John Deere Tractors 6405 & 6605 Diagnosis and Tests Service Technical Manual (TM4867)

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere 2WD or MFWD Tractors 6405 and 6605, with technical information to maintain, diagnose, service like professional mechanics.

John Deere 2WD or MFWD - Brazilian Tractors 6405 and 6605 workshop Diagnostics & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm4867 - tractors 6405 and 6605 operation and tests Technical Manual.pdf

tm4867 - tractors 6405 and 6605 operation and tests Technical Manual.epub

Total Pages: 814 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Introduction

Safety

Norms of Safety

Electric System

Special Tools for Electricity

Electric Harness Connector Maintenance

Multitester Identification

Source Circuit and Starting

Power take-off - (PTO)

Front Wheel Drive

Differential Lock

Circuit of the lights

Recharge Circuit of the Battery

Tractor Monitoring

Hydraulic Control Unit - HCU

Cab

SyncroPlus Transmission

SyncroPlus Transmission Troubleshooting

Tests and Regulations

Operation - SyncroPlus Transmission

PermaClutch II

Gearbox

Group Gears

PowrQuad Transmission

Operation

Troubleshooting

Regulating the Gearshift Unit

Operation - PowrQuad Transmission

Power Transmission

Front Wheel Drive Clutch

Diagnosis of the FWD, Differential Lock and PTO

Steering and Brakes

Operation and Tests

Troubleshooting

Checking the Steering and Brakes

Hydrostatic Steering-Danfoss

Hydrostatic Steering-Eaton

Brakes

Hydraulic system

Troubleshooting - 100-liter Pump

Preliminary Tests

100 L Pump - Troubleshooting

Hydraulic System Diagnostic - Gear Pump

Diagnostic and Calibration of the Hydraulic Lift System

Hydraulic Circuits

Hydraulic Pump of External Gears

Valve, Oil Cooler, and Filter

Hydraulic Lift

Remote Control Valves

Hydraulic Pump of Axial Pistons

Cab

Tests of Operation

Troubleshooting - Air-conditioning System

Ventilation and Heating - Troubleshooting

Operation - Air-conditioning System

Various

tm4867 - tractors 6405 and 6605 operation and tests

Table of Contents

Introduction

Section 05: Safety

Group 05: Norms of Safety

Acknowledge the safety Information

Observe the Safety Messages

Replace the Safety Stickers

Safe Handling of Liquids and fuels

Avoiding the Explosion of Battery Gasses

Be Prepared in Case of Emergency

Remove the Paint Before Welding or Applying Heat.

Leaks in High Pressure Lines

Safe Maintenance of the Radiator

Avoid accidentally starting the machine.

Avoid applying heat near the pressurized fluid lines

Work in a well ventilated area

Wear Appropriate Clothing

Safe Maintenance

Parking the Tractor

Use Adequate Lifting Devices

Supporting the Machine Safely

Perform clean work

Adequate Lighting for the Working Area

Avoid Accidents

Use the Tools Correctly

Tire Installation

Safe Front Wheel Drive Maintenance

Roll Over Protection Structure

Correct Disposal of Waste Material

Safety Live with It

Section 240: Electric System

Group 10: Special Tools for Electricity

Special Tools

General Information

Group 15: Electric Harness Connector Maintenance

Disconnecting the Electrical Circuit

Metri Pack Connector

Weatherpack Connector

Extracting Terminals

Installing Terminals

Replacing the Terminals

Wire Stripper

Installation of a Terminal

Group 20: Multitester Identification

Voltage readings

Low Intensity Electrical Current Readings

Measuring the Electrical Current - Up to 10 Amperes

Measuring of Resistance

Continuity Readings

Measuring the Temperature

Group 25: Source Circuit and Starting

Source Circuit and Starting

Location of Fuses and Relays - Open Station Tractors

Location of the Fuses and Relays - Cab Tractor

Booster

General Fuse

General key

Switch of the neutral gear

Relay K2

Injection Pump Solenoid

Starter Relay

Starter Motor

K1 Relay

Starting Circuit Connectors

Source Circuit and Starting

Group 30: Power take-off - (PTO)

Power take-off - (PTO)

Power Take-Off Switch

K3 Relay

PTO Connectors

PTO Circuit

Group 35: Front Wheel Drive

Function of the Front Wheel Drive

Front-Wheel Drive Switch

Front Wheel Drive Solenoid

Front Wheel Drive Connectors

Front Wheel Drive Circuit

Group 40: Differential Lock

Function of the Differential Lock

Brake switch

K7 Relay

K4 relay

Solenoid of the Differential Lock

the Differential Lock

Differential Lock Circuit

Group 45: Circuit of the lights

Circuit of the lights

Light switches

K5 Relay

High / Low Beam change-over switch

Headlights

K6 Relay

Tail lights

Front / Rear Work Lights

Warning and Turn Signal Relay - K11

K8 Relay

K9 Relay

K10 Relay

Rotating Switch for the Flasher unit

Diodes Block

Light Circuit Connectors

Electrical Circuit for the Lights

Group 50: Recharge Circuit of the Battery

Recharge Circuit of the Battery

Alternator

Indicator Light

Hour Meter

Explosive Gases

Important Rules

To test the Delco Freedom Battery

Recharges the battery

Important recommendations About Batteries

Alternator Test

Connectors of the Circuit's charge for the Battery

Circuit charge of Battery

Checking a battery - Flowchart

Group 55: Tractor Monitoring

Instruments of the Panel

Temperature Indicator - Thermometer

Temperature Sensor

Fuel Level Indicator

Engine Oil Pressure Sensor

Engine tachometer

Rotation Sensor

Engine Oil Pressure Indicator

Air Filter Restriction Indicator

Air Filter Restriction Sensor

Transmission Oil Filter Blockage Indicator

Transmission Oil Filter Sensor

Low Pressure Transmission Oil Sensor

High Temperature Transmission Oil Sensor

Diodes Block

Electrical Circuit Connectors of the Instruments

Electrical Circuit of the Instruments

Group 60: Hydraulic Control Unit - HCU

Hydraulic Control Unit - HCU

Hydraulic Control Unit

Raise and Lower switch

Lift Control

Hydraulic Lift Shock Absorbers

Controlling the Lowering Speed

Height Limit Control

Load Sensitivity

Position Sensor

Load Sensor

Step Motor

Transient Suppressor

HCU Connectors

HCU Electrical Diagram

Group 65: Cab

Air-conditioning Electrical Controls

Electrical Diagram of the Cab

Various Connectors

Connectors of the Fuse Box

Identification of the Wires of the Electrical Circuits

Section 250: SyncroPlus Transmission

Group 05: SyncroPlus Transmission Troubleshooting

Troubleshooting Explanation

Norms of Safety

Special Tools

Heating the Hydraulic Oil

Test Connections in the Transmission Circuit

Specifications - Transmission Oil Circuit

Tests Sequence

Transmission Oil Circuit Troubleshooting

Sheet to Write Down the Hydraulic Tests

Engine clutch

Transmission

Group 10: Tests and Regulations

Norms of Safety

Special Tools

Specifications

Clutch Pedal Regulation

Checking the Clutch Control Valve

Checking the Clutch Safety Valve

Checking the Pressure of the Coolant - Oil

Checking Lubricating Oil Pressure

Checking the Clutch Cooling System

Measuring the Output Flow of the Oil Coolant

Checking the Group Gearshift.

Regulating the Gearshift Groups

Checking the Gearshift Activation

Regulating the Shifting of the Gears

Regulating the Starter Safety Switch

Checking the Starter Safety Switch

Checking the Shifting of the Gearshift.

Regulating of the Gearshift Lever

Regulating the Parking Lock

Group 15: Operation - SyncroPlus Transmission

Description of the Transmission of 12 Gears

Lubrication System

Gearshift Activation

Gearshift Synchronizer

SyncroPlus transmission (With the Gear in Neutral)

Operation of the Transmission Hydraulic Circuit

PermaClutch Clutch Components

Hydraulic Circuit of the Transmission

Oil Circuit of the Transmission

Group 20: PermaClutch II

Clutch components

Clutch components (continuation)

Description of the Drive Clutch

Clutch Action

Power transmission with the Clutch Disconnected

Power transmission with the Clutch Disconnected

Power Transmission with a Coupled Clutch

Transmission Clutch Pump

Hydraulic Diagram

Description of the valves

Other Components of the Transmission Oil Circuit

Operation of the Centrifugal Valve and the Suction Valve

Operation of the Clutch Control Valve and of the Starting Safety Valve (Clutch pedal up and engine running)

Operation of the Clutch Control Valve and of the Starting Safety Valve (Clutch pedal in)

Operation of the Clutch Control Valve and of the Starting Safety Valve (Clutch pedal returning slowly)

Clutch Cooling Operation (Clutch in slowly)

Operation of the Clutch Cooling System (Clutch almost all the way in)

Clutch Cooling Operation (Clutch in)

Clutch Cooling Operation (Slowly taking out the clutch)

Clutch Cooling Operation (Clutch out)

Clutch Cooling Operation (Quickly letting the clutch up)

Operation of the Pressure Regulating Valve and the Shunt Valve of the Filter - Normal Conditions (Clean oil filter)

Operation of the Pressure Regulating Valve and the Shunt Valve of the Filter - Contaminated oil filter

Operation of the Pressure Regulating Valve and the Shunt Valve of the Filter - Filter completely clogged

Protective Valve of the Oil Cooler

Operation of the Lubrication Discharge Valve

Group 25: Gearbox

Description of the Gearbox

Cross section of the SyncroPlus Transmission

Power Transmission in 1ª Gear

Power Transmission in 2ª Gear

Power Transmission in 3ª Gear

Power Transmission in - Reverse

Starting Safety Switch

Group 30: Group Gears

Group Gearbox - Cross Section

Description - Group of 12 Gears

Power Transmission, Group A

Power Transmission, Group B

Power Transmission, Group C

Power Transmission, Group D

Parking Lock (Park)

Section 255: PowrQuad Transmission

Group 05: Operation

Before Starting

Group 10: Troubleshooting

Using the Hydraulic Diagnostic Chart

Special Tools

Other Electric

Notice the Caution Warnings

Leaks in High Pressure Lines

Adjust the Pressure and Temperature Reference Levels

Shorter Diagnostic Procedure

Main Tests of the System

Data Sheet for the PowrQuad Transmission Tests

Static Pressure Test of the System

Group 15: Regulating the Gearshift Unit

Regulating the Gearshift Unit

Regulating the Forward and Reverse Cable

Regulating the Park Position Lock

Regulating the Reverse Gear Lock Position

Group 20: Operation - PowrQuad Transmission

Components of the PowrQuad Transmission (Identifying the Components)

Components of the PowrQuad Transmission (Hydraulic diagram)

Comments on the Operation of the PowrQuad Transmission

Description of the PowrQuad Transmission

Operation of the Set of Planetary gears.

Air pump

Lubrication Pump of the Transmission

Distributor of Clutch Oil

Reverse Brake Box

Oil deposit

Filter Discharge Valve

Pressure Regulating Valve

Gear Control Circuit

Circuit of the Starting Safety Valve (EOV)

Speed Modulation Position

Speed Modulator

Changing Gears Using the Gearshift Lever

Changing Gears Using the Gearshift Lever, Continuation

Gearshift Lever Changed from Neutral to the Second Gear or Reverse

Hydraulic Diagram of the Gear Modulation Valves

Forward/reverse Modulation

Forward/reverse Modulation

Forward/reverse Modulation

Engine in Gear and Transmission in Park

Forward/reverse Modulation

The Gearshift Lever Changes from Neutral to Forward or Reverse

Forward/reverse Modulation

Forward/Reverse or Neutral Lever

Cooling Elements of the Traction Clutch

Oil Cooler

Low Pressure Clutch Cooling Valve

Forward/Reverse Cooling Control Valve

High Pressure Clutch Cooling Valve

Control of the Cooling Output Flow Through the Clutch Pedal

Oil Cooler and Lubrication Circuit

Lubrication of the Modules

Module Lubrication Circuit

Operation of the Clutch Cooling Circuit

Oil Cooler

Group Gearbox

PowrQuad Transmission Components (Symbols)

Section 256: Power Transmission

Group 15: Front Wheel Drive Clutch

Cross section of the Front Wheel Drive Clutch up to Series 114447

Power Transmission Oil Circulation with the FWD Turned On

Power Transmission Oil Circulation with the FWD Turned Off

Cross section of the Front Wheel Drive Clutch From Series 114448 to Series 161066

Power Transmission Oil Circulation with the FWD Connected

Power Transmission Oil Circulation with the FWD Disconnected

Group 20: Diagnosis of the FWD, Differential Lock and PTO

Before Starting

Front Wheel Drive (FWD) Diagnostic

Diagnostic of the Differential Lock

Diagnostic of the Differential Lock

Diagnostic of the PTO

Section 260: Steering and Brakes

Group 05: Operation and Tests

Checking the Steering

Checking the Brakes

Group 10: Troubleshooting

Hydrostatic Steering

Group 15: Checking the Steering and Brakes

Special Tools

Specifications

Checking the Leaf Springs on the Steering Valve Set

External Leaks Test

Internal Leaks Test

Steering Valve Set Test

Hydraulic Connections of the Steering Valve Set

Testing and Adjusting the Safety Valve

Checking the Brakes

Tests to Detect Air in the Brake System

External Leaks Tests

Brake Pump Internal Leaks Test

Regulating the Brake Pedals

Purge the Rear Brakes

Checking the Brakes

Group 20: Hydrostatic Steering-Danfoss

Description of the Steering Valve Set

Operation of the Dosing Unit

Steering Oil Circulation

Oil Circulation - Neutral Position

Oil Circulation - Emergency Steering

Group 21: Hydrostatic Steering-Eaton

Steering System Operation

Hydraulic Steering Circuit

Steering valve set

Cross section of the Steering Valve

Operation of the Doser

Steering in Neutral

Steering Oil Circuit

Turn to the Right

Steering Oil Circuit

Emergency Steering or Manual Steering

Emergency Steering Circuit

Operation of the Doser

Group 25: Brakes

Operation of the Brake Pistons, Plate, and Discs

Brake Pedal Up

Beginning of the Braking Process

Brake Pedal Pushed Down

Section 270: Hydraulic system

Group 05: Troubleshooting - 100-liter Pump

Explanation of the Troubleshooting for the Gear Pump

Norms of Safety

Special Tools

Connections

Heating the Hydraulic Oil

Problems with the Pumps

Diagnostic of Pump Failures

Diagnostic of the Oil Pump

Group 06: Preliminary Tests

Explanation of the Hydraulic Tests

Norms of Safety

Preliminary Hydraulic Tests

Remote Control valves, Checking

Regulating the Hydraulic Lift - Preliminary Tests

Group 07: 100 L Pump - Troubleshooting

Explanation of the Troubleshooting for the 100-liter Pump

Norms of Safety

Special Tools

Connections

Heating the Hydraulic Oil

Connections and Pressure Gauges

Connection for testing the pressure and cavitation (test 1 and 2)

Connection for testing the pressure of the system (test 3 and 7)

Connection for Testing to Load Sensor Pressure (test 6 and 7)

Connection for Testing to Steering Pressure (test 5)

Pressure Difference Test

Connections for Taking Pressure Readings

Test Specification

Sequence of Tests

Troubleshooting the Hydraulic Circuit - 100-liters

Additional Information

Hydraulic Tests Sheet

Group 08: Hydraulic System Diagnostic - Gear Pump

Explanation of the Hydraulic Tests - Gear Pump

Norms of Safety

Special Tools

Connections and Pressure Gauges

Test Connections

Heating the Hydraulic Oil

Specifications

Sequence of Tests

Diagnostic of the Hydraulic System with Gear Pump

Information About System Diagnostics

Response of the Hydraulic System with a Gear Pump when a Disc Valve is Lost

Measuring the Hydraulic Pump Output Flow

Chart of the Test Results

Group 10: Diagnostic and Calibration of the Hydraulic Lift System

Troubleshooting Explanation

Fluids Under Pressure

Special Tools

Heating the Hydraulic Oil

Identification of the Lift Controls

Device used for Diagnostic and Calibration

How to Read the Diagnostic and Calibration Monitor

Hardware and Software Information

Functions and Information Shown on the Monitor

How to Access the Functions of Diagnostic

Select the Diagnostic Functions of the HCU

Access the Functions of Diagnostic

Recommendations About the HCU

List of Error Codes of the Hydraulic lift

Diagnostic Functions of the Hydraulic Lift

Procedure of Calibration

Checking the Step Motor and the Hydraulic Lift Valve

Checking the Step Motor (continuation)

Checking the Hydraulic Lift Valve

Checking the Raising/Lowering Valve Installation Depth

Regulating the Traction Sensor - 6405 and 6605

Group 15: Hydraulic Circuits

Hydraulic Symbols

Description of the Hydraulic System

Hydraulic Circuit Operation

General Hydraulic Diagram

Hydraulic circuit with Pump of 100 Liters

Hydraulic Circuit on the Tractor

Description of the Hydraulic System With a Gear Pump

Operation of the Hydraulic Circuit With a Gear Pump

Hydraulic circuit with Gear Pump

Hydraulic circuit on the Tractor with Gear Pump

Group 20: Hydraulic Pump of External Gears

Pump of External Gears

Description of Hydraulic Pump

Problems with Gear Pumps - Albarus

Group 25: Valve, Oil Cooler, and Filter

Shunt Valve of the Filter and Hydraulic Oil Filter

Oil Cooler

Filter Screen

Operation of the Priority Valve for Pistons Pumps - 100 Liters

Function in Neutral and Remote Control Valves Activated - Pump of 100 Liters

Function and Remote Control Valves Activated - Pump of 100 Liters

Priority Valve and Remote Control Valves in Neutral - for Gear Pump

Steering in Neutral and RCVs Activated - for Gear Pump

Operation of the Disc Valves

Description of the Priority Valve

Exterior Intake Valve

Group 30: Hydraulic Lift

Description of the Hydraulic Lift

Operation of the Hydraulic Lift

Operation of the Hydraulic Lift Control Valve

Position Sensor

Traction Control Sensor

Control Console

Electronic Control Unit (HCU)

Direct Control of the Hydraulic Lift

Group 35: Remote Control Valves

Remote Control Valves

Remote Control Valves Series 101 - Neutral

Remote Control Valve Series 100 - Extension

Remote Control Valve Series 100 - Retraction

Remote Control Valve Series 100 - Float

Remote Control Valves Series 301 - Neutral

Remote Control Valves Series 301 - Extension

Remote Control Valves Series 301 - Retraction

Remote Control Valves Series 301 - Float

Quick Hitch

Group 40: Hydraulic Pump of Axial Pistons

Description of the Axial Piston Pump

Disposition of the Hydraulic Oil Tubes

Operation of the Hydraulic Pump

Hydraulic Pump

Hydraulic Pump, Engine Off

Operation

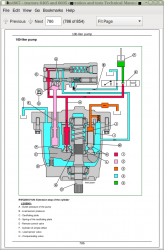

100-liter pump

100-liter pump

100-liter pump

Section 290: Cab

Group 05: Tests of Operation

Sequence of Tests

Group 10: Troubleshooting - Air-conditioning System

Norms of Safety

Handling the Coolant

In Case of an Emergency

Safety Equipment

Storing the Coolant Receptacles

Coolant R134a

Important

Special Tools

Specifications

Troubleshooting

Explanations of the Tests

Air-conditioning

Pressure Irregularities

Group 15: Ventilation and Heating - Troubleshooting

Ventilation and Heating

Group 20: Operation - Air-conditioning System

Operation of the Heat Exchanger

Coolant R134a

Cooling Circuit Layout

Cooling Circuit Operation

Cooling Circuit Operation

Compressor

Condenser

Dryer

Expansion Valve

Thermostatic Switch

Evaporator

Heating and Cooling Controls

Heating and Ventilation

Group 25: Various

Conversion Table

John Deere Tractors 6405 & 6605 Diagnosis and Tests Service Technical Manual (TM4867)