John Deere 1770NT, 1770NT CCS 12-Row Planter Repair Service Manual (TM2183)

John Deere 1770NT, 1770NT CCS 12-Row Planter Repair Service Manual (TM2183)

tm2183 - 1770NT and1770NT CCS12-Row Planter Repair Technical Manual.pdf

Complete Repair Service Technical Manual for John Deere 12-Row Planters Models 1770NT and 1770NT CCS (SN.–740100), with all the workshop information to maintain, diagnose, repair, and service like professional mechanics.

John Deere 12-Row Planters Models 1770NT and 1770NT CCS workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

Total Pages: 894 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

Lubricants

General Information

Vacuum System

Vacuum System

Central Commodity System

Seed Tanks and Manifolds

Seed Delivery Hose

Central Commodity System Fan

Planting Units

MaxEmerge Plus™ / MaxEmerge XP™ Vacuum Seed Meters

MaxEmerge Plus™ / MaxEmerge XP™ Plateless Seed Meters

PRO-SERIES™ / Pro-Series XP™ Vacuum Seed Meters

PRO-SERIES™ / Pro-Series XP™ Plateless Seed Meters

Seed Openers

Closing Wheels

Row Tillage

Insecticide/Herbicide Meter

Mechanical Row Unit Down Force

Pneumatic Row Unit Down Force

Hitch and Frame

Repair and Welding

Hitch Pads

Wheel Module Repair

Row Marker

Loading Platform

Electrical

Connector Repair

Frame Control Box

Relays, Sensors, and Switches

Lighting Repair

Drives

Specifications

Drive Wheels

Seed Drive Transmission

Half-Width Disconnect

Drillshaft

Variable Rate Drive

Fertilizer and Pesticide Systems

Liquid Fertilizer System

Variable Rate Fertilizer

Pesticide System

Hydraulics

General Information

Motors

Cylinders

Valve Block

Valves

Miscellaneous

Miscellaneous

Polyethylene Tank Repair

Dealer Fabricated Tools

tm2183 - 1770NT and1770NT CCS12-Row Planter Repair

Table of Contents

Foreword

Section 10: General Information

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Handle Fluids Safely—Avoid Fires

Prepare for Emergencies

Avoid Harmful Asbestos Dust

Practice Safe Maintenance

Avoid High-Pressure Fluids

Service Accumulator Systems Safely

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Use Steps and Handholds Correctly

Handle Agricultural Chemicals Safely

Avoid Contact with Agricultural Chemicals

Clean Vehicle of Hazardous Pesticides

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Remove Paint Before Welding or Heating

Servicing Electronic Control Units

Welding Near Electronic Control Units

Keep Electronic Control Unit Connectors Clean

Keep Electronic Control Unit Connectors Clean

Avoid Heating Near Pressurized Fluid Lines

Service Tires Safely

Use Proper Tools

Construct Dealer-Made Tools Safely

Dispose of Waste Properly

Live With Safety

Group 10: Lubricants

Grease

Gear Oil

Alternative and Synthetic Lubricants

Lubricant Storage

Group 15: General Information

Service Information Bulletins

Unauthorized Modifications

Specifications

Dimensions— Raised Field Position

Dimensions—Folded Transport Position

Record Serial Number

Sealants and Adhesives Cross-Reference Chart

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Face Seal Fittings Assembly and Installation—All Pressure Applications

Metric Face Seal Fitting Torque Chart—Standard Pressure Applications

SAE Face Seal Fitting Torque Chart—Standard Pressure Applications

Section 20: Vacuum System

Group 05: Vacuum System

Essential or Recommended Tools

Other Material

Specifications

Adjust Vacuum Gauge

Check Row Vacuum — MaxEmerge Row Units

Check Row Vacuum — Pro-Series Row Units

Vacuum Manifold Blower System

Vacuum Manifold Tube Orifice Locations

Clean Vacuum Manifold System

Repair Vacuum Monitoring Assembly —Two Vacuum Gauges

Repair Vacuum Monitoring Assembly with SeedStar™

Remove and Install Vacuum Blower Assembly (S.N. —715100)

Remove and Install Vacuum Blower Motor (S.N. —715100)

Remove and Install Vacuum Blower Motor (S.N. 715101—)

Section 25: Central Commodity System

Group 05: Seed Tanks and Manifolds

Other Material

Specifications

Service Parts Kits

Remove and Install Central Commodity Seed Tank

Remove and Install Refuge Plus Third Tank

Tank Repair

Seal Central Commodity System Tanks To Prevent Water Leakage

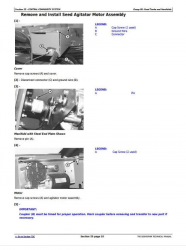

Remove and Install Seed Agitator Motor Assembly

Remove and Install Seed Delivery Manifold Seal

Remove and Install Seed Delivery Manifold Nozzle

Repair Central Commodity System Seed Tank Manifold (with Steel End Plates)

Repair Central Commodity System Seed Tank Manifold (with Plastic End Plates)

Remove and Install Seed Tank Lid Ring and Seal

Group 10: Seed Delivery Hose

Other Material

Remove and Install Seed Delivery Hose

Repair Seed Delivery Hose

Group 15: Central Commodity System Fan

Specifications

Remove and Install Central Commodity System Blower Fan (S.N. —715100)

Remove and Install Central Commodity System Blower Fan (S.N. 715101—)

Repair Central Commodity System Blower Fan Assembly (S.N. —715100)

Repair Central Commodity System Blower Fan Assembly (S.N. 715101—)

Section 30: Planting Units

Group 05: MaxEmerge Plus™ / MaxEmerge XP™ Vacuum Seed Meters

Essential or Recommended Tools

Other Material

Specifications

Remove Vacuum Meter

Vacuum Meter Field Test

Vacuum Seed Meter Exploded View

Repair Vacuum Meter

Inspect Vacuum Meter

Remove and Install Vacuum Meter Brush

Adjust Vacuum Meter Baffle

Inspect Seed Disk

Adjust Meter Hub

Install New Vacuum Seal

Install Knockout Assembly

Install Double Eliminator for ProMax 40, Small Sweet Corn, or Edible Bean Disks

Install Seed Disk

Repair MaxEmerge XP™ Pro-Shaft Drive

Adjust MaxEmerge XP™ Pro-Shaft Drive-to-Meter Alignment

Remove and Install RowCommand Row Unit Clutch with Chain Drive

Adjust Chain Drive-to-Meter Drive Alignment

Group 10: MaxEmerge Plus™ / MaxEmerge XP™ Plateless Seed Meters

Specifications

Finger Pick-Up Exploded View

Inspect Finger Pick-Up

Remove and Install Finger Pick-Up

Disassemble Feed Cup

Assemble Feed Cup

Install Feed Cup

Disassemble Radial Bean Meter

Assemble Radial Bean Meter

Group 15: PRO-SERIES™ / Pro-Series XP™ Vacuum Seed Meters

Essential or Recommended Tools

Other Material

Specifications

PRO-SERIES™ / Pro-Series XP™ Row Unit Vacuum Seed Meter Exploded View

Remove and Install Vacuum Meter Seal

Remove and Install Vacuum Meter

Remove and Install Seed Disk

Remove and Install Double Eliminator Plate

Repair Vacuum Meter

Inspect Vacuum Meter

Remove and Install Knockout Assembly

Remove and Install Vacuum Meter Brush

Adjust Meter Hub

Install Dust Seal

Adjust Meter Latch

Repair Pro-Shaft™ Drive

Group 20: PRO-SERIES™ / Pro-Series XP™ Plateless Seed Meters

Specifications

Finger Pick-Up Meter Exploded View

Inspect Finger Pick-Up Meter

Disassemble and Assemble Finger Pick-Up Meter

Radial Bean Meter Exploded View

Disassemble Radial Bean Meter

Assemble Radial Bean Meter

Group 25: Seed Openers

Essential or Recommended Tools

Other Material

Specifications

MaxEmerge Double Disk Opener Exploded View

PRO-SERIES Double Disk Opener Exploded View

High Performance Row Unit Double Disk Opener Exploded View

MaxEmerge XP Runner Opener (S.N. 730101— ) Exploded View

Remove and Install Seed Tube

Inspect and Adjust Seed Opener Blades

Replace Seed Opener Blades and Seed Tube Guard

Gauge Wheels— Exploded View (S.N. —710100)

Gauge Wheels—Exploded View (S.N. 710101— )

Gauge Wheel Bearing Replacement (S.N. —710100)

Gauge Wheel Bearing Replacement (S.N. 710101— )

Remove and Install Gauge Wheel Depth Adjusting Handle

Adjust Gauge Wheels

Replace Scrapers

Replace Heavy-Duty Scrapers

Replace Rigid Scrapers

Group 30: Closing Wheels

Other Material

Specifications

MaxEmerge™ Closing Wheels Repair

PRO-SERIES Closing Wheels Repair

Center Closing Wheels

Adjust Closing Wheel Spacing

Stagger Closing Wheels

Adjust Closing Wheel Down Force

Group 35: Row Tillage

Other Material

Specifications

Adjust Coulter Bearing

Disassemble and Assemble Unit Mounted Row Cleaner Unit with Tapered Wheels

Remove and Install Floating Row Cleaner for Unit Mounted Coulter

Group 40: Insecticide/Herbicide Meter

Other Material

Specifications

Calibrate Insecticide/Herbicide Meter

Insecticide/Herbicide Meter Drive Alignment

Group 45: Mechanical Row Unit Down Force

Specifications

Remove and Install Row Unit

Remove and Install Heavy-Duty Down Force Spring Assembly

Repair Heavy-Duty Down Force Spring Assembly (Regular Parallel Arms)

Repair Heavy-Duty Down Force Spring Assembly (Long Parallel Arms)

Group 46: Pneumatic Row Unit Down Force

Other Material

Specifications

Depressurize Pneumatic Down Force System

Adjust and Inspect Pneumatic Down Force

Install Integrated Pneumatic Down Force Air Pressure Gauges

Remove and Install Integrated Pneumatic Down Force Control Valve

Disassemble and Assemble Pneumatic Down Force Control Valve

Remove and Install Pneumatic Down Force Control Valve Poppet

Remove and Install Integrated Pneumatic Down Force Air Reservoir

Integrated Pneumatic Down Force Air Compressor—Exploded View

Cab-Mounted Pneumatic Down Force Air Compressor—Exploded View

Remove and Install Integrated Pneumatic Down Force Air Compressor

Remove and Install Air Compressor Filter

Remove and Install Air Compressor Isolators

Remove and Install Hydraulically Driven Air Compressor Filter

Remove and Install Hydraulically Driven Air Compressor

Disassemble and Assemble Hydraulically Driven Air Compressor

Section 35: Hitch and Frame

Group 05: Repair and Welding

Frame Repair

Welding

Emergency Crack Repair

Emergency “T” Joint Repair

Skip Welding

Stress Relief (Normalizing)

Group 10: Hitch Pads

Specifications

Remove and Install Hitch Pads

Group 15: Wheel Module Repair

Other Material

Specifications

Center Wheel Frame Exploded View

Wing Wheel Frame Exploded View

Axle and Hub Assembly (8-Bolt)

Axle and Hub Assembly (6-Bolt)

Remove and Install Center Frame Wheel Assembly

Remove and Install Wing Wheel Assembly

Adjust Tire Scraper

Group 20: Row Marker

Specifications

Remove and Install Row Marker

Disassemble and Assemble Row Marker Disk and Arms

Disassemble and Assemble Row Marker Pivot

Replace Marker Breakaway Bolt

Adjust Marker Length

Adjust Marker Disk

Group 25: Loading Platform

Specifications

Remove and Install Loading Platform Step

Section 40: Electrical

Group 05: Connector Repair

Essential or Recommended Tools

Other Material

Use Electrical Insulating Compound

Using High-Pressure Washers

Repair Procedure R-A

Repair Procedure R-B

Repair Procedure R-C

Repair Procedure R-D

Repair Procedure R-E

Repair Procedure R-F

Repair Procedure R-G

Repair Procedure R-I

Repair Procedure R-J

Repair Procedure R-K

Repair Procedure R-M

Repair Procedure R-N

Repair Procedure R-T

Repair Procedure R-AA

Repair Procedure R-AE

Group 10: Frame Control Box

Remove and Install Relay

Test Relay

Remove and Install Circuit Board

Remove and Install Toggle Switch

Group 15: Relays, Sensors, and Switches

Other Material

Specifications

Replace Marker Switch

Adjust Marker Switch

Replace Fold Control Switch (S.N. —710100)

Replace Fold Control Switch (S.N. 710101—)

Replace Central Commodity System Cleanout Switch

Replace Central Commodity System Push Button Shut-Off Switch

Remove and Install Seed Level Sensor

Replace Integrated Pneumatic Down Force Compressor Pressure Switch

Remove and Install Height Sensor

Remove and Install Gauge Wheel Down Force Sensor

Remove and Install Sensor Node Controllers (SeedStar XP only)

Remove and Install Seed Tube Sensor

Remove and Install Integrated Pneumatic Down Force Pressure Sensor

Remove and Install Vacuum Sensor

Remove and Install Wheel Motion Sensor

Remove and Install Hopper Level Sensor

Remove and Install Liquid Fertilizer Sensor

Remove and Install Variable Rate Fertilizer Pump Speed Sensor

Remove Variable Rate Fertilizer Cam Position Sensor

Install Variable Rate Fertilizer Cam Position Sensor

Remove and Install Variable Rate Drive Motor Speed Sensor

Relay Identification

Group 20: Lighting Repair

Repair Red Warning Lamp—1770NT

Repair Amber Warning Lamp—1770NT

Amber Warning Lamp—1770NT CCS

Red Warning Lamp—1770NT CCS

Section 50: Drives

Group 05: Specifications

Drive Chains Specifications

Shear Pin Specifications

Sprocket Specifications

Group 10: Drive Wheels

Transmission Drive Wheel Exploded View

Group 15: Seed Drive Transmission

Specifications

Seed Drive Transmission Exploded View

Remove and Install Seed Drive Transmission

Adjust Seed Drive Transmission

Check and Adjust Transmission Spur Gear Backlash

Group 20: Half-Width Disconnect

Other Material

Specifications

Remove and Install Half-Width Disconnect Clutch

Disassemble and Assemble Half-Width Disconnect Clutch

Group 25: Drillshaft

Remove and Install Wing Frame Drillshaft

Remove and Install Center Frame Drillshaft (Left-Hand Side)

Remove and Install Center Frame Drillshaft (Right-Hand Side)

Remove and Install Upper Jackshaft

Align Drillshaft Coupler and Flex Shaft

Sprocket Location Drawings

Group 30: Variable Rate Drive

Variable Rate Drive

Section 60: Fertilizer and Pesticide Systems

Group 05: Liquid Fertilizer System

Essential or Recommended Tools

Other Material

Specifications

Flush Fertilizer System

Remove and Install Fertilizer Tank

Replace Fertilizer Tank Fitting

Adjust Pump Number Setting

Fertilizer Drive Wheel Exploded View

Adjust Contact Link

Fertilizer Pump Repair

Fertilizer Pump Lubrication

Remove and Install Fertilizer Flow Divider

Repair Fertilizer Flow Divider

Remove and Install Liquid Fertilizer Block Manifold

Repair Liquid Fertilizer Block Manifold

Remove and Install Liquid Fertilizer In-Line Orifice

Remove and Install Liquid Fertilizer Coupler

Remove and Install Liquid Fertilizer Check Valve

Remove and Install Liquid Fertilizer Delivery Tube

Repair Double-Disk Fertilizer Opener

Repair Single-Disk Fertilizer Opener

Bottom Mounted Single-Disk Fertilizer Opener

Frame Mounted Single-Disk Fertilizer Opener (S.N. —720100)

Frame Mounted Single-Disk Fertilizer Opener (S.N. 720101—)

Group 10: Variable Rate Fertilizer

Other Material

Specifications

Remove and Install Variable Rate Fertilizer Pump

Variable Rate Fertilizer Pump Exploded View

Variable Rate Fertilizer Pump Repair

Replace Variable Rate Drive Pump Crankcase Seal

Group 15: Pesticide System

Pesticide Tanks

Remove and Install Pesticide Tank

Repair Pesticide Tank

Section 70: Hydraulics

Group 00: General Information

Relieve Hydraulic System Pressure

Group 05: Motors

Other Material

Specifications

Inspect Vacuum Blower Motor

Repair Vacuum Blower Motor (S.N. 710101—715100)

Repair Vacuum Blower Motor (S.N. 715101—745100)

Repair Vacuum Blower Motor (S.N. 745101—)

Inspect Central Commodity System Blower Motor

Repair Central Commodity System Blower Motor—Type A

Remove and Install Central Commodity System Blower Motor—Type B

Repair Central Commodity System Blower Motor—Type B

Group 10: Cylinders

John Deere 100 Series Hydraulic Cylinder Repair—Use CTM

John Deere 120 Series Hydraulic Cylinder Repair—Use CTM

Remove and Install Main Frame Wheel Cylinder

Remove and Install Wing Wheel Cylinder

Remove and Install Wing Fold Cylinder

Remove and Install Marker Cylinder

Group 15: Valve Block

Valve and Port Locations

Group 20: Valves

Specifications

Flow Control Valve

Remove and Install Solenoid Valves

Inspect Solenoid Valve Body

Remove and Install Cartridge Valves

Group 25: Miscellaneous

Hydraulic Fitting Torque Values

Remove and Install Hydraulic Oil Cooler

Section 80: Miscellaneous

Group 05: Polyethylene Tank Repair

Essential or Recommended Tools

Repair Polyethylene Plastic

Install Bollhoff Rivnut® Threaded Inserts

Section 99: Dealer Fabricated Tools

Group 05: Dealer Fabricated Tools

DFAXT1—Set Screw Wrench