Case IH Tractors MXM Series (MXM120, MXM130, MXM140, MXM155, MXM175, MXM190) Repair Service Manual (6-66002)

Case IH Tractors MXM Series (MXM120, MXM130, MXM140, MXM155, MXM175, MXM190) Repair Service Manual (6-66002)

6-66002-01-2006 - Case IH Tractors MXM Series Service Manual (MXM120, MXM130, MXM140, MXM155, MXM175, MXM190).pdf

Complete service repair manual with Electrical Wiring Diagrams for Case IH Tractors MXM Series (MXM120, MXM130, MXM140, MXM155, MXM175, MXM190), with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Case IH Tractors MXM120, MXM130, MXM140, MXM155, MXM175, MXM190 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 7,523 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

1 GENERAL

General Instructions and Health and Safety

2 Section 1000

ENGINE

Separating and Removing The Engine

Section 2001

Torques . . . . 2

Special Tools . . . 3

Separating Front Axle and Front Support from Engine . . . . 4

Separating Engine and Front Support from Transmission . . . . 14

Engine Removal . . . 21

7.5L CNH Engine

Section 2002

Specifications . . . . 2

Greases and Sealants . . . 8

Tightening Torques . . . 10

Special Tools . . . . 12

Fault Finding . . . . 13 and Operation . . . 17

Engine Overhaul--Introduction . . . 24

Injection Pump Timing Check . . . . 25

Engine Disassembly and Overhaul:--

Cylinder Head, Valves and Related Parts . . . . 28

Hydraulic Tappets--Adjustment . . . 38

Front Cover and Timing Gears . . . 40

Oil Pan . . . 44

Flywheel . . . . 45

Rear Cover Plate . . . . 46

Oil Pump . . . . 47

Oil Pressure Relief Valve . . . . 49

Camshaft, Tappets and Camshaft Bearings . . . . 50

Pistons and Cylinder Block . . . . 53

Crankshaft . . . . 62

Crankshaft Front Seal Installation . . . . 66

Engine compression test . . . . 67

Cooling System of Operation . . . . 68

Troubleshooting . . . . 70

Specifications . . . 71

Overhaul . . . . 72

3

FUEL

Fuel System

Section 3001

Specifications . . . . 2

Torques . . . . 2

Special Tools . . . 3 and Operation . . . . 4

Bosch VE Type Mechanically Controlled Fuel Injection System -- Removal . . . 10

Bosch VE Type Pump Timing and Installation . . . 11

Bosch VP Electronically Controlled Fuel Injection System -- Removal . . . 15

Bosch VP Electronically Controlled Fuel Injection System -- Timing Check . . . 16

Injection System Bleeding . . . 19

Injection System Testing and Overhaul . . . . 20

Electric Lift Pump -- Removal . . . . 22

Electric Lift Pump -- Testing . . . . 22

Turbocharger -- Removal . . . . 23

Turbocharger -- Dissassembly . . . 25

Turbocharger -- Inspection -- Reassembly-- Installation . . . . 25

Air Cleaner -- Removal -- Overhaul . . . 28

Main Fuel Tank -- Removal and Installation . . . . 31

Auxiliary Fuel Tank -- Removal and Installation . . . 32

Crankcase Ventilation . . . . 32

Foot Throttle Cable -- Replacement and Adjustment . . . . 33

Hand Throttle Cable -- Replacement and Adjustment . . . . 33

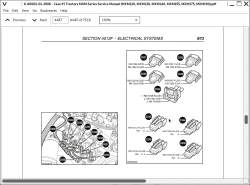

ELECTRICAL

Electrical Introduction

Section 4001

Electrical System and Fuses Description . . . 1

Fuses and Relays . . . 4

Controllers . . . . 10

Diagnostic Connectors . . . . 13

System Precautions For Battery Charging and Welding . . . 14

Temporary Wiring Repair . . . . 15

System Diagrams . . . . 17

Electronic Management Unit and Digital Instrument Cluster (175 &190 Models) . . 18

Central Controller (XCM) (175 & 190 Models) . . . 20

Secondary Controller (EDC and Transmission) (175 & 190 Models) . . . . 22

Engine Control Module (175 & 190 Models) . . . 24

Electro--Hydraulic Remote Valves (175 & 190 Models) . . . 26

Electronic Management Unit and Digital Instrument Cluster

Full Powershift (120 to 155 Models) . . . 28

Secondary Controller ( Full Powershift EDC and Transmission) (120 to 155 Models) . . . 30

General Control Module (GCM) (Full Powershift -- Front Suspension) (120 to 155 Models) . . . 32

Small Control Module (Vistronic Fan) (All 120 to 155 Models) . . . 34

Electronic Management Unit and Digital Instrument Cluster

Semi Powershift (120 to 155 Models) . . . . 36

General Control Module (GCM) (Semi Powershift -- EDC and Front Suspension)

(120 to 155 Models) . . . 36

Transmission Control Module (TCM) (Semi Powershift) (120 to 155 Models) . . . . 40

Electronic Management Unit (EMU)

Section 4002

Introduction . . . . 1

Worklamp Operation . . . 2

Functions controlled by the Electronic Management Unit . . . 2

Electronic Management Unit with Auto Difflock . . . . 3

Touch Panels t . . . . 5

Calibrations . . . . 6

Brake Switch Adjustment . . . 7

Removal and Installation . . . 7

Error Codes . . . . 8

Electronic Instrument Cluster

Section 4003

Introduction . . . . 2

Senders and Sensors . . . . 9

Programming Central LCD . . . . 21

Programming Performance Monitor . . . 23

Serviceability . . . . 25

Fault Codes . . . 26

Diagnostic Memory . . . 27

Instrument Panel Byte Level Set--up . . . . 28

Software Revision Level Check . . . . 29

Analogue Electronic Instrument Cluster

Section 4004A

Introduction . . . . 1

Senders and Sensors . . . . 5

Serviceability . . . 11

Analogue Electronic Instrument Cluster

Introduction . . . . 1

Senders and Sensors . . . . 4

Serviceability . . . 9

Starting System

Section 4005

Specifications . . . . 1

Tightening Torques . . . . 1 and Operation . . . . 2

Fault Finding . . . 4

System Testing . . . 5

Removal and Installation . . . 7

Overhaul . . . 8

Bench Tests . . . . 9

Charging System

Section 4006

Specifications . . . . 1

Tightening Torques . . . . 1 and Operation . . . . 2

Fault Finding . . . 4

Removal, Installation and Overhaul . . . 10

Battery

Section 4007

Specifications . . . . 1 and Operation . . . . 1

Removal and Installation . . . 2

Battery Maintenance and Testing . . . . 3

Battery Charging . . . . 4

Common Causes of Battery Failure . . . . 7

Wiring Diagrams

Section 4008

Wiring Diagram Circuit Descriptions (All Models) 1

How To Use The Linear Wiring Diagrams 2

Symbols 4

Component Identification and Wiring Diagram Location Key 5

Wiring Diagrams:

Full PowerShift Transmission 175 & 190 Models 13

Full PowerShift Transmission, 120 to 155 Models 73

Semi--PowerShift Transmission, 120 to 155 Models 133

Wire Identification Key 193

Fault Codes

Section 4009

Introduction . . . . 3

Special Tools . . . 4

Wiring Harness Repairs . . . 4

Digital Multi--Meter -- Basic Operation . . . 7

Electrical Test Procedures . . . 10

Circuit Components -- Basic Description . . . 13

Fault Code ’Logic’ and Display Areas . . . 24

Displaying and Clearing Fault Codes . . . . 31

Fault Code Lists . . . 37

Fault Code Charts 175 & 190 Models with Full Powershift Transmission

Full Powershift Transmission (’F’ codes) . . . . 77

Electronic Draft Control (No prefix) . . . . 291

Suspended Front Axle (’L’ codes) . . . 389

Power Take Off (’P’ codes) . . . 435

Electronic Management Unit (’P’ codes) . . . . 475

Digital Instrument Cluster (No prefix) . . . . 509

Electronic Hydraulic Remotes (’R’ & ’Flash’ codes) . . . . 541

Hand throttle and PTO Torque (’T’ codes) . . . . 673

Engine (’T’ codes) . . . 725

Full Powershift Transmission (’F’ codes) . . . 943

Fault Code Charts 120 to 155 Models with Full Powershift Transmission

Electronic Draft Control (No prefix) . . . 1119

Suspended Front Axle (’L’ codes) . . . . 1215

Electronic Management Unit (’P’ codes) . . . 1259

Digital Instrument Cluster (No prefix) . . . 1339

Fault Code Charts 120 to 155 Models with Semi Powershift Transmission

Semi Powershift Transmission (’F’ codes) . . . 1369

Electronic Draft Control (No prefix) . . . 1531

Suspended Front Axle (’L’ codes) . . . . 1625

Electronic Management Unit (’P’ codes) . . . 1669

Digital Instrument Cluster (No prefix) . . . 1749

Fault Code Charts 120 to 155 Models with 24 X 12 Transmission

Dual Command Transmission (’E’ codes) . . . . 1789

Electronic Draft Control (No prefix) . . . 1903

Electronic Management Unit (’P’ codes) . . . 1995

Digital Instrument Cluster (No prefix) . . . . 2075

Fault Code Charts 120 to 140 Models with 20 X 16 Transmission

Electronic Management Unit (’P’ codes) . . . 2105

Diagnostic ’H’ Routines

Section 4010

Introduction . . . . 2

Full Powershift Transmission “H” Routine . . . 3

Semi Powershift Transmission “H” Routine . . . . 18

24 X 12 Transmission “H” Routine . . . 36

Electronic Draft Control “H” Routine . . . . 51

Central Controller (XCM) 175 and 190 Models and Front Suspension 120 to 155 Models

H--Routines, includes the following systems:--

Front Suspension, Electronic Engine Control, Electro--Hydraulic Remotes

and Rear PTO . . . . 59

Connectors and Harnesses

Full Powershift 175 & 190 Models

Section 4011A

Wiring Harnesses . . . 2

Main Connectors . . . . 3

Wire Identification and Colour Coding . . . . 4

Lighting Harness . . . . 6

Front Main (Engine) Harness . . . . 10

Rear Main (Transmission) Harness, . . . . 16

Cab Main Harness, . . . 25

Electronic Right Hand Console . . .34

viContents Continued:

MAIN HARNESS CONNECTORS FROM SERIAL NUMBER ACM263461 ONWARDS

Main Connectors . . . 51

Front Main (Engine) Harness . . . . 52

Rear Main (Transmission) Harness, . . . . 54

Cab Main and Right Hand Console Harnesses, . . . . 56

Connectors and Harnesses

Full Powershift 120 to 155 Models

Section 4011B

Wiring Harnesses . . . 2

Main Connectors . . . . 3

Wire Identification and Colour Coding . . . . 4

Lighting Harness . . . . 6

Front Main (Engine) Harness . . . . 10

Rear Main (Transmission) Harness . . . 16

Cab Main Harness . . . 25

MAIN HARNESS CONNECTORS FROM SERIAL NUMBER ACM262719 ONWARDS

Main Connectors . . . 47

Front Main (Engine) Harness . . . . 48

Rear Main (Transmission) Harness . . . 50

Cab Main Harness . . . 52

Connectors and Harnesses

Semi--Powershift 120 to 155 Models

Section 4011C

Wiring Harnesses . . . 2

Main Connectors . . . . 3

Wire Identification and Colour Coding . . . . 4

Lighting Harness . . . . 6

Front Main (Engine) Harness . . . . 10

Rear Main (Transmission) Harness, . . . . 17

Cab Main Harness, . . . . 25

MAIN HARNESS CONNECTORS FROM SERIAL NUMBER ACM263458 ONWARDS

Main Connectors . . . 45

Front Main (Engine) Harness . . . . 46

Rear Main (Transmission) Harness, . . . . 48

Cab Main Harness, . . . . 50Contents Continued:

Connectors and Harnesses

24 X 12 120 to 140 Models

Section 4011D

Wiring Harnesses . . . 2

Main Connectors . . . . 3

Wire Identification and colour coding . . . 4

Lighting Harness . . . . 6

Front Main (Engine) Harness . . . . 10

Rear Main (Transmission) Harness, . . . . 17

Cab Main Harness . . . 25

MAIN HARNESS CONNECTORS FROM SERIAL NUMBER ACM262036 ONWARDS

Main Connectors . . . 45

Front Main (Engine) Harness . . . . 46

Rear Main (Transmission) Harness, . . . . 48

Cab Main Harness . . . 50

Calibration Procedures

Section 4012

Set Up Procedures . . . . 1

Full Powershift Transmission controller Configuration . . . . 2

Selectable Speed Shift Configuration . . . . 3

Calibration Error Codes (’U’ Codes) . . . . 4

24 x 12 Transmission -- Clutch and Synchroniser Calibration . . . . 7

Semi Powershift Transmission -- Clutch and Synchroniser Calibration . . . . 9

Full Powershift Transmission -- Clutch Calibrations . . . . 12

Full Powershift -- Automatic Clutch Calibration Procedure . . . . 14

Creeper Calibration . . . 14

Electronic Draft Control -- Calibration of Lift Lever/Arm Potentiometers . . . . 15

Electronic Draft Control -- Calibration of EDC Valve Solenoids . . . . 17

Electronic Management Unit -- Ground Speed/Steering Angle Calibration . . . . 20

Digital Instrument Cluster -- Ground Speed Calibration . . . . 21

With Radar / Less Radar connector Selection . . . 22

Engine Speed Sensor Calibration . . . . 23

Suspended Front Axle -- Suspended Front Axle Calibration . . . . 24

P.T.O. Calibration . . . . 25

Electro--Hydraulic Remote Valve Lever Calibration . . . . 26

Electro--Hydraulic Remote Valve Renumbering procedure . . . 27

viiiContents Continued:

Electrical Introduction

Semi Powershift Models from Serial No. ACM265009

Section 4013A

Electrical System and Fuses Description . . . 1

Fuses and Relays . . . 4

Controllers . . . 8

Diagnostic Connectors . . . . 10

System Precautions For Battery Charging and Welding . . . . 11

Temporary Wiring Repair . . . . 12

System Diagrams . . . . 15

Wiring Diagrams

Full Powershift (175-- 190 Models) from Serial No. ACM263461

Full Powershift (120-- 155 Models) from Serial No. ACM262719

Semi--Powershift Models from Serial No. ACM263458 to ACM265009

Power Shuttle (24x12) Models from Serial No. ACM262036

Mechanical Transmission Models from Serial No. ACM262853 Section 4013B

Wiring diagram circuit descriptions (All Models) 1

How to use the linear wiring diagrams 2

Symbols 4

Component identification and wiring diagram location key 5

Wiring Diagrams:

Full Power Shift Transmission, 175 to 190 Models

Full Power Shift Transmission, 120 to 155 Models

Semi Power Shift Transmission, 120 to 155 Models

Power Shuttle (24X12) Transmission, 120 to 140 Models

Mechanical Transmission, 120 to 140 Models 13

Wire identification key 313

Wiring Diagrams

Semi--Powershift Models from Serial No. ACM265009

Section 4013C

Wiring diagram circuit descriptions 1

How to use the linear wiring diagrams 2

Symbols 4

Component identification and wiring diagram location key 5

Wiring Diagrams:

Semi Power Shift Transmission, 120 to 155 Models xx

Wire identification key xx

ixContents Continued:

Electrical Harnesses

Semi--PowerShift Models From Serial No. ACM265009

Section 4013D

PROCESSOR REDUCTION CHANGE FROM SERIAL NUMBER ACM265009

Cab Main Harness, . . . 2

Right Hand Console Harness, . . . 14

Diagnostic ‘H’ Routines

Semi PowerShift Models from Serial No. ACM265009

Section 4013E

Introduction . . . . 2

Range Command Transmission (F -- --) ‘H’ Routine . . . . 5

Front Axle Suspension (L -- --) ‘H’ Routine . . . 23

Electronic Draft Control (EDC) (H -- --) ‘H’ Routine . . . . 33

Power Take Off (PTO) (P -- --) ‘H’Routine . . . . 45

Vistronic Fan (t -- --) ‘H’ Routine . . . . 53

Fault Codes

SECTION 4013F

Full Powershift (175--190 Models) from Serial No. ACM263461

Full Powershift (120--155 Models) from Serial No. ACM262719

Semi--Powershift Models from Serial No. ACM263458 to ACM265009

Power Shuttle (24x12) Models from Serial No. ACM262036

Mechanical Transmissions Models from Serial No. ACM262853 . . Refer to EST or RM CD

Fault Codes

SECTION 4013G

Semi--Powershift Models from Serial No. ACM265009 . . . . Refer to EST or RM CD

STEERING

Hydrostatic Steering Systems

SECTION 5001

Specifications . . . . 2

Tightening Torques . . . . 3

Special Tools . . . 3 and Operation . . . . 4

Fault Finding . . . . 12

System Testing . . . . 13

Steering Motor -- Removal and Installation . . . 15

Steering Motor Overhaul . . . . 17

Steering Column -- Removal and installation . . . 25

Two Wheel Drive Steering Cylinder -- Removal and Installation . . . . 27

Two Wheel Drive Steering Cylinder -- Overhaul . . . 28

Four Wheel Drive Steering Cylinder -- Removal and Installation . . . . 29

Four Wheel Drive Steering Cylinder -- Overhaul . . . . 30

xContents Continued:

Front Axle 2 Wheel Drive

Section 5002

Specifications . . . . 1

Tightening Torques . . . . 2

Special Tools . . . 3 and Operation . . . . 3

Troubleshooting . . . 3

Sectional Views . . . 4

Removal -- Installation -- Overhaul . . . 6

Front Wheel Camber and Toe--in . . . 18

POWER TRAIN

Clutch

Section 6001A

Specifications . . . . 1

Tightening Torques . . . . 2

Sectional Views . . . 3

Special Tools . . . 4 and Operation . . . . 4

Troubleshooting . . . 4

Clutch Removal--Installation . . . . 6

Hydraulic Control Assembly Removal--Installation . . . 8

Hydraulic Control Assembly Disassembly--Reassembly . . . . 10

Semi--Powershift Transmission

Section 6001B

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 5

Sectional Views . . . 9 and Operation . . . 12

Pressure Testing . . . 20

Calibration . . . . 24

Fault Finding . . . see Section 4009

Removal -- Installation -- Overhaul . . . . 27

xiContents Continued:

Full Powershift 30 and 40 kph Transmission,

120 -- 155 Models

Section 6002

Specifications . . . . 2

Tightening Torques . . . . 5

Special Tools . . . . 10

Transmission Cross Section . . . 13 and Operation and Power Flows . . . 16

Clutch Calibrations . . . 34

Pressure Testing . . . 39

Error Codes and Fault Finding . . . 42

Limp Home Tool . . . 46

Transmission Removal and Installation . . . . 47

Transmission Overhaul -- Disassembly . . . . 53

Transmission Overhaul -- Reassembly . . . . 78

Full Powershift Transmission, 175 - 190 Models

Section 6003

Specifications . . . . 2

Tightening Torques . . . . 5

Special Tools . . . 7 and Operation . . . 10

Power Flows . . . . 18

Input Sensors and Output Devices . . . 24

Controls . . . . 27

Clutch Calibration . . . . 40

Pressure Testing . . . 44

Error Codes and Fault Finding . . . 47

Limp Home . . . . 51

Transmission Housing -- Removal and Installation . . . . 52

Transmission Disassembly . . . . 59

Oil Manifold Bushes, Removal and Installation . . . 72

Transmission Upper Speed Shaft End Float Adjustment . . . 73

Clutch Overhaul . . . 74

Transmission Rear Housing -- Disassembly . . . . 86

Transmission Reassembly . . . 88

Output Shaft End Flow Adjustment . . . 96

Medium Shaft End Float Adjustment . . . . 97

24 X 12 Transmission, 120 -- 140 Models

Section 6003A

Specifications . . . . 1

Tightening Torques . . . . 4

Special Tools . . . 7

Sectional Views . . . . 10

xiiContents Continued: and Operation . . . 12

Clutch and Synchroniser Calibration . . . . 16

Pressure testing . . . 19

Error Codes and fault Finding . . . . 22

Limp Home . . . . 28

Transmission Removal and Installation . . . 29

Transmission Overhaul . . . 32

Shuttle Gear Bearing Adjustment . . . 46

Range Input and Output Shaft Bearing Adjustment . . . 48

Transmission Valve -- Overhaul . . . . 51

Transmission Control Assembly . . . . 54

20 X 16 Transmission, 120 -- 140 Models

Section 6003B

Specifications . . . . 2

Tightening Torques . . . . 4

Special Tools . . . 6

Sectional Views . . . . 10 and Operation . . . 14

Troubleshooting . . . . 14

Mechanical Transmission Housing Removal -- Installation . . . 15

Mechanical Transmission Housing Removal -- Overhaul . . . . 18

Mechanical Transmission Housing Adjustments . . . . 31

Mechanical Transmission Housing Removal -- Installation 5th Speed Gear . . . . 35

Speed and Range Control Rail Assembly Removal -- Installation . . . 40

Creeper Gears Removal -- Installation . . . . 42

Creeper Gears External Control Lever adjustment . . . . 43

Rear Axle, 120 -- 155 Models

Section 6004

Specifications . . . . 2

Tightening Torques . . . . 4

Special Tools . . . 6

Sectional Views . . . 9 and Operation . . . . 11

Fault Finding . . . . 14

Rear Axle Housing -- Removal and Installation . . . 16

Rear Axle Housing -- Overhaul . . . 21

Rear Axle Adjustments . . . 30

Pinion and Crown Wheel Adjustments . . . . 31

Hydraulic Pump Idler Gear Bearing Adjustment . . . . 37

Hydraulic Differential Lock -- Removal and Installation . . . 40

Hydraulic Differential Lock Control Unit -- Dog Type Clutch . . . . 44

Hydraulic Differential Lock Control Unit -- Multi Plate Clutch . . . 46

Final Drive Case -- Removal and Installation . . . 47

xiiiContents Continued:

Drive Wheel Shaft -- Removal and Installation . . . . 51

Rear Axle ,175-- 190 Models

Section 6005

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 5

Sectional Views . . . 7 and Operation . . . . 9

Troubleshooting . . . 11

Removal -- Installation -- Overhaul . . . 13

Rear Axle Adjustments . . . 28

Hydraulic Differential Lock Control . . . . 36

50KPH Clutch . . . 40

Drive Wheel Shaft -- Removal-- Installation . . . . 49

Mechanical Front Drive Electro-- Hydraulic Clutch

24 x12 and 20 X 16 Transmissions

Section 6006A

Specifications . . . .

Tightening Torques . . . .

Special Tools . . .

Sectional Views . . . and Operation . . . .

Troubleshooting . . .

Hydraulic Flow Diagrams . . .

Removal--Installation--Overhaul . . .

Mechanical Front Drive Electro-- Hydraulic Clutch

Semi--Powershift and Full Powershift Transmissions

Section 6006B

Specifications . . . .

Tightening Torques . . . .

Special Tools . . .

Sectional Views . . .

Troubleshooting . . . and Operation . . . .

Hydraulic Flow Diagrams . . .

Drive shaft Removal--Installation . . . .

Electro Hydraulic Clutch Removal--Installation--Overhaul . . .

Mechanical Front Axle

Section 6007

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 4

Sectional Views . . . 6

xivContents Continued: and Operation . . . . 7

Troubleshooting . . . . 10

Standard Axle -- Removal/Installation . . . . 11

Suspended Axle -- Removal/Installation . . . 14

Hub Cassette Seal Replacement . . . 19

Front Axle Overhaul -- All Options . . . . 23

Dog Clutch Differential Lock -- Disassembly/Reassembly . . . . 28

Multi Wet Plate Differential Lock -- Disassembly/Reassembly . . . 30

Crown Wheel/Differential -- Disassembly/Reassembly -- All Options . . . 32

Pinion Shaft Removal -- All Options . . . 33

Pinion Shaft Adjustment/Installation -- All Options . . . 36

Crown Wheel Adjustments -- All Options . . . . 44

Swivel Pin & Potentiometer -- Disassembly/Reassembly . . . 47

Axle Reassembly -- All Options . . . . 5

Checking the Alignment of Steering and Drive Wheels . . . 5

Refer to Brake Section Of Repair Manual For Overhaul Of Front Axle Brakes

Where Fitted . . .

Front Axle With Suspension System

Section 6008

Specifications . . . . 2

Tightening Torques . . . . 2 and Operation . . . . 3

System Schematics . . . 6

Suspended Front Axle Calibration Procedure . . . . 18

Error Code Listing . . . . 20

Suspended Front Axle Assembly--Removal and Installation . . . . 22

Suspension Cylinder Removal and Overhaul . . . 30

Suspension Control Valve Assembly--Removal . . . 34

Suspension Control Valve Assembly--Overhaul . . . 35

Rear Power Take--Off, 120--155 Models

Section 6009

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 3

Sectional Views . . . 4 and Operation . . . . 6

Hydraulic Flow Diagrams . . . 11

Fault Finding . . . . 14

Removal--Installation--Overhaul . . . . 16

Ground Speed Interlock Switch Adjustment . . . . 27

xvContents Continued:

Rear Power Take--Off, 175--190 Models

Section 6010

Specifications . . . . 2

Tightening Torques . . . . 4

Special Tools . . . 5

Sectional Views . . . 6 and Operation . . . . 8

Hydraulic Operation of Power Take Off (PTO) . . . . 12

Fault Finding . . . . 18

Removal--Installation--Overhaul . . . . 20

Calibration . . . . 29

Hydraulic Front Lift and Power Take Off

Section 6011

Specifications . . . . 2

Torques . . . . 2 and Operation

Front Hydraulic Lift. . . 3

Front P.T.O. . . 5

Fault Finding . . . . 10

Overhaul

Front Hydraulic Lift . . . . 11

Front P.T.O.. . . . 16

Hydraulic and Electrical Connections . . . 24

BRAKES

Tractor Brakes

Section 7001

Specifications . . . . 2

Special Tools . . . 3

Tightening Torques . . . . 5

Sectional Views . . . 5 and Operation . . . . 8

Operation, Power Brake Coloured Diagrams . . . 11

Fault Finding . . . . 15

Tasks Before Carrying Out Brake Overhaul . . . . 17

Removal--Installation--Overhaul, Service Brakes Models 120--155 . . . . 17

Removal--Installation--Overhaul, Service Brakes Models 175--190 . . . . 21

Removal--Installation--Overhaul, Front Brakes All Models . . . . 26

Removal--Installation, Service Brake Master Cylinder . . . 32

Pedal Adjustments, Service Brakes . . . 33

Removal--Installation, Front Brake Booster . . . . 35

Overhaul, Front Brake Booster . . . 37

Hydraulic Brake System, Air Bleeding . . . 38

xviContents Continued:

Removal--Installation--Overhaul, Parking Brake Assembly . . . 42

Handbrake Control--Travel Adjustment . . . . 46

Pneumatic Trailer Brakes

Section 7002

Specifications . . . . 1

Tightening Torques . . . . 2 and Operation . . . . 3

Fault Finding . . . . 13

Removal and Installation . . . . 15

Overhaul . . . . 20

Pressure Testing . . . 30

HYDRAULICS

Introduction

Section 8001

Introduction and Circuit Identification . . . 2

Variable Displacement Pump High Pressure Hydraulic Circuits . . . . 8

Fixed Displacement Pump High Pressure Hydraulic Circuits . . . 23

Low Pressure Hydraulic Circuits . . .

Tractors with Full Powershift Transmission -- 175 and 190 Models . . . 28

Tractors with Full Powershift Transmission -- 120 to 155 Models . . . . 35

Tractors with Semi Powershift Transmission . . . . 41

Tractors with 2 Speed Powershift Transmission . . . 47

Tractors with Synchroshift Transmission . . . 53

General Hydraulic Fault Finding . . . . 57

Initial Fault Finding Check . . . 57

Transmission Low Pressure Warning Light ‘ON’ . . . 58

Charge Pressure Light . . . . 59

Intake Filter Restriction Warning Light . . . 59

Power Steering . . . 60

Trailer Brakes . . . . 60

Hydraulic Lift . . . 61

Remote Control Valves . . . . 62

Variable Flow Hydraulic Pump Assembly

120 to 155 Models

Section 8002A

Special Tools . . . 3

Specifications . . . . 4

Tightening Torques . . . . 5 and Operation . . . 12

Hydraulic Circuit Operation . . . . 12

Low Pressure Standby . . . . 14

xviiContents Continued:

High Pressure Circuit High Demand . . . 16

High Pressure Circuit Low Demand . . . 17

Controlling Maximum System Pressure . . . . 18

Fault Finding . . . . 19

Initial Fault Finding Check . . . 19

Transmission Low Pressure Warning Light ‘ON’ . . . 21

Charge Pressure Light . . . . 23

Intake Filter Restriction Warning Light . . . 23

Power Steering . . . 24

Trailer Brakes . . . . 24

Hydraulic Lift . . . 25

Remote Control Valves . . . . 26

Pump Pressure and Flow Testing . . . 27

Low Pressure Standby . . . . 27

High Pressure Standby . . . . 28

Load Sensing Circuit Test . . . . 29

Charge Pressure Test . . . 29

Variable Flow Piston Pump Flow Test . . . 30

Steering Pump/Low Pressure Pump Test . . . . 31

Hydraulic Pump Leak Test . . . 32

Overhaul . . . . 33

Charge Pressure Valve . . . 34

Charge Pressure Filter Dump Valve . . . . 34

Steering Flow Control Valve . . . 35

Pressure and Flow Compensating Valve . . . . 36

Pump Removal and Installation . . . . 38

Steering Pump Overhaul . . . . 41

Charge Pump Overhaul . . . 43

Variable Flow Piston Pump Overhaul . . . 45

Pump Drive Gear and Bearing Overhaul . . . . 48

Fixed Displacement Gear Pump

Section 8002B

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 4

Sectional Views -- Description and Operation . . . 5

Troubleshooting . . . see 8004B

Removal -- Installation -- Overhaul . . . 6

xviiiContents Continued:

Variable Flow Hydraulic Pump Assembly

175 to 190 Models

Section 8003

Special Tools . . . 2

Specifications . . . . 3

Tightening Torques . . . . 4 and Operation . . . . 6

Hydraulic Circuit Operation . . . . 14

Generating Low Pressure Standby . . . . 16

Regulating Low Pressure Standby . . . . 18

High Pressure Circuit High Demand . . . 20

High Pressure Circuit Low Demand . . . 22

Limiting Maximum System Pressure . . . . 24

Low Pressure Regulating valve operation . . . . 26

Fault Finding . . . . 29

Initial Fault Finding Check . . . 29

Transmission Low Pressure Warning Light ‘ON’ . . . 30

Charge Pressure Light . . . . 31

Intake Filter Restriction Warning Light . . . 31

Power Steering . . . 32

Trailer Brakes . . . . 32

Hydraulic Lift . . . 33

Remote Control Valves . . . . 34

Pump Pressure and Flow Testing . . . 36

Low Pressure Standby . . . . 36

High Pressure Standby . . . . 37

Load Sensing Circuit Test . . . . 38

Charge Pressure Test . . . 38

Variable Flow Piston Pump Flow Test . . . 39

Steering Pump/Low Pressure Pump Test . . . . 40

Hydraulic Pump Leak Test . . . 41

Overhaul . . . . 42

Steering Pump Overhaul . . . . 43

Steering Flow Control Valve . . . 45

Pressure and Flow Compensating Valve . . . . 46

Pump Removal and Installation . . . . 48

Charge Pump Overhaul . . . 52

Variable Flow Piston Pump Overhaul . . . 54

Hydraulic Lift Assembly with Electronic Draft Control

Section 8004A

Specifications . . . . 2

Special Tools . . . 2

Tightening Torques . . . . 3 and Operation . . . . 4

xixContents Continued:

Principal of Draft Control . . . 4

Components . . . 7

Operation of Draft Control . . . . 13

Hydraulic Operation of Lift Control Valve . . . . 16

Trouble Shooting and Calibration . . . 24

Overhaul

Electronic Draft Control Valve -- Removal and Installation . . . 33

Disassembly . . . . 35

Load Sensing Pin Replacement . . . 40

Hydraulic Lift Cover -- Removal and Installation (120 to 155 Models Only)

Disassembly . . . . 44

Hydraulic Lift Assembly with Mechanical Draft Control

Section 8004B

Specifications . . . . 1

Tightening Torques . . . . 3

Special Tools . . . 5

Sectional Views . . . 6 and Operation . . . . 9

Troubleshooting . . . . 13

Removal -- Installation -- Overhaul . . . 15

Hydraulically Adjustable Right Hand Lift

and Top Link Cylinders

Section 8005

Specifications . . . . 1

Sectional Views . . . 2

Tightening Torques . . . . 3 and Operation . . . . 4

Removal -- Installation -- Overhaul . . . 5

Closed Centre Remote Control Valves

Section 8006

Special Tools . . . 2

Specifications . . . . 2

Tightening Torques . . . . 2

Fault Finding and Pressure Testing Mechanical Remote Valves . . . . 3

Fault Finding and Pressure Testing Electro--Hydraulic Remote Valves . . . . 4

Electro--Hydraulic Remote Valve Fault Code list . . . 6 and Operation -- Mechanical Remote Valves . . . . 7

Oil Flow In Neutral . . . 12

Oil Flow in Raising (Cylinder Extend) . . . 14

Oil Flow in Lowering (Cylinder Retract) . . . . 16

Oil Flow in Float . . . 18

xxContents Continued:

Operation of Detent Pressure Regulating Valve . . . . 20

Operation of Two or More Control Valves Simultaneously . . . . 23 and Operation -- Electro--Hydraulic Remote Valves . . . 25

Re--Calibrating Remote Valve Levers . . . 34

Oil Flow In Neutral . . . 40

Oil Flow in Raising (Cylinder Extend) . . . 42

Oil Flow in Lowering (Cylinder Retract) . . . . 44

Oil Flow in Float . . . 46

Operation of Two or More Control Valves Simultaneously . . . . 49

Overhaul -- Mechanical Remote Valves . . . 51

Individual Valve Section Removal . . . . 51

Complete Valve Stack Removal . . . . 53

Remote Valve Disassembly . . . . 55

Overhaul -- Electro--Hydraulic Remote Valves . . . . 61

Electro--Hydraulic Remote Valves Number Programming . . . . 62

Electro--Hydraulic Remote Valves Removal and Installation . . . . 64

Electro--Hydraulic Remote Valve Disassembly . . . 68

Open Centre Remote Control Valves

Section 8006B

Specifications --Tightening Torques..... 1

Special Tools . . . 2

Sectional Views . . . 3 and Operation . . . . 6

Removal -- Installation -- Overhaul . . . 11

Trailer Brake Valves

Section 8007

Specifications . . . . 2

Torques . . . . 2

Special Tools . . . 2 and Operation . . . . 3

Italian Trailer Brakes . . . . 10

Pressure Testing . . . 17

External Lift Rams

Section 8008

120 TO 155 MODELS

Specifications . . . . 2

Sectional Views . . . 2 and Operation . . . . 3

xxiContents Continued:

Removal -- Installation -- Overhaul . . . 3

Disassembly -- Reassembly . . . . 3

175 AND 190 MODELS

Specifications . . . . 4

Sectional Views . . . 4 and Operation . . . . 5

Removal -- Installation -- Overhaul . . . 5

Disassembly -- Reassembly . . . . 6

Hydraulic Pressure Testing

Section 8009

Introduction . . . . 3

Special Tools . . . 4

Specifications . . . . 5

Variable Displacement Hydraulic Pump Installation . . . . 6

Fault Finding . . . 8

Transmission Low Pressure Warning Light On . . . . 9

Charge Pressure Light Flashing . . . 11

Intake Filter Restriction Light On . . . . 11

Power Steering Not Working Correctly . . . . 12

Trailer Brakes Not Working Correctly . . . 13

Hydraulic Lift Not Working Correctly . . . . 14

Remote Control Valves Not Working . . . . 16

Pump Pressure and Flow Testing . . . 18

Low Pressure Standby . . . . 18

High Pressure Standby . . . 19

Lift Ram Pressure Test . . . . 20

Load Sensing Circuit Test . . . 21

Charge Pressure Test . . . . 22

Variable Flow Piston Pump Flow Test . . . 23

Hydraulic Pump Leak Test . . . . 24

Steering Pump/Low Pressure Pump Test . . . . 25

Steering Test . . . . 25

Steering Circuit Pressure Test . . . 25

Steering Relief Valve Pressure Test . . . 26

Low Pressure Test . . . 26

Full Powershift Transmission Clutch Pressure Test . . . 29

Semi--Powershift Transmission Clutch Pressure Test . . . . 35

Trailer Brake Testing and Troubleshooting . . . 36

Trailer Brake Valve Electro--Hydraulic Operation Diagram (Italy Only) . . . 36

Trailer Brake Disengagement Pressure Test (Italy Only) . . . 37

Trailer Brake System Pressure Test . . . . 38

Trailer Brake System Leak Test . . . . 38

Trailer Brake Engagement Test (Italy Only) . . . . 39

Trailer Brake Circuit Safety Switch Test . . . 39

xxiiContents Continued:

Cooler By--pass Valve -- Lubrication Pressure . . . . 40

PTO Clutch lubrication (175 and 190 Models) . . . . 40

Brake Booster Valve Pressure Test . . . 40

Power Brake Supply and Accumulator Test (175 and 190 Models) . . . . 41

Mid Mount Remote Valves

Section 8013

Specifications . . . . 2

Torque Values . . . . 3 and Operation . . . . 4

Mid Mount Valve Hydraulic Circuit 120 -- 155 Models . . . . 9

Mid Mount Valve Hydraulic Circuit 175 -- 190 Models . . . . 11

Mid Mount Valve Removal . . . . 15

Mid Mount Valve Disassembly . . . 15

Mid Mount Valve Overhaul . . . . 17

Mid Mount Valve Installation . . . 20

Third Mid Mount Valve -- Description and Operation . . . 21

Removal . . . . 23

Disassembly . . . . 23

Reassembly . . . . 24

CAB

Cab Removal

Section 9001

Torques . . . . 2

Special Tools . . . 2

Cab Removal and Installation . . . 3

Suspension Adjustment . . . . 11

Air Conditioning

Section 9002

Specifications . . . . 2

Tightening Torques . . . . 2

Special Tools . . . 2

Safety Precautions . . . . 2 and Operation . . . . 4

Fault Finding and System Testing . . . . 15

Leak Testing, Charging, Discharging and System Flushing . . . 32

Component Overhaul (excluding compressor) . . . . 37

Compressor Removal and Installation . . . 44

Compressor Overhaul . . . . 44

...