Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Excavators Repair Service Manuals

Complete service repair manual with electrical wiring diagrams for Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Excavators, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Excavators workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

Total Pages: 1,472 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MANUAL LIST:

TOJAE-EN-00 - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Technical Manual (Operational Principle).pdf

TTJAE-EN-00 (attach to) - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Electrical Circuit Diagram.pdf

TTJAE-EN-00 - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Technical Manual (Troubleshooting).pdf

WJAE-EN-00 - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Workshop Manual.pdf

TABLE OF CONTENTS

TECHNICAL MANUAL (Operational Principle)

SECTION 1 GENERAL

Group 1 Specification

CONTENTS

Group 2 Component Layout

Group 3 Component Specifications

SECTION 2 SYSTEM

Group 1 Controller

Group 2 Control System

Group 3 ECM System

Group 4 Hydraulic System

Group 5 Electrical System

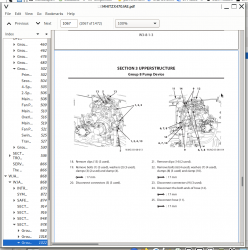

SECTION 3 COMPONENT OPERATION

Group 1 Pump Device

Group 2 Swing Device

Group 3 Control Valve

Group 4 Pilot Valve

Group 5 Travel Device

Group 6 Signal Control Valve

Group 7 Others (Upperstructure)

Group 8 Others (Undercarriage)

MAIN SECTIONS

TOJAE-EN-00......1

INTRODUCTION......3

SYMBOL AND ABBREVIATION......5

SECTION AND GROUP CONTENTS......7

SECTION 1 GENERAL......9

Group 1 Specifications......11

Specifications ZX470-5A, 470LC-5A......11

Working Ranges ZX470-5A, 470LC-5A......12

Specifications ZX490H-5A, 490LCH-5A, 490LCH-5A (Bolt-joint Track)......13

Working Ranges ZX490H-5A, 490LCH-5A, 490LCH-5A (Bolt-joint Track)......14

Specifications ZX530LCH-5A......15

Working Ranges ZX530LCH-5A......16

Group 2 Component Layout......17

Main Component......17

Electrical System (Overview)......19

Electrical System (Rear Tray)......20

Electrical System (Switch Panel)......21

Electrical System (Utility Space)......22

Engine......24

Pump Device......25

Around Pump Device......26

Control Valve......27

Check Valve/Accumlator......28

Signal Control Valve......28

Swing Device......30

Travel Device......30

4-Spool Solenoid Valve Unit......31

Fan Valve (Option)......31

2-Spool Solenoid Valve Unit......31

Group 3 Component Specifications......33

Engine......33

Engine Accessories......37

Hydraulic Component......38

Electrical Component......42

SECTION 2 SYSTEM......45

Group 1 Controller......47

Outline......47

CAN Circuit......48

Group 2 Control System......51

Outline......51

Engine Control......54

Pump Control......76

Valve Control......100

Other Control......118

Group 3 ECM System......131

Outline......131

Fuel Injection Control......132

Fuel Injection Amount Correction Control......140

EGR Control......142

Preheating Control......144

Alarm Control......145

Fuel Bleeding Air Control......146

Group 4 Hydraulic System......147

Outline......147

Pilot Circuit......148

Main Circuit......160

Oil Cooler Fan Reverse Rotation Control Circuit (Option)......182

Group 5 Electrical System......183

Outline......183

Main Circuit......184

Electric Power Circuit (Key Switch: OFF)......186

CAN Circuit......188

Accessory Related Circuit (Key Switch: ACC)......190

Starting Circuit (Key Switch: START)......192

Charging Circuit (Key Switch: ON)......194

Surge Voltage Prevention Circuit......198

Pilot Shut-Off Circuit (Key Switch: ON)......200

Auto Shut-Down Circuit......202

Engine Stop Circuit......204

Monitor Circuit......207

Security Circuit......208

Radio Circuit......210

Air Conditioner Circuit......210

Accessory Circuit......213

Work Light Circuit......214

Wiper/Washer Circuit......218

Cab Light Circuit......220

SECTION 3 COMPONENT OPERATION......225

Group 1 Pump Device......227

Outline......227

Main Pump......228

Regulator......230

Pump Control Solenoid Valve......238

Fan Pump......240

Fan Pump Flow Rate Control......242

Pilot Pump......244

Pump Delivery Pressure Sensor......244

Pump Control Pressure Sensor......244

Group 2 Swing Device......245

Outline......245

Swing Reduction Gear......246

Swing Motor......247

Swing Parking Brake......248

Valve Unit......250

Group 3 Control Valve......253

Outline......253

Hydraulic Circuit......270

Flow Combiner Valve......276

Main Relief valve......278

Overload Relief Valve (with Make-Up Function)......282

Boom Overload Relief Valve (Low Pressure)......288

Regenerative Valve......290

Anti-Drift Valve......294

Flow Rate Control Valve......298

Boom Lower Meter-In Cut Valve......306

Bypass Shut-Out Valve......308

Auxiliary Flow Combiner Valve......312

Group 4 Pilot Valve......315

Outline......315

Operation (Front Attachment/Swing and Travel Pilot Valves)......317

Shockless Function (Only for Travel Pilot Valve)......325

Group 5 Travel Device......327

Outline......327

Travel Reduction Gear......328

Travel Motor......330

Parking Brake......332

Travel Brake Valve......334

Overload Relief Valve......338

Travel Mode Control......340

Group 6 Signal Control Valve......345

Outline......345

Pilot Port......346

Shuttle Valve......350

Shockless Valve......354

Pump 1 and Pump 2 Flow Rate Control Valves......358

Arm Flow Rate Control Valve Control Spool, Flow Combiner Valve Control Spool, Swing Parking Brake Release Spool......360

Group 7 Others (Upperstructure)......361

Pilot Shut-Off Solenoid Valve......361

Solenoid Valve......363

Fan Motor......366

Fan Valve (Option)......367

Pilot Relief Valve......373

Shockless Valve......374

Accumulator (Pilot Circuit)......376

Distribution Valve......377

Group 8 Others (Undercarriage)......381

Swing Bearing......381

Centerjoint......382

Track Adjuster......383

SERVICE MANUAL REVISION REQUEST FORM......387

TTJAE-EN-00 (attach to) - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Electrical Circuit Diagram......389

ELECTRICAL DIAGRAM......389

AIR CONDITIONER CIRCUIT DIAGRAM......390

CONNECTORS......391

CAB HARNESS......392

MAIN HARNESS......393

ENGINE HARNESS......394

PUMP HARNESS......395

CONTROL VALVE HARNESS......396

MONITOR HARNESS......397

KEY SWITCH HARNESS......398

OIL COOLER FAN REVERSE ROTATION SWITCH HARNESS......399

ENGINE STOP SWITCH HARNESS......400

PILOT SHUT-OFF SOLENOID VALVE HARNESS......401

GSM (MOBILE COMMUNICATION TERMINAL) HARNESS......402

SATELLITE COMMUNICATION HARNESS......403

AUTO LUBRICATION ON/OFF SWITCH HARNESS......404

CAMERA HARNESS......405

BOOM MODE SWITCH AND SEAT HEATER SWITCH HARNESS (OPTION)......406

WORK LIGHT (ON THE CAB ROOF) HARNESS 1 (OPTION)......407

WORK LIGHT (ON THE CAB ROOF) HARNESS 2 (OPTION)......408

HYDRAULIC CIRCUIT DIAGRAM......409

TTJAE-EN-00 - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Technical Manual (Troubleshooting)......410

TTJAE-EN-00......410

INTRODUCTION......412

SYMBOL AND ABBREVIATION......414

SAFETY......416

SECTION AND GROUP CONTENTS......456

SECTION 4......458

Group 1 Introduction......460

Operational Performance Tests......460

Preparation for Performance Tests......461

Group 2 Standard......462

Operational Performance Standard Table......462

Main Pump P-Q Diagram......466

Fan Pump P-Q Diagram......467

Sensor Activating Range......468

Monitor Indicating Values (MC)......469

Monitor Indicating Values (ECM)......475

Group 3 Engine Test......476

Engine Speed......476

Lubricant Consumption......479

Group 4 Machine Performance Test......480

Travel Speed......480

Track Revolution Speed......481

Mistrack Check......482

Travel Parking Leakage......483

Swing Speed......484

Swing Function Drift Check......485

Swing Motor Leakage......487

Maximum Swingable Slant Angle......489

Swing Bearing Play......491

Hydraulic Cylinder Cycle Time......493

Dig Function Drift Check......495

Control Lever Operating Force......498

Control Lever Stroke......499

Combined Operation of Boom Raise and Swing Function Check......500

Group 5 Component Test......502

Primary Pilot Pressure......502

Secondary Pilot Pressure......504

4-Spool Solenoid Valve Set Pressure......505

2-Spool Solenoid Valve Set Pressure......506

Main Pump Delivery Pressure......508

Fan Pump Delivery Pressure......509

Main Relief Set Pressure......510

Overload Relief Set Pressure......516

Main Pump Flow Rate Measurement......519

Fan Pump Flow Rate Measurement......521

Swing Motor Drainage......525

Travel Motor Drainage......527

Group 6 Adjustment......530

PUMP LEARNING......530

TORQUE ADJUSTMENT......531

CONNECTION......532

SECTION 5......536

Group 1 Diagnosing Procedure......538

Introduction......538

Diagnosis Procedure......539

Electrical System Inspection......542

Precautions for Inspection and Maintenance......543

Instructions for Disconnecting Connectors......545

Fuse Inspection......547

Fusible Link Inspection......550

Battery Voltage Check......551

Alternator Check......552

Continuity Check......553

Voltage and Current Measurement......555

Check by False Signal......562

Test Wire Harness......563

Group 2 Monitor......566

Outline......566

Operating Procedures of Service Menu......567

Setting Menu......604

Inspection of Engine Oil Level, Coolant Level, Hour Meter, and Fuel Gauge......606

Fuel Gauge and Coolant Temperature Gauge......607

Group 3 e-Service......608

Outline......608

List of Operation Data......609

Snapshot Data......613

Communication System......614

Group 4 Component Layout......616

Main Component......616

Electrical System (Overview)......618

Electrical System (Rear Tray)......619

Electrical System (Switch Panel)......620

Electrical System (Utility Space)......621

Engine......623

Pump Device......624

Around Pump Device......625

Control Valve......626

Check Valve/Accumlator......627

Signal Control Valve......627

Swing Device......629

Travel Device......629

4-Spool Solenoid Valve Unit......630

2-Spool Solenoid Valve Unit......630

Fan Valve (Option)......630

Layout of Control Valve......631

Pilot Port (Signal Control Valve)......647

Group 5 Troubleshooting A......652

Troubleshooting A (Base Machine Diagnosis......652

MC Fault Code List......654

ECM Fault Code List......673

Monitor Controller (Monitor) Fault Code List......678

Monitor Controller (Information) Fault Code List......679

Air Conditioner Controller Fault Code List......682

Communication Terminal Fault Code List......683

MC Fault Codes 11000 to 11002......684

MC Fault Code 11003......685

MC Fault Codes 11006, 11007,11009......688

Monitor Controller (Monitor) Fault Codes 13002, 13003, 13005......688

CAN0 Harness Check......689

MC Fault Codes 11008, 11010......692

Monitor Controller (Monitor) Fault Codes 13004, 13006, 13007......692

CAN1 Harness Check......693

MC Fault Code 11100......696

MC Fault Code 11101......697

MC Fault Codes 11200, 11202......698

MC Fault Codes 11301, 11302......699

MC Fault Code 11303......700

MC Fault Codes 11304, 11325......701

MC Fault Code 11405......702

MC Fault Code 11408......703

MC Fault Code 11412......704

MC Fault Code 11428......705

MC Fault Code 11802......706

MC Fault Code 11901......707

MC Fault Codes 11942, 11944......708

MC Fault Codes 11945......709

MC Fault Code 11948......710

MC Fault Code 11950......711

MC Fault Code 11951......712

MC Fault Code 11953......713

MC Fault Codes 11978, 11979......714

MC Fault Code 11982......715

MC Fault Codes 11985, 11986......716

MC Fault Code 11989......717

MC Fault Codes 11992, 11994......718

MC Fault Codes 11995, 11997......719

MC Fault Code 11998......720

MC Fault Codes 20062......721

Monitor Controller (Information) Fault Codes 13304, 13310......722

Monitor Controller (Information) Fault Code 13311......723

Monitor Controller (Information) Fault Codes 20100 to 20104, 20106......724

Monitor Controller (Information) Fault Codes 20107, 20109, 20110, 20114, 20146, 20149......725

Air Conditioner Controller Fault Codes 11 to 22......726

Air Conditioner Controller Fault Codes 43 to 92......727

Group 6 Troubleshooting B......728

Troubleshooting B (Machine Diagnosis by......728

Relationship between Machine Trouble Symptoms and Related Parts......730

Correlation Between Trouble Symptoms and Part Failures......756

Engine System Troubleshooting......774

All Actuator System Troubleshooting......781

Front Attachment System Troubleshooting......789

Swing System Troubleshooting......802

Travel System Troubleshooting......805

Other System Troubleshooting......809

Exchange Inspection......816

How to Lowering Boom When Emergency and When Engine Stops......819

Group 7 Air Conditioner......820

Outline......820

Functions of Main Parts......823

Troubleshooting......828

Air Conditioner Controller Fault Code List......829

Air Conditioner Controller Fault Codes 11 to 22......830

Air Conditioner Controller Fault Codes 43 to 92......831

Work after Replacing Components......853

Refill Compressor Oil......854

Charge Air Conditioner with Refrigerant......855

Hose and Pipe Tightening Torque......863

SERVICE MANUAL REVISION REQUEST FORM......866

The Attached Diagram List......866

WJAE-EN-00 - Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Hydraulic Excavator Workshop Manual......868

WJAE-EN-00......868

INTRODUCTION......870

To The Reader......870

Additional References......870

Manual Composition......870

Page Number......870

Safety Alert Symbol and Headline Notations......871

Units Used......871

SYMBOL AND ABBREVIATION......872

SAFETY......874

Recognize Safety Information......874

Understand Signal Words......874

Follow Safety Instructions......875

Prepare for Emergencies......876

Wear Protective Clothing......876

Protect Against Noise......877

Inspect Machine......877

General Precautions for Cab......878

Use Handholds and Steps......879

Adjust the Operator's Seat......879

Ensure Safety Before Rising from or Leaving Operator’s Seat......880

Fasten Your Seat Belt......880

Move and Operate Machine Safely......881

Operate Only from Operator's Seat......881

Jump Starting......882

Keep Riders off Machine......882

Precautions for Operations......883

Investigate Job Site Beforehand......884

Install OPG Guard......885

Restriction of Attachment Installation......886

Provide Signals for Jobs Involving Multiple Machines......886

Confirm Direction of Machine to Be Driven......886

Drive Machine Safely......887

Avoid Injury from Rollaway Accidents......889

Avoid Injury from Back-Over and Swing Accidents......890

Keep Person Clear from Working Area......891

Never Position Bucket Over Anyone......891

Avoid Undercutting......892

Avoid Tipping......892

Never Undercut a High Bank......893

Dig with Caution......893

Operate with Caution......893

Avoid Power Lines......894

Precautions for Lightning......894

Object Handling......895

Protect Against Flying Debris......895

Park Machine Safely......896

Handle Fluids Safely−Avoid Fires......896

Transport Safely......897

Practice Safe Maintenance......898

Warn Others of Service Work......899

Support Machine Properly......899

Stay Clear of Moving Parts......900

Prevent Parts from Flying......900

Avoid Injury from Attachment Falling Accident......901

Prevent Burns......901

Replace Rubber Hoses Periodically......902

Avoid High-Pressure Fluids......902

Prevent Fires......903

Evacuating in Case of Fire......905

Beware of Exhaust Fumes......905

Precautions for Welding and Grinding......906

Avoid Heating Near Pressurized Fluid Lines......907

Avoid Applying Heat to Lines Containing Flammable Fluids......907

Precautions for Handling Accumulator and Gas Damper......907

Remove Paint Before Welding or Heating......908

Beware of Asbestos and Silicon Dust and Other Contamination......908

Prevent Battery Explosions......909

Service Air Conditioning System Safely......909

Handle Chemical Products Safely......910

Dispose of Waste Properly......910

Never Ride Attachment......911

Precautions for Communication Terminal......911

Precautions for Communication Terminal Equipment......912

Before Returning the Machine to the Customer......913

SECTION AND GROUP CONTENTS......914

SECTION 1 GENERAL......916

Group 1 Precautions for Disassembling and Assembling......918

Precautions for Disassembling and Assembling......918

Group 2 Tightening......924

Tightening Bolts and Nuts......924

Piping Joint......927

Group 3 Painting......934

Painting specification......934

Final painted color......934

Group 4 Bleeding Air......936

Bleeding Air from Hydraulic Oil Tank (Pressure Release)......936

Bleeding Air from Hydraulic System......937

Bleeding Air from Fuel System......938

Bleeding Air from Expansion Tank (Radiator) (Pressure Release)......940

Group 5 Pressure Release Procedure......942

Hydraulic Circuit Pressure Release Procedure......942

Group 6 Preparation......944

Preparation before Inspection and Maintenance......944

SECTION 2 MAINTENANCE STANDARD......948

Group 1 Upperstructure......950

Main Pump......950

Fan Pump......951

Swing Motor......952

Group 2 Undercarriage......954

Travel Motor......954

Sprocket......955

Center Joint......956

Front Idler......958

Upper Roller......960

Lower Roller......961

Track......962

Group 3 Front Attachment......966

Remove and Install Bushing......966

Pin and Bushing......968

Side Cutter......970

Point......970

Standard Dimensions for Arm and Bucket Connection......971

Standard Dimensions for Arm and Boom Connection......973

Cylinder......974

SECTION 3 UPPERSTRUCTURE......978

Group 1 Cab......980

Removal and Installation of Cab......980

Dimensions of Cab Glass (Standard Cab)......996

Dimensions of Cab Glass (H Cab)......1015

Group 2 Counterweight......1018

Removal and Installation of Counterweight......1018

Group 3 Main Frame......1022

Removal and Installation of Main Frame......1022

Group 4 Engine......1030

Removal and Installation of Engine......1030

Group 8 Pump Device......1064

Removal and Installation of Pump Device......1064

Disassembly of Main Pump......1088

Assembly of Main Pump......1093

Disassembly of Regulator for Main Pump......1100

Assembly of Regulator for Main Pump......1102

Disassembly of Fan Pump......1106

Assembly of Fan Pump......1110

Structure of Pilot Pump......1114

Group 9 Control Valve......1116

Removal and Installation of Control Valve......1116

Disassembly and Assembly of Valve Unit......1130

Disassembly of Control Valve (4-Spool Side)......1136

Assembly of Control Valve (4-Spool Side)......1144

Disassembly of Control Valve (5-Spool Side)......1152

Assembly of Control Valve (5-Spool Side)......1159

Group 10 Swing Device......1166

Removal and Installation of Swing Device......1166

Disassembly of Swing Device......1170

Assembly of Swing Device......1176

Disassembly of Swing Motor......1182

Assembly of Swing Motor......1185

Group 11 Pilot Valve......1190

Removal and Installation of Pilot Valve (Left)......1190

Removal and Installation of Pilot Valve (Right)......1196

Removal and Installation of Travel Pilot Valve......1204

Disassembly of Pilot Valves (Right and Left)......1208

Assembly of Pilot Valves (Right and Left)......1211

Disassembly of Travel Pilot Valve......1214

Assembly of Travel Pilot Valve......1218

Group 12 Solenoid Valve......1224

Removal and Installation of Pilot Shut-Off Solenoid Valve......1224

Removal and Installation of 4-Spool Solenoid Valve Unit......1228

Removal and Installation of 2-Spool Solenoid Valve Unit......1232

Removal and Installation of Fan Pump Control Solenoid Valve......1236

Disassembly of Pilot Shut-Off Solenoid Valve......1240

Assembly of Pilot Shut-Off Solenoid Valve......1242

Structure of 4-Spool Solenoid Valve Unit......1244

Structure of 2-Spool Solenoid Valve Unit......1246

Structure of Fan Pump Solenoid Valve......1248

Group 13 Signal Control Valve......1250

Removal and Installation of Signal Control Valve......1250

Structure of Signal Control Valve......1256

Group 14 Shockless Valve......1260

Removal and Installation of Shockless Valve......1260

Structure of Shockless Valve......1262

Group 15 Fan Valve......1264

Removal and Installation of Fan Valve......1264

Structure of Fan Valve......1300

Group 16 Fan Motor......1302

Removal and Installation of Fan Motor......1302

Structure of Fan Motor......1310

SECTION 4 UNDERCARRIAGE......1314

Group 1 Swing Bearing......1316

Removal and Installation of Swing Bearing......1316

Disassembly of Swing Bearing......1320

Assembly of Swing Bearing......1323

Group 2 Travel Device......1326

Removal and Installation of Travel Device......1326

Disassembly of Travel Device......1330

Assembly of Travel Device......1337

Disassembly of Travel Motor......1346

Assembly of Travel Motor......1350

Disassembly of Brake Valve......1356

Assembly of Brake Valve......1359

Group 3 Center Joint......1364

Removal and Installation of Center Joint......1364

Disassembly of Center Joint......1368

Assembly of Center Joint......1370

Replacement of Body and Spindle......1373

Group 4 Track Adjuster......1374

Removal and Installation of Track Adjuster......1374

Disassembly of Track Adjuster......1376

Assembly of Track Adjuster......1381

Group 5 Front Idler......1386

Removal and Installation of Front Idler......1386

Disassembly of Front Idler......1388

Assembly of Front Idler......1391

Group 6 Upper and Lower Rollers......1396

Removal and Installation of Upper Roller......1396

Removal and Installation of Lower Roller......1400

Disassembly of Lower Roller......1404

Assembly of Lower Roller......1406

Group 7 Track......1412

Removal and Installation of Track......1412

SECTION 5 FRONT ATTACHMENT......1428

Group 1 Front Attachment......1430

Removal and Installation of Front Attachment......1430

Removal and Installation of Bushing......1438

Group 2 Cylinder......1440

Removal and Installation of Boom Cylinder......1440

Removal and Installation of Arm Cylinder......1444

Removal and Installation of Bucket Cylinder......1448

Disassembly of Boom Cylinder......1452

Assembly of Boom Cylinder......1455

Disassembly of Arm Cylinder......1458

Assembly of Arm Cylinder......1461

Disassembly of Bucket Cylinder......1464

Assembly of Bucket Cylinder......1467

SERVICE MANUAL REVISION REQUEST FORM......1472

Hitachi ZX470-5A, 470LC-5A, 490H-5A, 490LCH-5A, 530LCH-5A Excavators Repair Service Manuals