John Deere 6090 Diesel Engine (Level 24 ECU - Worldwide) Component Technical Manual - CTM115419

Catalog:

Model:

Price: US$ 49.00

Complete Component Technical Manual (CTM) for John Deere 6090 Diesel Engine (Level 24 ECU - Worldwide), with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

ctm115419 - 6090 Diesel Engine — Level 24 ECU - (Worldwide Edition) Component Technical Manual.pdf

ctm115419 - 6090 Diesel Engine — Level 24 ECU - (Worldwide Edition) Component Technical Manual.epub

Total Pages: 1,912 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

ctm115419 - 6090 Diesel Engine — Level 24 ECU -: (Worldwide Edition) Component Technical Manual

TABLE OF CONTENTS

Foreword

Identification Views - 6090 Stage II Emissions Certified Engines

Related Manuals

Training Information

Definition of Terms

Section 01: General Information

Group 000: Safety

Understand Signal Words

Avoid Heating Near Pressurized Fluid Lines

Avoid High-Pressure Fluids

Avoid Hot Exhaust

Avoid Static Electricity Risk When Refueling

Construct Dealer-Made Tools Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Follow Safety Instructions

Handle Fluids Safely—Avoid Fires

Handling Batteries Safely

Illuminate Work Area Safely

Install All Guards

Live With Safety

Practice Safe Maintenance

Precautions for Welding

Prepare for Emergencies

Prevent Acid Burns

Prevent Battery Explosions

Prevent Machine Runaway

Protect Against High Pressure Spray

Protect Against Noise

Recognize Safety Information

Remove Paint Before Welding or Heating

Replace Safety Signs

Service Cooling System Safely

Service Machines Safely

Stay Clear of Rotating Drivelines

Support Machine Properly

Use Proper Lifting Equipment

Use Proper Tools

Wait Before Opening High-Pressure Fuel System

Wear Protective Clothing

Work in Clean Area

Work In Ventilated Area

Group 001: Engine Identification

Engine Model Designation

Engine Serial Number Plate Information

OEM Engine Option Code Label

Group 002: Fuels, Lubricants, and Coolant

Diesel Fuel

Supplemental Diesel Fuel Additives

Handling and Storing Diesel Fuel

Lubricity of Diesel Fuel

Testing Diesel Fuel

BioDiesel Fuel

Fuel Filters

Minimizing the Effect of Cold Weather on Diesel Engines

John Deere Break-In Plus™ Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV

Engine Oil and Filter Service Intervals — Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV — OEM Applications

Engine Oil and Filter Service Intervals

Oil Filters

Lubricant Storage

Mixing of Lubricants

Alternative and Synthetic Lubricants

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Water Quality for Mixing with Coolant Concentrate

Operating in Warm Temperature Climates

Testing Coolant Freeze Point

Disposing of Coolant

Section 02: Repair and Adjustments

Group 010: Engine Rebuild

Check Air Intake System

Check and Service Cooling System

Check Crankcase Ventilation System

Check Electrical System

Check Exhaust System

Clean Engine

Disconnect Turbocharger Oil Inlet Line

Engine Assembly Sequence

Engine Break-In Guidelines

Engine Disassembly Sequence

Engine Repair Stand

General Tune-Up Recommendations

Install Adapters on Engine Repair Stand

Install Engine Lift Straps

Lifting Procedure

Mount Engine on Repair Stand

Overhaul Guidelines

Perform Engine Break-In

Safety Precautions

Sealant Application Guidelines

Group 020: Cylinder Head and Valves Repair and Adjustment

Cylinder Head — Cleaning and Inspection

Cylinder Head — Flatness Check

Cylinder Head — Installation

Cylinder Head Cap Screw Torque Procedure

Cylinder Head — Removal

Cylinder Head — Thickness Measurement

Fuel Injector Sleeves — Install

Fuel Injector Sleeves — Remove

Push Rod — Cleaning and Inspection

Rocker Arm Cover Vent hose — Inspection

Rocker Arm, Intake and Exhaust — Inspection

Rocker Arm Shaft — Inspection

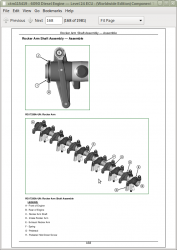

Rocker Arm Shaft Assembly — Assemble

Rocker Arm Shaft Assembly — Installation

Rocker Arm Shaft Assembly — Removal and Tear Down

Valve — Assembly Removal

Valve — Cleaning and Inspection

Valve — Clearance Adjustment

Valve — Grinding

Valve — Lift Check

Valve — Measurement

Valve — Recess Measurement

Valve Assembly — Installation

Valve Guide — Measurement

Valve Guide — Cleaning

Valve Guide — Installation

Valve Guide — Removal

Valve Retainer, Valve Bridges, and Valve Retainer Locks — Inspection

Valve Seat — Cleaning and Inspection

Valve Seat — Grinding

Valve Seat — Recess Measurement

Valve Seat Inserts — Installation

Valve Seat Inserts — Removal

Valve Springs — Inspection and Measurement

Group 030: Block, Liners, Pistons, and Rods Repair and Adjustment

Piston Ring — Installation

Piston and Connecting Rod — Installation

Connecting Rod and Cap — Inspection

Connecting Rod Bearings — Inspection and Measurement

Connecting Rod Cap Screw — Torque Procedure

Cylinder Block — Cleaning and Inspection

Cylinder Block — Measurements

Cylinder Block Oil, Coolant, and Camshaft Frost Plugs — Installation

Cylinder Liner — Cleaning

Cylinder Liner — Deglazing

Cylinder Liner — Installation

Cylinder Liner — Packing Installation

Cylinder Liner — Height Measurement

Cylinder Liner — Manufacturing Date Code Explanation

Cylinder Liner — Measure Liner Flange Thickness

Cylinder Liners — Removal

Cylinder Liners — Visual Inspection

Pistons — Cleaning

Piston — Visual Inspection

Pistons and Connecting Rod Assembly — Removal

Piston and Connecting Rod Assembly — Tear Down

Piston Ring — Removal

Piston Cooling Orifice — Removal and Inspection

Piston Cooling Orifice — Installation

Piston Pin and Bore — Inspection

Dipstick Assembly — Inspection

Dipstick Assembly — Installation

Dipstick Assembly — Removal

Piston Pin and Bushing (A) — Inspection

Piston Pin and Bushing (B) — Inspection

Piston Pin Bushing — Installation

Piston Pin Bushing and Pin Bore — Removal

Piston to Liner — Clearance Check

Group 040: Crankshaft, Bearings, Flywheel Repair and Adjustment

Crankshaft — End Play Check

Crankshaft — Removal

Crankshaft — Inspection

Crankshaft — Installation

Remove Crankshaft Front Unitized Oil Seal

Unitized Front Crankshaft Oil Seal — Installation

Crankshaft Unitized Rear Oil Seal — Removal

Crankshaft Rear Oil Seal Housing — Removal

Crankshaft Rear Oil Seal & Oil Seal Housing — Installation

Crankshaft Vibration Damper and Hub — Removal

Install Vibration Damper

Crankshaft Gear — Replace

Flywheel — Removal

Inspect and Measure Flywheel

Check Flywheel Housing Face Runout

Flywheel — Installation

Flywheel Housing — Removal

SAE 1 Flywheel Housing — Inspection

Install SAE 1 Flywheel Housing

Install SAE 2 and 3 Flywheel Housing

Check Main Bearing Oil Clearance

Replace Flywheel Ring Gear

Main Bearing Cap — Removal

Main Bearing Cap — Line Bore Specifications

Check Pilot Bearing Bore Concentricity

Thrust Bearings — Inspection

Group 050: Camshaft and Timing Gear Train Repair and Adjustment

Camshaft End Play and Gear Backlash — Check

Camshaft — Removal

Camshaft — Visual Inspection

Install Camshaft

Camshaft Gears — Installation

Service Camshaft Bushings Using JDG602 Adapter Set

Service Camshaft Bushings Using JDG606 Adapter Set

Measure Camshaft Journal O.D. and Bushing I.D.

Camshaft Lobe — Lift Measurement

Remove, Inspect, and Install Crankshaft Gear-Driven Auxiliary Drive — If Equipped

Fan Drive, Variable Speed — Removal

Fan Drive, Variable Speed — Installation

Camshaft Roller Followers — Install

Thrust Washer — Thickness Measurement

Remove Vibration Damper and Timing Gear Cover

Install Thrust Washer and Timing Gear Cover

Group 060: Lubrication System Repair and Adjustment

Oil Cooler — Assembly

Remove, Inspect, and Install Engine Oil Cooler

Oil Filter Assembly — Removal

Oil Filter — Changing

Oil Filter Assembly — Installation

Oil Pressure Regulating Valve — Removal

Oil Pressure Regulating Valve — Installation

Oil Pan — Removal

Oil Pan — Installation

Tighten Cap Screws on Front Frame/Oil Sump — Tractors

Oil Pump — Removal

Inspect and Clean Oil Pump

Oil Pump — Installation

Oil Pump — Remove Engine from Tractors for Access

Install Oil Bypass & Oil Pump Tubes & Oil Pump Adapter

Remove, Inspect, and Install Oil Pump Pickup Tube

Check Pumping Gear Backlash

Oil Pump Drive Gear — Inspection

Check Crankshaft Gear-to-Oil Pump Drive Gear Backlash

Check Drive Shaft End Play

Check Drive Shaft Side Movement

Oil Pump Oil Pickup Tube — Removal and Inspection

Oil Pump Oil Pickup Tube — Installation

Top-Load Oil Filter Assembly — Installation

Group 070: Cooling System Repair and Adjustment

Belt Tensioner — Spring Tension and Belt Wear Check

Fan Drive Assembly

Inspect Fan Hub & Replace Bearings in Heavy-Duty, Adjustable Fan Drive Assembly

Inspect and Install Fan Assembly

Replace Bearings in Coolant Manifold-Mounted, Fixed Fan Drive Assembly

Fixed Fan Drive Assembly — Removal

Visually Inspect Coolant Pump

Remove Coolant Pump Assembly

Install Coolant Pump Assembly

Bleed Air from Coolant System

Fan Assembly — Removal

Fan Assembly — Inspection and Installation

Remove and Test Thermostat

Install Thermostat

Install Thermostat Housing and Bypass Tube

Remove Thermostat Housing and Bypass Tube

Servicing of Engine Coolant Heater

Group 080: Air Intake and Exhaust System Repair and Adjustment

Remove and Install Air Bleed/Check Valve

Exhaust Manifold — Installation

Exhaust Manifold — Remove

Turbocharger — Failure Analysis

Turbocharger — Extending Life

Intake Manifold — Installation

Air Intake Assembly — Removal

Turbocharger Inspection

Turbocharger — Install

Turbocharger — Remove

Turbocharger Oil Drain Line — Installation

Turbocharger Oil Drain Line — Removal

Group 090: Electronic Fuel System Repair and Adjustments

General Information

Clean Electronic injectors (In Engine)

Clean Electronic Injector (EI) Body

Inspect Electronic Injector (EI) Body

Clean Electronic Injector (EI) Bore

Clean Electronic Injector (EI) Orifice

Remove and Install Flow Dampers

Remove and Install Fuel Filters

Fuel Filter Header Assembly and Jumper Harness Assembly — Remove

Fuel Filter Header — Inspect and Component Assembly

Fuel Filter Header Assembly and Jumper Harness Assembly — Installation

Remove and Install High Pressure Common Rail

Remove and Install High-Pressure Fuel Pump Assembly

Remove and Install Electronic Injectors (EIs)

Remove and Install Fuel Injector Wiring Harness

Remove and Install Leak-off Lines

Remove and Install Fuel Transfer Pump Assembly

Remove and Install Pressure Limiter

Remove and Install Fuel Suction Control Valve

Relieve Fuel System Pressure

Group 100: OEM Starting and Charging Systems Repair and Adjustment

Remove and Install Alternator (OEM Engines)

Remove and Install Starter Motor (OEM Engines)

Group 110: Electrical Engine Control Repair and Adjustment

Component Location

Remove and Install High Pressure Pump (Camshaft Timing) Sensor

Remove and Install Charge Air Cooler Outlet Air Temperature Sensor

Remove and Install Crankshaft Position Sensor

Remove and Install Engine Control Unit (ECU)

Remove and Install Coolant Temperature Sensor

Remove and Install Oil Pressure Sensor

Remove and Install Fuel Rail Pressure Sensor

Fuel Temperature Sensor — Installation

Fuel Temperature Sensor — Removal

Remove and Replace Air Intake Temperature - Turbocharger Compressor Inlet

Remove and Install Low Pressure Fuel Pressure Sensor

Remove and Install Manifold Air Pressure (MAP) Sensor

Remove and Install Manifold Air Temperature (MAT) Sensor

Remove and Install Water in Fuel (WIF) Sensor

Remove and Install Engine Wiring Harness

ECU Wiring Harness Routing

Engine Control Unit (ECU) Maintenance

Welding

Group 112: Connector Repair and Adjustment

Connector Repair and Adjustment

Installation of Repair Wire Assembly (RWA)

Repair AMP® Seal 16 - Type “A” Connectors

Repair AMP® Seal 16 - Type “B” Connectors

Repair AMP® Seal 16 - Type “C” Connectors

Repair Bosch Connectors

Repair DEUTSCH Connectors

Repair Metri-Pack™ Connectors

Repair WEATHER PACK® Connectors

Using High-Pressure Washing

Section 03: Theory of Operation

Group 120: Base Engine Operation

General Engine Operation

Engine Sectional View Component Location Diagram

Head Gasket Joint Construction and Operation

Group 123: Cooling System

Cooling Location Diagrams

Cooling System Operation

Group 126: Lubrication System

Component Location Diagrams

Lubrication System Operation

How the Turbocharger is Lubricated

Group 130: Electronic Fuel System

Component Location Diagram 1

Component Location Diagram 2

Component Location Diagram 3

Electronic Injector (EI) Operation

High-Pressure Common-Rail (HPCR) Operation

High-Pressure Fuel Pump Operation

High-Pressure Fuel System Operation

Low-Pressure Fuel Pump Operation

Low-Pressure Fuel System Operation

Primary and Secondary Fuel Filter Operation

Group 135: Air Intake and Exhaust System

Component Location Diagram 4

Component Location Diagram 5

Component Location Diagram 6

Air Intake and Exhaust System Operation

Fixed Turbocharger Operation

Group 140: Electrical Control System

Analog Throttle

B5100 — Fuel Rail Pressure Sensor

B5101 — Engine Oil Pressure Sensor

B5107 — Low-Pressure Fuel Pressure Sensor

B5206 — Manifold Air Temperature (MAT) Sensor

B5208 — Engine Coolant Temperature Sensor

B5209 — Fuel Temperature Sensor

B5301 — Crankshaft Position Sensor

B5302 — Camshaft Position Sensor

B5600 — Water-in-fuel Sensor

Barometric Air Pressure Sensor

CAN Throttle

Controller Area Network (CAN)

Determining Engine Speed and Piston Position

Engine Control Unit (ECU) System Operation

Engine Control Unit (ECU) Temperature Sensor

Engine Derate and Shutdown Protection

Measuring Pressure

Measuring Speed

Measuring Temperature

Pilot Injection Operation

Sensor Supply #1

Sensor Supply #2

Sensor Supply #4

Sensor Supply #5

Sensor Supply #8

Sensor Supply #9

X5000 — Fuel Injector Harness

Y5002 — Suction Control Valve

Y5501 — Low-Pressure Fuel Pump

Section 04: Diagnostics

Group 150: Observable Diagnostics and Tests

Abnormal Engine Noise

Coolant in Oil or Oil in Coolant

Coolant Leaking from Weep Hole

Coolant System Loses Pressure

ECU Does Not Communicate with Powerview

ECU Does Not Communicate with Service ADVISOR

ECU Does Not Program with Service ADVISOR

Engine Coolant Temperature Below Normal

Engine Cranks and will Not Start

Engine Does Not Develop Full Power

Engine Emits Excessive Black or Gray Exhaust Smoke

Engine Emits Excessive Blue Exhaust Smoke

Engine Emits Excessive White Exhaust Smoke

Engine Misfires or Runs Irregularly

Engine Will Not Crank

Excessive Fuel Consumption

Excessive Oil Consumption

Check for Excessive Engine Crankcase Pressure (Blow-By) (Base Pressure)

Fuel in Coolant

Fuel in Oil

Throttle Not Responding

Group 155: Checks, Tests, and Procedures

Air in Fuel Check

Camshaft to Crankshaft Timing Check

CAN Diagnostics Procedure

CAN Message Not Received

CAN Message Received Error

CAN Message Received Is Incorrect

Charge Air Cooler Test

Cooling System Pressure Test

Crankcase Pressure (Blow-By) Test

Engine Cranking Speed Check

Engine Oil Pressure Check

Fuel Rail Cap and Plug Procedure

Fuel Return Line (Leak-off) Restriction Check

Fuel Supply Quality Check

Fuel System Bleeding

High-Pressure Fuel System Check

Low-Pressure Fuel System Check

Mechanical Compression Test

Problem Not Found Procedure

Short to Voltage Procedure

Terminal Test

Turbocharger Oil Seal Leak Check

Verification Procedure

Wiggle Test

Group 160: Diagnostic Instructions and Information

Communication Error Test Instructions

Connecting to Service ADVISOR

Control Unit Information and Overview Test

Cylinder Cutout Test Instructions

Cylinder Electronic Compression Test Instructions

Cylinder Misfire Test Instructions

Data Points Used in Service ADVISOR

Diagnostic Gauge — Active DTC Viewing Instructions

Diagnostic Gauge — Data Parameters Viewing Instructions

Diagnostic Gauge — Stored DTC Clearing Instructions

Diagnostic Gauge — Stored DTC Viewing Instructions

Diagnostic Test Box — Using

Diagnostic Trouble Code (DTC) Group Locator

Diagnostic Trouble Code Designations

Digital Multimeter — Using

Electrical Circuit Concepts

Electrical Noise — Possible Causes

Electronic Injector — Calibration Information

Enable Low-Pressure Fuel Pump

Engine Control Unit (ECU) — Level Identification

Engine Control Unit (ECU) — Donating this Engine’s ECU to be Used Elsewhere

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU — Cannot Communicate with Current ECU

Engine Control Unit (ECU) — Reprogramming Current ECU

Engine Control Unit (ECU) — Reprogramming Instructions

Engine Hours — Updating Instructions

Harness Diagnostic Mode Test

Interactive Tests and Calibration Results — Printing, Exporting, or Saving Instructions

Internal Data Monitor — Instructions

Keep Electronic Control Unit Connectors Clean

Load Profile Information Test — Instructions

Servicing Electronic Control Units

Snapshot Instructions

Software and Hardware Verification

Trim Options Information

Welding Near Electronic Control Units

Group 161: DTC SPN - 000001—000199

000028.03 - Digital Throttle Signal Out of Range High

000028.04 - Digital Throttle Signal Out of Range Low

000028.14 - Digital Throttle Inhibited

000029.03 - Secondary Analog Throttle Signal Out of Range High

000029.04 - Secondary Analog Throttle Signal Out of Range Low

000029.14 - Secondary Analog Throttle Inhibited

000091.03 - Primary Analog Throttle Signal Out of Range High

000091.04 - Primary Analog Throttle Signal Out of Range Low

000091.09 - Primary Analog Throttle Signal Erratic

000091.14 - Primary Analog Throttle Inhibited

000094.03 - Low-Pressure Fuel Signal Out of Range High

000094.04 - Low-Pressure Fuel Signal Out of Range Low

000094.16 - Low-Pressure Fuel Signal Moderately High

000094.17 - Low-Pressure Fuel Signal Slightly Low

000094.18 - Low-Pressure Fuel Signal Moderately Low

000097.00 - Water-In-Fuel Level Extremely High

000097.03 - Water-In-Fuel Signal Out Of Range High

000097.04 - Water-In-Fuel Signal Out Of Range Low

000097.16 - Water-In-Fuel Level Moderately High

000100.01 - Engine Oil Pressure Signal Extremely Low

000100.02 - Engine Oil Pressure is not Zero with Engine Stopped

000100.03 - Engine Oil Pressure Signal Out of Range High

000100.04 - Engine Oil Pressure Signal Out of Range Low

000100.18 - Engine Oil Pressure Signal Moderately Low

000105.00 - Manifold Air Temperature Signal Extremely High

000105.03 - Manifold Air Temperature Signal Out of Range High

000105.04 - Manifold Air Temperature Signal Out of Range Low

000105.15 - Manifold Air Temperature Signal Slightly High

000105.16 - Manifold Air Temperature Signal Moderately High

000107.00 - Air Filter Pressure Differential Extremely High

000107.03 - Engine Air Filter Differential Pressure Sensor Signal Out of Range High

000107.04 - Engine Air Filter Differential Pressure Sensor Signal Out of Range Low

000107.15 - Air Filter Pressure Differential Slightly High

000107.16 - Air Filter Pressure Differential Moderately High

000108.02 - Barometric Pressure Signal Invalid

000108.07 - Barometric Pressure Signal Mismatch

000110.00 - Engine Coolant Temperature Signal Extremely High

000110.03 - Engine Coolant Temperature Signal Out of Range High

000110.04 - Engine Coolant Temperature Signal Out of Range Low

000110.15 - Engine Coolant Temperature Signal Slightly High

000110.16 - Engine Coolant Temperature Signal Moderately High

000110.17 - Engine Coolant Temperature Signal Slightly Low

000157.01 - Fuel Rail Pressure Signal Extremely Low

000157.03 - Fuel Rail Pressure Signal Out of Range High

000157.04 - Fuel Rail Pressure Signal Out of Range Low

000157.16 - Fuel Rail Pressure Signal Moderately High

000157.17 - Fuel Rail Pressure Signal Slightly Low

000157.18 - Fuel Rail Pressure Signal Moderately Low

000158.12 - ECU Power Down Error

000160.02 - Primary Shaft Speed Invalid

000168.01 - Unswitched Battery Voltage Extremely Low

000168.16 - Unswitched Battery Voltage Moderately High

000168.18 - Unswitched Battery Voltage Moderately Low

000174.00 - Fuel Temperature Signal Extremely High

000174.03 - Fuel Temperature Signal Out Of Range High

000174.04 - Fuel Temperature Signal Out Of Range Low

000174.16 - Fuel Temperature Signal Moderately High

000189.31 - Engine Speed Derate Condition Exists

000190.00 - Engine Speed Extremely High

000190.16 - Engine Speed Moderately High

Group 162: DTC SPN - 000200—000699

000237.02 - VIN Security Data Invalid

000237.13 - VIN Option Code Security Data Conflict

000237.31 - VIN Security Data Missing

000611.03 - Injector Drive #1 Shorted to Voltage Source

000611.04 - Injector Drive #1 Shorted to Ground

000612.03 - Injector Drive #2 Shorted to Voltage Source

000612.04 - Injector Drive #2 Shorted to Ground

000629.11 - ECU Binary Input Error

000629.12 - ECU EEPROM Error

000636.02 - Camshaft Position Signal Invalid

000636.05 - Camshaft Position Circuit Has High Resistance

000636.06 - Camshaft Position Circuit Has Low Resistance

000636.08 - Camshaft Position Signal Missing

000636.10 - Camshaft Position Signal Rate of Change Abnormal

000637.02 - Crankshaft Position Signal Invalid

000637.05 - Crankshaft Position Circuit Has High Resistance

000637.06 - Crankshaft Position Circuit Has Low Resistance

000637.07 - Crankshaft Position and Camshaft Position Signals Out of Sync

000637.08 - Crankshaft Position Signal Missing

000637.10 - Crankshaft Position Signal Rate of Change Abnormal

000640.11 - External Engine Protection Activated

000640.31 - External Derate Activated

000647.05 - Engine Fan Drive Circuit Has High Resistance

000647.06 - Engine Fan Drive Circuit Has Low Resistance

000647.07 - Engine Fan Speed Decrease Circuit Fault

000651.02 - Injector #1 Part Number Data Invalid

000651.05 - Injector #1 Circuit Has High Resistance

000651.06 - Injector #1 Circuit Has Low Resistance

000651.13 - Injector #1 Calibration Fault

000651.18 - Injector #1 Not Responding

000652.02 - Injector #2 Part Number Data Invalid

000652.05 - Injector #2 Circuit Has High Resistance

000652.06 - Injector #2 Circuit Has Low Resistance

000652.13 - Injector #2 Calibration Fault

000652.18 - Injector #2 Not Responding

000653.02 - Injector #3 Part Number Data Invalid

000653.05 - Injector #3 Circuit Has High Resistance

000653.06 - Injector #3 Circuit Has Low Resistance

000653.13 - Injector #3 Calibration Fault

000653.18 - Injector #3 Not Responding

000654.02 - Injector #4 Part Number Data Invalid

000654.05 - Injector #4 Circuit Has High Resistance

000654.06 - Injector #4 Circuit Has Low Resistance

000654.13 - Injector #4 Calibration Fault

000654.18 - Injector #4 Not Responding

000655.02 - Injector #5 Part Number Data Invalid

000655.05 - Injector #5 Circuit Has High Resistance

000655.06 - Injector #5 Circuit Has Low Resistance

000655.13 - Injector #5 Calibration Fault

000655.18 - Injector #5 Not Responding

000656.02 - Injector #6 Part Number Data Invalid

000656.05 - Injector #6 Circuit Has High Resistance

000656.06 - Injector #6 Circuit Has Low Resistance

000656.13 - Injector #6 Calibration Fault

000656.18 - Injector #6 Not Responding

000676.05 - Cold Start Aid Drive Circuit has High Resistance

000676.06 - Cold Start Aid Drive Circuit Has Low Resistance

000676.14 - Cold Start Aid Relay Signal Not Received When Expected

000676.31 - Cold Start Aid Signal Received When Not Expected

000695.19 - Unapproved Engine Speed Request

Group 163: DTC SPN - 000700—001999

000970.31 - External Shutdown Commanded

000971.31 - External Derate Commanded

000974.03 - Remote Analog Throttle Signal Out of Range High

000974.04 - Remote Analog Throttle Signal Out of Range Low

001075.02 - Low-Pressure Fuel Pump Data Erratic

001075.04 - Low-Pressure Fuel Pump Supply Voltage Low

001075.06 - Low-Pressure Fuel Pump Circuit Has Low Resistance

001075.09 - Low-Pressure Fuel Pump Loss of Communication

001075.15 - Low-Pressure Fuel Pump Temperature Slightly High

001110.31 - Engine Protection System Activated

001136.00 - ECU Temperature Signal Extremely High

001136.02 - ECU Temperature Signal Invalid

001136.16 - ECU Temperature Signal Moderately High

001321.05 - Engine Starter Solenoid Lockout Relay Circuit Has High Resistance

001321.06 - Engine Starter Solenoid Lockout Relay Circuit Has Low Resistance

001321.16 - Engine Starter Engaged for Too Long

001321.31 - Engine Speed Zero with Starter Solenoid Energized

001347.01 - Suction Control Valve Sticking and Fuel Rail Pressure Extremely Low

001347.05 - Suction Control Valve Circuit Has High Resistance

001347.06 - Suction Control Valve Circuit Has Low Resistance

001347.16 - Suction Control Valve Sticking and Fuel Rail Pressure Moderately High

001347.18 - Suction Control Valve Sticking and Fuel Rail Pressure Slightly Low

001550.05 - Air Conditioner Compressor Current Low

001550.06 - Air Conditioner Compressor Current High

001569.31 - Engine Power Derate Condition Exists

001638.03 - Hydraulic Oil Temperature Signal Out of Range High

001638.04 - Hydraulic Oil Temperature Signal Out of Range Low

001639.01 - Fan Speed Signal Extremely Low

001639.16 - Fan Speed Signal Moderately High

001639.18 - Fan Speed Signal Moderately Low

Group 164: DTC SPN - 002000—002299

002005.09 - No CAN Message Received From Source Address 5

002005.14 - Incorrect CAN Message Received From Source Address 5

002005.19 - Communication Error with Source Address 5

002006.09 - No CAN Message Received From Source Address 6

002006.14 - Incorrect CAN Message Received From Source Address 6

002006.19 - Communication Error with Source Address 6

002030.09 - No CAN Message Received From Source Address 30

002030.14 - Incorrect CAN Message Received From Source Address 30

002030.19 - Communication Error with Source Address 30

002040.09 - No CAN Message Received From Source Address 40

002040.14 - Incorrect CAN Message Received From Source Address 40

002040.19 - Communication Error with Source Address 40

002071.09 - No CAN Message Received From Source Address 71

002071.14 - Incorrect CAN Message Received From Source Address 71

002071.19 - Communication Error with Source Address 71

Group 165: DTC SPN - 002300—529999

002797.03 - Injector High Voltage Supply #1 Out of Range High

002797.05 - Injector High Voltage Supply #1 Circuit Has High Resistance

002797.06 - Injector High Voltage Supply #1 Circuit Has Low Resistance

002798.03 - Injector High Voltage Supply #2 Out of Range High

002798.05 - Injector High Voltage Supply #2 Circuit Has High Resistance

002798.06 - Injector High Voltage Supply #2 Circuit Has Low Resistance

003509.03 - Sensor Supply #1 Voltage Out of Range High

003509.04 - Sensor Supply #1 Voltage Out of Range Low

003510.03 - Sensor Supply #2 Voltage Out of Range High

003510.04 - Sensor Supply #2 Voltage Out of Range Low

003512.03 - Sensor Supply #4 Voltage Out of Range High

003512.04 - Sensor Supply #4 Voltage Out of Range Low

003513.03 - Sensor Supply #5 Voltage Out of Range High

003513.04 - Sensor Supply #5 Voltage Out of Range Low

003597.01 - Injector High Voltage Supply Extremely Low

005126.03 - Sensor Supply #8 Voltage Out of Range High

005126.04 - Sensor Supply #8 Voltage Out of Range Low

005127.03 - Sensor Supply #9 Voltage Out of Range High

005127.04 - Sensor Supply #9 Voltage Out of Range Low

055010.31 - Illegal ECU Structure

Section 05: Tools and Other Materials

Group 180: Special Tools

75240

205466

D01062AA

D01168AA

D01207AA

D01209AA

D01251AA

D01299AA

D01300AA

D05012ST-A

D05104ST

D05223ST

D17015BR

D17024BR

D17030BR

D17525CI

D17526CI

D17527CI

DFRG3

DFRG9

DFRG11

J-35616-20

JDE6

JDE38-2

JDE38-3

JDE93

JDE98A

JDE138

JDE41296

JDG23

JDG337

JDG360

JDG361

JDG362

JDG363

JDG364

JDG405

JDG451

JDG602

JDG606

JDG681A

JDG719

JDG721

JDG777

JDG782A

JDG783

JDG820

JDG839

JDG865

JDG1020

JDG1069

JDG1145

JDG1449

JDG1571

JDG1649A

JDG1948

JDG1949

JDG1962

JDG1963

JDG2046

JDG2047A

JDG2047AP1

JDG10015

JDG10025

JDG10040

JDG10057

JDG10059A

JDG10205

JDG10233

JDG10243

JDG10254

JDG10263

JDG10273

JDG10273P1

JDG10273P2

JDG10416

JDG10451

JDG10452

JDG10453

JDG10456

JDG10457

JDG10460

JDG10461

JDG10466

JDG10467

JDG10519

JDG10539A

JDG10545

JDG10549

JDG10631

JDG10760

JDG10942

JDG10993

JDG10994

JDG10997

JDG10998

JDG10999

JDG11016

JDG11017

JDG11019

JDG11055

JDG11056

JDG11072

JDG11100A

JDG11186

JDG11202

JDG11243

JDG11263

JDG11264

JDG11409

JDG11864

JDH7

JT01674A

JT03513C

JT05470

JT05697A

JT05719

JT07042

JT07253

JT07306

JT07336

Group 190: Lubricants, Sealants, and Other Materials

Other Materials

Section 06: Specifications

Group 210: Diagnostic Specifications

9.0 L Wiring Diagram 1

9.0 L Wiring Diagram 2

9.0 L Wiring Diagram 3

9.0 L Engine Schematic

Wire Splice Location Diagram

John Deere 6090 Diesel Engine (Level 24 ECU - Worldwide) Component Technical Manual - CTM115419