Liebherr Diesel Engine D 934 A6 / D 936 A6 Repair Service Manual

Complete service repair manual with electrical wiring diagrams for Liebherr Diesel Engine D 934 A6 / D 936 A6 / D934S / L D936 L, with technical information to maintain, diagnose, repair, and service like professional mechanics.

Liebherr Diesel Engine D 934 A6 / D 936 A6 workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

10116428 - Workhsop Manual Liebherr Diesel Engine D 934 A6/D 936 A6.pdf

10301429 (09.2006) - Liebherr Diesel Engine D934S / L D936 L Service Manual.pdf

PRODUCT DETAILS:

Total Pages: 298 + 179 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

General information .. 1-11

1.1 Structure of this manual.. 1-14

1.2 Important notes within this manual .. 1-16

1.3 Symbols in this manual.. 1-17

1.4 Notes on safety.. 1-18

1.4.1 General notes on safety .. 1-18

1.4.2 Modifications to the diesel engine .. 1-19

1.4.3 Preventing injury to persons.. 1-19

1.4.4 Preventing damage to property .. 1-20

Technical Data.. 1-22

1.5.1 Engine in general .. 1-22

1.5.2 Standard tightening torques for screw connections .. 1-27

1.5.3 Standard torques for locking screws and banjo bolts.. 1-28

1.5.4 Special torques, tightening specifications and installation specifications.. 1-29

General notes.. 1-29

Tightening specification main bearing .. 1-29

Tightening specifications for piston cooling nozzle .. 1-29

Tightening specification for final regulating valve.. 1-30

Tightening specification oil drain valve.. 1-30

Tightening specification crankshafts accessories .. 1-31

Tightening specification connecting rod .. 1-32

Tightening specification cylinder head .. 1-32

Installation and tightening specification counterbalancing shafts (D 934).. 1-33

Tightening specification for camshaft sprocket on aggregate carrier and flywheel side.. 1-34

Tightening specification fitting in oil filter bracket .. 1-34

Tightening specification injection pump .. 1-35

Tightening specification cable harness on injection pump .. 1-35

Installation and tightening specification injection nozzle and pressure pipe tube .. 1-36

Tightening specification for nozzle retaining nut .. 1-37

Installation and tightening specification injection line .. 1-38

Tightening specification for sensoric .. 1-39

Installation and tightening specification speed sensor (camshaft sprocket) .. 1-40

Tightening specification heater flange.. 1-40

Tightening specification idler .. 1-41

Tightening specification air compressor gear.. 1-41

Tightening specification for coolant pump connector .. 1-41

Tightening specification turbocharger and flange on turbocharger .. 1-42

Tightening specification generator belt pulley .. 1-43

Tightening specification flywheel housing .. 1-43

Tightening specification flywheel.. 1-44

Tightening specification torsional vibration damper .. 1-45

Tightening specification for engine control unit plug .. 1-45

Tightening specification control unit-mount .. 1-45

Tightening specification power take-off .. 1-46

Cleaning agents, thread-locking adhesives and greases .. 1-47

Representations of the engine and engine components .. 1-48

1.6.1 View of the engine (aggregate carrier side and turbocharger side).. 1-48

1.6.2 View of the engine (flywheel side and injection system side).. 1-50

1.6.3 Engine cross-section .. 1-52

1.6.4 Crankshaft drive .. 1-53

1.6.5 Gear train (D 934).. 1-55

1.6.6 Gear train (D 936).. 1-56

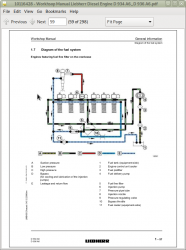

1.7 Diagram of the fuel system .. 1-57

1.8 Diagram of lube oil system .. 1-59

1.9 Diagram of coolant system .. 1-60

1.10 Allocation of ducts in the crankcase and in the cylinder head .. 1-62

1.11 Tools .. 1-63

Special tools .. 1-63

Fastening the engine onto the engine assembly stand .. 1-63

Fastening of lifting eyes on the crankcase .. 1-66

Turning gears .. 1-67

Angle of rotation devices .. 1-70

Checking excess length of the cylinder liners .. 1-73

Installing and dismantling crankshaft accessories .. 1-74

Installing and dismantling the front crankshaft seal.. 1-74

Installing and dismantling the crankshaft .. 1-74

Checking combustion pressure .. 1-74

Installing and dismantling the piston with connecting rod and piston rings .. 1-75

Installing and dismantling the piston rings.. 1-75

Installing and dismantling the cylinder head.. 1-75

Installing and dismantling valve stem seals, valve springs and valves .. 1-75

Installing and dismantling the counterbalancing shafts .. 1-77

Installing and dismantling the oil cooler housing with oil cooler .. 1-77

Installing and dismantling the injection lines .. 1-77

Installing and dismantling the pressure pipe tube and injection nozzle.. 1-78

Checking, dismantling and reassembling the injection nozzle (step-type holder) .. 1-78

Installing and dismantling the injection pump and roller tappet .. 1-78

Installing and dismantling the exhaust pipes .. 1-79

Installing and dismantling the flywheel .. 1-79

Installing and dismantling the rear crankshaft seal .. 1-79

Commercially-approved tools.. 1-80

Installing and dismantling the final regulating valve .. 1-80

Checking, dismantling and reassembling the injection nozzle (step-type holder) .. 1-80

Cylinder head, engine control and valves .. 2-81

2.1 Installing and dismantling the rocker arm support and push rods .. 2-82

2.2 Installing and dismantling the valve fitting (for engines with and without ZBS) .. 2-83

2.3 Installing and dismantling the cylinder head.. 2-84

2.4 Installing and dismantling valve stem seals, valve springs and valves .. 2-86

2.4.1 Removing .. 2-88

2.4.2 Installation .. 2-88

2.5 Installing and dismantling the roller tappet (valve control).. 2-90

2.6 Dismantling and installing the camshafts .. 2-91

2.6.1 Removing .. 2-92

2.6.2 Installation .. 2-93

Engine .. 3-95

3.1 Checking combustion pressure .. 3-97

3.2 Installing and dismantling the piston with connecting rod and piston rings .. 3-100

3.2.1 Summary .. 3-100

3.2.2 A: Installing and dismantling the piston with connecting rod from the engine .. 3-101

Removing .. 3-102

Installation .. 3-105

B: installing and dismantling the piston rings .. 3-107

Removing .. 3-108

Installation .. 3-108

C: installing and dismantling the piston .. 3-109

3.3 Installing and dismantling the cylinder liner .. 3-110

3.4 Checking excess length of the cylinder liners.. 3-112

3.5 Installing and dismantling the generator mount .. 3-113

3.6 Installing and dismantling the air-conditioning compressor and generator mount.. 3-115

3.7 Installing and dismantling crankshaft accessories.. 3-117

3.8 Installing and dismantling the front crankshaft seal .. 3-119

3.8.1 General notes.. 3-120

3.8.2 Removing .. 3-120

Installation .. 3-121

Installing and dismantling the aggregate carrier .. 3-125

3.10 Installing and dismantling the flywheel .. 3-127

3.10.1 Removing .. 3-130

3.10.2 Installation .. 3-130

3.11 Installing and dismantling the rear crankshaft seal.. 3-133

3.11.1 General notes .. 3-134

3.11.2 Removing .. 3-134

3.11.3 Installation .. 3-135

3.12 Dismantling and installing the flywheel housing .. 3-138

3.13 Dismantling and installing the idler .. 3-140

3.14 Installing and dismantling the crankshaft .. 3-142

3.14.1 Removing .. 3-145

3.14.2 Installation .. 3-148

3.15 Installing and dismantling the crankshaft gear wheel .. 3-151

4.1 Notes regarding working on the fuel system and injection system .. 4-154

4.2 Installing and dismantling fuel lines .. 4-155

4.3 Installing and dismantling the fuel prefilter with bracket .. 4-162

4.4 Installing and dismantling the fuel fine filter with bracket .. 4-163

4.5 Installing and dismantling the fuel multiplier .. 4-165

4.6 Installing and dismantling the fuel delivery pump .. 4-166

4.7 Installing and dismantling the injection lines.. 4-167

4.7.1 Removing .. 4-168

4.7.2 Installation .. 4-169

Installing and dismantling the pressure pipe tube and injection nozzle .. 4-170

4.8.1 Removing .. 4-171

4.8.2 Installation .. 4-172

Checking, dismantling and reassembling the injection nozzle (step-type holder).. 4-174

Check the injection nozzle.. 4-177

Check the opening pressure .. 4-178

Adjusting the opening pressure .. 4-178

Spray formation test and buzz test .. 4-180

Checking for leaks .. 4-180

Dismantling and reassembling the injection nozzle.. 4-181

4.10 Draining the fuel ducts in the crankcase.. 4-184

4.11 Installing and dismantling the injection pump and roller tappet .. 4-189

4.11.1 Removing .. 4-191

4.11.2 Installation .. 4-191

Belt drive .. 5-195

5.1 Installing and dismantling the ribbed V-belt tensioning device .. 5-196

5.2 Installing and dismantling the ribbed V-belt deflection pulley .. 5-197

Charge air and exhaust system .. 6-199

6.1 Installing and dismantling the air induction pipe .. 6-200

6.2 Installing and dismantling the connecting line (turbocharger - intercooler) .. 6-201

6.3 Installing and dismantling the exhaust pipes .. 6-205

6.4 Installing and dismantling the engine brake .. 6-207

6.5 Installing and dismantling the intake manifold .. 6-208

6.6 Installing and dismantling the adapter .. 6-209

6.7 Installing and dismantling the exhaust stack .. 6-210

6.8 Installing and dismantling the flange .. 6-211

6.9 Installing and dismantling the thermal protection plate on the exhaust pipe .. 6-212

6.10 Installing and dismantling the thermal protection plate on the turbocharger .. 6-213

6.11 Installing and dismantling the turbocharger .. 6-214

6.12 Checking axial clearance and radial clearance of the turbocharger .. 6-216

Electrical system .. 7-217

7.1 Installing and dismantling the heater flange .. 7-218

7.2 Installing and dismantling the generator .. 7-220

7.3 Installing and dismantling the generator belt pulley.. 7-221

7.4 Installing and dismantling the starter .. 7-223

7.5 Installing and dismantling the sensors.. 7-224

7.6 Installing and dismantling the engine control unit .. 7-226

7.7 Installing and dismantling the engine control unit-mount.. 7-228

Lubrication system .. 8-233

8.1 Installing and dismantling the crankcase breather .. 8-234

8.2 Installing and dismantling the oil return-flow line (crankcase breather) .. 8-236

8.3 Installing and dismantling the oil dipstick and guide tube .. 8-237

8.4 Installing and dismantling the oil intake .. 8-238

8.5 Installing and dismantling the multi-part oil sump and ladder frame (D 936) .. 8-240

8.6 Installing and dismantling the single-unit oil sump.. 8-246

8.7 Installing and dismantling the connector (oil sump - crankcase) (D 934) .. 8-250

8.8 Installing and dismantling the oil suction pipe (D 936).. 8-251

8.9 Installing and dismantling the ladder frame .. 8-252

8.10 Installing and dismantling the oil cooler housing with oil cooler.. 8-253

8.11 Dismantling and installing the oil pressure pump .. 8-255

8.12 Installing and dismantling the oil suction pump (D 936) .. 8-257

8.13 Installing and dismantling the piston cooling nozzle .. 8-258

8.14 Dismantling and installing the sealing parts of the oil suction pump.. 8-260

8.15 Installing and dismantling the final regulating valve.. 8-261

8.16 Check the oil pressure, adjust as necessary .. 8-264

Cooling system .. 9-267

9.1 Installing and dismantling the coolant vent line .. 9-268

9.2 Installing and dismantling the coolant pump .. 9-269

9.3 Installing and dismantling the coolant manifold (on the thermostat housing or aggregate carrier) .. 9-271

9.4 Installing and dismantling the thermostat housing and thermostat .. 9-273

9.5 Checking the thermostat .. 9-274

Power take-off and air / air-conditioning compressor .. 10-277

10.1 Installing and dismantling the power take-off for fuel delivery pump .. 10-278

10.2 Dismantling and removing power take-off 1 .. 10-279

10.3 Dismantling and removing power take-off 2 .. 10-281

10.4 Dismantling and removing power take-off 3 .. 10-282

10.6 Installing and removing the power take-off on the flywheel housing .. 10-285

10.6.1 Removing .. 10-286

10.6.2 Installation .. 10-287

10.7 Dismantling and installing the switchable power take-off on the flywheel housing .. 10-289

10.7.1 Removing .. 10-290

10.7.2 Installation .. 10-291

10.8 Installing and dismantling the air-conditioning compressor .. 10-293