John Deere Tractors 6225, 6325, 6425, 6525 Diagnosis and Tests Service Technical Manual (TM400919)

John Deere Tractors 6225, 6325, 6425, 6525 Diagnosis and Tests Service Technical Manual (TM400919)

tm400919 - 6225 to 6525 Tractors Diagnostics Technical Manual.pdf

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere 6225, 6325, 6425, 6525 European Tractors, with all the shop information to maintain, diagnose, rebuild like professional mechanics.

John Deere 2WD or MFWD - European Tractors 6225, 6325, 6425, 6525 workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,672 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety Information

General References

Diagnostic Trouble Codes

ECU Control Unit

Observable Symptoms

Electrical System

SyncroPlus Transmission

PowrReverser Transmission

Drive Systems

Steering and Brakes

Hydraulic System

System Diagnostics

Electronics

Engine

General Information

Operational Checks

Tests and Adjustments

Fuel, Air Intake and Cooling Systems

Tests and Adjustments

Fuel System

Air Intake System

Cooling System

Cold-Weather Starting Aids

Electrical System

Starting Motor and Charging Circuit

Fuel Preheater

Electrical Starting Aid

Instrument Unit

Horn

Lights

Worklights

3-Terminal Socket (ECE)

Connector for Accessories

Hazard Warning and Turn Signal Lights

Brake Lights

Differential Lock

Front-Wheel Drive

Service Socket

7-Terminal Socket (ECE)

Level 16 ECU Control Unit (Electronic Engine Control) for 2-Valve Engine with HPCR

Component Information - Connectors

Component Information - Wiring Harnesses

Component Information - Electrical Parts/Components

Component Information - Ground Connections

Component Information - CAN BUS System

Electronic Control Units

Operation and General Information on Diagnostics

Data BUS Systems

ECU Control Unit

SyncroPlus Transmission

Operational Checks

Tests and Adjustments

Theory of Operation

PowrReverser Transmission

Operational Checks

Tests and Adjustments

Theory of Operation

Drive Systems

Operational Checks

Tests and Adjustments

Front-Wheel Drive Clutch

Differential

Final Drives

Rear PTO Options

Steering and Brakes

Introductory Checks

Operational Checks

Tests and Adjustments

Hydrostatic Steering

Brake Valve

Rear Wheel Brakes

Handbrake

Hydraulic Trailer Brake

Hydraulic System

Operational Checks

Tests and Adjustments

Theory of Operation

Oil Filter and Hydraulic Pump

Hitch

Selective Control Valves

Special Tools

Special Tools (Dealer-Fabricated)

Special Tools (Available as Spare Parts)

tm400919 - 6225 to 6525TractorsDiagnostics

Table of Contents

Foreword

Section 210: General Information

Group 05: Safety Information

General Information - Safety - Summary of References

Recognize Safety Information

”Important” Information

”Note” Information

Prevent Machine Runaway

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Service Cooling System Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Support Machine Properly

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Safety Information - Air Brake System

Avoid Eye Contact With Radar

Keep ROPS Installed Properly

Replace Safety Signs

Replace Safety Signs

Dispose of Waste Properly

Live With Safety

Safety Measures on Electronic Control Units

Servicing Electronic Control Units

Welding Near Electronic Control Units

Keep Electronic Control Unit Connectors Clean

Safety Instructions for Replacing a Halogen Bulb

Safety Instructions for Replacing Xenon (HID) Bulbs and Ballast Units

Group 10: General References

General Information - General References, Summary of References

General Information - Transmission and Hydraulic System, Introductory Checks

General Information - Inch Bolt and Cap Screws, Torque Values

General Information - Metric Bolt and Cap Screws, Torque Values

General Information - Hydraulic System Inch Fittings, Torque Values

General Information - Hydraulic System Metric Fittings, Torque Values

General Information - Electrical System, Component Identification Table

General Information - Electrical System, How to Read a Diagnostic Schematic

General Information - Electrical System, Lead Numbers and Color Codes

General Information - Electrical System, Symbols in Schematic, Wiring and Harness Diagrams

General Information - Electrical System, Approach to Tabular Diagnostic Procedures

General Information - Electrical System, Troubleshooting Unsolved Problems

General Information - Electrical System, Worksheet for Circuit/Harness Test

General Information - Electrical System, Visual Check

General Information - Electrical System, Electrical Circuit Malfunctions

General Information - Electrical System, Seven-Step Test Procedure

General Information - Hydraulic System, Symbols in Circuit Diagrams

General Information - Check the Oil Sight-Glass (when the Tire Combination has been Changed)

General Information - Country Version

Section 211: Diagnostic Trouble Codes

Group ECU: ECU Control Unit

ECU 000029.03 - B96 - Hand Throttle Potentiometer, Voltage Too High

ECU 000029.04 - B96 - Hand Throttle Potentiometer, Voltage Too Low

ECU 000091.03 - B79 - Accelerator Pedal Potentiometer, Voltage Too High

ECU 000091.04 - B79 - Accelerator Pedal Potentiometer, Voltage Too Low

ECU 000097.03 - Water-in-Fuel Sensor Signal Voltage Too High

ECU 000097.04 - Water-in-Fuel Sensor Signal Voltage Too Low

ECU 000097.16 - Water In Fuel Detected

ECU 000105.00 - Intake Air Temperature Extremely High

ECU 000105.03 - Intake Air Temperature Sensor Input Voltage Too High

ECU 000105.04 - Intake Air Temperature Sensor Input Voltage Too Low

ECU 000105.15 - Intake Air Temperature Slightly Too High

ECU 000105.16 - Intake Air Temperature Slightly High

ECU 000108.02 - Barometric Air Pressure Invalid

ECU 000110.00 - Engine Coolant Temperature Extremely High

ECU 000110.03 - Engine Coolant Temperature Sensor Input Voltage Too High

ECU 000110.04 - Engine Coolant Temperature Sensor Input Voltage Too Low

ECU 000110.15 - Engine Coolant Temperature Slightly High

ECU 000110.16 - Engine Coolant Temperature Moderately High

ECU 000157.03 - Fuel Rail Pressure Sensor Input Voltage Too High

ECU 000157.04 - Fuel Rail Pressure Sensor Input Voltage Too Low

ECU 000157.10 - Fuel Rail Pressure Loss Detected

ECU 000157.17 - Fuel Rail Pressure Not Developed

ECU 000158.17 - ECU Power Down Error

ECU 000174.00 - Fuel Temperature Extremely High

ECU 000174.03 - Fuel Temperature Sensor Input Voltage Too High

ECU 000174.04 - Fuel Temperature Sensor Input Voltage Too Low

ECU 000174.16 - Fuel Temperature Moderately High

ECU 000189.00 - Engine Speed Derate

ECU 000190.00 - Engine Overspeed Extreme

ECU 000190.16 - Engine Overspeed Moderate

ECU 000611.03 - Electronic Injector Wiring Shorted To Power Source

ECU 000611.04 - Electronic Injector Wiring Shorted To Ground

ECU 000627.01 - High Resistance In All Injector Circuits

ECU 000629.12 - ECU Error (EEPROM)

ECU 000629.13 - ECU Error

ECU 000636.02 - Pump Position Sensor Input Noise

ECU 000636.05 - Pump Position Sensor Current Too Low

ECU 000636.06 - Pump Position Sensor Current Too High

ECU 000636.08 - Pump Position Sensor Input Missing

ECU 000636.10 - Pump Position Sensor Input Pattern Error

ECU 000637.02 - Crank Sensor Input Noise

ECU 000637.05 - Crank Sensor Current Too Low

ECU 000637.06 - Crank Sensor Current Too High

ECU 000637.07 - Crank Position/Pump Position Timing Moderately Out of Sync

ECU 000637.08 - Crank Sensor Signal Input Missing

ECU 000637.10 - Crank Sensor Input Pattern Error

ECU 000651.02 - Cylinder No.1 Electronic Injector Part Number Invalid

ECU 000651.05 - Cylinder No.1 Electronic Injector Circuit Open

ECU 000651.06 - Cylinder No.1 Electronic Injector Circuit Shorted

ECU 000651.13 - Calibration Fault, Cylinder No.1 Injector

ECU 000652.02 - Cylinder No.2 Electronic Injector Part Number Invalid

ECU 000652.05 - Cylinder No.2 Electronic Injector Circuit Open

ECU 000652.06 - Cylinder No.2 Electronic Injector Circuit Shorted

ECU 000652.13 - Calibration Fault, Cylinder No.2 Injector

ECU 000653.02 - Cylinder No.3 Electronic Injector Part Number Invalid

ECU 000653.05 - Cylinder No.3 Electronic Injector Circuit Open

ECU 000653.06 - Cylinder No.3 Electronic Injector Circuit Shorted

ECU 000653.13 - Calibration Fault, Cylinder No.3 Injector

ECU 000654.02 - Cylinder No.4 Electronic Injector Part Number Invalid

ECU 000654.05 - Cylinder No.4 Electronic Injector Circuit Open

ECU 000654.06 - Cylinder No.4 Electronic Injector Circuit Shorted

ECU 000654.13 - Calibration Fault, Cylinder No.4 Injector

ECU 000655.02 - Cylinder No.5 Electronic Injector Part Number Invalid

ECU 000655.05 - Cylinder No.5 Electronic Injector Circuit Open

ECU 000655.06 - Cylinder No.5 Electronic Injector Circuit Shorted

ECU 000655.13 - Calibration Fault, Cylinder No.5 Injector

ECU 000656.02 - Cylinder No.6 Electronic Injector Part Number Invalid

ECU 000656.05 - Cylinder No.6 Electronic Injector Circuit Open

ECU 000656.06 - Cylinder No.6 Electronic Injector Circuit Shorted

ECU 000656.13 - Calibration Fault, Cylinder No.6 Injector

ECU 000676.03 - Glow Plug Relay Voltage Too High

ECU 000676.05 - Glow Plug Relay Voltage Too Low

ECU 001347.03 - Suction Control Valve Current Too High

ECU 001347.05 - Suction Control Valve Current Mismatch

ECU 001347.07 - Fuel Rail Pressure Control Error

ECU 001569.31 - Fuel Derate

ECU 003509.03 - Sensor Supply Voltage 1 Too High

ECU 003509.04 - Sensor Supply Voltage 1 Too Low

ECU 003510.03 - Sensor Supply Voltage 2 Too High

ECU 003510.04 - Sensor Supply Voltage 2 Too Low

ECU 003511.03 - Sensor Supply Voltage 3 Too High

ECU 003511.04 - Sensor Supply Voltage 3 Too Low

Section 212: Observable Symptoms

Group 40: Electrical System

Control Unit not Displayed

Problems with the CAN-BUS Connection to Service ADVISOR

Problems While Reprogramming Control Units

Charging Circuit Problem

Problem with the Starting Motor

Problem with the Battery

Problem with Fuel Preheater Element

Problem with the Fuel Pump

Problem with Heating Element of Electrical Starting Aid (2-Valve Engine with HPCR)

Problem with the Instrument Unit

Problem with the Horn

Problem with the Parking Lights

Problem with the Low-Beam Headlights

Problem with the High-Beam Headlights

Problem with the Front Corner Worklights

Problem with Worklights on Rear Fenders

Problem with the 3-Terminal Power Outlet Socket

Problem with the 2-Pin Plug of Front Loader

Problem with the Hazard Warning Lights

Problem with the Turn Signals

Problem with Brake Lights

Problem with the Differential Lock

Problem with the Front-Wheel Drive

Problem with the 7-Terminal Power Outlet Socket

Group 50: SyncroPlus Transmission

Problem with SyncroPlus Transmission

Group 51: PowrReverser Transmission

Problem with PowrReverser Transmission

Group 56: Drive Systems

Problem with the rear PTO

Problem with the Front-Wheel Drive

Problem with the Differential Lock

Group 60: Steering and Brakes

Problem with the Brakes

Problem with the Steering

Problem with the Handbrake

Group 70: Hydraulic System

Hitch lowers too fast

Hitch: Incorrect reaction of position or draft control

Hitch: Lift arms rise too slowly or erratically

Section 213: System Diagnostics

Group 45: Electronics

Check for Vehicle CAN BUS

Section 220: Engine

Group 05: General Information

Information on Engine

Group 10: Operational Checks

Engine - Safety Measures

Engine - Preliminary Engine Tests

Group 15: Tests and Adjustments

Engine - Tests and Adjustments, Summary of References

Engine - Measure PTO Power Output

Engine - Engine Tests with Service ADVISOR

Section 230: Fuel, Air Intake and Cooling Systems

Group 15: Tests and Adjustments

Fuel, Air Intake and Cooling Systems - Tests and Adjustments, Summary of References

Fuel, Air Intake and Cooling Systems - General Information

Fuel, Air Intake and Cooling Systems - Explanation of Checks

Fuel, Air Intake and Cooling Systems - Safety Measures

Fuel, Air Intake and Cooling Systems - Special Tools, Summary of References

Fuel, Air Intake and Cooling Systems - Specifications

Air Intake System - System Check

Cooling System - Fill/Bleed the System

Cooling System - Leak Test

Cooling System - Test Thermostat Opening Temperature

Cooling System - Flow Testing in the Low-Temperature Circuit

Cooling System - Check the Viscous Fan Drive

Fuel System - Check the Fuel Transfer Pump

Group 20A: Fuel System

Fuel System - Theory of Operation, Summary of References

Fuel System - Theory of Operation

Fuel System - Fuel Cooler, Component Information

Fuel System - Fuel Transfer Pump, Component Information

Group 20B: Air Intake System

Air Intake System - Theory of Operation, Summary of References

Air Intake System - Theory of Operation

Group 20C: Cooling System

Cooling System - Summary of References

Cooling System - Coolant Circuit, Description

Cooling System - Radiator Description, Component Information

Cooling System - Intercooler, Component Information

Cooling System - Transmission Oil Cooler, Component Information

Cooling System - Viscous Fan Drive, Theory of Operation

Cooling System - Automatic Drive Belt Tensioner, Theory of Operation

Group 20D: Cold-Weather Starting Aids

Cold-Weather Starting Aids - Summary of References

Cold-Weather Starting Aids - General Information

Cold-Weather Starting Aids - Coolant Heater - Component Information

Cold-Weather Starting Aids - Transmission Oil Heater - Component Information

Cold-Weather Starting Aids - Charge Pump Preheater - Component Information

Section 240: Electrical System

Group SE01: Starting Motor and Charging Circuit

SE01 - Starting Motor and Charging Circuit - Summary of References

Diagnostic Schematic, SE01 - Starting Motor and Charging Circuit

Group SE01A: Fuel Preheater

SE01A - Fuel Preheater - Summary of References

Diagnostic Schematic, SE01A - Fuel Preheater

Group SE01C: Electrical Starting Aid

SE01C - Electrical Starting Aid - Summary of References

Diagnostic Schematic, SE01C - Electrical Starting Aid

Group SE02: Instrument Unit

SE02 - Instrument Unit - Summary of References

Diagnostic Schematic, SE02 - Instrument Unit

Group SE03: Horn

SE03 - Horn - Summary of References

Diagnostic Schematic, SE03 - Horn

Group SE06: Lights

SE06 - Lights - Summary of References

Diagnostic Schematic, SE06 - Lights

Group SE07: Worklights

SE07 - Worklights - Summary of References

Diagnostic Schematic, SE07 - Worklights

Group SE14: 3-Terminal Socket (ECE)

SE14 - 3-Terminal Socket (ECE) - Summary of References

Diagnostic Schematic, SE14 - 3-Terminal Socket (ECE)

Group SE14A: Connector for Accessories

SE14A - Plug for Accessories - Summary of References

Diagnostic Schematic, SE14A - Plug for Accessories

Group SE16A: Hazard Warning and Turn Signal Lights

SE16A - Hazard Warning and Turn Signal Lights - Summary of References

Diagnostic Schematic, SE16A - Hazard Warning and Turn Signal Lights

Group SE16C: Brake Lights

SE16C - Brake Lights - Summary of References

Diagnostic Schematic, SE16C - Brake Lights

Group SE16D: Differential Lock

SE16D - Differential Lock - Summary of References

Diagnostic Schematic, SE16D - Differential Lock

Group SE16E: Front-Wheel Drive

SE16E - Front-Wheel Drive - Summary of References

Diagnostic Schematic, SE16E - Front-Wheel Drive

Group SE17: Service Socket

SE17 - Service Socket - Summary of References

Diagnostic Schematic, SE17 - Service Socket

Group SE17A: 7-Terminal Socket (ECE)

SE17A - 7-Terminal Socket (ECE) - Summary of References

Diagnostic Schematic, SE17A - 7-Terminal Socket (ECE)

Group SE23: Level 16 ECU Control Unit (Electronic Engine Control) for 2-Valve Engine with HPCR

SE23 - Level 16 ECU (Electronic Engine Control) for 2-Valve Engine with HPCR - Summary of References

Diagnostic Schematic, SE23 - Level 16 ECU Control Unit (Electronic Engine Control)

B79 - Accelerator Pedal Potentiometer, Circuit/Harness Test

B96 - Hand Throttle Potentiometer, Circuit/Harness Test

K02PLB/01 - Relay for Electrical Starting Aid, Circuit/Harness Test

Group 105: Component Information - Connectors

F01PLB - Fuses

F02PLB - Fuses

F02 - Fuses (Open Operator's Station)

F05 - Fuses (Open Operator's Station)

G02-1 - Terminal with Ring for Alternator

K01PLB - Starting Motor Relay

K02PLB - Relay for Electrical Starting Aid

K03PLB - Relay

K01 - Relays (Open Operator's Station)

K03 - Relays (Open Operator's Station)

K04 - Relays (Open Operator's Station)

K05 - Relays (Open Operator's Station)

K20-1 - Plug of Turn-Signal Relay

M01-50 - Terminal for Starting Motor

S01F - Plug of Main (Key) Switch

S01F-1 - Terminal for Main (Key) Switch

S04F - Plug of Horn Switch

S08F - Plug of Turn-Signal Switch

S10F - Plug of High-/Low-Beam Switch

X05F - Plug of 7-Terminal Power Outlet Socket (ECE)

X37F - Plug for Front Loader

X66F - Plug of Horn

X67F - Plug of Right Headlight

X68F - Plug of Left Headlight

X69F-1 - Plug of Left Front Corner Worklight

X69F-2 - Plug of Right Front Corner Worklight

X70F - Plug of Sensor for Air Cleaner Restriction Warning Light

X77F - Plug of Sensor for Coolant Temperature Gauge

X78F - Plug of Engine Oil Pressure Switch

X79F - Plug of Heating Element of Fuel Preheater

X80M - Plug of Transmission Oil Filter Pressure Switch

X81F - Terminal of Low-Temperature Switch (Transmission Oil)

X82F - Terminal of High-Temperature Switch (Transmission Oil)

X83M - Plug of Transmission Oil Pressure Switch

X87F - Plug of Differential Lock Solenoid Valve

X88F-3 - Plug of Wheel Speed Sensor

X91F - Plug of Front-Wheel Drive Solenoid Valve

X93F - Plug of Neutral-Start Switch

X112F-1 - Plug of Worklight on Rear of Left Fender

X112F-2 - Plug of Worklight on Rear of Right Fender

X113F - Plug for License Plate Light

X122F - Plug of Differential Lock Switch

X234F - Connecting Point between Harnesses W07 and W21 (ECE)

X234M - Connecting Point between Harnesses W21 and W07

X239F - Connecting Point between Harnesses W21 and W04

X261F - Plug of Coolant Temperature Sensor

X286F - Connecting Point between Harnesses W21 and W61

X286M - Connecting Point between Harnesses W61 and W21

X287F - Connecting Point between Harnesses W21 and W63

X287M - Connecting Point between Harnesses W63 and W21

X301F - Plug of Intake Air Temperature Sensor

X305F - Plug of Radiator Ground Connection

X315F - Plug of Handbrake Monitor Switch

X321F - Plug of Hand Throttle Potentiometer

X324F - Plug of Sensor Unit for Brake Pedal

X356F - Plug of Crankshaft Speed Sensor

X359F - Plug of Camshaft Speed Sensor (Pump Position)

X371F - Plug of Accelerator Pedal Potentiometer

X392F-L - Plug for Clearance, Tail, Brake and Turn Signal Lights (Left)

X392F-R - Plug for Clearance, Tail, Brake and Turn Signal Lights (Right)

X402M - Plug of Switch for Front Corner Worklights

X406F - Plug of Light Switch

X411F - Connecting Point between Harnesses W51 and W11

X411M - Connecting Point between Harnesses W11 and W51

X433M - Plug of Switch for Worklights on Rear of Fender

X473F - Connecting Point between Harnesses W01 and W21

X473M - Connecting Point between Harnesses W21 and W01

X516M - Plug of Hazard Warning Light Switch

X547F - Connecting Point between Harnesses W51 and W01

X547M - Connecting Point between Harnesses W01 and W51

X550F - Plug of Fuel Temperature Sensor

X566F - Plug of Suction Control Valve

X567F - Plug of Water-in-Fuel Sensor

X568F - Plug of Injection Valves (4-Cylinder, 2-Valve Engine with HPCR)

X571M - Service Socket (CAN BUS)

X579F - Plug of Preheater Indicator Light

X617F - Plug of Instrument Unit

X618F - Plug of Instrument Unit

X625F - Plug of Rail Pressure Sensor

X780F - Connecting Point between Harnesses W22 and W21

X780M - Connecting Point between Harnesses W21 and W22

X782F - Connecting Point between Harnesses W51 and W21

X782M - Connecting Point between Harnesses W21 and W51

X803F - Plug of Fuel Level Sensor

X804 - Plug of Fuel Pump

X844F-1 - Plug of ECU Control Unit (Level 16) (4-Cylinder Engine)

X844F-1 - Plug of ECU Control Unit (Level 16) (6-Cylinder Engine)

X844F-2 - Plug of ECU Control Unit (Level 16)

X845F - Plug of Injection Valves (6-Cylinder, 2-Valve Engine with HPCR)

X858 - Terminal with Ring for Battery Connection

X861 - Terminal with Ring for Alternator

X885 - Terminal with Ring, for Heater Element (Electrical Starting Aid)

X920M - Plug of Front-Wheel Drive Switch

XGND1 - Ground Point

XGND1-1 - Collective Ground Point for XGND1

XGND2 - Ground Point

XGND2-1 - Collective Ground Point for XGND2

XGND4A - Ground Point

XGND4-1 - Collective Ground Point for XGND4

XGND9 - Ground Point

Group 110: Component Information - Wiring Harnesses

Component Information - Wiring Harnesses - Summary of References

General Information

W01/7: Front Fuse Box Wiring Harness

W07/1: Wiring Harness for 7-Terminal Socket (ECE)

W11/5: Hood Wiring Harness

W21/5: Wiring Harness for Open Operator's Station

W22/5: Wiring Harness for Cowl

W51/7: Wiring Harness for 4-Cylinder Engine (2V-HPCR, Level 16)

W51/8: Wiring Harness for 6-Cylinder Engine (2V-HPCR, Level 16)

W61/16: Front Transmission Wiring Harness

W63/7: Rear Transmission Wiring Harness

Group 115: Component Information - Electrical Parts/Components

Component Information - Electrical Parts/Components - Summary of References

1-/3-amp Diode

10-/20-amp Relay

20-/40-amp Relay

70-amp Relay

70-/100-amp Relay

A86 - ECU Control Unit (Level 16)

B02 - Sensor for Air Cleaner Restriction

B04 - Engine Oil Pressure Switch

B05 - Handbrake Monitor Switch

B07 - Transmission Oil Filter Pressure Switch

B08 - Sensor for Coolant Temperature Gauge

B29 - Switch, Low Transmission Oil Temperature

B30 - Switch, High Transmission Oil Temperature

B31 - Transmission Oil Pressure Switch

B35 - Wheel Speed Sensor on Tractors without Creeper

B36 - Neutral Start Switch

B56 - Coolant Temperature Sensor

B59 - Intake Air Temperature Sensor

B72 - Crankshaft Speed Sensor

B74 - Camshaft Speed Sensor (Pump Position)

B79 - Accelerator Pedal Potentiometer

B96 - Hand Throttle Potentiometer

B112 - Brake Pedal Sensor Unit

B114 - Fuel Temperature Sensor

B121 - Water-in-Fuel Sensor

B137 - Rail Pressure Sensor

B176 - Fuel Level Sensor

E01 - R.H. Headlight

E02 - L.H. Headlight

E03 - L.H. Clearance Light (ECE)

E04 - R.H. Clearance Light (ECE)

E09-L - Front Corner Worklight (Left)

E09-R - Front Corner Worklight (Right)

E13 - L.H. Tail Light

E14 - R.H. Tail Light

E15-L - Worklight on Rear of Left Fender

E15-R - Worklight on Rear of Right Fender

E21 - License Plate Light (ECE)

F01PLB to F02PLB - Fuses (Fuse Box in Engine Compartment)

F02 to F05 - Fuses (Open Operator's Station)

G01 - Battery

G02 - Alternator

H01 - Horn

H32 - Left Brake Light

H33 - Right Brake Light

H34 - Front Left Turn Signal Light (ECE)

H35 - Rear Left Turn Signal Light

H42 - Front Right Turn Signal Light (ECE)

H43 - Rear Right Turn Signal Light

H77 - Indicator Light for Heater Element (Electrical Starting Aid)

K01PLB to K03PLB - Relays (Fuse Box in Engine Compartment)

K01 to K05 - Relays (Open Operator's Station)

K20 - Turn-Signal Relay

M01 - Starting Motor

M31 - Fuel Pump

P21 - Instrument Unit

R02 - Heating Element of Fuel Preheater

R15 - Heating Element of Electrical Starting Aid (2-Valve Engine with HPCR)

R19 - CAN BUS Terminating Resistor

S01 - Main (Key) Switch

S04 - Horn Switch

S08 - Turn Signal Lever

S09 - Light Switch

S10 - High Beam Switch

S22 - Differential Lock Switch

S59 - Switch for Front Corner Worklights

S92 - Switch for Worklight on Rear Fender

S107 - Hazard Warning Light Switch

S161 - Front-Wheel Drive Switch

X05 - 7-Terminal Power Outlet Socket (ECE) at Rear

X571M - Service Socket (CAN BUS)

Y03 - Solenoid Valve for Front-Wheel Drive

Y05 - Solenoid Valve for Differential Lock

Y44 - Suction Control Valve

Y82 - Injector for Cylinder 1 (4-Cylinder Engines)

Y83 - Injector for Cylinder 2 (4-Cylinder Engines)

Y84 - Injector for Cylinder 3 (4-Cylinder Engines)

Y85 - Injector for Cylinder 4 (4-Cylinder Engines)

Y86 - Injector for Cylinder 1 (6-Cylinder Engines)

Y87 - Injector for Cylinder 2 (6-Cylinder Engines)

Y88 - Injector for Cylinder 3 (6-Cylinder Engines)

Y89 - Injector for Cylinder 4 (6-Cylinder Engines)

Y90 - Injection Valve for Cylinder 5 (6-Cylinder Engines)

Y91 - Injector for Cylinder 6 (6-Cylinder Engines)

Group 120: Component Information - Ground Connections

Component Information - Ground Connections - Summary of References

XGND1

XGND2

XGND4

XGND9

Group 125: Component Information - CAN BUS System

Component Information - CAN BUS System - Summary of References

CAN Bus System

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

Operation and General Information on Diagnostics - Summary of References

Operation and General Information on Diagnostics - Special Tools

Operation and General Information on Diagnostics - Abbreviations for Control Units

Operation and General Information on Diagnostics - Operation and Entering the Program Mode using the Performance Monitor

Operation and General Information on Diagnostics - Accessing Addresses and Diagnostic Trouble Codes

Operation and General Information on Diagnostics - Approved Software for Control Units

Operation and General Information on Diagnostics - Locations and Allocations of Control Units

Group 20: Data BUS Systems

Data BUS Systems - Summary of References

Data BUS Systems - CAN BUS Systems

Data BUS Systems - CAN BUS Systems on Engines with Level 16 Control Unit (2-Valve HPCR Fuel System)

Data BUS Systems - CAN BUS Systems, Plug Layout

Group ECU: ECU Control Unit

ECU - Summary of References

ECU - Summary of Addresses (Level 16 ECU for 2-Valve Engine with HPCR)

ECU - Calibration and Input Addresses (Level 16 ECU for 2-Valve Engine with HPCR)

ECU - Theory of Operation (Level 16 ECU for 2-Valve Engine with HPCR)

Section 250: SyncroPlus Transmission

Group 10: Operational Checks

SyncroPlus Transmission - Operational Check-Out, Summary of References

SyncroPlus Transmission - Operational Check-Out

Group 15: Tests and Adjustments

SyncroPlus Transmission - Tests and Adjustments, Summary of References

SyncroPlus Transmission - Special Tools, Summary of References

SyncroPlus Transmission - System Check

SyncroPlus Transmission - Check the System Pressure

SyncroPlus Transmission - Adjust the System Pressure

SyncroPlus Transmission - Check the Components Dependent On System Pressure

SyncroPlus Transmission - Check the Filter Bypass Valve

SyncroPlus Transmission - Check the Engagement Override Valve and the Clutch Pedal Valve

SyncroPlus Transmission - Check the Modulation of the Clutch Pedal Valve

SyncroPlus Transmission - Check the Lube Oil Pressure

SyncroPlus Transmission - Check the Cooling System

SyncroPlus Transmission - Check the Flow Rate

SyncroPlus Transmission - Check the Cooler Relief Valve

SyncroPlus Transmission - Check the Transmission Oil Filter

SyncroPlus Transmission - Layout of Test Ports and Sensors

SyncroPlus Transmission - Check and Adjust the Shift Mechanism/Linkage

SyncroPlus Transmission - Check and Adjust the Park Lock

SyncroPlus Transmission - Adjust the Clutch Pedal

Group 20: Theory of Operation

SyncroPlus Transmission - Theory of Operation, Summary of References

SyncroPlus Transmission - Layout

SyncroPlus Transmission - Lubrication System

SyncroPlus Transmission - Shift Operation

SyncroPlus Transmission - Synchronization

SyncroPlus Transmission - Operation of Transmission Oil Circuit (including Diagram)

SyncroPlus Transmission - Transmission Oil Pump

SyncroPlus Transmission - Perma Clutch II Module, Exploded View

SyncroPlus Transmission - Perma Clutch II Module, Layout

SyncroPlus Transmission - Perma Clutch II Module, Power Flow

SyncroPlus Transmission - Perma Clutch II Module, Hydraulic Diagram

SyncroPlus Transmission - Perma Clutch II Module, Description of Various Valves and Components

SyncroPlus Transmission - Perma Clutch II Module, Pressure Regulating and Filter Bypass Valves

SyncroPlus Transmission - Perma Clutch II Module, Clutch Pedal Valve and Engagement Override Valve

SyncroPlus Transmission - Perma Clutch II Module, Cooling

SyncroPlus Transmission - Gear Transmission, Layout

SyncroPlus Transmission - Gear Transmission, Power Flow

SyncroPlus Transmission - Gear Transmission, Neutral Start Switch

SyncroPlus Transmission - Range Transmission, Layout

SyncroPlus Transmission - Range Transmission, Power Flow

SyncroPlus Transmission - Range Transmission, Park Lock

Section 251: PowrReverser Transmission

Group 10: Operational Checks

PowrReverser Transmission - Operational Check-Out, Summary of References

PowrReverser Transmission - Operational Check-Out

Group 15: Tests and Adjustments

PowrReverser Transmission - Tests and Adjustments, Summary of References

PowrReverser Transmission - Special Tools, Summary of References

PowrReverser Transmission - System Check

PowrReverser Transmission - Check System Pressure

PowrReverser Transmission - Adjust the System Pressure

PowrReverser Transmission - Check the Components Dependent On System Pressure

PowrReverser Transmission - Check the Filter Bypass Valve

PowrReverser Transmission - Check the Engagement Override Valve and the Clutch Pedal Valve

PowrReverser Transmission - Check the Disk Clutch and the Disk Brake

PowrReverser Transmission - Check Lube Oil Pressure

PowrReverser Transmission - Check the Cooling System

PowrReverser Transmission - Check the Flow Rate

PowrReverser Transmission - Check the Cooler Relief Valve

PowrReverser Transmission - Check the Transmission Oil Filter

PowrReverser Transmission - Adjust the Modulation Time

PowrReverser Transmission - Layout of Test Ports and Sensors

PowrReverser Transmission - Check and Adjust the Shift Mechanism/Linkage

PowrReverser Transmission - Adjust the Park Lock

PowrReverser Transmission - Adjust the Reverse Drive Linkage with Mechanically Actuated PowrReverser Module

PowrReverser Transmission - Adjust the Reverse Drive Lever with Mechanically Actuated PowrReverser Module

PowrReverser Transmission - Adjust the Clutch Pedal

Group 20: Theory of Operation

PowrReverser Transmission - Theory of Operation, Summary of References

PowrReverser Transmission - Layout

PowrReverser Transmission - Lubrication System

PowrReverser Transmission - Shift Operation

PowrReverser Transmission - Synchronization

PowrReverser Transmission - Operation of Transmission Oil Circuit (including Diagram)

PowrReverser Transmission - Transmission Oil Pump

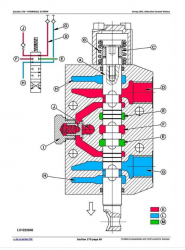

PowrReverser Transmission - PowrReverser Module, Sectional View

PowrReverser Transmission - PowrReverser Module, Components

PowrReverser Transmission - PowrReverser Module, Layout and Power Flow

PowrReverser Transmission - PowrReverser Module, Valves and Other Hydraulic Components

PowrReverser Transmission - PowrReverser Module, Hydraulic Schematic

PowrReverser Transmission - PowrReverser Module, Description of the Individual Valves and Components

PowrReverser Transmission - PowrReverser Module, Operation of the Pressure Regulating and Filter Bypass Valves

PowrReverser Transmission - PowrReverser Module, Operation of the Forward/Reverse Modulation

PowrReverser Transmission - PowrReverser Module, Operation of the Clutch Pedal Valve

PowrReverser Transmission - PowrReverser Module, Operation of the Engagement Override Valve

PowrReverser Transmission - PowrReverser Module, Operation of the Cooling System

PowrReverser Transmission - Gear Transmission, Layout and Power Flow

PowrReverser Transmission - Range Transmission, Layout

PowrReverser Transmission - Range Transmission, Power Flow

PowrReverser Transmission - Range Transmission, Park Lock

Section 256: Drive Systems

Group 10: Operational Checks

Drive Systems - Operational Checks, Summary of References

Drive Systems - Operational Checks

Group 15: Tests and Adjustments

Drive Systems - Tests and Adjustments, Summary of References

Tests and Adjustments - Special Tools

Tests and Adjustments - System Check

Tests and Adjustments - Check the Front-Wheel Drive Clutch

Tests and Adjustments - Check the Differential Lock

Tests and Adjustments - Check the Rear PTO

Tests and Adjustments - Test Result Table

Group 20A: Front-Wheel Drive Clutch

Drive Systems - Front-Wheel Drive Clutch, Summary of References

Front-Wheel Drive Clutch - Cooling and Lubrication

Front-Wheel Drive Clutch - Layout

Front-Wheel Drive Clutch - Oil and Power Flows

Group 20B: Differential

Drive Systems - Differential, Summary of References

Differential - Layout

Differential - Power Flows

Differential - Oil Flows

Group 20C: Final Drives

Drive Systems - Final Drives, Summary of References

Final Drives - Operation and Layout

Group 20D: Rear PTO Options

Drive Systems - Rear PTO Options, Summary of References

Rear PTO - Description

Rear PTO - Modulating Valve with Lever Detent

Rear PTO - PTO Clutch and PTO Brake

Rear PTO Options - 540 rpm Power Flow

Rear PTO Options - 540/1000 rpm Power Flows

Section 260: Steering and Brakes

Group 05: Introductory Checks

Steering and Brakes - Test and Adjustments, Summary of References

Steering and Brakes - Steering, Preliminary Check

Steering and Brakes - Brakes, Preliminary Check

Group 10: Operational Checks

Steering and Brakes - Operational Checks, Summary of References

Steering and Brakes - Safety Measures

Steering and Brakes - Checking the Steering

Steering and Brakes - Check the Brakes

Group 15: Tests and Adjustments

Steering and Brakes - Tests and Adjustments, Summary of References

Steering and Brakes - Special Tools, Summary of References

Steering and Brakes - Connecting SensoControl Test Equipment

Tests and Adjustments - Specifications

Steering and Brakes - Check the Steering Unit

Steering and Brakes - Check the Brake System

Steering and Brakes - Bleed the Brakes

Tests and Adjustments - Adjust the Brake Pedals and Switches

Tests and Adjustments - Check and Adjust the Handbrake

Tests and Adjustments - Check the Hydraulic Trailer Brake Valve

Group 20A: Hydrostatic Steering

Steering and Brakes - Hydrostatic Steering, Summary of References

Steering and Brakes - Description of Steering Valves, Operation

Group 20B: Brake Valve

Steering and Brakes - Brake Valve, Summary of References

Steering and Brakes - Brake Valve, Description

Steering and Brakes - Two-Stage Brake Valve, Operation

Group 20C: Rear Wheel Brakes

Steering and Brakes - Rear Wheel Brakes, Summary of References

Rear Wheel Brakes - Operation and Layout

Group 20D: Handbrake

Steering and Brakes - Handbrake, Summary of References

Handbrake - Operation and Layout (Tractor Models up to 6630)

Group 20E: Hydraulic Trailer Brake

Steering and Brakes - Trailer Brake Valve, Summary of References

Steering and Brakes - Ascertain Pressure Ratio

Steering and Brakes - Hydraulic Trailer Brake Valve, Description

Section 270: Hydraulic System

Group 10: Operational Checks

Hydraulic System - Operational Checks

Group 15: Tests and Adjustments

Hydraulic System - Tests and Adjustments, Summary of References

Hydraulic System - Special Tools, Summary of References

Hydraulic System - Safety Measures for Hydraulic Checks

Hydraulic System - Worksheet for the Hydraulic System Diagnostics

Hydraulic System - Heat Up Hydraulic Oil

Hydraulic System - Oil Pressure Test Points

Hydraulic System - Check the LS Oil Pressure for Steering

Hydraulic System - Check the Oil Pressure for Steering

Hydraulic System - Check and Adjust System Oil Pressure

Hydraulic System - Check Lube Oil Pressure

Hydraulic System - Hydraulic Pump, Check Rate of Delivery

Hydraulic System - Selective Control Valves, Check for Leaks at Valve Spools

Hydraulic System - Hitch Valve, Check and Adjust Pressure Relief Valve

Hydraulic System - Hitch Valve, Check for Leaks

Hydraulic System - Check and Adjust Hitch Control

Hydraulic System - Hitch, Control Lever Friction Adjustment

Group 20: Theory of Operation

Hydraulic System - Theory of Operation, Summary of References

Hydraulic System - Hydraulic Circuit Diagram and Theory of Operation

Hydraulic System - Priority Valve, Theory of Operation

Group 20A: Oil Filter and Hydraulic Pump

Hydraulic System - Oil Filter and Hydraulic Pump, Summary of References

Hydraulic System - Hydraulic Oil Filter, Operation

Hydraulic System - Hydraulic Pump, Operation

Hydraulic System - Hydraulic Oil Primary Filter, Component Information

Hydraulic System - Hydraulic Oil Filter, Component Information

Hydraulic System - Hydraulic Pump, Component Information

Group 20B: Hitch

Hitch - Summary of References

Hitch - Hitch Control, Operation

Hitch - Hitch Control Valve, Operation

Group 20C: Selective Control Valves

Selective Control Valves - Summary of References

Selective Control Valves - Operation

Section 299: Special Tools

Group 05: Special Tools (Dealer-Fabricated)

DFLX9 - Adjusting Tool

DFLX10 - Holding Tool

DFLX12 - CAN BUS - E-SCV/E-ICV and CAN BUS - Vehicle/Power Train

DFLX14 - Solenoid Valve Test Harness

DFLX39 - Support

Group 10: Special Tools (Available as Spare Parts)

AR52361 - Socket

D01019AA - Single-Stage, Manually Operated Pump

D05104ST - Pump

FKM10002 / JT05470 - Universal Pressure Test Kit

FKM10242 - Pressure Gauge

FKM10443 - Charging Valve

FKM10444 - Electronic Refrigerant Leak Detector

FKM10445 - Universal Pressure Test Kit

FKM10447 - MINI CAN

FKM10464 - Single-Acting Hydraulic Ram

FKM10470 - Pressure Measuring System (Stage 1)

FKM10471 - Pressure Measuring System (Stage 2)

FKM10472 - Flow Measurement System

FKM10472-4 - Temperature Sensor

FKM10474 - Fill and Check Device

Adjusting Tool FKM10475

JDG839 - Adapter

JDH43A - Tester for Pressure-Relief Valves

JT03248 - Fitting

JT05470 / FKM10002 - Universal Pressure Test Kit

Pressure Gauge JT05473

JT05719 - Hand-Held Digital Tachometer

JT05791A or JDG1478 - Analog/Digital Multimeter

JT05800 - Digital Thermometer

JT07115 - Pressure Test Kit

JT07120 - Adjustable Restrictor

KJD10128 - Fitting

KJD10194 - Pressure Gauge Set for Air Brake System

KJD10265 - Test Harness

KJD10431 - Flow Tester

FKM10440 - RD5N Vacuum Pump

KJD10352 - Adapter

KJD10444 - Pressure Tool

KJD10502 - Adapter Plate

KJD10292 - Test Harness

RE200689 - Performance Monitor