John Deere 644H Loader Operator's Manual (OMT195362)

John Deere 644H Loader Operator's Manual (OMT195362)

Complete Operator's Manual for John Deere 644H Loader, with all the shop information to maintain & operate.

omt195362 - 644h loader (s.n. 585561-) Operator's Manual.pdf

Total Pages: 430 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

omt195362 - 644h loader (s.n. 585561-)

Table of Contents

Foreword

Emission Control Statement

Technical Information Feedback Form

Section 1-1: Safety-Safety Features

Safety Features

Section 1-2: Safety-General Precautions

Recognize Safety Information

Follow Safety Instructions

Operate Only If Qualified

Wear Protective Equipment

Avoid Unauthorized Machine Modifications

Add Cab Guarding For Special Uses

Inspect Machine

Stay Clear Of Moving Parts

Avoid High-Pressure Fluids

Beware Of Exhaust Fumes

Prevent Fires

Prevent Battery Explosions

Handle Chemical Products Safely

Dispose of Waste Properly

Prepare for Emergencies

Section 1-3: Safety-Operating Precautions

Use Steps And Handholds Correctly

Start Only From Operator's Seat

Use And Maintain Seat Belt

Prevent Unintended Machine Movement

Avoid Work Site Hazards

Use Special Care When Operating Loader

Keep Riders Off Machine

Avoid Backover Accidents

Avoid Machine Tip Over

Operating on Slopes

Operating Or Traveling On Public Roads

Inspect and Maintain ROPS

Add And Operate Attachments Safely

Section 1-4: Safety-Maintenance Precautions

Park And Prepare For Service Safely

Service Cooling System Safely

Remove Paint Before Welding or Heating

Make Welding Repairs Safely

Drive Metal Pins Safely

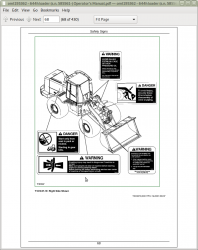

Section 1-5: Safety-Safety Signs

Safety Signs

Section 2-1: Operation-Operator’s Station

Levers

Pedals

Deluxe Monitor Panel

Deluxe Monitor Panel Functions

Console Switches and Accessories (Single Lever Design)

Console Switch and Accessory Functions (Single Lever Design)

Console Switches and Accessories (Two Lever Design)

Console Switch and Accessory Functions (Two Lever Design)

Monitor Display Unit

Monitor Display Unit-Normal Display

Monitor Display Unit-Accessory Menu-Clutch Cut-Off (A 01)

Monitor Display Unit-Accessory Menu-Quick Shift Mode (A 02)

Monitor Display Unit-Accessory Menu-Auto Mode to First (A 03)

Monitor Display Unit-Accessory Menu-Job Timer Mode (A 04)

Monitor Display Unit-Accessory Menu-Stop Watch Mode (A 05)

Monitor Display Unit-Accessory Menu-0.1 Hour Meter Mode (A 06)

Monitor Display Unit-Accessory Menu-Metric Units Mode (A 07)

Monitor Display Unit-User Diagnostics Menu-Service Codes (d01)

Monitor Display Unit-User Diagnostics Menu-Continuity Check (d 02)

Monitor Display Unit-User Diagnostics Menu-Battery Monitor (d 03)

Monitor Display Unit-User Diagnostics Menu-Engine Sensors (d 04)

Monitor Display Unit-User Diagnostics Menu-Transmission Sensors (d 05)

Monitor Display Unit-User Diagnostics Menu-Hydraulic Sensors (d 06)

Monitor Display Unit-User Diagnostics Menu-Fuel Sensor (d 07)

Monitor Display Unit-User Diagnostics Menu-(d 08)-Not Used

Monitor Display Unit-User Diagnostics Menu-Spin Control Mode (d 09)

Monitor Display Unit-User Diagnostics Menu-Machine I.D. Mode (d 10)

Horn Button

Turn Signals

Heating and Air Conditioning Controls

Heater Operation

Air Flow Knob

Adjusting Steering Wheel Tilt

Opening and Securing Side Door

Opening Side Window/Secondary Exit

Opening Rear Side Window

Adjusting Seat

Seat Belt

Section 2-2: Operation-Operating the Machine

Inspect Machine Daily Before Starting

Check Instruments Before Starting

Starting the Engine

Starting Fluid-If Equipped (Cold Weather Starting Aid)

Using Booster Batteries-24 Volt System

Engine Air Heater-If Equipped

Using Coolant Heater-If Equipped

Warm-Up

Cold Weather Warm-Up

Neutral Lock

Shifting the Transmission

Park Brake Switch

Boom and Bucket Control Lever-One Lever Design

Boom and Bucket Control Lever-Two Lever Design

Quick Shift Switch

Ride Control-If Equipped

Secondary Steering-If Equipped

Differential Lock Switch

Boom Height Kickout Adjustment

Return-to-Carry Kickout Adjustment

Return-To-Dig Adjustment

Fork Attachment

Arm Attachment

Parking the Machine

Loading Machine on a Trailer

Towing Procedure

Lifting the Machine

Section 3-1: Maintenance-Machine

Diesel Fuel

Low Sulfur Diesel Fuel Conditioner

Dieselscan Fuel Analysis

Handling and Storing Diesel Fuel

Alternative And Synthetic Lubricants

Diesel Engine Break-In Oil

Diesel Engine Oil

Transmission, Hydraulic System, Park Brake, and Differential Oil

Grease

Diesel Engine Coolant

Section 3-2: Maintenance-Periodic Maintenance

Service Your Machine at Specified Intervals

Check the Monitor Display Unit Regularly

Prepare Machine for Maintenance

Locking Machine Frame

Boom Lock

Opening Engine Side Shields and Service Doors

Opening Grille Door

Fuel Tank

Check Windshield Washer Fluid Level

Maintenance And Repair Record Keeping System

OILSCAN PLUS OILSCAN PLUS is a trademark of Deere & Company , COOLSCAN PLUSCOOLSCAN PLUS is a trademark of Deere & Company , and 3-Way Coolant Test Kit

Service Intervals

Required Parts

Section 3-3: Maintenance-As Required

Check Tire Pressure

Tire Pressures

Tighten Wheel Retainer Cap Screws

Clean or Replace Air Cleaner Elements

Check Air Inlet Cap

Inspect Serpentine Belt

Drain Fuel Tank Sediment

Drain Water Separator Sediment

Section 3-4: Maintenance-Every 10 Hours or Daily

Check Recovery Tank Coolant Level

Clean Air Cleaner Dust Unloader Valve

Check Engine Oil Level

Check Hydraulic Oil Level

Check Transmission Oil Level

Section 3-5: Maintenance-After 100 Hours

Change Engine Break-In Oil and Replace Filter

Change Transmission Oil

Replace Transmission Oil Filter

Section 3-6: Maintenance-Every 100 Hours

Grease Loader Linkage and Cylinder Pivots

Grease Front Steering Cylinder Pivots

Grease Oscillating Rear Axle and Rear Steering Cylinder Pivots

Check Cab Fresh Air Filter-If Equipped With Cab

Check Cab Recirculating Air Filter-If Equipped With Cab

Section 3-7: Maintenance-Every 250 Hours

Grease Front Driveline Sliding Joint

Check Receiver Dryer Moisture Indicator

Check Radiator Coolant Level

Change Engine Oil and Replace Filter

Section 3-8: Maintenance-Every 500 Hours

Grease Upper and Lower Drive Line Sliding Joints and U-Joints

Check Air Intake Hoses

Check Battery Electrolyte Level and Terminals

Clean Fuel Filter Strainer

Replace Final Fuel Filter

Replace Hydraulic System Return Filter

Grease Rear Oscillating Support Cover

Replace Hydraulic Reservoir Breather Filter

Replace Transmission Oil Filter

Check Park Brake Oil Level

Check Front and Rear Differential Oil Level

Section 3-9: Maintenance-Every 1000 Hours

Clean Engine Crankcase Vent Tube

Replace Air Cleaner Dust Unloader Valve

Replace Air Cleaner Elements

Check Coolant

Check Radiator Hoses

Change Transmission Oil

Grease Frame Hinge Pivots

Change Park Brake Oil

Section 3-10: Maintenance-Every 2000 Hours

Adjust Engine Valve Lash (Clearance)

Section 3-11: Maintenance-Every 3000 Hours

Change Hydraulic System Oil

Clean Hydraulic System Strainer

Change Front and Rear Differential Oil

Clean Axle Differential Recirculation Screen

Section 4-1: Miscellaneous-Machine

Draining the Cooling System

Filling the Cooling System

Replacing Engine Vibration Damper

Checking Fuel Tank Vent Hose

Adjusting Pilot Controller Tower

Bleeding Fuel System

Checking Fire Extinguisher-If Equipped

Precautions for Alternator and Regulator

Handling, Checking And Servicing Batteries Carefully

Replacing Batteries

Removing and Installing Batteries

Replacing Fuses

Fuse (Blade-Type) Color Codes

Replacing Halogen Bulbs

Engine Speeds

Checking Neutral Start System

Servicing Air Conditioning System-If Equipped

Welding on Machine

External Service Brake Inspection

Checking Ride Control Accumulator-If Equipped

Transmission Oil Cooler, Hydraulic Oil Cooler, Air-to-Air Aftercooler, and Radiator External Cleaning Procedure

Service Recommendations For STC® STC is a registered trademark of the Aeroquip Corporation. Fittings

Do Not Service Control Valves, Cylinders, Pumps or Motors

Hardware Torque Specifications

Keep ROPS Installed Properly

Metric Bolt and Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values

Section 4-2: Miscellaneous-Operational Checkout

Operational Checkout

Section 4-3: Miscellaneous-Troubleshooting

Troubleshooting Procedure

Diagnostic Trouble Codes Quick Reference List

Engine

Transmission

Differential And Axle

Service Brake

Drive Line

Park Brake

Hydraulic System

Steering

Air Conditioning System

Heater System

Section 4-4: Miscellaneous-Storage

Prepare Machine For Storage

Section 4-5: Miscellaneous-Machine Numbers

Record Product Identification Number (PIN)

Record Engine Serial Number

Record Transmission Serial Number

Record Hydraulic Pump Serial Number

Record Axle Serial Number

Section 4-6: Miscellaneous-Specifications

644H Specifications

644H High Lift Specifications

Drain and Refill Capacities-644H

Section 4-7: Miscellaneous-Crime Prevention Tips

Help Prevent Crime

Record Identification Numbers

Keep Proof of Ownership

Park Indoors Out of Sight

When Parking Outdoors

Reduce Vandalism

Report Thefts Immediately