Komatsu Dump Trucks 830E Operation & Maintenance Manuals

Komatsu Dump Trucks 830E Operation & Maintenance Manuals

Complete operator's manual for Komatsu Dump Trucks 830E, with all the shop information to maintain & operate the trucks.

Total Pages: 5,305 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM006200 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM010400 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM010600 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM011500 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM013204 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM013400 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM015001 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM015201 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM016303 - Dump Truck 830E-AC Operation & Maintenance Manual.pdf

CEAM016800 - Dump Truck 830E Operation & Maintenance Manual.pdf

CEAM018802 - Dump Truck 830E-AC Operation & Maintenance Manual.pdf

CEAM018903 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM019102 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM019302 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM019903 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM020101 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM020801 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM021501 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM022303 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM024100 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM024403 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM025001 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM026901 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEAM027001 - Dump Truck 830E-1AC Operation & Maintenance Manual.pdf

CEBM010501 - Dump Truck 830E Operation & Maintenance Manual.pdf

DG621 - Dump Truck 830E Operator Handbook.pdf

DG723 - Dump Truck 830E Operation & Maintenance Manual.pdf

TABLE OF CONTENTS

INTRODUCTION ___________________________________________________________________ SECTION 1

Foreword . . . 1-1

ALERTS Page - a description of the DANGER, WARNING, and CAUTION symbols used in this manual. . . 1-2

TABLE OF CONTENTS . . . 1-3

Truck Model Illustration . . . 1-6

About This Manual . . . 1-7

STANDARD CHARTS and TABLES. . . 1-9

SAFETY _________________________________________________________________________ SECTION 2

Safety records of most organizations will show that the greatest percentage of accidents are caused by unsafe acts

of persons. The remainder are caused by unsafe mechanical or physical conditions. Report all unsafe conditions to

the proper authority. These safety rules are provided as a guide for the operator. However, local conditions and

regulations may add many more to this list.

GENERAL SAFETY . . . 2-1

PRECAUTIONS DURING OPERATION . . . 2-5

Operating The Machine . . . 2-6

Towing . . . 2-9

Battery . . . 2-10

PRECAUTIONS FOR MAINTENANCE . . . 2-11

Before Carrying Out Maintenance . . . 2-11

During Maintenance . . . 2-12

Tires . . . 2-15

Additional Job Site Rules . . . 2-16

WHEN REPAIRS ARE NECESSARY . . . 2-17

WARNING, CAUTION, and Instruction Plates / Decals . . . 2-19 thru 2-26

OPERATION _____________________________________________________________________ SECTION 3

This portion of the manual covers Identification, location, and operation of the controls, switches, and indicators in

the Operator’s Cab and use / function of these controls, switches, and indicators.

OPERATING INSTRUCTIONS

Preparing For Operation . . . 3-1

Safety Is Thinking Ahead . . . 3-1

At The Truck - Ground Level Walk-Around Inspection . . . 3-1

Walk-Around Inspection - Illustration . . . 3-2

ENGINE START-UP SAFETY PRACTICES . . . 3-4

AFTER ENGINE HAS STARTED . . . 3-5

MACHINE OPERATION SAFETY PRECAUTIONS . . . 3-5

LOADING . . . 3-6

HAULING . . . 3-6

PASSING . . . 3-6

DUMPING . . . 3-7

OPERATION (Continued) ___________________________________________________________ SECTION 3

TOWING . . .3-8

SUDDEN LOSS OF ENGINE POWER . . .3-9

SAFE PARKING PROCEDURES . . .3-9

ENGINE SHUTDOWN PROCEDURE . . .3-9

DELAYED ENGINE SHUTDOWN PROCEDURE . . .3-10

RESERVE ENGINE OIL SYSTEM . . . 3-11

OPERATOR CAB and CONTROLS . . .3-13

STEERING WHEEL AND CONTROLS. . .3-14

SERVICE BRAKE PEDAL. . .3-15

DYNAMIC RETARDER PEDAL. . .3-15

THROTTLE PEDAL. . .3-15

HEATER / AIR CONDITIONER VENTS . . .3-15

HEATER / AIR CONDITIONER COMPARTMENT AND CONTROLS. . .3-16

CENTER CONSOLE . . .3-18

INSTRUMENT PANEL AND INDICATOR LIGHTS . . .3-22

Control Symbols . . .3-22

INSTRUMENT PANEL (Figure 3-6) . . .3-23

PANEL GAUGES, INDICATORS, AND CONTROLS (Discussion of items 1 - 28, Figure 3-6) . . .3-24

OVERHEAD STATUS / WARNING INDICATOR LIGHT PANEL (Figure 3-7) . . .3-29

INDICATOR LIGHT SYMBOLS - Refer to Figure 3-7 by rows (A-E) and columns (1 - 6). . .3-30

Hazard Warning Lights (7) . . .3-34

Lamp Test Switch (8) . . .3-34

OPERATOR SEAT . . .3-35

MAINTENANCE __________________________________________________________________ SECTION 4

This portion of the manual pertains mainly to the periodic Lubrication and Service required to keep the truck oper-

ating at its design potential. Routine lubrication and maintenance procedures are provided in this section. For

major repairs, refer to the appropriate section in the Truck Shop Manual. Refer to the engine manufacturer’s ser-

vice manual when servicing the engine.

LUBRICATION AND SERVICE . . .4-1

Hydraulic Tank . . .4-1

Coolant Level Check . . .4-2

Reserve Engine Oil System . . .4-2

Lubrication Chart . . .4-3

10 HOUR (DAILY) Lubrication And Maintenance Checks . . .4-4

50 HOUR Lubrication And Maintenance Checks . . .4-6

100 HOUR Lubrication And Maintenance Checks . . .4-7

250 HOUR Lubrication And Maintenance Checks . . .4-8

500 HOUR Lubrication And Maintenance Checks . . .4-10

1000 HOUR Lubrication And Maintenance Checks . . . 4-11

MAINTENANCE (Continued) ________________________________________________________ SECTION 4

2500 HOUR Lubrication And Maintenance Checks . . . 4-12

5000 HOUR Lubrication And Maintenance Checks . . . 4-12

10000 HOUR Lubrication And Maintenance Checks . . . 4-12

LINCOLN AUTOMATIC LUBRICATION SYSTEM . . . 4-13

General Description . . . 4-13

System Components . . . 4-15

System Operation . . . 4-16

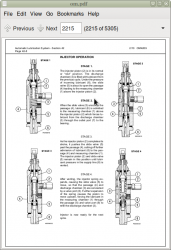

Injector Operation . . . 4-18

General Instructions . . . 4-19

Lubricant Required . . . 4-19

System Priming . . . 4-19

Filter Assembly . . . 4-19

Lubricant Pump . . . 4-20

System Checkout . . . 4-22

Lubrication Cycle Timer Check . . . 4-22

System Troubleshooting Chart . . . 4-23

Preventative Maintenance Procedures. . . 4-25

SPECIFICATIONS __________________________________________________________________ SECTION 5

This portion of the manual covers major component descriptions and truck specifications.

Major Component Description . . . 5-1

Specifications . . . 5-3

OPTIONAL EQUIPMENT ____________________________________________________________ SECTION 6

This portion of the manual covers operation/maintenance of OPTIONAL EQUIPMENT.

PAYLOAD METER III INDEX . . . 6-1

CAB RADIO (AM/FM STEREO CASSETTE) . . . 7-1