John Deere Planters Models 1770 12RW-36, 12RW-38, 16RN-30, and 24RN-30 Plus Diagnosis and Tests Service Technical Manual (TM1709)

John Deere Planters Models 1770 12RW-36, 12RW-38, 16RN-30, and 24RN-30 Plus Diagnosis and Tests Service Technical Manual (TM1709)

tm1709 - John Deere 1770/1775 12RW-36, 12RW-38, 16RN-30, and 24RN-30 Plus Planters Technical Manua.pdf

Complete Diagnosis & Tests Manual with electrical wiring diagrams for John Deere Planters Models 1770 12RW-36, 12RW-38, 16RN-30, and 24RN-30 Plus, with all the technical information to maintain, test, repair, service like professional mechanics.

John Deere 1770 12RW-36, 12RW-38, 16RN-30, 24RN-30 plus Planters workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 925 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

Lubricants

General Information/Dimensions

Welding

Repair and Welding

Planting Units

Vacuum Seed Metering Mechanisms

Plateless Seed Metering Mechanisms

Seed Openers

Closing Wheels

Insecticide/Herbicide Meter

Coulter

Pneumatic Down Force

Troubleshooting

Electrical

Specifications

Harness Repair

Control Console Repair

Switch Repair

Lighting Repair

Drives

Specifications

Drive Wheels

Countershaft Drive System

Seed Drive Transmission

Fertilizer Drive

Variable Rate Drive

Wheel Modules and Tires

Wheel Module Repair

Hydraulics

Vacuum Meter

Cylinders

Manifold Repair

Solenoid Valves

Electrical Operation and Tests

General Information

System Schematics

Planter Operational Checks

Diagnosing and Testing

Hydraulic System Operation and Tests

General Information

Planter Operational Checks

Unlevel Frame for Machines Equipped WITHOUT Auto Rephase

Unlevel Frame for Machines Equipped WITH Auto Rephase

General Operations

Non-SEEDSTAR™ Operations

SEEDSTAR™ Operations

Theory of Operations

tm1709 - 1770/1775 12RW-36, 12RW-38, 16RN-30, and 24RN-30 Plus Planters

Table of Contents

Foreword

Section 10: General Information

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Operate the Planter Safely

Keep Riders Off Machine

Prevent Machine Runaway

Prevent Acid Burns

Handle Chemical Products Safely

Transport Safely

Use Safety Lights and Devices

Use a Safety Chain

Avoid High-Pressure Fluids

Park Machine Safely

Free Dry Fertilizer Augers Safely

Handle Chemical Products Safely

Support Machine Properly

Wear Protective Clothing

Service Machines Safely

Work In Ventilated Area

Remove Paint Before Welding or Heating

Illuminate Work Area Safely

Avoid Heating Near Pressurized Fluid Lines

Replace Safety Signs

Use Proper Lifting Equipment

Service Tires Safely

Work in Clean Area

Practice Safe Maintenance

Perform Service Safely

Use Proper Tools

Dispose of Waste Properly

Store Attachments Safely

Use Adequate Service Facilities

Insecticide and/or Herbicide Hoppers Lid Fill Closed Handling System

Observe Environmental Protection Regulations

Live With Safety

Group 10: Lubricants

Grease

Gear Oil

Alternative and Synthetic Lubricants

Lubricant for Finger Pickup Meters

Lubricant for Radial Bean Meter Only

Special Lubricants for Vacuum Seed Meters

Lubricant Storage

Group 15: General Information/Dimensions

Service Information Bulletins

Unauthorized Modifications

Specifications (Specifications and design and subject to change without notice.)

Serial Number Location—12-Row Wide and 16-Row Narrow

Serial Number Location—24-Row Narrow

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Service Recommendations For O-Ring Boss Fittings

Service Recommendations For 37° Flare and 30° Cone Seat Connectors

Section 20: Welding

Group 05: Repair and Welding

Frame Repair

Welding

Emergency Crack Repair

Emergency “T” Joint Repair

Skip Welding

Stress Relief (Normalizing)

Section 30: Planting Units

Group 05: Vacuum Seed Metering Mechanisms

Special or Essential Tools

Other Material

Vacuum

Vacuum Meter Operating Characteristics

Use of Talc Lubricant

Vacuum Meter Field Test

Diagnosing Vacuum Meter Malfunctions

Vacuum Meter Inspection and Service

Repair Vacuum Seed Meter

Install New Vacuum Seal

Adjust Vacuum Meter Baffle

Check Seed Disk Cell

Install Seed Disk

Adjust Meter Hub

Sugar Beet, Sorghum Seed and Sweet Corn Knockout Wheel

Install Knockout Assembly (Sugar Beets, Sorghum and Sweet Corn)

Select Correct Vacuum Meter Brush

Change Brush

Install Brush

Double Eliminator (Sweet Corn/Edible Bean Disk - Flat Type)

Group 10: Plateless Seed Metering Mechanisms

Other Material

Specifications

Plateless General Information

Finger Pickup Metering Unit Operating Characteristics

Diagnosing Finger Pickup Malfunctions

Inspect Finger Pickup Meter

Repair Finger Pickup

Feed Cup Operating Characteristics

Diagnosing Feed Cup Malfunctions

Inspect Feed Cup

Inspect Regular Rate Sorghum Feed Cup

Radial Bean Meter Operating Characteristics

Radial Bean Meter Lubricant

Diagnosing Malfunctions

Radial Bean Meter Inspection and Service

Repair Radial Bean Meter

Group 15: Seed Openers

Special or Essential Tools

Other Material

Specifications

TRU-VEE TRU-VEE is a trademark of Deere & Company. Double Disk

Changing Planting Depth

Inspect Openers

Adjusting Gauge Wheels

Replacing Seed Opener Blades and Seed Tube Guard

Diagnosing Seed Opener Malfunctions

TRU-VEE TRU-VEE is a trademark of Deere & Company. Double Disk Opener MaxEmerge MaxEmerge is a trademark of Deere & Company Plus Units

Replace Scrapers

Repair Gauge Wheels

Gauge Wheel Bearing Replacement

Walking Gauge Wheel

Group 20: Closing Wheels

Closing Wheels

Adjust Closing Wheel Down Force

Adjust Closing Wheel When Planting Small Seeds at Shallow Depths

Center (Align) Closing Wheels

Closing Wheels—MaxEmerge MaxEmerge is a trademark of Deere & Company Plus Units

Group 30: Insecticide/Herbicide Meter

Specifications

Calibrating Insecticide/Herbicide Meter

Insecticide/Herbicide Meter Drive Alignment

Group 35: Coulter

Specifications

Coulter Maintenance

Group 40: Pneumatic Down Force

Pneumatic Down Force

Group 45: Troubleshooting

Row Units

Vacuum Meter

Plateless Meter

Section 40: Electrical

Group 05: Specifications

Electrical Specifications

Group 10: Harness Repair

Essential or Recommended Tools

Service Parts Kits

Connector Identification

Electrical Connector Handling

Replace CPC, Large MATE-N-LOK and METRIMATE CPC, MATE-N-LOK, and METRIMATE are trademarks of AMP Inc. Pin Type Connectors

Replace CPC Blade Type Connectors

Replace Small MATE-N-LOK MATE-N-LOK is a trademark of AMP Inc. Socket Connector

Replace Small MATE-N-LOK MATE-N-LOK is a trademark of AMP Inc. Pin Connector

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector

Remove Connector Body from Blade Terminals

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Replace (Pull Type) METRI-PACK METRI-PACK is a trademark of AMP Inc. Connectors

Replace (Push Type) METRI-PACK METRI-PACK is a trademark of AMP Inc. Connectors

Use Terminal Cleaner and Di-Electric Grease

Harness Repair (Splice Broken or Cut Wire)

Harness Repair—Splice Connector

Group 15: Control Console Repair

Console Diagram

Group 20: Switch Repair

Replace “P” Switch

Group 25: Lighting Repair

Repair Warning Lamp, 12/16 Row (SN—680100)

Repair Warning Lamp, 24 Row (SN—680100)

Repair Red Warning Lamp (SN 680101—)

Repair Amber Warning Lamp (SN 680101—)

Section 50: Drives

Group 05: Specifications

Drive Chains Specifications

Shear Pin Specifications

Sprocket Specifications

Group 10: Drive Wheels

Repair Drive Wheel

Drive Wheel Cross Section Drawing

Group 15: Countershaft Drive System

Service Equipment and Tools

Specifications

Clutch Operation

Clutch Adjustment and Assembly

Group 20: Seed Drive Transmission

Repair Seed Drive Transmission

Group 25: Fertilizer Drive

Repair Fertilizer Drive

Fertilizer Drive Location Drawing

Group 30: Variable Rate Drive

Variable Rate Drive

Section 60: Wheel Modules and Tires

Group 05: Wheel Module Repair

Wheel Frame 12 W and 16 N

Drive Wheel Assembly Rigid Wing Frame 12 W and 16 N

Non-Drive Wheel Assermbly Center Frame 12 W and 16 N

Wing Wheel Frame 24-Row

Rear Frame

Drive Wheel Assembly Wing Frame 24-Row

Non-Drive Wheel Assembly Center Frame 24-Row

Section 70: Hydraulics

Group 05: Vacuum Meter

Service Equipment and Tools

Other Material

Specifications

Set Vacuum Level

Flow Control Valve

Check Row Vacuum Reading

Inspect Vacuum Motor

Clean Vacuum Pump Motor Guard

Repair Vacuum Pump

Assemble Pump

Clean Vacuum Manifold System

Vacuum Manifold System

Repair Vacuum Monitor Assembly

Group 10: Cylinders

Essential or Recommended Tools

Service Equipment and Tools

Specifications

Avoid High-Pressure Fluids

Master Cylinder System Location Drawing

Master Cylinder Hydraulics Location Drawing — 12-Row Wide, 16-Row Narrow, and 24-Row Narrow (Serial No. 670101 — )

Remove and Install Master Cylinder

Disassemble Master Cylinder

Inspect Master Cylinder

Assemble Master Cylinder

Rephasing and Charging Master Cylinder System

Remove Latch Cylinder

Repair Latch Cylinder

Install Latch Cylinder

Repair Wheel Frame Cylinder

Remove Double Acting Wheel Cylinder

Disassemble Cylinder

Inspect Cylinder

Installation

Remove Marker Cylinders

Replace Marker Wing-Fold Fittings and Hoses

Remove Marker Wing Cylinders

Repair Fold Over Marker Wing Cylinder—12-Row Wide and 16-Row Narrow

Repair Folding Marker Wing Cylinder—24-Row Narrow

Repair Regular Marker Cylinder—12-Row Wide and 16-Row Narrow (Style A)

Repair Regular Marker Cylinder—12-Row Wide and 16-Row Narrow (Style B)

Repair Folding Marker Cylinder—24-Row Narrow

Replace Wing-Fold Cylinder Fittings and Hoses

Repair Assist Cylinder—24-Row Narrow

Replace Assist Cylinder Fittings and Hoses—24-Row Narrow

Remove Cylinder

Repair Wing Frame Cylinder—12-Row Wide and 16-Row Narrow

Repair Wing Frame Cylinder—24-Row Narrow

Disassemble WRY-LOC WRY-LOC is a trademark of Eaton Corp. Cylinder

Inspect Cylinder

Assemble WRY-LOC WRY-LOC is a trademark of Eaton Corp. Cylinder

Install Cylinder

Filling Marker Hydraulic Cylinders

Group 15: Manifold Repair

Main Frame Manifold Repair, 12–Row Wide/16–Row Narrow

Main Frame Manifold Repair, 24 Row Narrow

Wing Frame Manifold Repair, 12–Row Wide/16–Row Narrow

Wing Frame Manifold Repair, 24–Row Narrow

Group 20: Solenoid Valves

Specifications

Remove and Install Solenoid Valve

Inspect Valve

Section 240: Electrical Operation and Tests

Group 05: General Information

Electrical Schematic Symbols

Inspect Electrical System

Seven-Step Electrical Test Procedure

Circuit Information

Electrical Circuit

Electronic Circuit

Electrical Circuit Malfunctions

Abbreviations and Explanations—Wiring Diagrams

Communication System Terminators— SEEDSTAR SEEDSTAR is a trademark of Deere & Company Monitor Controller With Frame Control

Protect Monitor and Control System From High Voltage

Planters Equipped with Auto Rephase

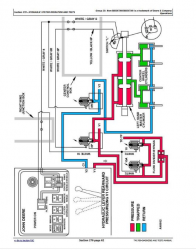

Group 10: System Schematics

SEEDSTAR SEEDSTAR is a trademark of Deere & Company and Variable Rate Drive

Frame Control Schematic—Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company Monitor— Without Auto Rephase 12/16/24 Row

Frame Control Schematic—Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company Monitor — With Auto Rephase 12/16/24 Row

Frame Control Schematic—With SEEDSTAR SEEDSTAR is a trademark of Deere & Company Monitor— Without Auto Rephase 12/16/24 Row

Frame Control Schematic—With SEEDSTAR SEEDSTAR is a trademark of Deere & Company Monitor— With Auto Rephase 12/16/24 Row

Planter Harness Adapter, 12W/16N-Row

Planter Harness Adapter, 24N-Row

Electrical Components Location

Schematic—SEEDSTAR SEEDSTAR is a trademark of Deere & Company Tractor Harness SN—690100

Communications Cable Connector (Tractor) (1 of 2) (SN—690100)

Communications Cable Connector (Tractor) (2 of 2) (SN—690100)

Schematic—SEEDSTAR SEEDSTAR is a trademark of Deere & Company Tractor Harness SN 690101—

Implement Harness SN 690101—

Communications Cable Connector (Tractor) (SN 690101—)

Plant Mode (Drive Clutch Disengaging While Raising Planter)— 12W/16N/24N-Row (With or Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company )

Plant Mode (Manually Disengaging Clutch) (Right-Hand Clutch Shown)—12W/16N/24N-Row (Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company )

Plant Mode (Manually Disengaging Clutch) (Right-Hand Clutch Shown)—12W/16N/24N-Row (With SEEDSTAR SEEDSTAR is a trademark of Deere & Company )

Plant Mode (Manually Disengaging Clutch) Left-Right Clutch with SeedStar (730100 –)

Lighting Enhancement Module—Theory of Operation

Schematic—Lighting Enhancement Module (SN 680101—)

Group 15: Planter Operational Checks

Planter Operational Checks

Group 20: Diagnosing and Testing

Service Equipment and Tools

Specifications

Planter Control System Diagnostics—(With SEEDSTAR SEEDSTAR is a trademark of Deere & Company )

Plant Mode Diagnostics (With SEEDSTAR SEEDSTAR is a trademark of Deere & Company )

Drive Clutch Diagnostics

Drive Clutch (730100 – ) Diagnostics

CAN Bus Diagnostics

Planter Control System Tests—Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company

Plant Mode Diagnostics—Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company

Drive Clutch Diagnostics—Without SEEDSTAR SEEDSTAR is a trademark of Deere & Company

Test Passive Terminator

Test Console Switches

Valve Solenoids Energized

Test Relays

Fold Down Marker Solenoid and Valve Assembly

Solenoid Valve Locations—12-Row Wide and 16-Row Narrow (Serial No. 670101— )

Solenoid Valve Locations—24-Row Narrow (Serial No. 670101— )

Solenoid and Valve Assembly

Test Clutch Solenoid

Checking Solenoids

Checking Valves

Testing Diodes

Test 7-Pin Connector

7-Pin Connector

Mercury Switches

Diagnosing and Testing

Frame Control (Black Connector)—12W, 16N and 24N

Master Cylinder Switches

Setting Cams for Master Cylinder Switches

Adjusting "J" Switch

Adjusting "K" Switch

Adjusting "L" Switch

Using Valves to Diagnose Malfunctions

Junction Boxes—12-Row Wide and 16-Row Narrow (Serial No. 670101— )

Serial No. (670101— )

Section 270: Hydraulic System Operation and Tests

Group 05: General Information

Abbreviations and Explanation

JIC Hydraulic Symbols

Common Planter Hydraulic Symbols

Hydraulic Schematic—12/16 Row

Hydraulic Schematic—24 Row

Hydraulics Location Call-Out

Hydraulic Valve Function

Valve Solenoids Energized

Group 10: Planter Operational Checks

Planter Operational Checks

Group 15: Unlevel Frame for Machines Equipped WITHOUT Auto Rephase

General Information

Proper Planter Operation

Hydraulic Diagnostics

Mechanical Frame Problems

Group 15A: Unlevel Frame for Machines Equipped WITH Auto Rephase

Auto Rephase Center Wheel System Theory Of Operation

Auto Rephase Schematic for 1770, 1775 16 & 24 Row Center Wheels

Auto Rephase Wing Wheel System Theory of Operation

Auto Rephase Schematic for 1770, 1775 16 Row Wing Wheels

Auto Rephase Schematic for 1770, 1775 24 Row Wing Wheels

Unlevel Frame Diagnostics for Machines Equipped WITH Auto Rephase

Auto Rephase Valve Identification

Group 20: General Operations

Manifold Valve Location Drawing—12-Row Wide and 16-Row Narrow (Serial No. 670101— )

Manifold Valve Location Drawing—24-Row Narrow Serial No. (670101— )

Solenoid Operated Check Valve (SV1 and SV3)

Solenoid Valves

Flow Divider/Combiner Valves

Flow Divider and Bypass (Plant Mode)

Flow Divider and Bypass (Transport Mode)

Flow Divider

Flow Divider Location Drawing

Master Cylinder Switches

Mercury Switches

Group 25: Non-SEEDSTARSEEDSTAR is a trademark of Deere & Company Operations

Detailed System Operation—12-Row Wide and 16-Row Narrow

From Storage Position (Folded and Lowered) to Transport (Extending Center Wheels)—12-Row Wide and 16-Row Narrow

From Storage Position (Folded and Lowered) to Transport (Extending Wing Wheels)—12-Row Wide and 16-Row Narrow

Lowering from Transport (For Unlatching Transport Locks)—12-Row Wide and 16-Row Narrow

From Transport Position (Unfolding)—12-Row Wide and 16-Row Narrow

From Transport Position (Unfolding Marker Wing) (Right-Hand Marker Wing Shown)—12-Row Wide and 16-Row Narrow

Lowering Planter (Lowering Center Wheels)—12-Row Wide and 16-Row Narrow

Lowering Planter (Lowering Wing Wheels)—12-Row Wide and 16-Row Narrow

Lowering Planter (Lowering Right-Hand Marker)—12-Row Wide and 16-Row Narrow

Plant Mode (Automatic Mode) (Right-Hand Marker Shown)—12-Row Wide and 16-Row Narrow

Plant Mode (Raising Planter) (Center Wheels Shown)—12-Row Wide and 16-Row Narrow

Plant Mode (Raising Planter) (Wing Wheels Shown)—12-Row Wide and 16-Row Narrow

Plant Mode (Raising Markers)—12-Row Wide and 16-Row Narrow

Transport Mode (Folding Marker Wing) (Right-Hand Marker Wing Shown)—12-Row Wide/16-Row Narrow/24-Row Narrow

Transport Mode (Folding Planter)—12-Row Wide and 16-Row Narrow

Transport Mode (Latching)—12-Row Wide and 16-Row Narrow

Transport Mode (Retracting Wing Wheels)—12-Row Wide and 16-Row Narrow

Warning—Wing Wheels Are Not Retracted

Detailed System Operation 24-Row Narrow

Transport Mode (Extending Center Wheels)—24-Row Narrow

Transport Mode (Extending Transport Cylinders)—24-Row Narrow

Transport Mode (Extending Wing Wheels)—24-Row Narrow

Transport Mode (Unlatching)—24-Row Narrow

Transport Mode (Unfolding)—24-Row Narrow

Transport Mode (Unfolding Marker Wing) (Right-Hand Marker Wing Shown)—24-Row Narrow

Plant Mode (Lowering Planter) (Center Wheels Shown)—24-Row Narrow

Plant Mode (Lowering Planter) (Wing Wheels Shown)—24-Row Narrow

Plant Mode (Manually Lowering Marker) (Right Marker Shown)— 24-Row Narrow

Plant Mode (Auto Mode) (Right-Hand Marker Shown)—24-Row Narrow

Plant Mode (Raising Planter) (Center Wheels Shown)—24-Row Narrow

Plant Mode (Raising Planter) (Wing Wheels Shown)—24-Row Narrow

Plant Mode (Raising Markers)—24-Row Narrow

Transport Mode (Folding Marker Wing) (Right-Hand Marker Shown)—24-Row Narrow

Transport Mode (Folding Planter)—24-Row Narrow

Transport Mode (Latching)—24-Row Narrow

Transport Mode (Retracting Wing Wheels)—24-Row Narrow

Transport Mode (Retracting Transport Cylinders)—24-Row Narrow

Transport Mode (Retracting Center Wheels)—24-Row Narrow

Group 30: SEEDSTARSEEDSTAR is a trademark of Deere & Company Operations

Center Wheels (Raising)—12W/16N-Row

Center Wheels (Raising)—12W/16N-Row

Planter (Lowering)—12W/16N/24N-Row

Planter (Raising)—12W/16N/24N-Row

Wing Wheels (Retracting)—12W/16N/24N-Row

Transport Mode (Extending Wing Wheels)—12W/16N

Transport Mode (Wing Wheels Extending) 24-Row Narrow

Transport Mode (Wing Wheels Retracting) 24-Row Narrow

Plant Mode (Auto Mode)(Right-Hand marker Shown)—12W/16N

Transport Mode (Folding Marker Wing)(Right-Hand Marker Wing Shown)—12W/16N/24N-Row

Plant Mode (Manually Lowering Marker)(Right Marker Shown)—12W/16N/24N-Row

Transport Mode (Unfolding)—12W/16N-Row

Transport Mode (Folding)—12W/16N-Row

Transport Mode (Latching)—12W, 16N and 24N-Row

SEEDSTAR SEEDSTAR is a trademark of Deere & Company Warning—Wing Wheels Are Not Retracted

Group 35: Theory of Operations

12W/16N-Row Planter Fully Raised —V1 Pressurized

12W/16N-Row Planter Fully Lowered—V2 Pressurized

12W/16N-Row—Rephasing Hydraulic System without Auto Rephase

24 Row Planter Fully Raised—V1 Pressurized

24 Row Planter Fully Lowered—V2 Pressurized

24 Row Rephasing without Auto Rephase Hydraulic System

Rephaseing Planters with Auto Rephase