John Deere Tractors 6215, 6415, 6615, 6715 Diagnosis and Tests Service Technical Manual (TM4648)

Complete Diagnosis & Tests Technical Manual with Electrical Wiring Diagrams for John Deere 2WD or MFWD Tractors Models 6215, 6415, 6615, 6715 , with all the workshop information to maintain, diagnose, and rebuild your tractor.

John Deere 2WD or MFWD Tractors Models 6215, 6415, 6615, 6715 workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM4648 - 6215 to 6715 Tractors, Diagnostics and Operation and Tests Technical Manual.pdf

Total Pages: 2,301 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English etc.

MAIN SECTIONS

Foreword

Version date

General Information

Safety Measures

General References

Diagnostic Codes

BCU Diagnostic Trouble Codes

ECU Diagnostic Trouble Codes

Observable Symptoms

Engine

Electrical System

SyncroPlus™ Transmission

PowrReverser™ Transmission

PowrQuad™ Transmission

Steering and Brakes

Operator's Cab

System Diagnostics

Electronics

Engine

Functional Tests

Tests and Adjustments

Fuel, Air Intake and Cooling Systems

Tests and Adjustments

Theory of Operation

Electrical System

Sub-System Diagnostics (Cab)

Sub-System Diagnostics (Open Operator's Station)

Component Testing

Functional Schematics (Cab)

Functional Schematics (Open Operator's Station)

Wiring Harnesses, Survey

Wiring Harnesses

Wiring Harnesses from Serial Number 398656

Electronic Control Units

Operation and General Information on Diagnostics

Data BUS Systems, Diagnosis

Data BUS Systems

BCU - Basic Control Unit

ECU - Engine control unit

SyncroPlus™ Transmission

Preliminary Checks

Functional Tests

Tests and Adjustments

Theory of Operation

PowrReverser™ Transmission

Functional Tests

Tests and Settings

Theory of Operation

PowrQuad™ and Range Transmission

Functional Tests

Tests and Settings

Theory of Operation

Power Train (without Transmission)

Functional Tests

Tests and Adjustments

Theory of Operation

Steering and Brakes

Introductory Checks

Operational Check-Out

Tests and Adjustments

Theory of Operation

HydraVantage™ Hydraulic System

Operational Check-Out

Tests and Adjustments

Theory of Operation

Operator's Cab

Operational Check-Out

Tests and Adjustments

Theory of Operation

Special Tools

Special Tools (Dealer-Fabricated)

Special Tools and Test Equipment

tm4648 - 6215 to 6715 Tractors, Diagnostic and Operation and Tests - Table of Contents

Foreword

Version date

Section 210: General Information

Group 05: Safety Measures

Recognize Safety Information

”Important” Information

”Note” Information

Prevent Machine Runaway

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Service Cooling System Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Support Machine Properly

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Safety Information - Air Brake System

Avoid Eye Contact With Radar

Keep ROPS Installed Properly

Replace Safety Signs

Dispose of Waste Properly

Live With Safety

Safety Measures on Electronic Control Units

Group 15: General References

Reference 210-15-001, General References - Summary

Reference 210-15-010, Unified Inch Bolt and Cap Screw Torque Values

Reference 210-15-015, Metric Bolt and Cap Screw Torque Values

210-15-020, Hydraulic System Inch Fitting Torques

210-15-025, Hydraulic System Metric Fitting Torques

210-15-030, Component Identification Table

Reference 210-15-035, How to Read a Functional Schematic

210-15-040, How to Read a Diagnostic Schematic

210-15-042, Wire Numbers and Color Codes

210-15-045, Schematic, Wiring and Harness Symbols

Reference 210-15-046, Troubleshooting Unsolved Problems

210-15-050, Visual Check of the Electrical System

Reference 210-15-055, Electrical Circuit Malfunctions

Reference 210-15-060, Seven Step Electrical Test Procedure

210-15-065, Hydraulic System - Circuit Symbols

Section 211: Diagnostic Codes

Group BCU: BCU Diagnostic Trouble Codes

BCU 000084.02-Wheel Speed Sender, Circuit Fault

BCU 000168.16- System Voltage Too High (Engine Running)

BCU 000168.17-System Voltage Too Low (Idle Over 1500 rpm)

BCU 000168.18- System Voltage Too Low (Idle Until 1500 rpm)

BCU 000186.02- Rear PTO Speed Sender, Circuit Fault

BCU 000186.15- Rear PTO Speed Registered After Switch-Off

BCU 000186.17-Rear PTO Speed Not Registered

BCU 000190.02-Engine Speed Sender, Circuit Fault

BCU 000629.12- Control Unit, Internal Error

BCU 000639.12-Control Unit, Internal Error

BCU 000746.31-Differential Lock Solenoid Valve, Circuit Fault

BCU 000980.07- Rear PTO, Switch Error

BCU 001882.02-Front PTO Speed Sender, Circuit Fault

BCU 001882.15-Front PTO Speed Registered After Switch-Off

BCU 001882.17-Front PTO Speed Not Registered

BCU 001893.07- Front PTO, Switch Error

BCU 299780.07-Malfunction at Turn Signal Switch

BCU 302001.31- INFORMATION FOR OPERATOR: 250-Hour Service

BCU 302002.31-INFORMATION FOR OPERATOR: 500-Hour Service

BCU 302003.31- INFORMATION FOR OPERATOR: 750-Hour Service

BCU 302004.31- INFORMATION FOR OPERATOR: 1500-Hour Service

BCU 302071.31- INFORMATION FOR OPERATOR: Turn Off the Rear PTO Switch

BCU 302073.31-INFORMATION FOR OPERATOR: Turn Off the Rear PTO Switch

BCU 302077.31-INFORMATION FOR OPERATOR: Sit on Seat or Turn Off the Rear PTO

BCU 302080.31- Differential Lock, Switch Error

BCU 302082.31- INFORMATION FOR OPERATOR: Actuate the Front-Wheel Drive Switch

BCU 302085.31- Front Wheel Drive, Switch Error

BCU 302086.31-Front Wheel Drive Clutch Solenoid Valve, Circuit Fault

BCU 302106.31-Control Unit, Internal Error

BCU 302120.31- Front PTO Solenoid Valve, Circuit Fault

BCU 302131.31-Fault in Turn Signal Circuit

BCU 302133.31-Rear PTO Preselector, Switch Error

BCU 302240.31-Control Unit Connected to Wrong Wiring Harness Connector

BCU 303027.31-Calibration of Hitch Control Unit Not Successful

BCU 303028.31- Hitch Control Unit Not Calibrated

BCU 303037.03- 5 Volt Supply Voltage too High

BCU 303037.04-5 Volt Supply Voltage too Low

BCU 303041.02-Stepper Motor Coil 1, Open Lead

BCU 303042.02- Stepper Motor Coil 2, Open Lead

BCU 303043.02-Coil 1 of Stepper Motor, Circuit Fault

BCU 303044.02-Coil 2 of Stepper Motor, Circuit Fault

BCU 303045.04-System Voltage Too Low

BCU 303047.03-System Voltage Too High

BCU 303049.02- Conflicting Signals from Quick Raise/Lower Switch and Remote Switch

BCU 303049.03- Quick Raise/Lower Rocker Switch, Signal Voltage too High

BCU 303049.04- Quick Raise/Lower Rocker Switch, Signal Voltage too Low

BCU 303051.03-Left Draft Sensor, Signal Voltage Too High

BCU 303051.04-Left Draft Sensor, Signal Voltage too Low

BCU 303052.03-Right Draft Sensor, Signal Voltage too High

BCU 303052.04-Right Draft Sensor, Signal Voltage too Low

BCU 303053.03-Sensitivity Potentiometer, Signal Voltage too High

BCU 303053.04-Sensitivity Potentiometer, Signal Voltage too Low

BCU 303054.03-Depth-Setting Potentiometer (B27), Signal Voltage too High

BCU 303054.04- Depth-Setting Potentiometer (B27), Signal Voltage too Low

BCU 303055.03- Position Sensor, Signal Voltage too High

BCU 303055.04-Position Sensor, Signal Voltage too Low

BCU 303056.03-Raise Limit Potentiometer, Signal Voltage too High

BCU 303056.04- Raise Limit Potentiometer, Signal Voltage too Low

BCU 303057.03- Rate-of-Drop Potentiometer, Signal Voltage too High

BCU 303057.04- Rate-of-Drop Potentiometer, Signal Voltage too Low

BCU 303058.02-Remote Control Switch, Erroneous Signal

BCU 303060.02- Stepper Motor Deadband Out of Range

BCU 303177.18- Oil Temperature During Calibration Too Low

BCU 303251.02- Left Draft Sender, Disrupted Signal During Calibration

BCU 303251.03- Left Draft Sender, Signal Voltage Too High During Calibration

BCU 303251.04-Left Draft Sender, Signal Voltage Too Low During Calibration

BCU 303252.02- Right Draft Sender, Disrupted Signal During Calibration

BCU 303252.03- Right Draft Sender, Signal Voltage Too High During Calibration

BCU 303252.04- Right Draft Sender, Signal Voltage Too Low During Calibration

BCU 303255.03- Position Sender, Signal Voltage Too High During Calibration

BCU 303255.04- Position Sender, Signal Voltage Too Low During Calibration

BCU 303260.16- Stepper Motor Raising Deadband Above Valid Range During Calibration

BCU 303260.18- Stepper Motor Raising Deadband Below Valid Range During Calibration

BCU 303261.16- Stepper Motor Lowering Deadband Above Valid Range During Calibration

BCU 303261.18- Stepper Motor Lowering Deadband Below Valid Range During Calibration

Group ECU: ECU Diagnostic Trouble Codes

ECU 000028.03-Cruise Control Potentiometer Input Voltage High

ECU 000028.04-Cruise Control Potentiometer Input Voltage Low

ECU 000029.03-Hand Throttle Potentiometer Input Voltage High

ECU 000029.04-Hand Throttle Potentiometer Input Voltage Low

ECU 000091.03-Accelerator Pedal Potentiometer Input Voltage High

ECU 000091.04-Accelerator Pedal Potentiometer Input Voltage Low

ECU 000097.03-Input Voltage from Water-in-Fuel Sensor High

ECU 000097.04-Input Voltage from Water-in-Fuel Sensor Low

ECU 000097.16-Water in Fuel Detected

ECU 000105.03-Manifold Air Temperature Input Voltage High

ECU 000105.04-Manifold Air Temperature Input Voltage Low

ECU 000105.16-Manifold Air Temperature Moderately High

ECU 000110.00-Engine Coolant Temperature Extremely High

ECU 000110.03-Engine Coolant Temperature Input Voltage High

ECU 000110.04-Engine Coolant Temperature Input Voltage Low

ECU 000110.15-Engine Coolant Temperature Slightly High

ECU 000110.16-Engine Coolant Temperature Moderately High

ECU 000158.17-ECU Power Down Error

ECU 000174.03-Fuel Temperature Input Voltage High

ECU 000174.04-Fuel Temperature Input Voltage Low

ECU 000174.16-Fuel Temperature Moderately High

ECU 000189.00-Engine Speed Derate

ECU 000190.00-Engine Racing Excessively

ECU 000190.16-Engine Speed Slightly High

ECU 000620.03-Sensor Supply 2 Voltage High

ECU 000620.04-Sensor Supply 2 Voltage Low

ECU 000629.13-ECU Error

ECU 000637.02-Crank Position Input Noise

ECU 000637.10-Crank Position Input Pattern Error

ECU 000729.03-Inlet Air Heater Signal High

ECU 000729.05-Inlet Air Heater Signal Low

ECU 001076.00-Pump Control Valve Closure Too Long

ECU 001076.01-Pump Control Valve Closure Too Short

ECU 001076.03-Pump Solenoid Current High

ECU 001076.05-Pump Solenoid Circuit Open

ECU 001076.06-Pump Solenoid Circuit Severely Shorted

ECU 001076.07-Pump Control Valve Closure Not Detected

ECU 001076.10-Pump Solenoid Circuit Moderately Shorted

ECU 001076.13-Current Drop - Time Fault

ECU 001569.31-Fuel Derate

ECU 002000.06-Internal ECU Failure

ECU 002000.13-Security Violation

Section 212: Observable Symptoms

Group 20: Engine

Engine Observable Symptom Diagnostics

Problem with Fuel Pump (Tractors with Cab)

Problem with Fuel Pump (Tractors with Open Operator's Station)

Problem with Electrical Starting Aid (Tractors with Cab)

Problem with Electrical Starting Aid (Tractors with Open Operator's Station)

Problem with Fuel Preheater (Tractors with Cab)

Problem with Fuel Preheater (Tractors with Open Operator's Station)

Group 40: Electrical System

Control Unit(s) Not Displayed

No Access to Diagnostic Mode Possible or Connection Difficulties with Service ADVISOR (Tractors with TIER I Engines; no ECU)

No Access to Diagnostic Mode Possible or Connection Difficulties with Service ADVISOR (Tractors with TIER II Engines; ECU Level 12)

Reprogramming was aborted.

Problem with the Instrument Unit

Problem with the Battery

Problem with the Starting Motor

Problem with the Horn

Problem with the Front Wiper and Washer System (Tractors with Cab)

Problem with the Rear Wiper and Washer System (Tractors with Cab)

Problem with Cigarette Lighter E05

Problem with Beacon Light

Problem with the Worklights (Tractors with Cab)

Problem with the Worklights (Tractors with Open Operator's Station)

Problem with Battery Cut-Off Switch S117 (Version 1)

Group 50: SyncroPlus™ Transmission

Problem with SyncroPlus™ Transmission

Group 51: PowrReverser™ Transmission

Problem with Power Reverser™ Transmission

Group 55: PowrQuad™ Transmission

Problem with PowrQuad™ Transmission

Group 60: Steering and Brakes

Problem with the Brakes

Problem with the Steering

Group 90: Operator's Cab

Problem with Air Comfort Seat

Problem with the Fan

Problem with the Air-Conditioning System

Section 213: System Diagnostics

Group 45: Electronics

29-bit CAN BUS - Check (Tractors with Open Operator's Station and Operator's Cab with TIER I Engines)

29-bit CAN BUS - Check (Tractors with Open Operator's Station and Operator's Cab with TIER II Engines; Level 12)

Section 220: Engine

Group 10: Functional Tests

Reference 220-10-010, Safety

Reference 220-10-020, Preliminary Engine Tests

Group 15: Tests and Adjustments

Reference 220-15-001, Tests and Adjustments-Summary of References

Reference 220-15-010, Dynamometer Test

Reference 220-15-020, Measuring PTO Power Output

Reference 220-15-030, Engine Tests with Service ADVISOR

Section 230: Fuel, Air Intake and Cooling Systems

Group 15: Tests and Adjustments

Reference 230-15-001, Tests and Adjustments - Summary of References

Reference 230-15-010, General information

Reference 230-15-020, Explanation of Checks

Reference 230-15-030, Safety

Reference 230-15-040, Special Tools

Reference 230-15-050, Specifications

Reference 230-15-060, Testing the Air Intake System

Reference 230-15-070, Checking the Cooling System for Leaks

Reference 230-15-075, Flow-testing in the Low-Temperature Circuit

Reference 230-15-080, Testing the Temperature at which the Thermostat opens

Reference 230-15-090, Checking the Viscous Fan Drive

Reference 230-15-100, Checking the fuel transfer pump

Reference 230-15-110, Hand Throttle Lever and Accelerator Pedal Adjustment

Reference 230-15-120, Accelerator Pedal Adjustment

Group 20: Theory of Operation

Reference 230-20-001, Component Description - Summary of References

Reference 230-20-010, Fuel System - Description

Reference 230-20-020, Air Intake System - Theory of Operation

Reference 230-20-030, Coolant Circuit - Description

Reference 230-20-040, Cooling System Radiator - Description

Reference 230-20-050, Intercooler - Description

Reference 230-20-060, Ring-Shaped (Transmission Oil) Cooler - Description

Reference 230-20-070, Viscous Fan Drive - Theory of Operation

Reference 230-20-080, Automatic Drive Belt Tensioner - Theory of Operation

Reference 230-20-090, Cold Weather Starting Aids - Theory of Operation

Section 240: Electrical System

Group 10: Sub-System Diagnostics (Cab)

Reference 240-10-001, Sub-System Diagnostics (Cab) - Summary of References

Reference 240-10-002, Special Tools

Reference 240-10-003, SE1 - Starter Motor and Charging Circuit

Reference 240-10-004, SE2 - Instrument Unit

Reference 240-10-005, SE3 - Horn

Reference 240-10-006, SE4 - Operator's Seat

Reference 240-10-007, SE6 - Lighting System

Reference 240-10-008, SE7 - Worklights

Reference 240-10-009, SE9 - Radio, Dome Light and Console Light

Reference 240-10-010, SE10 - Fan and Air-Conditioning System

Reference 240-10-011, SE11 - Windshield Wiper and Washer

Reference 240-10-012, SE13 - Beacon Light

Reference 240-10-013, SE14 - Power Outlet Sockets, 3- and 7-Terminal

Reference 240-10-014, SE15 - Electronic Hitch Control (BCU)

Reference 240-10-015, SE16A - Basic Control Unit (BCU) (Rear PTO)

Reference 240-10-016, SE16B - Basic Control Unit (BCU) (Front PTO)

Reference 240-10-017, SE16C - Basic Control Unit (BCU) (Front-Wheel Drive)

Reference 240-10-018, SE16D - Basic Control Unit (BCU) (Differential Lock)

Reference 240-10-019, SE16E - Basic Control Unit (BCU) (Hazard Warning and Turn Signal Lights)

Reference 240-10-020, SE16F - Basic Control Unit (BCU) (Speed Sending Units)

Reference 240-10-021, SE16H - Basic Control Unit (BCU) (Power Supply, Acoustic Alarm and CAN-BUS Connection)

Reference 240-10-022, SE16J - Basic Control Unit (BCU) (Braking System)

Reference 240-10-023, SE17 - Signal Socket

Reference 240-10-024, SE22 - CAN-BUS Terminating Resistor

Reference 240-10-025, SE23 - Engine Control Unit (ECU)

Reference 240-10-046, SE25 - Back-Up Alarm

Group 10A: Sub-System Diagnostics (Open Operator's Station)

Reference 240-10A-001, Sub-System Diagnostics (Open Operator's Station) - Summary of References

Reference 240-10A-002, Special Tools

Reference 240-10A-003, SE1 - Starter Motor and Charging Circuit

Reference 240-10A-004, SE2 - Instrument Unit

Reference 240-10A-005, SE3 - Horn

Reference 240-10A-006, SE4 - Operator's Seat

Reference 240-10A-007, SE6 - Lighting System

Reference 240-10A-008, SE7 - Worklights

Reference 240-10A-009, SE14 - Power Outlet Sockets, 3- and 7-Terminal

Reference 240-10A-010, SE15 - Electronic Hitch Control (BCU)

Reference 240-10A-011, SE16A - Basic Control Unit (BCU) (Rear PTO)

Reference 240-10A-012, SE16B - Basic Control Unit (BCU) (Front PTO)

Reference 240-10A-013, SE16C - Basic Control Unit (BCU) (Front-Wheel Drive)

Reference 240-10A-014, SE16D - Basic Control Unit (BCU) (Differential Lock)

Reference 240-10A-015, SE16E - Basic Control Unit (BCU) (Hazard Warning and Turn Signal Lights)

Reference 240-10A-016, SE16F - Basic Control Unit (BCU) (Speed Sending Units)

Reference 240-10A-017, SE16H - Basic Control Unit (BCU) (Power Supply, Acoustic Alarm and BUS Connection)

Reference 240-10A-018, SE16J - Basic Control Unit (BCU) (Braking System)

Reference 240-10A-019, SE17 - Signal Socket

Reference 240-10A-020, SE22 - CAN-BUS Terminating Resistor

Reference 240-10A-021, SE23 - Engine Control Unit (ECU)

Reference 240-10A-046, SE25 - Back-Up Alarm

Group 15: Component Testing

Reference 240-15-101, Component Tests - Summary of References

Reference 240-15-001, SE01 - Starter Motor and Charging Circuit

Reference 240-15-002, SE02 - Instrument Unit

Reference 240-15-003, SE03 - Horn

Reference 240-15-004, SE04 - Operator's Seat

Reference 240-15-005, SE06 - Lighting System

Reference 240-15-006, SE07 - Worklights

Reference 240-15-007, SE09 - Radio, Dome Light and Console Light

Reference 240-15-008, SE10 - Fan and Air-Conditioning System

Reference 240-15-009, SE11 and SE12 - Windshield Wiper and Washer

Reference 240-15-010, SE13 - Beacon Light

Reference 240-15-011, SE14 - 3- and 7-Terminal Power Outlet Sockets

Reference 240-15-012, SE15 - Electronic Hitch Control (BCU)

Reference 240-15-013, SE16A - Basic Control Unit (BCU) (Rear PTO)

Reference 240-15-014, SE16B - Basic Control Unit (BCU) (Front PTO)

Reference 240-15-015, SE16C - Basic Control Unit (BCU) (Front-Wheel Drive)

Reference 240-15-016, SE16D - Basic Control Unit (BCU) (Differential Lock)

Reference 240-15-017, SE16E - Basic Control Unit (BCU) (Hazard Warning and Turn Signal Lights)

Reference 240-15-019, SE16H - Basic Control Unit (BCU) (Power Supply, Acoustic Alarm)

Reference 240-15-021, SE16J - Basic Control Unit (BCU) (Brake System)

Reference 240-15-025, SE23 - Engine Control Unit (ECU) (Level 12)

Group 25: Functional Schematics (Cab)

Reference 240-25-001, Functional Schematic and Wiring Harnesses (Cab) - Summary of References

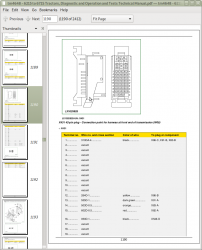

Reference 240-25-010, Fuses and Relays (Cab)

Reference 240-25-011, Designation of Parts Shown in Functional Schematic and Harness Diagram

Reference 240-25-012, Designation of Sections Shown in Functional Schematic

Reference 240-25-013, Wiring Harness Designations

Reference 240-25-014, Functional Schematic (Complete Tractor)

Group 25A: Functional Schematics (Open Operator's Station)

Reference 240-25A-001, Functional Schematic and Wiring Harnesses (Open Operator's Station) - Summary of References

Reference 240-25A-002, Fuses and Relays (Open Operator's Station)

Reference 240-25A-003, Designation of Parts Shown in Functional Schematic and Harness Diagram

Reference 240-25A-004, Designation of Sections Shown in Functional Schematic

Reference 240-25A-005, Wiring Harness Designations

Reference 240-25A-006, Functional Schematic (Complete Tractor)

Group 26: Wiring Harnesses, Survey

Reference 240-26-001, Wiring Harnesses for Tractors with Open Operator's Station and TIER I Engine - Summary of References

Reference 240-26-002, Wiring Harnesses for Tractors with Open Operator's Station and TIER II engines - Summary of References

Reference 240-26-005, Wiring Harnesses for Tractors with Open Operator's Station from Serial No. 399888 - Summary of References

Reference 240-26-003, Wiring Harnesses for Tractors with Operator's Cab and TIER I Engine - Summary of References

Reference 240-26-004, Wiring Harnesses for Tractors with Operator's Cab and TIER II Engine - Summary of References

Reference 240-26-006, Wiring Harnesses for Tractors with Operator's Cab from Serial No. 391068 - Summary of References

Group 26A: Wiring Harnesses

Reference 240-26-011, W01 - Wiring Harness - Power Supply (Open Operator's Station)

Reference 240-26-012, W01 - Wiring Harness - Power Supply (Operator's Cab)

Reference 240-26-021, W02 - Wiring Harness - TIER I Engine (Open Operator's Station)

Reference 240-26-521, W02 - Wiring Harness - TIER II Engine (Open Operator's Station).

Reference 240-26-022, W02 - Wiring Harness - TIER I Engine (Operator's Cab)

Reference 240-26-522, W02 - Wiring Harness - TIER II Engine (Operator's Cab)

Reference 240-26-031, W03 - Wiring Harness - Starting Aid

Reference 240-26-041, W04 - Wiring Harness - Headlights

Reference 240-26-071, W07 - Wiring Harness - Front PTO (Operator's Cab)

Reference 240-26-081, W08 - Wiring Harness - Open Operator's Station (TIER I Engine)

Reference 240-26-581, W08 - Wiring Harness - Open Operator's Station (TIER II Engine)

Reference 240-26-082, W08 - Wiring Harness - Operator's Cab (TIER I Engine)

Reference 240-26-582, W08 - Wiring Harness - Operator's Cab (TIER II Engine)

Reference 240-26-091, W09 - Wiring Harness - Cowl, for TIER I Engine (Open Operator's Station)

Reference 240-26-591, W09 - Wiring Harness - Cowl, for TIER II Engine (Open Operator's Station)

Reference 240-26-092, W09 - Wiring Harness - Cowl, for TIER I Engine (Operator's Cab)

Reference 240-26-592, W09 - Wiring Harness - Cowl, for TIER II Engine (Operator's Cab)

Reference 240-26-141, W14 - Wiring Harness - 3-Terminal Power Outlet Socket

Reference 240-26-191, W19 - Wiring Harness - Cab Roof

Reference 240-26-201, W20 - Wiring Harness - Lights on Cab Frame

Reference 240-26-263, W26 - Wiring Harness - Fan and Air Conditioner

Reference 240-26-271, W27 - Wiring Harness - Turn Signal Light

Reference 240-26-281, W28 - Wiring Harness - Front Part of Transmission (Open Operator's Station)

Reference 240-26-288, W28 - Wiring Harness - Front Part of Transmission (Operator's Cab)

Reference 240-26-301, W30 - Wiring Harness - Rear Part of Transmission (Open Operator's Station)

Reference 240-26-307, W30 - Wiring Harness - Rear Part of Transmission (Operator's Cab)

Reference 240-26-311, W31 - Wiring Harness - 7-Terminal Power Outlet Socket

Reference 240-26-431, W43 - Wiring Harness - Back-up Alarm

Reference 240-26-441, W44 - Wiring Harness - Back-up Alarm / Switch for Power Reverser or PowrQuad Transmission

Reference 240-26-451, W45 - Wiring Harness - Back-up Alarm / Switch for SyncroPlus Transmission

Reference 240-26-591, W59 - Wiring Harness - Lights on Cab Frame, Adapter

Group 26B: Wiring Harnesses from Serial Number 398656

W03/2 - Starting Aid Wiring Harness (ECU Level 12) from Serial No. 398656

W03/2 - D31

W03/2 - F09

W03/2 - F11

W03/2 - G02

W03/2 - K01

W03/2 - K36

W03/2 - R15

W03/2 - X547

W08/2 - Wiring Harness - Open Operator's Station from Serial No. 399888

W08/2 - F101 - F120

W08/2 - F21/1 - F21/3

W08/2 - K101 - K113

W08/2 - X2

W08/2 - X14/1

W08/2 - X14/2

W08/2 - X35

W08/2 - X37

W08/2 - X58

W08/2 - X86

W08/2 - X92

W08/2 - X96

W08/2 - X106

W08/2 - X107

W08/2 - X108

W08/2 - X109

W08/2 - X112/1

W08/2 - X112/2

W08/2 - X113

W08/2 - X122

W08/2 - X125

W08/2 - X127

W08/2 - X160

W08/2 - X161

W08/2 - X188

W08/2 - X230

W08/2 - X234

W08/2 - X236

W08/2 - X238

W08/2 - X239

W08/2 - X245

W08/2 - X269F

W08/2 - X269M

W08/2 - X286

W08/2 - X287

W08/2 - X288

W08/2 - X289

W08/2 - X311

W08/2 - X315

W08/2 - X317/1

W08/2 - X317/2

W08/2 - X321

W08/2 - X324

W08/2 - X406/1F

W08/2 - X406/1M

W08/2 - X473

W08/2 - X504

W08/2 - X505

W08/2 - X570/1

W08/2 - X571

W08/2 - X582

W08/2 - X587F

W08/2 - X587M

W08/2 - X588

W08/2 - X614

W08/2 - X615

W08/2 - X616/1

W08/2 - X616/2

W08/2 - X616/3

W08/2 - XGND1

W08/2 - GND1/1

W08/2 - XGND2

W08/2 - XGND2/1

W08/2 - XGND5

W08/2 - XGND5/1

W08/3 - Wiring Harness - Cab from Serial No. 391068

W08/3 - F101 - F120

W08/3 - F021/1 - F021/3

W08/3 - F023/1 - F023/3

W08/3 - F025/1 - F025/3

W08/3 - K101 - K113

W08/3 - M5

W08/3 - S17

W08/3 - X14/1

W08/3 - X14/2

W08/3 - X28

W08/3 - X35

W08/3 - X37

W08/3 - X58

W08/3 - X106

W08/3 - X107

W08/3 - X112/1A

W08/3 - X112/1B

W08/3 - X112/2A

W08/3 - X112/2B

W08/3 - X113/1

W08/3 - X113/2

W08/3 - X120/1

W08/3 - X120/2

W08/3 - X122

W08/3 - X125

W08/3 - X127

W08/3 - X158

W08/3 - X182

W08/3 - X188

W08/3 - X230

W08/3 - X236

W08/3 - X238

W08/3 - X239

W08/3 - X245

W08/3 - X269F

W08/3 - X269M

W08/3 - X311

W08/3 - X315

W08/3 - X321

W08/3 - X324

W08/3 - X400

W08/3 - X406/1F

W08/3 - X406/1M

W08/3 - X430

W08/3 - X431

W08/3 - X450

W08/3 - X473

W08/3 - X504

W08/3 - X505

W08/3 - X515

W08/3 - X544

W08/3 - X560F

W08/3 - X560M

W08/3 - X570/1

W08/3 - X571

W08/3 - X587F

W08/3 - X587M

W08/3 - X588

W08/3 - X613

W08/3 - X614

W08/3 - X615

W08/3 - X616/1

W08/3 - X616/2

W08/3 - X616/3

W08/3 - XGND1

W08/3 - XGND1/1

W08/3 - XGND2

W08/3 - XGND2/1

W08/3 - XGND5

W08/3 - XGND5/1

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

Essential Tools

Reference 245-05-001, General Operation and Entering the Program Mode

Reference 245-05-002, Accessing Addresses and Diagnostic Trouble Codes

Reference 245-05-009, Instrument Unit Adjustment

Reference 245-05-004, Electronic Control Units - Summary of Addresses

Reference 245-05-006, Approved Software for Control Units

Reference 245-05-007, Electronic Control Units - Location and Allocation

Group 10: Data BUS Systems, Diagnosis

29-bit CAN BUS - Check (Tractors with TIER I Engines; no ECU)

29-bit CAN BUS - Check (Tractors with TIER II Engines; ECU Level 12)

Group 20: Data BUS Systems

Reference 245-20-001, Data BUS Systems - Summary of References

Reference 245-20-002, Data-BUS Systems

Reference 245-20-003, Operation of the CAN BUS System

Reference 245-20-011, CAN BUS Systems on Tractors with TIER I Engine

Reference 245-20-012, CAN BUS Systems on Tractors with TIER II Engine and Level 12 Engine Control Unit (ECU)

Group BCU: BCU - Basic Control Unit

Reference 245-BCU-001, Calibration and Input Addresses of Basic Functions

Reference 245-BCU-002, Calibration and Input Addresses of Hitch Control

Refernce 245-BCU-100, Pre-test of BCU electrical circuit

Reference 245-BCU-101, Circuit Test for Rear PTO Switch (S21)

Reference 245-BCU-102, Circuit Test for Front PTO Switch (S06)

Reference 245-BCU-103, Circuit Test for Front-Wheel Drive Switch (S63)

Reference 245-BCU-104, Circuit Test for Differential Lock Switch (S22)

Reference 245-BCU-105, Circuit Test for Hazard Warning Switch (S106)

Reference 245-BCU-106, Circuit Test for Turn Signal Switch (S08)

Reference 245-BCU-107, Circuit Test for Wheel Speed Sensor (B35)

Reference 245-BCU-108, Circuit Test for Engine Speed Sender (B01)

Reference 245-BCU-109, Circuit Test for PTO Speed Sender (B06)

Reference 245-BCU-110, Circuit Test for Front PTO Speed Sender (B58)

Reference 245-BCU-111, Circuit Test on Sensitivity Potentiometer (B26)

Reference 245-BCU-112, Circuit Test for Depth-Setting Potentiometer (B27)

Reference 245-BCU-113, Circuit Test for Position Sensor (B21)

Reference 245-BCU-114, Circuit Test on Rate-of-Drop Potentiometer (B27)

Reference 245-BCU-115, Circuit Test on Raise-Limit Potentiometer (B27)

Reference 245-BCU-116, Circuit Test for Quick-Raise Switch (S24)

Reference 245-BCU-117, Circuit Test for Rear PTO Solenoid Valve (Y04)

Reference 245-BCU-118, Circuit Test for Front-Wheel Drive Solenoid Valve (Y03)

Reference 245-BCU-119, Circuit Test for Differential Lock Solenoid Valve (Y05)

Reference 245-BCU-120, Circuit Test for Front PTO Solenoid Valve (Y01)

Reference 245-BCU-121, Circuit Test for R.H. Draft Sensor (B19)

Reference 245-BCU-122, Circuit Test for L.H. Draft Sensor (B20)

Reference 245-BCU-123, Circuit Test for Left Remote Control Switch (S68)

Reference 245-BCU-124, Circuit Test for Rockshaft Control Stepper Motor (M08)

Reference 245-BCU-147, Circuit Test for Brake Pedal Switch (B88)

Reference 245-BCU-149, Circuit Test for Seat Switch (S40)

Reference 245-BCU-125, Circuit Test for Rear PTO Switch (S21) - Open Operator's Station

Reference 245-BCU-126, Circuit Test for Front PTO Switch (S06) - Open Operator's Station

Reference 245-BCU-127, Circuit Test for Front-Wheel Drive Switch (S63) - Open Operator's Station

Reference 245-BCU-128, Circuit Test for Differential Lock Switch (S22) - Open Operator's Station

Reference 245-BCU-129, Circuit Test for Turn Signal Switch (S08) - Open Operator's Station

Reference 245-BCU-130, Circuit Test for Wheel Speed Sending Unit (B35) (Open Operator's Station)

Reference 245-BCU-131, Circuit Test for Engine Speed Sender (B01) - Open Operator's Station

Reference 245-BCU-132, Circuit Test for PTO Speed Sender (B06) - Open Operator's Station

Reference 245-BCU-133, Circuit Test for Front PTO Speed Sender (B58) (Open Operator's Station)

Reference 245-BCU-134, Circuit Test on Sensitivity Potentiometer (B26) (Open Operator's Station)

Reference 245-BCU-135, Circuit Test on Depth-Setting Potentiometer (Open Operator's Station)

Reference 245-BCU-136, Circuit Test for Position Sensor (B21) (Open Operator's Station)

Reference 245-BCU-137, Circuit Test on Rate-of-Drop Potentiometer (Open Operator's Station)

Reference 245-BCU-138, Circuit Test on Raise-Limit Potentiometer (Open Operator's Station)

Reference 245-BCU-139, Circuit Test for Rapid-Raise Switch (S24) - Open Operator's Station

Reference 245-BCU-140, Circuit Test for Rear PTO Solenoid Valve (Y04) - Open Operator's Station

Reference 245-BCU-141, Circuit Test for Front-Wheel Drive Solenoid Valve (Y03) - Open Operator's Station

Reference 245-BCU-142, Circuit Test for Front PTO Solenoid Valve (Y01) - Open Operator's Station

Reference 245-BCU-142, Circuit Test for Differential Lock Solenoid Valve (Y05) - Open Operator's Station

Reference 245-BCU-143, Circuit Test on R.H. Draft Sensor (B19) - Open Operator's Station

Reference 245-BCU-144, Circuit Test on L.H. Draft Sensor (B20) - Open Operator's Station

Reference 245-BCU-145, Circuit Test for Left Remote Control Switch (S68) - Open Operator's Station

Reference 245-BCU-146, Circuit Test for Rockshaft Control Stepper Motor (M08) - Open Operator's Station

Reference 245-BCU-148, Circuit Test for Brake Pedal Switch (B88) - Open Operator's Station

Reference 245-BCU-150, Circuit Test for Seat Switch (S40) - Open Operator's Station

Reference 245-BCU-201, Theory of Operation (Basic Functions)

Reference 245-BCU-202, Theory of Operation (Hitch Control)

Group ECU: ECU - Engine control unit

Reference 245-ECU-001, Calibration and Input Addresses

Reference 245-ECU-100, Diagnosis of Electrical Circuits for Level 12 Engine Control Unit (ECU)

Reference 245-ECU-204, Theory of Operation (TIER II Engines Level 12)

Section 250: SyncroPlus™ Transmission

Group 05: Preliminary Checks

Reference 250-05-001, Introductory Checks for Transmission and Hydraulic Diagnosis

Group 10: Functional Tests

Reference 250-10-001, Syncroplus Transmission-Operational Checkout

Group 15: Tests and Adjustments

Reference 250-15-001, SyncroPlus Transmission-System Check

Reference 250-15-002, SyncroPlus Transmission-Checking System Pressure

Reference 250-15-003, SyncroPlus Transmission-Adjusting System Pressure

Reference 250-15-004, SyncroPlus Transmission-Checking Components Dependent on System Pressure

Reference 250-15-005, SyncroPlus Transmission-Checking the Filter Relief Valve

Reference 250-15-006, SyncroPlus Transmission-Checking the Engagement Override Valve and Clutch Pedal Valve

Reference 250-15-007, SyncroPlus Transmission-Checking the Modulation of the Clutch Pedal Valve

Reference 250-15-008, SyncroPlus Transmission-Checking the Lube Oil Pressure

Reference 250-15-009, SyncroPlus Transmission-Checking the Cooling System

Reference 250-15-010, SyncroPlus Transmission-Checking the Rate of Flow

Reference 250-15-011, SyncroPlus Transmission-Checking the Cooler Relief Valve

Reference 250-15-012, SyncroPlus Transmission-Checking the Transmission Oil Filter

Reference 250-15-013, SyncroPlus Transmission-Layout of Test Ports and Sending Units

Reference 250-15-014, SyncroPlus Transmission-Checking and Adjusting the Shift Units

Reference 250-15-015, SyncroPlus Transmission-Adjusting the Park Lock

Reference 250-15-016, SyncroPlus Transmission-Checking and Adjusting the Linkage on the Range Transmission

Reference 250-15-017, SyncroPlus Transmission-Checking and Adjusting the Linkage on the Gear Transmission

Reference 250-15-018, SyncroPlus Transmission-Checking and Adjusting the Neutral Start Switch

Reference 250-15-019, SyncroPlus Transmission-Adjusting the Clutch Pedal

Group 20: Theory of Operation

250-20-001, Syncroplus Transmission-Summary of References

250-20-010, Syncroplus Transmission-Layout

250-20-020, SyncroPlus Transmission-Lubrication System

250-20-030, Syncroplus Transmission-Shift Linkage

250-20-040, Syncroplus Transmission-Synchronization

250-20-050, Syncroplus Transmission-Operation of Transmission Oil Circuit (including Diagram)

250-20-100, Perma Clutch II Module-Exploded View

250-20-110, Perma Clutch II Module-Layout

250-20-120, Perma Clutch II Module-Powerflow

250-20-130, Perma Clutch II Module-Transmission Oil Pump

250-20-140, Perma Clutch II Module-Hydraulic Circuit Diagram

Reference 250-20-150, Perma Clutch II Module-Description of Various Valves and Components

250-20-160, Perma Clutch II Module-Operation of Pressure Regulating Valve and Filter Relief Valve

250-20-170, Perma Clutch II Module-Operation of Clutch Pedal Valve and Engagement Override Valve

250-20-180, Perma Clutch II Module-Operation of Cooling System

250-20-200, Gear Transmission- Layout

250-20-210, Gear Transmission- Powerflow

250-20-220, Gear Transmission- Neutral Start Switch

250-20-300, Creeper Transmission- Layout and Operation

250-20-310, Creeper Transmission- Powerflow

Section 251: PowrReverser™ Transmission

Group 10: Functional Tests

Reference 251-10-001, Power Reverser-Operational Checkout

Group 15: Tests and Settings

Reference 251-15-001, Power Reverser Transmission-System Check

Reference 251-15-002, Power Reverser Transmission-Checking System Pressure

Reference 251-15-003, Power Reverser Transmission-Adjusting System Pressure

Reference 251-15-004, Power Reverser Transmission-Checking Components Dependent on System Pressure

Reference 251-15-005, Power Reverser Transmission-Checking the Filter Relief Valve

Reference 251-15-006, Power Reverser Transmission-Checking the Engagement Override Valve and Clutch Pedal Valve

Reference 251-15-007, Power Reverser Transmission-Checking the Disk Clutch and Disk Brake

Reference 251-15-008, Power Reverser Transmission-Checking the Lube Oil Pressure

Reference 251-15-009, Power Reverser Transmission-Checking the Cooling System

Reference 251-15-010, Power Reverser Transmission-Checking the Rate of Flow

Reference 251-15-011, Power Reverser Transmission-Checking the Cooler Relief Valve

Reference 251-15-012, Power Reverser Transmission-Checking the Transmission Oil Filter

Reference 251-15-013, Power Reverser Transmission-Adjusting the Modulation Time

Reference 251-15-014, Power Reverser Transmission-Layout of Test Ports and Sending Units

Reference 251-15-015, Power Reverser Transmission-Checking and Adjusting the Shift Units

Reference 251-15-016, Power Reverser Transmission-Adjusting the Park Lock

Reference 251-15-017, Power Reverser Transmission-Checking and Adjusting the Linkage on the Range Transmission

Reference 251-15-018, Power Reverser Transmission-Checking and Adjusting the Linkage on the Gear Transmission

Reference 251-15-019, Power Reverser Transmission-Adjusting the Reverse Drive Linkage

Reference 251-15-020, Power Reverser Transmission-Adjusting the Reverse Drive Lever

Reference 251-15-021, Power Reverser Transmission-Adjusting the Clutch Pedal

Group 20: Theory of Operation

Reference 251-20-001, Power Reverser - Summary of References

Reference 251-20-010, Power Reverser Transmission-Layout

Reference 251-20-020, Power Reverser Transmission-Lubrication System

Reference 251-20-030, Power Reverser-Shift Linkage

Reference 251-20-040, Power Reverser Transmission-Synchronization

Reference 251-20-050, Power Reverser Transmission-Operation of Transmission Oil Circuit (including Diagram)

Reference 251-20-100, Power Reverser Module-Sectional View

Reference 251-20-110, Power Reverser Module-Components

Reference 251-20-120, Power Reverser Module-Layout and Powerflow

Reference 251-20-130, Power Reverser Module-Transmission Oil Pump

Reference 251-20-140, Power Reverser Module-Valves and Other Hydraulic Components

Reference 251-20-150, Power Reverser Module-Hydraulic Circuit Diagram

Reference 251-20-160, Power Reverser Module-Description of Various Valves and Components

Reference 251-20-170, Power Reverser Module-Operation of Pressure Regulating Valve and Filter Relief Valve

Reference 251-20-180, Power Reverser Module-Operation of Forward/Reverse Modulation

Reference 251-20-190, Power Reverser Module-Operation of Clutch Pedal Valve

Reference 251-20-200, Power Reverser Module-Operation of Engagement Override Valve

Reference 251-20-210, Power Reverser Module-Operation of Cooling System

Reference 251-20-300-Gear Transmission, Layout and Powerflow

Section 255: PowrQuad™ and Range Transmission

Group 10: Functional Tests

Reference 255-10-001, PowrQuad Transmission-Operational Checkout

Group 15: Tests and Settings

Reference 255-15-001, PowrQuad Transmission - System Check

Reference 255-15-002, PowrQuad Transmission-Test Ports

Reference 255-15-003, PowrQuad Transmission-Checking Rate of Flow at Cooler

Reference 255-15-021, PowrQuad Transmission-Checking the Cooler Relief Valve

Reference 255-15-004, PowrQuad Transmission - Checking System Pressure

Reference 255-15-005, PowrQuad transmission - Checking Lubricating Oil Pressure

Reference 255-15-006, PowrQuad Transmission - Checking the Cooling Oil Control Valves

Reference 255-15-008, PowrQuad transmission - Checking Pressure at Forward Clutch

Reference 255-15-009, PowrQuad Transmission-Checking Pressure at Reverse Brake

Reference 255-15-010, PowrQuad Transmission-Checking Pressure at B1 Brake

Reference 255-15-011, PowrQuad Transmission-Checking Pressure at B2 Brake

Reference 255-15-012, PowrQuad Transmission-Checking Pressure at B3 Brake

Reference 255-15-013, PowrQuad Transmission-Checking Pressure at C4 Clutch

Reference 255-15-014, PowrQuad transmission - Adjusting System Pressure

Reference 255-15-015, PowrQuad transmission - Test Result Table

Reference 255-15-016, PowrQuad Transmission-Adjusting the Reverse Drive Linkage

Reference 255-15-017, PowrQuad Transmission-Adjusting the Shift Linkage and Park Lock

Reference 255-15-018, Adjusting the Reverse Drive Lever (Reverser Control on Steering Column)

Reference 255-15-022, PowrQuad Transmission - Adjusting the Clutch Pedal

Group 20: Theory of Operation

Reference 255-20-001, PowrQuad Transmission-Summary of References

Reference 255-20-050, PowrQuad Transmission - Layout

Reference 255-20-100, PowrQuad Module-Layout

Reference 255-20-280, PowrQuad Module-Sectional and 3D View

Reference 255-20-290, PowrQuad Module-Location of Valves, Sensors and Switches

Reference 255-20-110, PowrQuad Module-Element Engagement Chart

Reference 255-20-120, PowrQuad Module-Pneumatic Pump

Reference 255-20-130, PowrQuad Module-Transmission Oil Pump

Reference 255-20-140, PowrQuad Module - Pressure Regulating Valve and Filter Bypass Valve

Reference 255-20-150, PowrQuad Module-Overspeed Relief Valve and Anti-Cavitation Check Valve

Reference 255-20-160, PowrQuad Module-Clutch Cooling Components

Reference 255-20-170, PowrQuad Module-Clutch Cooling Valve (Forward/Reverse)

Reference 255-20-180, PowrQuad Module - System 1 Oil and System 2 Oil

Reference 255-20-190, PowrQuad Module-Hydraulic Schematic, Mechanically Actuated PowrQuad Module

Reference 255-20-200, PowrQuad Module-Operation of Forward/Reverse Modulation, Mechanically Actuated PowrQuad Module

Reference 255-20-210, PowrQuad Module-Neutral Start Circuit, Mechanically Actuated PowrQuad Module

Reference 255-20-220, PowrQuad Module-Operation of Gear-to-Gear Modulation, Mechanically Actuated PowrQuad Module

Reference 255-20-260, PowrQuad Module-Reverse Drive Lever and Gear Shift Lever, Mechanically Actuated PowrQuad Module

Reference 255-20-500 - Range Transmission, Layout

Reference 255-20-510 - Range Transmission, Power Flow

Reference 255-20-520 - Range Transmission, Park Lock

Reference 255-20-700, Creeper Transmission - Operation

Reference 255-20-710, Creeper Transmission - Powerflow

Section 256: Power Train (without Transmission)

Group 10: Functional Tests

Reference 256-10-001, Drive Systems - Operational Check

Group 15: Tests and Adjustments

Reference 256-15-001, Drive Systems-System Check

Reference 256-15-002, Checking Pressure at the Front-Wheel Drive Clutch

Reference 256-15-003, Checking Pressure at the Hydraulic Differential Lock

Reference 256-15-004, Checking Pressure at the Rear PTO

Reference 256-15-005, Checking Pressure at the Front PTO

Reference 256-15-006, Drive Systems - Test Result Table

Reference 256-15-007, Front PTO-Adjusting System Pressure

Group 20: Theory of Operation

Reference 256-20-001, Drive Systems - Summary of References

Reference 256-20-100, Front-Wheel Drive Clutch - Layout

Reference 256-20-110, Front-Wheel Drive Clutch - Oil and Power Flows

Reference 256-20-120, Front-Wheel Drive Clutch - Cooling and Lubrication

Reference 256-20-200, Differential-Layout

Reference 256-20-220, Differential - Power Flows

Reference 256-20-230, Differential-Oil-Flows

Reference 256-20-300, Final Drives-Operation and Layout

Reference 256-20-400, Rear PTO Options-Description

Reference 256-20-410, Rear PTO Options-PTO Modulating Valve and Solenoid Valve

Reference 256-20-420, Rear PTO Options-PTO Clutch and PTO Brake

Reference 256-20-440, Rear PTO Options-Power Flows

Reference 256-20-500, Front PTO Options - Operation

Reference 256-20-510, Front PTO Options-Description, Hydraulic Circuit

Reference 256-20-520, Front PTO Options-PTO Modulating Valve and Solenoid Valve

Reference 256-20-530, Front PTO Options-Hydraulic Pump

Reference 256-20-540, Front PTO options - Oil cooler

Section 260: Steering and Brakes

Group 05: Introductory Checks

Reference 260-05-001, Tests and Adjustments - Summary of References

Reference 260-05-002, Preliminary Checks - Brake System

Reference 260-05-003, Preliminary Checks - Steering System

Group 10: Operational Check-Out

Operational Checkout (Summary of References)

Reference 260-10-001, Safety Information

Reference 260-10-010, Steering Check

Reference 260-10-020, Brake Check

Group 15: Tests and Adjustments

Reference 260-15-001, Tests and Adjustments-Summary of References

Reference 260-15-010, Special Tools

Reference 260-15-020, Connecting SensoControl Test Equipment

Reference 260-15-030, Specifications

Reference 260-15-040, Checking the Leaf Springs on the Steering Valve

Reference 260-15-050, Checking the Brake System

Reference 260-15-060, Bleeding the Brakes

Reference 260-15-070, Adjusting the Brake Pedals and Switches

Group 20: Theory of Operation

Reference 260-20-001, Operation - Summary of References

Reference 260-20-010, Description of Steering Valves, Operation

Reference 260-20-040, Rear Wheel Brakes, Operation

Section 270: HydraVantage™ Hydraulic System

Group 10: Operational Check-Out

Reference 270-10-010, Hydraulic System Load Check

Reference 270-10-020, Hitch Control - Operational Check

Reference 270-10-030, External Control of Hitch - Operational Checkout

Reference 270-10-040, Selective Control Valves - Operational Checkout

Group 15: Tests and Adjustments

Reference 270-15-000, Summary of References

Reference 270-15-001, Safety Measures for Hydraulic Checks

Reference 270-15-010, Heating Up Hydraulic Oil

Reference 270-15-020, Checking the HYDRAVANTAGEHYDRAVANTAGE is a trademark of Deere & Company Hydraulic System

Reference 270-15-021, HYDRAVANTAGEHYDRAVANTAGE is a trademark of Deere & Company Hydraulic System - Test Result Table

Reference 270-15-051, Rockshaft-Testing and Adjusting the Draft Sensors

Reference 270-15-052, Hydraulic Pump-Checking the Delivery Rate

Reference 270-15-092, 301 Series Selective Control Valves-Adjust Detent Kickout Relief Valve Parts

Reference 270-15-093, Selective Control Valves - Adjusting Left Endplate (with LS Pressure Port and Adjustable LS Pressure Relief)

Reference 270-15-094, Selective Control Valves-Adjusting Right Endplate (with Extra Ports and Adjustable LS Pressure Relief)

Reference 270-15-095, Selective Control Valves - Adjusting the Spacer Housing (with Extra Ports and Adjustable LS Pressure Relief)

Reference 270-15-110, Checking the Stepper Motor and Rockshaft Valve

Reference 270-15-130, Rockshaft Valve - Checking for Leaks

Reference 270-15-131, Rockshaft Valve (Wide Version) - Checking the Pressure-Relief Valve

Reference 270-15-132, Rockshaft Valve - Checking Depth to Which Pressure and Discharge Valves are Screwed In

Reference 270-15-150, Rockshaft Valve - Checking the Position Sensor

Reference 270-15-170, Adjusting the Power Beyond Valve

Group 20: Theory of Operation

Reference 270-20-002, Hydraulic System-Summary of References

Reference 270-20-060, Hydraulic System-Description

Reference 270-20-070, Hydraulic System-Operation

Reference 270-20-080, PC Hydraulic System - Symbolic Representation

Reference 270-20-090, Hydraulic System-Schematic View

Reference 270-20-100, Hydraulic System-Three-Dimensional View

Reference 270-20-160, Hydraulic System-Description of Hydraulic Pump

Reference 270-20-170, Hydraulic System-Oil Lines of Hydraulic Pump

Reference 270-20-180, Hydraulic System-Operation of Hydraulic Pump

Reference 270-20-190, Primary Hydraulic Oil Filter - Description

Reference 270-20-200, Hydraulic Oil Cooler - Description

Reference 270-20-220, Hydraulic System-Description of Hydraulic Oil Filter

Reference 270-20-230, Hydraulic System-Description of Lube Priority Valve

Reference 270-20-260, Hydraulic System-Description and Arrangement of Shuttle Valves

Reference 270-20-290, Hydraulic System-Description of Main Block with Priority Valve and By-Pass Valve

Reference 270-20-300, Hydraulic System-Operation of Priority Valve and By-Pass Valve

Reference 270-20-320, Rockshaft - Description

Reference 270-20-330, Rockshaft - Operation of Rockshaft Control

Reference 270-20-340, Rockshaft - Operation of Rockshaft Valve

Reference 270-20-350, Rockshaft - Operation of Position Sensor

Reference 270-20-360, Rockshaft - Operation of Draft Sensor

Reference 270-20-370, Rockshaft - Description of Controls

Reference 270-20-380, Rockshaft - Direct Actuation

Reference 270-20-400, 101 Series Selective Control Valve (Mechanically Actuated) - Operation

Reference 270-20-410, 201 Series Selective Control Valve (Mechanically Actuated) - Operation

Reference 270-20-420, 301 Series Selective Control Valve (Mechanically Actuated) - Operation

Reference 270-20-470, 101, 201 and 301 Series Selective Control Valves - Description

Reference 270-20-490, Endplate of Selective Control Valves - Summary

Reference 270-20-500, Independent Control Valve-Description

Reference 270-20-510, Independent Control Valve - Operation

Section 290: Operator's Cab

Group 10: Operational Check-Out

Reference 290-10-001, Air Conditioning System and Heater Unit-Test Sequence

Group 15: Tests and Adjustments

Reference 290-15-001, Tests/Adjustments - Summary of References

Reference 290-15-010, Safety at Work

Reference 290-15-015, Handling Refrigerant

Reference 290-15-020, Safety Equipment

Reference 290-15-025, In an Emergency

Reference 290-15-030, Storage of Refrigerant Containers

Reference 290-15-035, R134a Refrigerant

Reference 290-15-040, Important

Reference 290-15-050, Special tools

Reference 290-15-052, Service Equipment and Tools

Reference 290-15-054, Other Material

Reference 290-15-055, Specifications

Reference 290-15-065, Explanation of Checks

Reference 290-15-070, Pressure Deviations

Group 20: Theory of Operation

Reference 290-20-010, Principle of Heat Exchange

Reference 290-20-015, R134a Refrigerant

Reference 290-20-030, Refrigerant Circuit Operation

Reference 290-20-035, Component Description

Reference 290-20-040, Ventilation and Heater Operation

Section 299: Special Tools

Group 05: Special Tools (Dealer-Fabricated)

Reference 299-05-001, Special Tools (Dealer-Fabricated) - Summary

Reference 299-05-010, Holding Tool

Reference 299-05-011, Adjusting Tool

Reference 299-05-012, DFRW2-Needle Valve Test Hose Assembly

Reference 299-05-013, DFRW85-Reverse Brake Test Plate

Reference 299-05-014, DFLX10 and DFLX11-Test Harnesses

Reference 299-05-015, DFLX12 - Special tool for 11-BIT and 29-BIT CAN BUS

Reference 299-05-016, DFLX14-Solenoid Test Harness

Group 10: Special Tools and Test Equipment

D01019AA - Manually operated hydraulic pump

FKM10002 or JT05470 - Pressure test kit

Battery Load Tester FKM10409

FKM10443 - Charging valve

FKM10444 - Leak detector

FKM10445 - Universal pressure test kit

FKM10447 - Refrigerant container (R134a; 920g; 750 ml)

FKM10470 - Pressure Measuring System (stage 1)

FKM10471 - Pressure measuring system (stage 2)

FKM10472 - Flow measurement system

FKM10472-4 - Temperature sensor

Clamp-on Current Probe JT02153

JT03248 - Fitting

JT05791A - Multimeter

JT07115 - Pressure test kit

KJD10128 - Fitting

KJD10292 - Diagnostic harness

KJD10352 - Restriction fitting

RE200689 - Performance monitor

RE37996 - Adjusting tool

John Deere Tractors 6215, 6415, 6615, 6715 Diagnosis and Tests Service Technical Manual (TM4648)