD6060HZ001 Engines)

Coolant Heater Operation (4 and 6 Cyl. Engines)

Replacing the Coolant Heater (4 and 6 Cyl. Engines)

Coolant Heater Operation (All Engines)

Group 35: Air Intake and Exhaust System

Specifications

Torques for Hardware

Intake Manifold Inspection

Exhaust Manifold Inspection

Turbocharger Removal

Radial Bearing End Play Check (GARRETT Turbocharger)

Check Radial Bearing Clearance (SCHWITZER Turbocharger)

Axial End Play Check

Turbocharger Repair

Turbocharger Disassembly

Turbocharger Reassembly

SCHWITZER Turbocharger Model S2A

Prelube Turbocharger

Turbocharger Installation

Turbocharger Break-In

Recommendations for Turbocharger Use

Group 40: Fuel System

Special or Essential Tools

Self-Manufactured Tool Template for Front Plate Replacement

Self-Manufactured Tool Example of Stationary Pointer for Dynamic Timing

Specifications

Specifications - Mannheim Tractors

Torques for Hardware

Rectangular Fuel Filter Element Replacement

Replace Round Fuel Filter Element

Replace Round Fuel Filter Assembly

Fuel Pump Replacement

Lucas CAV Fuel Injection Pump Removal

Repairs to Fuel Injection Pump

Lucas CAV Fuel Injection Pump Installation

Lucas CAV Fuel Injection Pump Static Timing

STANADYNE DB2 or DB4 Fuel Injection Pump Removal

Repairs to Fuel Injection Pump

Replace Throttle Lever (STANADYNE)

STANADYNE DB2 or DB4 Fuel Injection Pump Installation

STANADYNE DB2 or DB4 Fuel Injection Pump Static Timing

Engine Front Plate Replacement

STANADYNE DM4 Fuel Injection Pump Removal

Repairs to Fuel Injection Pump

STANADYNE DM4 Fuel Injection Pump Installation and Timing

Remove Fuel Supply Pump on MICO In-Line Fuel Injection Pump

Test MICO Fuel Supply Pump for Leaks

Disassemble MICO Fuel Supply Pump

Assemble MICO Fuel Supply Pump

Install Fuel Supply Pump On In-Line Fuel Injection Pump

Service Injection Pump Overflow Valve (In-Line Injection Pump)

Remove MICO In-Line Injection Pump

JDG670A Modification

Repair MICO In-Line Fuel Injection Pump

Install MICO In-Line Fuel Injection Pump

Dynamic Timing (All Pump Types)

Install Timing Sensor

Install Magnetic Probe (For Use Without Stroboscopic Lamp)

Install Stationary Pointer (For Use With Stroboscopic Lamp)

Timing Sensor and Magnetic Probe Connection

Dynamic Timing at Full Load Rated Speed Using Magnetic Probe

Dynamic Timing at No-Load

Aneroid Replacement

Aneroid Field Adjustment

Aneroid Workshop Adjustment

Fuel Injection Nozzle Removal

Clean Fuel Injection Nozzle

Fuel Injection Nozzle Test

Fuel Injection Nozzle Disassembly

Adjust Fuel Injection Nozzle

Install Fuel Injection Nozzle

Bleed the Fuel System at Fuel Filter

Bleed Fuel System (Lucas-CAV)

Bleed Fuel System (STANADYNE)

Bleed Fuel System (MICO In-Line Injection Pump)

Bleed Fuel System at Fuel Injection Nozzles

Adjust Engine Speed On Distributor Injection Pump

Adjust Engine Speed on MICO In-Line Injection Pump

Group 205: Engine System - Operation

Engine-Sectional View

General Information

Lubrication System

Cooling System (4-Cylinder Engine)

How the 37 kW Auxiliary Drive Works

Group 210: Engine System - Diagnosis and Tests

Special or Essential Tools

Specifications

Engine Break-In Instructions

Engine Break-In Oil

Diagnosing Engine Malfunctions

Checking Engine Compression

Checking Engine Oil Pressure

Measuring Engine Blow-By

Using STANADYNE “TIME-TRAC” as Tachometer

Inspect Thermostat and Test Opening Temperature

Group 215: Air Intake System - Operation and Tests

Special or Essential Tools

Specifications

Turbocharger Operation

Turbocharger Boost Pressure Check

Diagnosing Turbocharger Malfunctions

Air-to-Air Aftercooler Operation

Group 220: Fuel System - Operation and Tests

Fuel Filter Operation

Specifications

Fuel System Operation - Distributor Injection Pump

Fuel Transfer Pump Operation (Distributor Injection Pump)

Lucas CAV Fuel Injection Pump - Sectional View

Lucas CAV Fuel Injection Pump - Operation

Test Shut-Off Solenoid on Lucas-CAV Injection Pump

STANADYNE Fuel Injection Pump (Type DM4) - Sectional View

STANADYNE Fuel Injection Pump (DM4) - Operation

STANADYNE Fuel Injection Pump (Type DB2/DB4) - Sectional View

STANADYNE Fuel Injection Pump (DB2/DB4) - Operation

Specifications (In-Line Pump)

Fuel System Operation - In-Line Injection Pump (6 Cyl. Shown)

Fuel System Operation-In-Line Injection Pump

Fuel Transfer Pump Operation (In-Line Injection Pump)

Diagnose Fuel Supply Pump Malfunctions-In-Line Injection Pump

In-Line Fuel Injection Pump Operation

Governor Operation (In-Line Pump)

Diagnose In-Line Fuel Injection Pump Malfunctions

Fuel Injection Nozzles - General Information

Diagnosing Fuel System Malfunctions

Testing Fuel Injection Nozzles On a Running Engine

Timing of Fuel Injection Pumps On Diesel Engines Using Stroboscopic Lamp

John Deere 3029, 4039, 4045, 6059, 6068 Engines Component Technical Manual (CTM3274)