John Deere 730LL, 1830, 1835, 1840, 1870, 1890, 1895, 1990 Air Seeding Tools Technical Manual (TM2303)

John Deere 730LL, 1830, 1835, 1840, 1870, 1890, 1895, 1990 Air Seeding Tools Technical Manual (TM2303)

tm2303 - 730LL, 1830, 1835,1840, 1870, 1890, 1895, and 1990 CCS Air Seeding Tools Technical Manual.pdf

Complete All Inclusive Technical Manual with electrical wiring diagrams for 1830, 1835, 1840, 1870, 1890, 1895, 1990, 730, 730LL, with all the shop information to maintain, test, repair, service like professional mechanics (Diagnosis, Operation, Tests, Repair, Service, Troubleshooting).

John Deere CCS Air Seeding Tools used in Planters Models 730LL, 1830, 1835, 1840, 1870, 1890, 1895 & 1990 (Worldwide Edition) workshop technical service manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 890 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

Foreword

Safety and General Information

Safety

Lubricants

General Information

Repair Specifications

Welding

Repair and Welding

Ground Tools, Openers, Press Wheels

Ground Tools-1830, 1835 and 1840

Ground Tools and Openers-730 and 730 LL Air Disk Drill

Openers-1835/1890/1895/1990 CCS

Ground Tools and Openers-1870 Air Hoe Drill

Press Wheels-730, 730 LL, 1830 and 1835

Press, Gauge, and Closing Wheel-1870, 1890, 1895 and 1990 CCS

Electrical

Connector Repair

Sensors and Switches

Air System

Component Inspect and Repair

Caster Wheels and Walking Beams

Bearings

Caster Wheel Mount

Hydraulics

Valves

Cylinders

Accumulators

Frames

Wing Repair

Center Frame Repair

Electrical System Diagnostics

1870 Wiring Diagrams-Warning Lights

Tests and Diagnosis

1830, 1835 Lighting Diagnostics - US

1830, 1835 Lighting Diagnostics - Russian

1830, 1835 TouchSet™ Harness Diagnostics

730 LL Lighting Diagnostics - North American

730 LL Lighting Diagnostics - International

730 LL Disk Lowering Solenoid Diagnostics

1890/1895 Lighting Diagnostics - North American

1890/1895 Lighting Diagnostics - International

730 LL Electrical Component Identification

730 LL Electrical Connector Information

1890/1895 Electrical Connector Information

Hydraulic System Diagnostics

Diagrams and Descriptions

Component Operation

Troubleshooting

Adjustments

1870 Raise Lower Diagnostics

1870 Fertilizer Shank and Packer Wheel Diagnostics Type Identification

1870 Fertilizer Shank and Packer Wheel Diagnostics Type A

1870 Fertilizer Shank and Packer Wheel Diagnostics Type B

1870 Wing Fold 3-Section 40' Diagnostics

1870 Wing Fold 5-Section 56' Diagnostics

1830, 1835 Fold/Unfold Diagnostics

1830, 1835 Raise/Lower Diagnostics

730 LL Wing Fold Diagnostics

730 LL Depth Control and Down Pressure Diagnostics

1890 Rockshaft Raise/Lower and Opener Down Force - 3-Section Fame Diagnostics

1890 Rockshaft Raise/Lower and Opener Down Force - 5-Section Fame Diagnostics

1890 Wing Fold - 3-Section Frame Diagnostics

1890 Wing Fold - 5-Section Frame Diagnostics

1895 Rockshaft Raise/Lower and Opener Down Force Diagnostics

1895 Wing Fold Diagnostics

1990 Rockshaft Raise/Lower and Opener Down Force Diagnostics

1990 Wing Fold Diagnostics

1870 Component Location

730 LL Hydraulic Component Identification

tm2303 - 730LL, 1830, 1835,1840, 1870, 1890, 1895, and 1990 CCS Air Seeding Tools

Table of Contents

Foreword

Section 10: Safety and General Information

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Avoid High-Pressure Fluids

Avoid Heating Near Pressurized Fluid Lines

Service Accumulator Systems Safely

Prepare for Emergencies

Support Machine Properly

Work in Clean Area

Wear Protective Clothing

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Service Tires Safely

Servicing Electronic Control Units

Welding Near Electronic Control Units

Keep Electronic Control Unit Connectors Clean

Keep Electronic Control Unit Connectors Clean

Avoid Heating Near Pressurized Fluid Lines

Practice Safe Maintenance

Use Proper Tools

Remove Paint Before Welding or Heating

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Live With Safety

Group 10: Lubricants

Grease

Alternative and Synthetic Lubricants

Lubricant Storage

Group 15: General Information

Unauthorized Modifications

Product Identification—730 Air Disk Drill

Product Identification—730 LL Air Disk Drill

Product Identification—1830 Flex Air Hoe Drill

Product Identification—1835 Flex Air Hoe Drill

Product Identification—1840 Air Seeding Tool

Product Identification—1870 Air Hoe Drill

Product Identification—1890 No-Till Air Drill

Product Identification—1895 Separate Fertilizer Placement No-Till Air Drill

Product Identification—1990 CCS

Tractor Hydraulic System Requirements

Specifications—730 Air Disk Drill

Specifications—730 LL Air Disk Drill

Width, Height and Weight—730 Air Disk Drill

Width, Height and Weight—730 LL Air Disk Drill

Specifications—1830 Flex Air Hoe Drill

Width, Height and Weight—1830 Flex Air Hoe Drill

Specifications—1835 Flex Air Hoe Drill

Width, Height and Weight—1835 Flex Air Hoe Drill

Specifications—1840 Air Seeding Tool

Width, Height, and Weight—1840 Air Seeding Tool

Specifications—1870 Air Hoe Drill

Width, Height and Weight—1870 Air Hoe Drill

Specifications—1890 No-Till Drill

Width, Height and Weight—1890 No-Till Drill

Specifications—1895 Separate Fertilizer Placement No-Till Air Drill

Width, Height and Weight—1895 Separate Fertilizer Placement No-Till Air Drill

Specifications—1990 CCS

Width, Height and Weight—1990 CCS

Group 20: Repair Specifications

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Face Seal Fittings Assembly and Installation—All Pressure Applications

Metric Face Seal Fitting Torque Chart—Standard Pressure Applications

Metric Face Seal Fitting Torque Chart—High Pressure Applications

SAE Face Seal Fitting Torque Chart—Standard Pressure Applications

SAE Face Seal Fitting Torque Chart—High Pressure Applications

External Hexagon Port Plug Torque Chart

Section 20: Welding

Group 05: Repair and Welding

Unauthorized Modifications

Frame Repair

Welding

Emergency Crack Repair

Emergency “T” Joint Repair

Skip Welding

Stress Relief (Normalizing)

Section 30: Ground Tools, Openers, Press Wheels

Group 05: Ground Tools—1830, 1835 and 1840

Specifications

Repair Spring Reset Openers—1840

Replace Ground Tools and Boots—Spring Reset Opener

Repair Spring Cushion Opener—1830 and 1835

Replace Ground Tools and Boot—Spring Cushion Opener

Replace Tru-Position Opener Spring & Split Bushing—1830, 1835 and 1840

Replace Tru-Position Opener Shank—1830, 1835 and 1840

Group 10: Ground Tools and Openers—730 and 730 LL Air Disk Drill

Specifications

Repair Spring Reset Openers—730

Replace Spring Reset Opener Split-Tension Bushings—730

Replace Tru-Position Opener Spring and Split Bushing—730 and 730 LL

Replace Tru-Position Opener Shank—730 and 730 LL

Replace Double-Disk Blades and Bearings

Replace Wing-Style Scrapers—Old

Assemble and Install Blade Scrapers—New

Group 15: Openers—1835/1890/1895/1990 CCS

Specifications

Opener Theory of Operation—1835/1890/1895

Opener Size/Angle

Lock-Up Rockshafts and Openers

Replace Disk Openers

Replace Disk Bearings

Replace Opener Arm Pivot Bushings

Replace Seed Deflectors and Boots

Inspect Boots and Disk Openers

Group 20: Ground Tools and Openers—1870 Air Hoe Drill

Relieve Hydraulic System Pressure

Specifications

Remove and Install Fertilizer Opener

Remove and Install Fertilizer Tube and Shank

Remove and Install Seed Tube

Remove and Install Opener Assembly

Disassemble and Assemble Opener Assembly

Group 25: Press Wheels—730, 730 LL, 1830 and 1835

Specifications

Repair Press Wheel and Press Wheel Arm—730 and 730 LL Air Drill

Repair Press Wheel Axle Assembly—1830 and 1835

Replacing Semi-Pneumatic Press Wheel Tire —1830 and 1835

Installing Press Wheel Caps

Constructing Installation Band

Attaching Press Wheel Caps to Wheel

Group 30: Press, Gauge, and Closing Wheel—1870, 1890, 1895 and 1990 CCS

Specifications

Replace Closing Wheel Bearing and Arm

Repair Press Wheel Assembly

Repair Press Wheel Assembly—1870

Repair Gauge Wheel Assembly

Repair Smooth-Sided Gauge Wheel Assembly

Check Gauge Wheel Clearance—All Gauge Wheels

Section 40: Electrical

Group 05: Connector Repair

Essential or Recommended Tools

Using High-Pressure Washers

Connector Information

Repair Procedure R-A

Repair Procedure R-B

Repair Procedure R-C

Repair Procedure R-D

Repair Procedure R-E

Repair Procedure R-F

Repair Procedure R-G

Repair Procedure R-I

Repair Procedure R-J

Repair Procedure R-K

Repair Procedure R-M

Repair Procedure R-N

Repair Procedure R-AE

Group 10: Sensors and Switches

Specifications

Remove and Install Remote Seeder Switch—730 and 1890

Remove and Install Remote Seeder Switch—730 LL

Remove and Install Remote Seeder Switch—1830 and 1835

Remove and Install TouchSet Depth Control Potentiometer—1830 and 1835

Remove and Install Remote Seeder Switch—1840

Remove and Install Work Switch—1870

Disassemble and Assemble Workswitch—1870

Remove and Install Blockage Warning Sensors (If Equipped)

Section 50: Air System

Group 05: Component Inspect and Repair

Other Material

Protect Air Hoses

Inspect Air System Seals, Hoses And Header Rings

Section 60: Caster Wheels and Walking Beams

Group 05: Bearings

Specifications

Replace Caster Wheel and Pivot Bearings

Replace Walking Beam Bearings—730 LL

Replace Walking Beam Bearings—730 and 1840

Repair Dual Caster Wheels and Walking Beam—1890 50 ft. and 60 ft.

Repair Rear Wheel Support—1890 50 ft. and 60 Ft.

Replace Wheel Bearings—6-Bolt Hub

Replace Wheel Bearings—8-Bolt Hub

Replace Wheel Bearings—8-Bolt Hub

Group 10: Caster Wheel Mount

Other Material

Adjust Stabilizer Wheel—730

Section 70: Hydraulics

Group 05: Valves

Specifications

Prevent Hydraulic System Contamination

Repair Active Down-Pressure Control Valve—730 (S.N. —408)

Repair Active Down-Pressure Control Valve—730 (S.N. 409— ), 730 LL, 1835, 1890, and 1895

Remove and Install Active Down-Force Control Valve—1835, 1890, and 1990 CCS (S.N. 745101—)

Repair Active Downforce Control Valve—1835, 1890, and 1990 CCS (S.N. 745101—)

Repair Single-Point Depth Control Valve (730, 730 LL, & 1840)/ Transport Stop Valve (1830 & 1835)

Repair Fold/Marker Selector Valve

Repair Marker Sequence Valve—730 (S.N. —408)

Repair Marker Sequence Valve—730 (S.N. 409—), 1890 and 1895

Repair Wing-Fold Flow Control Valve—730 (S.N. —408)

Repair Disk Lowering Solenoid Valve—730 and 730 LL

Repair Opener Lift Sequence Valve—730 (S.N. —408)

Repair Opener Lift Sequence Valve—730 (S.N. 409—) and 730 LL

Remove and Install Wing Fold/Transport Lift Sequence Valve—1830/1835

Repair Wing Fold/Transport Lift Sequence Valve—1830/1835

Remove and Install Wing Fold Sequence Valve—1840

Group 10: Cylinders

Service Equipment and Tools

Service Parts Kit

Specifications

Specifications—Wyr-Loc and 580 Cylinders (Specifications and design subject to change without notice.)

Specifications—Tie-Rod Cylinders (Specifications and design subject to change without notice.)

Prevent Hydraulic System Contamination

Remove Hydraulic Cylinders

Wyr-Loc Cylinder Identification

Disassemble Wyr-Loc Cylinder

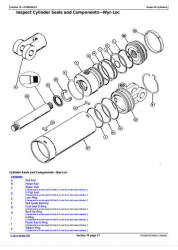

Inspect Cylinder Seals and Components—Wyr-Loc

Inspect Cylinder Barrel

Assemble Cylinder

580 Series Cylinder Identification

Disassemble 580 Series Cylinder

Inspect Cylinder Seals and Components—580 Series

Inspect Cylinder Barrel

Assemble 580 Series Cylinder

1870 Shank Depth Control Cylinder Identification

1870 Press Wheel Depth Control Cylinder Identification

Remove and Install 1870 Depth Control Cylinders

Bleed Shank and Press Wheel Depth Control Cylinder System—1870

1870 Overall Wing and Lift Cylinder Location—40'

1870 Overall Wing and Lift Cylinder Location—56'

1870 Wing Cylinder Identification

1870 Lift Cylinder Identification

Repair 1870 Lift and Wing Cylinder

Install and Bleed Wing-Fold Cylinders—All Series

Bleed Lift Cylinders—1870

Charge Hydraulic System

Install and Bleed Depth-Control Cylinders—1830, 1835, 1840, 1890, 1895 and 1990 CCS

Repair Tie-Rod Cylinder (John Deere)

Replace Cylinder Rod End Seal—John Deere

Repair Disk Gang Lift Cylinder—730

Repair John Deere Hydraulic Cylinders

Group 15: Accumulators

Service Equipment and Tools

Specifications

Remove and Install Accumulators—S.N. ( —735100)

Remove and Install Accumulators—S.N. (735101— )

Charge Accumulator—S.N. ( —735100)

Charge Accumulator—S.N. (735101— )

Section 80: Frames

Group 05: Wing Repair

Specifications

Repair Wing Stops—730

Repair Wing Stops—730 LL

Repair Wing-Lift Cylinder Anchors—730

Repair Wing-Lift Cylinder Anchors—730 LL

Repair Wing Stops and Cylinder Anchors—1890 and 1895

Repair Horizontal Fold Hinges—1890

Repair Over-Center Fold Hinges and Stop—1840

Repair Horizontal Fold Hinges and Stop—1840

Remove and Install Fertilizer Opener Rockshaft and Bearings—1835

Repair Front Depth Control Assembly—1830 and 1835

Remove and Install Wing Bell Crank and Link Assembly—1830 and 1835

Repair Depth Control Shim Pack—1830 and 1835

Group 10: Center Frame Repair

Specifications

Remove and Install Rockshaft Link and Bell Crank Assembly—1830 and 1835

Remove and Install Fertilizer Opener Rockshaft and Bearings—1835

Replace Center Frame First Rank—1830

Replace Center Frame First Rank (With Fertilizer Openers)—1835

Repair Front Depth Control Assembly—1830 and 1835

Repair Transport Height Stop Linkage

Section 240: Electrical System Diagnostics

Group 05: 1870 Wiring Diagrams—Warning Lights

Wiring Diagram—Warning Lights (With Enhancement Module)

Light Enhancement Module—Theory of Operation

Schematic—Light Enhancement Module

Group 10: Tests and Diagnosis

Visually Inspect Electrical System

Common Circuit Test

Electrical Circuit Malfunctions

High Resistance or Open Circuit

Grounded Circuit

Shorted Circuit

Probe Light to Check Voltage From Battery

Probe Light to Check Continuity to Ground

Seven Step Electrical Test Procedure

Group 15A: 1830, 1835 Lighting Diagnostics - US

Theory of Operation

Schematic

Group 15B: 1830, 1835 Lighting Diagnostics - Russian

Theory of Operation

Schematic

Group 15C: 1830, 1835 TouchSetTouchSet is a trademark of Deere & Company Harness Diagnostics

Theory of Operation

Schematic

Group 15D: 730 LL Lighting Diagnostics - North American

Theory of Operation

Schematic

Diagnostics

Group 15E: 730 LL Lighting Diagnostics - International

Theory of Operation

Schematic

Diagnostics

Group 15F: 730 LL Disk Lowering Solenoid Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15G: 1890/1895 Lighting Diagnostics - North American

Theory of Operation

Schematic

Diagnostics

Group 15H: 1890/1895 Lighting Diagnostics - International

Theory of Operation

Schematic

Diagnostics

Group 20A: 730 LL Electrical Component Identification

730 LL Electrical Component Identification

Group 20B: 730 LL Electrical Connector Information

X601 - 7-Pin Trailer Lighting and Accessory Outlet

X605 - Enhanced Lighting Module

X606 - Right-Hand Amber Hazard Lamp

X607 - Right-Hand Red Tail Lamp

X608 - Left-Hand Red Tail Lamp

X609 - Left-Hand Amber Hazard Lamp

X620 - Disk Lowering Solenoid

X621 - Solenoid Extension Harness

X622 - Solenoid Lock Adapter Harness

X623 - Main Clutch Solenoid

X701 - 7-Pin Trailer Lighting and Accessory Outlet

X706 - Right-Hand Amber Hazard Lamp

X707 - Right-Hand Red Tail Lamp

X708 - Left-Hand Red Tail Lamp

X709 - Left-Hand Amber Hazard Lamp

Group 20C: 1890/1895 Electrical Connector Information

X601 - 7-Pin Trailer Lighting and Accessory Outlet

X602 - 7-Pin Trailer Lighting and Accessory Outlet (to air cart)

X605 - Enhanced Lighting Module

X606 - Right-Hand Amber Hazard Light

X607 - Right-Hand Red Tail Light

X608 - Left-Hand Red Tail Light

X609 - Left-Hand Amber Hazard Light

X701 - 7-Pin Trailer Lighting and Accessory Outlet

X702 - 7-Pin Trailer Lighting and Accessory Outlet (to air cart)

X706 - Right-Hand Amber Light

X707 - Right-Hand Position/Stop Light

X708 - Left-Hand Position/Stop Light

X709 - Left-Hand Amber Light

Section 270: Hydraulic System Diagnostics

Group 05: Diagrams and Descriptions

Depth Control and Down-Pressure System Description—730

Parallel-Series Hydraulic Depth-Control System—1840

Down Pressure System Description—1890

Wing-Fold and Row Marker System Description—730/1890 If Equipped

Wing Fold Sequence Valve Schematic—1840

Hydraulic Component Location—1870

Group 10: Component Operation

Depth-Control Cylinder Filter Operation

Single-Point Depth-Control Valve Operation—730 and 1840

Active Down-Pressure Valve Operation—730 and 1890

Row Marker Sequence Valve Operation—730 and 1890 (Optional)

Fold/Marker Selector Valve Operation

Wing Fold Sequence Valve Operation—1840

Group 10A: Troubleshooting

Troubleshooting—Active Down-Pressure

Troubleshooting—Single-Point Depth Stop

Troubleshooting—Tractor With Open-Center Hydraulics (Active Down-Pressure)

Troubleshooting—Row Markers

Check For Depth-Control Cylinder Leakage—730 and 1840

Group 15: Adjustments

Adjust Single Point Depth-Control Channel—730 and 1840

Adjust Wing Fold/Transport Lift Sequence Valve

Adjusting Wing-Fold Sequence Valve—1840

Group 15A: 1870 Raise Lower Diagnostics

Theory of Operation

1870 Raise Lower Schematic

Raise Lower Diagnostics

Group 15B: 1870 Fertilizer Shank and Packer Wheel Diagnostics Type Identification

1870 Fertilizer Shank and Packer Wheel Diagnostics Type Identification

Group 15C: 1870 Fertilizer Shank and Packer Wheel Diagnostics Type A

Theory of Operation

Fertilizer Shank and Packer Wheel Schematic

Fertilizer Shank and Packer Wheel Diagnostics

Group 15D: 1870 Fertilizer Shank and Packer Wheel Diagnostics Type B

Theory of Operation

Fertilizer Shank and Packer Wheel Schematic

Fertilizer Shank and Packer Wheel Diagnostics

Group 15E: 1870 Wing Fold 3-Section 40' Diagnostics

Theory of Operation

Wing Fold Schematic

1870 Wing Fold 3-Section 40' Diagnostics

Group 15F: 1870 Wing Fold 5-Section 56' Diagnostics

Theory of Operation

Wing Fold Schematic

1870 Wing Fold 5-Section 56' Diagnostics

Group 15G: 1830, 1835 Fold/Unfold Diagnostics

Theory of Operation, 5 Section

Schematic, 5 Section

Theory of Operation, 3 Section

Schematic, 3 Section

Group 15H: 1830, 1835 Raise/Lower Diagnostics

Theory of Operation

Schematic

Group 15I: 730 LL Wing Fold Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15J: 730 LL Depth Control and Down Pressure Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15K: 1890 Rockshaft Raise/Lower and Opener Down Force — 3-Section Frame Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15L: 1890 Rockshaft Raise/Lower and Opener Down Force — 5-Section Frame Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15M: 1890 Wing Fold — 3-Section Frame Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15N: 1890 Wing Fold — 5-Section Frame Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15O: 1895 Rockshaft Raise/Lower and Opener Down Force Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15P: 1895 Wing Fold Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15Q: 1990 Rockshaft Raise/Lower and Opener Down Force Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 15R: 1990 Wing Fold Diagnostics

Theory of Operation

Schematic

Diagnostics

Group 20A: 1870 Component Location

1870 Hydraulic Component Location - 3 section 40'

1870 Hydraulic Component Location - 5 section 56'

Group 20B: 730 LL Hydraulic Component Identification

730 LL Hydraulic Component identification