John Deere Tractors 7600, 7700, 7800 Diagnosis and Tests Service Technical Manual (TM1501)

Complete Diagnosctics & Tests Technical Manual with electrical wiring diagrams for John Deere 7600, 7700 and 7800 (2WD or MFWD) Tractors, with all the technical information to maintain, diagnose and service like professional mechanics.

John Deere 2WD or MFWD Tractors 7600, 7700 and 7800 workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm1501 - 7600, 7700 and 7800 Tractors Technical Manual - Operation and Test.pdf

Total Pages: 1,561 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Safety Information

Safety

General Information

Operational Checks

General Reference Information

Test Equipment Calibration

Diagnostic Service Codes

CCU

HCU

LHP

PCU

Observable Symptoms

Brakes

Hitch

Operators Station

Hydraulics

Engine Operation and Tests

General Information

Fuel, Air Intake and Engine Cooling Systems

Fuel/Air/Cooling System Theory of Operation

Electrical Operation and Tests

Diagnostic Codes and Addresses

Electrical System Information

System Diagrams

Sub-System Diagnostics

Calibration and References

Power Shift Transmission

Operational Checks

Power Shift Transmission Diagnosis

Theory of Operation

PowrQuad PowrQuad is a trademark of Deere & Company.

Transmission

PowrQuad PowrQuad is a trademark of Deere & Company.

Transmission Operational Checks

PowrQuad PowrQuad is a trademark of Deere & Company.

Transmission Diagnosis

Theory of Operation

Drive Systems

Operational Checks

Drive System Diagnosis

Adjustments

Theory of Operation

Steering and Brakes

Tests and Adjustments

Theory of Operation

Hydraulic System

Operational Checks

Hydraulic System Diagnosis

Calibration and Adjustments

Theory of Operation

Operator Station

Air Conditioning Operational Checks

Air Conditioning System Diagnosis

Air Conditioning Theory of Operation

Dealer Fabricated Tools

tm1501 - 7600, 7700 and 7800 Tractors Operation and Test

Table of Contents

Foreword

Section 205: Safety Information

Group 05: Safety

Recognize Safety Information

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Avoid High-Pressure Fluids

Service Accumulator Systems Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Keep ROPS Installed Properly

Service Tires Safely

Avoid Harmful Asbestos Dust

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Prevent Machine Runaway

Handle Starting Fluid Safely

Service Cooling System Safely

Stay Clear of Rotating Drivelines

Protect Against High Pressure Spray

Construct Dealer-Made Tools Safely

Clean Vehicle of Hazardous Pesticides

Live With Safety

Section 210: General Information

Group 05: Operational Checks

Electrical System Checks

Before You Start

Transmission Checks

Before You Start

Hydraulic System Checks

Air Conditioning System Checks

Group 10: General Reference Information

JT03412—Supplemental Pressure Test Kit

JT03413—Supplemental Flow Test Kit

JT03419—ORFS Fitting Kit

JT05406—Master Hydraulic Flow Test Fitting Kit

JT05416—Consumer Products Hydraulic Flow Test Kit

JT05452—Power Shift Transmission Test Kit

JT03134—Power Shift Transmission Optional Accessories

JT05469—Flowmeter Kit

JT05470—Agricultural Universal Pressure Test Kit

Required Test Fittings

List of Diagnostic Adapters—ORFS

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

JIC Hydraulic Symbols

Glossary of Terms

Group 15: Test Equipment Calibration

JDG282 Temperature Gauge Check

Calibration Check of OTC Flow Meters

Method No. 1: Flow Meter (Main Pump Quick Check From SCV)

Method No. 2: Volume Check From Flow Meter

Pressure Gauge Calibration Checker

Section 211: Diagnostic Service Codes

Group 05: CCU

CCU 001 - Fuel Level Sensor Circuit, Repair

CCU 003 - Fuel Level Low

CCU 010 - Engine Coolant Temperature High, Repair

CCU 011 - Engine Coolant Temperature Very High, Repair

CCU 012 - Coolant Temperature Sensor / Circuit Open, Repair

CCU 013 - Coolant Temperature Sensor / Circuit Shorted, Repair

CCU 015 - Hydraulic Oil Temperature High, Repair

CCU 016 - Hydraulic Oil Temperature Very High, Repair

CCU 017 - Hydraulic Oil Temperature Sensor Circuit Open, Repair

CCU 018 - Hydraulic Oil Temperature Sensor Circuit Shorted, Repair

CCU 021 - Engine Oil Pressure Low (Pressure Switch), Repair

CCU 026 - Transmission Oil Pressure Low, Repair

CCU 030 - Engine Air Filter Restricted, Repair

CCU 035 - Transmission Oil Filter Restricted, Repair

CCU 045 - System Voltage Too Low (Idle-to-1500 rpm), Repair

CCU 046 - System Voltage Too Low (Above 1500 rpm), Repair

CCU 047 - System Voltage Too High (Engine running), Repair

CCU 048 - CCU Supply Voltage Low w/Engine OFF

CCU 050 - Hydraulic Oil Filter Restricted, Repair

CCU 055 - Secondary Hand Brake ON when Moving

CCU 060 - High Pressure In Steering Hydraulic System, Repair

CCU 067 - Sensor Power Source (12V) Missing Fuse F1, Repair

CCU 070 - Operator Not Seated w/Rear PTO ON

CCU 071 - PTO Switch ON at Power Up

CCU 072 - Rear PTO Control Switch/Circuit Failed, Repair

CCU 073 - Rear PTO Solenoid/Circuit Failed, Repair

CCU 075 - Rear PTO Speed Too Low with PTO ON, Repair

CCU 077 - Operator Not Seated w/Front PTO ON

CCU 078 - Front PTO-Switch OFF But Solenoid ON, Repair

CCU 080 - Differential Lock Switch Stuck ON, Repair

CCU 081 - Differential Lock Circuit Fault With Switch ON, Repair

CCU 085 - MFWD Control Switch Error, Repair

CCU 086 - MFWD Circuit Fault With Switch OFF, Repair

CCU 093 - Clutch Cooling Solenoid Circuit Failure

CCU 094 - Fuel Advance Solenoid Circuit Failure

CCU 101 - Clutch Cooling Not Allowed

CCU 102 - HMS Not Allowed

CCU 103 - HMS Disabled w/Towed Implement Mode Active

CCU 104 - Remote PTO Operation Not Allowed

CCU 105 - Self-Canceling Turn Signals Not Allowed

CCU 255 - Phantom Code

Group 10: HCU

HCU 022 - Battery Voltage Out of Range, Repair

HCU 027 - Calibration Not Successful, Repair

HCU 028 - Calibration Memory Failure, Repair

HCU 029 - Calibration Selected For Less Than 30 Seconds, Repair

HCU 041 - Pressure Valve Solenoid Circuit, Repair

HCU 042 - Return Valve Solenoid Circuit, Repair

HCU 043 - Pressure Valve Solenoid Circuit, Repair

HCU 044 - Return Valve Solenoid Circuit, Repair

HCU 045 - Sensor Supply Voltage Out of Range, Repair

HCU 049 - Raise/Lower Rocker Switch Circuit, Repair

HCU 050 - HCU Failure, Repair

HCU 052 - Draft Sensor Circuit, Repair

HCU 053 - Load/Depth Control Potentiometer Circuit, Repair

HCU 054 - Hitch Control Lever Potentiometer Circuit, Repair

HCU 055 - Hitch Position Feedback Sensor Circuit, Repair

HCU 056 - Raise Limit Control Potentiometer Circuit, Repair

HCU 057 - Rate-of-Drop Control Potentiometer Circuit, Repair

HCU 058 - External Raise/Lower Switch Circuit, Repair

Group 15: LHP

LHP 022 - Battery Voltage Out of Range, Repair

LHP 027 - Calibration Not Successful, Repair

LHP 028 - Calibration Memory Failure or Never Calibrated, Repair

LHP 029 - Calibration Selected For Less Than 30 Seconds, Repair

LHP 045 - Sensor Supply Voltage Out of Range, Repair

LHP 050 - Row-Trak Control Unit Failure, Repair

LHP 054 - Position Control Circuit, Repair

LHP 055 - Pivot Angle Circuit, Repair

LHP 056 - Response Rate Control Circuit, Repair

LHP 057 - Row Sensor Circuit, Repair

LHP 058 - Row Sensor Raise Circuit, Repair

LHP 059 - Row Sensor Lower Circuit, Repair

LHP 060 - CCD Communication Line Failure, Repair

LHP 141 - Extend Valve Solenoid Circuit, Repair

LHP 142 - Retract Valve Solenoid Circuit, Repair

LHP 143 - Extend Valve Solenoid Circuit, Repair

LHP 144 - Retract Valve Solenoid Circuit, Repair

Group 20: PCU

PCU 008 - Manifold Absolute Pressure Sensor Out of Range, Repair

PCU 011 - Oil Temperature Is Cold For Proper Input Planetary Operation, Repair

PCU 012 - Oil Pressure Is Low For Proper Input Planetary Operation, Repair

PCU 016 - Excessive Engine Oscillation During Calibration, Repair

PCU 018 - Fault Detected In Diagnostic Mode, Repair

PCU 019 - PCU Not Calibrated For 30 km/h-40 km/h Speed, Repair

PCU 027 - Transmission Not Calibrated, Repair

PCU 028 - B4 Element Not Calibrated, Repair

PCU 030 - Clutch Engaged and Disengaged Switch Conflict (Both Closed), Repair

PCU 031 - Both Clutch Engaged and Disengaged Switches Open For Too Long (“Riding the Clutch”), Repair

PCU 038 - EOL Data Error, Repair

PCU 039 - Reverse Enable Circuit Fault, Repair

PCU 040 - Forward Enable Circuit Fault, Repair

PCU 041 - Forward and Reverse Enable Circuit Conflict (Both Enabled), Repair

PCU 042 - Command Conflicts With Enable Circuit (Reverse Commanded/Forward Enabled), Repair

PCU 043 - Command Conflicts With Enable Circuit (Forward Commanded/Reverse Enabled), Repair

PCU 044 - Command Conflicts With Enabled Circuit (Forward or Reverse Commanded/Transmission Not Enabled), Repair

PCU 045 - Command Conflicts With Enabled Circuit (Neutral or Park Commanded/Transmission IS Enabled), Repair

PCU 047 - Shift Lever Between “N' and “1F” or “1R” Too Long, Repair

PCU 050 - No Tractor Motion-Engine OFF, Repair

PCU 051 - No Tractor Motion-Engine Running, Repair

PCU 058 - Tractor Moved During Calibration, Repair

PCU 065 - PCU Fault (Checksum Error), Repair

PCU 066 - Key Switch ON with Transmission in Gear, Repair

PCU 067 - Transmission Enable Circuit Fault, Repair

PCU 068 - Gear Command Fault

PCU 069 - Calibration Failure, Repair

Section 212: Observable Symptoms

Group 10: Brakes

Brakes Function Erratically

Group 20: Hitch

Hitch only moves with External Switch

Group 30: Operators Station

Digital Tachometer Display Not Functioning

Poor AM & FM Radio Reception or Electrical Noise

Key Switch Won't Return to Run Position

Group 70: Hydraulics

Grapple Valve Holds System Pressure Above Standby for Several Seconds

Section 220: Engine Operation and Tests

Group 05: General Information

Engine Operation and Tests

Section 230: Fuel, Air Intake and Engine Cooling Systems

Group 20: Fuel/Air/Cooling System Theory of Operation

Fuel System

Air Intake System

Engine Cooling System

Section 240: Electrical Operation and Tests

Group 04: Diagnostic Codes and Addresses

Diagnostic Codes and Addresses

Diagnostic Codes

CCU Diagnostic Code Numbers

HCU Diagnostic Code Numbers

LHP Diagnostic Code Numbers

PCU Diagnostic Code Numbers

CCU Addresses

HCU Addresses

LHP Addresses

PCU Addresses

PRF Addresses

Group 05: Electrical System Information

Service Equipment and Tools

Other Material

Specifications

Using Electrical Section

Wiring Diagram and Schematic Information

Electrical Schematic Symbols

Reading a System Functional Schematic

Reading a Wiring Diagram

Reading a Diagnostic Schematic

Visually Inspect Electrical System

Seven Step Electrical Test Procedure

Electrical Circuit Malfunctions

High Resistance or Open Circuit

Grounded Circuit

Shorted Circuit

Understanding Electrical vs. Electronic Circuit Voltage Test Readings

Intermittent Electronic Problems

Group 10: System Diagrams

Component Identification Legend

Component Identification Table

Legend for System Functional Schematic (Cab)

Legend for System Functional Schematic (Open Station)

Ground Locations

System Functional Schematic—Cab—SE1 (Power Supply, Starting and Charging Circuits), SE2 (Wiper, Seat Control and Lighter Circuits), and SE3 (Air Quality System and Convenience Outlet

System Functional Schematic—Cab—SE4 (Radio, Dome Lamp and Multi-Function Switch) and SE5A (Lighting System - Region I)

System Functional Schematic—Cab—SE4 (Radio, Dome Lamp and Multi-Function Switch) and SE5B (Lighting System - Region II)

System Functional Schematic—Cab—SE6 (Hitch Control Unit - HCU), SE7 (PST Control Unit - PCU) and SE8 (Radar and Front PTO Circuits)

System Functional Schematic—Cab—SE9 (Central Control Unit - CCU) and SE10 (Display Modules)

System Functional Schematic—Open Station—SE1 (Power Supply, Starting System), SE2 (Seat Control System), SE3 (Convenience Outlet), SE4 (Radio, Lighter, Multi-Function Switch)

System Functional Schematic—Open Station—SE5 (Domestic Lighting) and SE6 (Hitch Control Unit - HCU)

System Functional Schematic—Open Station—SE7 (PST Control Unit - PCU), SE8 (Radar and Front PTO Circuits) and SE9 (Central Control Unit - CCU)

System Functional Schematic—Open Station—SE10 (Display Modules)

Fuse Panel (W2, W3, W4, W5, W28) (F1—F12)

Fuse Panel (W2, W3, W4, W5, W28) (F13—F20)

Fuse Panel (W2, W3, W4, W5, W28) (F21—F33)

Fuse Panel (W2, W3, W4, W5, W28) (F34—F36)

Load Center Relays (W2, W3, W4, W5, W28) (K1—K5)

Load Center Relays (W2, W3, W4, W5, W28) (K6—K9)

Load Center Relays (W2, W3, W4, W5, W28) (K10—K18)

Diode Blocks (W2, W3, W4, W5, W28) (V2—V3)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (A1—A2)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (A3)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (A4)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (A5—E3)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (E4—E9)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (E10—H5)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (J1—K18)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (K24—K31)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (K32—R3)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (R7—S5)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (S7—S18)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (S19—S33)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (S34—X1)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (X2—X10)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (X11—X21)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (X22—X30)

Cab/Open Operator Station Harness (W2, W3, W4, W5, W28) (X31—Y9)

PST and PowrQuad PowrQuad is a trademark of Deere & Company. Cab Harness Routing/Component Location (North American)

PST and PowrQuad PowrQuad is a trademark of Deere & Company. Cab Harness Routing/Component Location (European)

Open Operator Station Harness Routing/Component Location

Engine Harness (W6, W7) (B2—K21)

Engine Harness (W6, W7) (K22—X3)

Engine Harness (W6, W7) (X27—Y7)

Engine Harness Routing/Component Location (7600)

Engine Harness Routing/Component Location (7700)

Engine Harness Routing/Component Location (7800)

Transmission Sensor Harness (W8 and W9) (B5—S37)

Transmission Sensor Harness (W8 and W9) (W31—Y24)

PST Transmission Solenoid Harness (W10) (S27—Y19)

Transmission Harnesses Routing/Component Location (PST)

Transmission Harnesses Routing/Component Location (PQT)

Turn Signal Switch Harness (W15)

Wiper Switch Harness (W16)

Roof Lights Harness (W11 and W12) and Front Floods Harness (W13)

Hitch Controls Harness (W14) and Convenience Outlet Harness (W17)

Seat Harnesses (Air Suspension—W25 and Mechanical Suspension—W26)

Front PTO Harness (W29 and W34)

Group 15: Sub-System Diagnostics

Starting Circuit

Starting Circuit Operational Information

Starting Circuit Theory of Operation

Voltage Checks

Power Supply Circuit

Power Circuit Operational Information

Power Circuit Theory of Operation

Temperature Correction Chart

Charging Circuit

Charging System Operational Information

Charging Circuit Theory of Operation

Voltage Checks

Wiper Circuit

Wiper Circuit Operational Information

Wiper Circuit Theory of Operation

Voltage Checks

Ground Fault Circuit Interrupter/Heaters

Ground Fault Circuit Operational Information

G.F.C.I. Circuit Theory of Operation

Voltage Checks

Seat Circuit

Seat Circuit Operational Information

Seat Circuit Theory of Operation

Voltage Checks

Cigarette Lighter Circuit

Lighter Circuit Operational Information

Lighter Circuit Theory of Operation

Voltage Checks

AQS and Convenience Outlet Circuits Schematic

AQS and Convenience Outlet Circuits Diagnostic Schematic

Air Quality System Diagnosis

Voltage Checks

Radio, Dome Lamp and Multi-Function Control Circuits Schematic

Radio, Dome Lamp and Multi-Function Control Circuits Diagnostic Schematic

Horn Circuit Operational Information

Horn Circuit Theory of Operation

Voltage Checks

Dome Lamp Circuit Operational Information

Dome Lamp Circuit Theory of Operation

Voltage Checks

Radio and Clock Circuit Operational Information

Radio and Clock Circuit Theory of Operation

Voltage Checks

Lighting System Schematic (North American)

Lighting System Diagnostic Schematic (North American)

Lighting Circuit Operational Information (North American)

Lighting Circuit Operation (North American)

Lighting Circuit Theory of Operation (North American)

Turn Signal and Warning Lights Circuit Theory of Operation

Voltage Checks

Lighting System Schematic (European)

Lighting System Diagnostic Schematic (European)

Lighting Circuit Operational Information (European Version)

Lighting Circuit Operation (European)

Lighting Circuit Theory of Operation (European)

Turn Signal and Warning Lights Circuit Theory of Operation

Voltage Checks

Hitch Control Circuit Schematic

Hitch Control Circuit Diagnostic Schematic

Hitch System Diagnosis

PST Control Circuit Schematic

PST Control Circuit Diagnostic Schematic

Power Shift Transmission Control Circuit Diagnosis

Radar Sensor Circuit

Front PTO Circuit (North American)

Front PTO Circuit Theory of Operation

Front PTO Circuit (EUR)

CCU Fault Code Numbers

CCU Input—Output Signals

Differential Lock Circuit

Differential Lock Circuit Theory of Operation

Voltage Checks

MFWD Circuit

MFWD Circuit Theory of Operation

Voltage Checks

Rear PTO Circuit

Rear PTO Circuit Theory of Operation

Voltage Checks

Clutch Cooling Circuit (Early PowrQuad PowrQuad is a trademark of Deere & Company. Transmissions)

Clutch Cooling Circuit Theory of Operation (Early PowrQuad PowrQuad is a trademark of Deere & Company. Transmissions)

Wheel Speed Sensor Circuit

Wheel Speed and True Ground Speed

Voltage Checks

Engine Speed Sensor Circuit

Voltage Checks

Fuel Level Sender Circuit

Voltage Checks

System Voltage Monitoring Circuit

Engine Coolant Temperature Sensor Circuit

Voltage Checks

Hydraulic Oil Temperature Circuit

Voltage Checks

Engine Oil Pressure Sensor Circuit

Voltage Checks

Transmission Oil Pressure Sensor Circuit

Voltage Checks

Air Filter Restriction Sensor Circuit

Voltage Checks

Transmission Oil Filter Restriction Sensor Circuit

Voltage Checks

Hydraulic Oil Filter Restriction Sensor Circuit

Voltage Checks

Hand Brake Switch Circuit

Sensor Excitation Circuit

Sensor Excitation Detection Circuit

CCD Communication Line

Voltage Checks

Engine Hours Circuit

Engine Hours and Engine Starts

Display Modules Circuit Schematic

Display Modules Circuit Diagnostic Schematic

Display Modules Circuit Operational Information

Tachometer Input—Output Signals

Performance Monitor Operational Information

Performance Monitor Features

Performance Monitor Normal Operating Mode

Performance Monitor Set Mode

Performance Monitor Input—Output Signals

Control Modules Diagnostic Schematic

Group 20: Calibration and References

CCU Addresses

Accessing Tachometer Modes

CCU Modes/Addresses Navigational Flow Chart

CCU “Read Only” Addresses

Circuit Address Numbers

Address Numbers “20” through “99”

CCU Non-Diagnostic “Read Only” Addresses

Performance Monitor—Calibration and Diagnostic Tool

Calibrating Radar and Wheel Speed Sensors

Wheel Rolling Circumference and Percent Slip Zeroing

Battery Specifications

Battery Operation

Check Battery Electrolyte Level and Terminals

Procedure for Testing Batteries

Diagnose Battery Malfunctions

Using a Booster Battery or Battery Charger

Section 250: Power Shift Transmission

Group 05: Operational Checks

Before You Start

Group 10: Power Shift Transmission Diagnosis

Use Step-by-Step Hydraulic Diagnostic Charts

Special or Essential Tools

Service Equipment and Tools

Other Material

Transmission Cooler Flow Check

System and Lube Pressure Check

MFWD Clutch Element Leak Check

Avoid High-Pressure Fluids

Adjust for Correct Pressure and Temperature References

Observe Safety Precautions

PCU Operation

Gear Number Display

Gear/Element Combinations

PCU Diagnostic Addresses

How to Enter Diagnostic Address

How to Display and Clear Stored Diagnostic Codes (Address 1)

PCU Addresses

PCU Diagnostic Codes

Operating Diagnostic Beep Addresses 02—13

Accessing Tachometer Addresses

Come-Home Feature and Operation

Transmission Calibration Procedure

Error Messages

Calibration Errors

Shortened Diagnostic Procedure

Isolating Transmission Problems

Major System Checks

Power Shift Transmission Record Sheet

Test Procedure No. 1

Test Procedure No. 2

Test Procedure No. 3

Group 20: Theory of Operation

Guide to Power Shift Transmission Theory

PST Transmission (Components)

Planetary Operation

Test Port/Sensor Location

Element Engagement Chart

Hydraulic Control of Transmission

Electro-Hydraulic (FEMA) Valve

Reduction Gear Box

Power Shift Transmission Schematic (Component Identification)

Section 255: PowrQuad PowrQuad is a trademark of Deere & Company. Transmission

Group 05: PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Operational Checks

Before You Start

Group 10: PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Diagnosis

Use Step-By-Step Hydraulic Diagnostic Charts

Special or Essential Tools

Service Equipment and Tools

Other Material

Transmission Cooler Flow Check

System and Lube Pressure Check

MFWD Clutch Element Leak Check

Avoid High-Pressure Fluids

Adjust for Correct Pressure and Temperature References

Observe Safety Precautions

Shortened Diagnostic Procedure

Major System Checks

Group 20: Theory of Operation

Guide To PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Theory

PowrQuad PowrQuad is a trademark of Deere & Company. Transmission

PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Schematic—Early Version (Component Identification)

PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Schematic—Early Version (Component Identification)

PowrQuad PowrQuad is a trademark of Deere & Company. Transmission Schematic—Later Version

Planetary Operation

Test Port and Sensor Identification

Air Pump

Transmission Oil Pump

Clutch Oil Manifold

Reverse Brake Housing

Filter Relief Valve

Pressure Regulating Valve

Speed Control Circuit

EOV Circuit

Speed Modulator

Shifting From One Speed to Another Using the Speed Control Lever

Speed Lever Moved from Neutral to Second Forward or Second Reverse

FWD-REV Modulation

Shift Lever Moved From Neutral to Forward or Reverse

Shift Lever Moved From Forward or Reverse to Neutral:

Traction Element Cooling Oil Components

Oil Cooler System

Creeper Transmission Operation

Range Box

Section 256: Drive Systems

Group 05: Operational Checks

Drive Systems

Group 10: Drive System Diagnosis

Special or Essential Tools

Avoid High-Pressure Fluids

Differential Lock Leak Check

Rear Differential Diagnosis

PTO Checks

Using MFWD Step By Step Test Procedure

Observe Service Precaution

MFWD Electrical Schematic

Group 20: Adjustments

MFWD Brake Pedal Switch Adjustment

Group 25: Theory of Operation

Differential Lock Operation

Rear Differential Operation

Final Drive Operation

PTO Modulating Valve Operation

Rear PTO

Rear PTO Clutch and Brake Operation

Dual Speed PTO— 1000 RPM Engagement

Dual Speed PTO— 540 RPM Engagement

Two-Speed Shiftable PTO— 1000 RPM Engagement

Two-Speed Shiftable PTO— 540 RPM Engagement

Front PTO

Front PTO Operation

MFWD Clutch Operation

MFWD Axle Operation

MFWD Differential Operation— Limited Slip

Section 260: Steering and Brakes

Group 15: Tests and Adjustments

Brake Operational Test

Group 20: Theory of Operation

Steering System Operation

Hydraulic System— Primary Circuit — Steering and Brakes

Steering Control Valve Assembly

Cutaway View of Steering Valve

Gerotor Operation

Neutral Steering

Right-Turn Steering

Emergency Steering

Gerotor Operation

Ground-Driven Auxiliary Steering Pump

Normal Steering Mode

Brake Pistons, Plates and Disks Operation

Brake Released

Brake Modulation

Brake Engaging

Manual Braking— Prefill

Manual Braking— Engaging

Section 270: Hydraulic System

Group 05: Operational Checks

Before You Start

Group 10: Hydraulic System Diagnosis

Use Step-by-Step Hydraulic Diagnostic Charts

Special or Essential Tools

Service Equipment and Tools

Hydraulic Filter Check

Main Pump Inlet Check

Primary Circuit Pressure Check

Hydraulic Pump Flow Check

Pump Load-Sense Pressure Check

Main Pump Flow Check

Avoid High-Pressure Fluids

Adjust for Correct Pressure and Temperature References

Observe Safety Precautions

Heating Hydraulic Oil

Navigational Flow Chart

Major System Checks—Hydraulics

Additional Troubleshooting Information

Hydraulic System Response to a Missing Shuttle Check Valve

SCV and Coupler Leak Test

Three-Position SCV Lever Kick Out Adjustment

Bleeding Load-Sense and Hydraulic Pressure Circuits

Electro-Hydraulic Depth Control (EHDC) Diagnosis

Hitch Troubleshooting Tips

Come Home Feature

Component Test Specifications

HCU Hardware and Software Information

Hitch Circuit Diagnosis

Test Procedure No. 1—HCU

Diagnostic Codes

HCU Diagnostic Code Numbers

Test Procedure No. 2

HCU Circuit Diagnostic “Beep” Addresses

Test Procedure No. 3

Test Procedure No. 4

Test Procedure No. 5

Test Procedure No. 6

Test Procedure No. 7

Test Procedure No. 8

Test Procedure No. 9

Test Procedure No. 10

Test Procedure No. 11

Test Procedure No. 12

Test Procedure No. 13

Test Procedure No. 14

Test Procedure No. 15

Test Procedure No. 16

Test Procedure No. 17

Adjust Hitch Valve

Test Procedure No. 18

Test Procedure No. 19

Test Procedure No. 20

Test Procedure No. 21

Test Procedure No. 22

Test Procedure No. 23

ROW-TRAK ROW-TRAK is a trademark of Deere & Company. (LHP) Tests

Diagnostic Codes

LHP Diagnostic Code Numbers

Test Procedure No. 2

LHP Circuit Diagnostic “Beep” Addresses

Test Procedure No. 3

Test Procedure No. 4

Test Procedure No. 5

Test Procedure No. 6

Test Procedure No. 7

Test Procedure No. 8

Test Procedure No. 9

Test Procedure No. 10

Test Procedure No. 11

Test Procedure No. 12

Test Procedure No. 13

Test Procedure No. 14

Test Procedure No. 15

Test Procedure No. 16

Test Procedure No. 17

Test Procedure No. 18

Test Procedure No. 19

Test Procedure No. 20

Test Procedure No. 21

Test Procedure No. 22

Test Procedure No. 23

Test Procedure No. 24

Hitch Control Circuit Schematic

Hitch Control Circuit Diagnostic Schematic

Group 15: Calibration and Adjustments

HCU Addresses

Set Hitch Controls for Calibration

LHP Addresses

Prepare ROW-TRAK ROW-TRAK is a trademark of Deere & Company. System for Calibration

Group 20: Theory of Operation

Hydraulic System Components

Hydraulic System Schematic

Hydraulic System Schematic (Component Identification)

Pump Operation

Hydraulic System—Charge Circuit Schematic

Hydraulic Filter Operation

Charge Pump

Hydraulic System Secondary Circuit (Component Identification)

Priority Valve

Neutral—at Start Up

Neutral

Steering Operation

Steering Relief

Steering Returned to Neutral

High Pressure Demand from Secondary

Two-Position Selective Control Valve—Neutral

Two-Position Selective Control Valve—Extend

Two-Position Selective Control Valve—Retract

Two-Position Selective Control Valve—Float

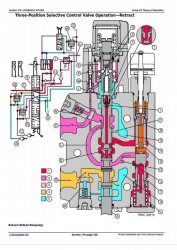

Three-Position Selective Control Valve Operation—Neutral

Three-Position Selective Control Valve Operation—Extend

Three-Position Selective Control Valve Operation—Retract

Three-Position Selective Control Valve Operation—Float

ISO Coupler—Closed

ISO Coupler—Coupling

ISO Coupler—Opening

ISO Coupler—Uncoupling

Hitch Control Valve

Pressure and Return Solenoid Valves

Hitch Control Valve—Neutral Position

Pressure Compensator Valve

Load Check Valve

Surge Relief Valve

Hitch Load-Sense Check Valve

Hitch Operation—Raised

Hitch Operation—Stopped

Hitch Operation—Lower

Hitch Operation—Full Lower

Three Point Hitch Hydraulic Operation

Hitch Controls

Electro-Hydraulic Hitch Circuit

Electro-Hydraulic Hitch Sensor Locations

Hitch Control Unit (HCU)

Operator Controls

Hitch Control Lever

Load/Depth Control Potentiometer

Rate-of-Drop Control Potentiometer

Raise Limit Control Potentiometer

Console Raise/Lower Rocker Switch

External Raise/Lower Switch

Hitch Sensing Devices

Hitch Position Feedback Sensor

Load/Draft Sensor

Remote Lift Assist (RLA) and Electro-Hydraulic Depth Control (EHDC) Features

Remote Lift Assist (RLA) Mode

Electro-Hydraulic Depth Control (EHDC)—Optional

Electro-Hydraulic Depth Control (EHDC) Mode

Wiring Harnesses

Hitch Harnesses

Section 290: Operator Station

Group 05: Air Conditioning Operational Checks

Before You Start

Group 10: Air Conditioning System Diagnosis

Service Equipment and Tools

Specifications

Air Conditioning System Components

Air Conditioning System

AQS and Convenience Outlet Circuits Schematic (SE3)

AQS and Convenience Outlet Circuits Diagnostic Schematic (SE3)

Group 25: Air Conditioning Theory of Operation

Refrigerant

Air Conditioning System Air Flow

Air Conditioning System Cycle

Compressor

Condenser

Receiver-Dryer

Expansion Valve

De-Icing Switch

Evaporator

Temperature Control Knob

Compressor On/Off Switch

High and Low Pressure Switches

Section 299: Dealer Fabricated Tools

Group 05: Dealer Fabricated Tools

DFRW2—Needle Valve Test Hose Assembly

DFRW51—Electronic Circuit Load Tester

DFRW85—Reverse Brake Test Plate

DFRW86—Spool Holding Tool

DFRW60 - DFRW61 - DFRW62—Extension Harnesses

DFRW63 - DFRW64 - DFRW65 - DFRW66 - DFRW81—Tap-Out Harnesses

John Deere Tractors 7600, 7700, 7800 Diagnosis and Tests Service Technical Manual (TM1501)