John Deere Tractors Models 6110E, 6125E, 6415, 6615 Repair Service Manual (TM800419)

Complete Repair Service Technical Manual for John Deere Tractors Models 6415 Classic, 6615 Classic, 6110E and 6125E (South America), with all the shop information to maintain, diagnose, repair, and service like professional mechanics.

John Deere Tractors 6110E, 6125E, 6415, 6615 workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm800419 - 6415 Classic, 6615 Classic, 6110E and 6125E Tractors Technical Repair Manual.pdf

Total Pages: 829 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety Regulations

General Information

Specifications

Adjustment

Engine

Removing and Installing Engine

Fuel System, Air Intake, Cooling and Exhaust Systems

Speed Control Link

Fuel System

Air Intake System

Cooling system

Exhaust System

Electrical System

Connectors

Wiring Harnesses

Charging circuit

Starter Motor Circuit

Fuses, Relays and Switches

Monitoring Systems

Electrical Components

SyncroPlus Transmission

Removing and Installing Transmission Components

Transmission selectors control

Perma Clutch Module II

Gearbox

Range Box - 20 Series

Drive Systems

Removing and Installing Component

U-Jointed Shafts and Torsional Damper

Front-Wheel Drive Clutch

Differential

Hydraulic Pump Drive

Final Drives

PTO Options

Steering and Brakes

Hydrostatic Steering

Brake Valve

Rear Brakes

Hydraulic System

Rockshaft Controls

Removing and Installing Hydraulic Pump

Repairing Hydraulic Pump

Hydraulic Hitch Valve

Hydraulic Cylinders and Center Link Bracket

Hydraulic Apparatus

Hydraulic Filter

Others

Removing and Installing Components - 4x2 Axle

Removing and Installing Components - 4x4 Axle

Main Chassis

Front Wheels and Rear Wheels

Swinging Drawbar

Operator's Platform

Open Operator Station

Roll-Over Protective Structure (ROPS)

Special Tools

tm800419 - 6415 Classic, 6615 Classic, 6110E and 6125E TractorsTechnical Repair Manual

Table of Contents

Foreword

Section 05: Safety

Group 05: Safety Regulations

Live With Safety

Recognize Safety Information

Follow Safety Instructions

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Handle Batteries Safely

Prevent Acid Burns

Prepare for Emergencies

Remove Paint Before Welding or Heating

Avoid High-Pressure Fluids

Engine Coolant

Prevent Machine Runaway

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Support Machine Safely

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Safe Servicing of Front-Wheel Drive

Use Seat Belt Properly

Keep ROPS Installed Properly

Dispose of Waste Properly

Section 10: General Information

Group 05: Specifications

Engine In accordance with SAE J 1995

SyncroPlus SYNCROPLUS is a registered trademark of the Deere & Company Transmission

Front axle

Clutch PermaClutch™

Drawbar

Hydraulic System

Brakes

PTO

Capacities Capacities are approximate values

Tractor Weight in Standard Configuration in kg (lb)

Dimensions

Tires

Electrical System

Transmission and Hydraulic Oil

Front Wheel Drive Axle Oil

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Hydraulic System Unified Inch Fitting Torques

Hydraulic system metric fitting torques

Group 10: Adjustment

Use of High-Pressure Washers

Preliminary Engine Test

Removing and Cleaning Main Air Filter Element

Checking Air Filter Safety Element

Installing Main Filter Element

Checking for Leaks in Air Intake System Connections

Checking for Plugging of Crankcase Vent Hose

Checking Expansion Tank Cap

Checking for Leaks in Radiator

Checking Engine Thermostat

Checking Fuel Filter

Cleaning the Water Separator

Run the Engine until it is Warm, and Check Engine Speeds

Checking Fuel Injection Pump Adjustment

Checking Engine Speed Control Link Adjustment

Cleaning Battery, Cables and Battery Box with a Clean Cloth

Check the Neutral Start Circuit

Checking Starter Motor

Checking Lighting Circuit

Final Engine Checks

Checking Tractor Operation

Section 20: Engine

Group 00: Removing and Installing Engine

Essential or Recommended Tools

Specifications

Removing Engine

Installing Engine

Section 30: Fuel System, Air Intake, Cooling and Exhaust Systems

Group 05: Speed Control Link

Hand Throttle Lever and Accelerator Pedal Adjustment

Speed Control Link Adjustment

Hand Throttle Lever - Exploded View

Accelerator Pedal, with Mechanical Speed Control

Accelerator Pedal Adjustment

Group 10: Fuel System

General information

Removing Fuel Tank

Installing Fuel Tank

Replacing Fuel Gauge Sensor Unit

Replacing Fuel Transfer Pump

Replacing Fuel Filter

Bleeding Fuel System

Group 15: Air Intake System

General information

Air Filter - Exploded View

Replacing Air Filter Restriction Sensor

Group 20: Cooling system

General information

Specifications

Identifying Cooling System Type

Removing Radiator - A-Type

Removing Radiator - B-Type

Installing Radiator

Replacing Fan

Removing and Installing Expansion Tank - A-Type

Removing and Installing Expansion Tank - B-Type

Removing and Installing Thermostat Valve - A-Type

Removing and Installing Thermostat Valve - B-Type

Filling Cooling System with Coolant

Replacing Engine Belt

Replacing Drive Belt Tensioner

Repairing Fan Console

Group 30: Exhaust System

General information

Exhaust Pipe

Section 40: Electrical System

Group 05: Connectors

Essential or Recommended Tools

General

Use of High-Pressure Washers

Disconnecting Electrical Circuits

Reconditioning Wire Ends

Installing a Terminal

WEATHER PACK connectors

METRI PACK connector with rear terminal lock

METRI PACK connector with Front Terminal Lock

METRIC PACK connectors

CAN BUS Terminating Resistor Connector

Electronic Control Unit Connectors

Connectors

CRIMP SNAP IN connectors

KOSTAL Connectors

DEUTSCH Connectors

Individual terminals

Fuse and Relay Box on Tractors with Open Operator's Station

Group 10: Wiring Harnesses

Disconnecting Electrical Circuits

Ground Point Locations

Removing and Installing Wiring Harness W01 — Power Supply

Removing and Installing Wiring Harness W02 — Engine Wiring Harness (Open Operator's Station)

Removing and Installing Wiring Harness W03

Removing and Installing Wiring Harness W04 — Headlights

Removing and Installing Wiring Harness W08 — Open Operator's Station

Removing and Installing Wiring Harness W09 — Hood (Open Operator's Station)

Removing and Installing Wiring Harness W28 — Front End of Transmission (Open Operator's Station)

Removing and Installing Wiring Harness W30 — Rear End of Transmission (Open Operator's Station)

Removing and Installing Harness W31 — 7-Terminal Power Outlet Socket

Group 15: Charging circuit

Essential or Recommended Tools

Specifications

Replacing Alternator

Disconnecting Electrical Circuits

Removing/Installing Alternator

Removing/Installing Alternator Pulley

Group 20: Starter Motor Circuit

Specifications

Repairing Starter Motor

Disconnecting Electrical Circuits

Removing and Installing the Starter Motor

Group 25: Fuses, Relays and Switches

Note

Essential or Recommended Tools

Specifications

Removing Hood Covers

Disconnecting Electrical Circuits

Fuse and Relay Box - Tractors with Open Operator Station

Replacing Main Fuses

Replacing Starter Motor Relay

Replacing Starter Switch

Replacing Brake Switches

Replacing Light Switch

Replacing Full/Low Beam Switch

Replacing Work Light Switches

Replacing Hazard Warning Light Switch

Replacing Turn Signal Switch

Replacing Horn Switch

Replacing Front-Wheel Drive Switch

Replacing Differential Lock Switch

Group 30: Monitoring Systems

Note

Note

Disconnecting Electrical Circuits

Replacing Engine Speed Sensor Unit (B01)

Replacing Engine Oil Pressure Sensor Unit (B04)

Replacing Coolant Temperature Gauge Sensor Unit (B08)

Group 40: Electrical Components

Note

Essential or Recommended Tools

Specifications

Disconnecting Electrical Circuits

Replacing Socket of 7-Terminal Power Outlet

Replacing Service Socket

Adjusting Headlights

Section 50: SyncroPlus Transmission

Group 00: Removing and Installing Transmission Components

Essential or Recommended Tools

Dealer-Manufactured Special Tools

Specifications

Removing Clutch Housing

Installing Clutch Housing

Removing Transmission

Installing Transmission

Group 05: Transmission selectors control

Specifications

Reconditioning Gear Shift Mechanism

Reconditioning Range Shift Lever Mechanism

Checking and Adjusting Shift Units

Adjusting the Clutch Pedal

Group 10: Perma Clutch Module II

Essential or Recommended Tools

Specifications

Removing Clutch

Repairing Clutch

Installing Clutch

Removing Transmission Oil Pump

Repairing Transmission Oil Pump

Installing Transmission Oil Pump

Valves and Other Hydraulic Components

Repairing Engagement Override Valve (EOV)

Repairing Clutch Cooling Valve

Repairing Cooling Pilot Valve

Repairing Bypass Valve

Repairing Pressure Regulating Valve

Repairing Lube Relief Valve

Repairing Cooler Relief Valve

Repairing Clutch Pedal Valve

Replacing Pressure and Temperature Sensor Units

Group 15: Gearbox

Essential or Recommended Tools

Specifications

Transmission—Cross-Sectional View

Disassembling Creeper Transmission

Repairing Transmission

Preparing to Install Transmission

Repairing Shift Cover

Adjusting Gear Shift Actuating Mechanism

Adjusting Neutral Start Switch

Group 20: Range Box — 20 Series

Specifications

Range box—Cross-Sectional View

Removing Range Box

Servicing Range Box

Installing Range Box

Servicing Shift Cover

Section 55: Drive Systems

Group 00: Removing and Installing Component

Essential or Recommended Tools

Special Tools (Dealer Fabricated)

Specifications

Removing Front-Wheel Drive Clutch

Installing Front-Wheel Drive Clutch

Removing Differential Housing

Installing Differential Housing

Removing Final Drives

Installing Final Drive

Removing PTO

Installing PTO

Group 05: U-Jointed Shafts and Torsional Damper

Essential or Recommended Tools

Using KJD10426 Special Tool

Specifications

Removing MFWD Universal-Joint Drive Shaft

Repairing MFWD Universal-Joint Drive Shaft

Installing MFWD Universal-Joint Drive Shaft

Removing Engine Universal-Joint Drive Shaft

Removing Torsional Damper

Replacing Torsional Damper Bearings

Installing Torsional Damper

Installing Engine Universal-Joint Drive Shaft

Group 10: Front-Wheel Drive Clutch

Essential or Recommended Tools

Other Material

Specifications

Disassembling Front-Wheel Drive Clutch

Front-Wheel Drive Clutch — Exploded View

Mounting Front-Wheel Drive Clutch

Group 15: Differential

Specifications

Removing Differential

Disassembly of Differential

Differential — Exploded View

Assembling the differential

Installing Differential

Group 20: Hydraulic Pump Drive

Essential or Recommended Tools

Specifications

Repairing Hydraulic Pump Drive

Adjusting Hydraulic Pump Drive

Group 25: Final Drives

Essential or Recommended Tools

Specifications

Repairing Final Drive

Group 30: PTO Options

Essential or Recommended Tools

Special Tools (Dealer Fabricated)

Other Material

Specifications

Replacing Output Shaft Retainer

Replacing O-Ring of Reversible PTO

Removing PTO Clutch

Repairing PTO Clutch

Installing PTO Clutch

Reconditioning PTO Brake

Disassembling PTO Transmission

Reconditioning Output Shaft (540/1000 RPM Reversible)

Mounting Output Shaft (540/1000 RPM)

Reconditioning Countershaft (540/1000 RPM)

Mounting PTO Transmission

Adjusting Output Shaft Cone Bearing

Adjusting Countershaft Cone Bearing

Installing Support and Adjusting Cone Bearings

Installing PTO Housing

Removing PTO Modulating Valve

Reconditioning PTO Modulating Valve

Installing PTO Modulating Valve

Repairing Solenoid Valve

Section 60: Steering and Brakes

Group 05: Hydrostatic Steering

Essential or Recommended Tools

Specifications

Preliminary Tasks

Disconnecting/Connecting Steering or Brake Hoses

Steering Valve - Removing

Disassembling Steering Valve

Exploded View of Steering Valve

Assembling the Steering Valve

Adjusting Shock Valves

Steering Valve - Installation

Group 15: Brake Valve

Essential or Recommended Tools

Specifications

Brake Valve

Group 20: Rear Brakes

Essential or Recommended Tools

Specifications

Removing the Rear Brakes

Installing Rear Brake

Checking Brake Piston Return Movement and Leaks

Final installation

Bleeding Brakes

Section 70: Hydraulic System

Group 05: Rockshaft Controls

Rockshaft Valve — Removing and Installing Control Lever

Selective Control Valves — Remove and Install Control Lever

Group 10: Removing and Installing Hydraulic Pump

Other Material

Specifications

Removing Hydraulic Pump

Hydraulic Pump - Removing Mounting Plate

Replacing Lube Priority Valve

Hydraulic Pump - Installing Mounting Plate

Installing Hydraulic Pump

Group 15: Repairing Hydraulic Pump

Repairing Hydraulic Pump

Group 20: Hydraulic Hitch Valve

Hydraulic System — General Safety and Repair Instructions

Repairing Priority Valve

Removing Rockshaft Valve

Rockshaft Valve - Removing Control Valve

Rockshaft Valve - Repairing Control Valve

Rockshaft Valve - Installing Control Valve

Rockshaft Valve — Removing and Installing Control Lever Console

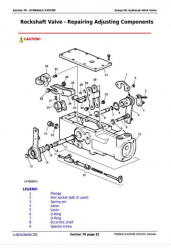

Rockshaft Valve - Repairing Adjusting Components

Installing Rockshaft Valve

Group 25: Hydraulic Cylinders and Center Link Bracket

Rockshaft — Removing Rockshaft Cylinders

Rockshaft — Repairing Rockshaft Cylinders

Rockshaft — Installing Rockshaft Cylinders

Removing Center Link Bracket

Repairing Center Link Bracket

Installing Center Link Bracket

Group 30: Hydraulic Apparatus

Essential or Recommended Tools

Other Material

Specifications

Removing Selective Control Valves

Repairing Selective Control Valves without Float Position

Repairing Selective Control Valves with Float Position

Selective Control Valves — Repairing Inlet Body

Selective Control Valves — Repairing Outlet Body

Installing Selective Control Valves

Selective Control Valves — Repairing Couplers

Quick Couplers — Service

Mounting Quick Coupler

Group 35: Hydraulic Filter

Repairing Hydraulic Oil Filter

Section 80: Others

Group 05: Removing and Installing Components — 4x2 Axle

Essential or Recommended Tools

Remove Front Axle

Installing Front Axle

Group 10: Removing and Installing Components — 4x4 Axle

Essential or Recommended Tools

Special Tools (Dealer Fabricated)

Specifications

Removing Main Chassis

Installing Main Chassis

Removing Front-Wheel Drive Axle

Installing Front-Wheel Drive Axle

Group 15: Main Chassis

Specifications

Reconditioning Main Chassis

Group 20: Front Wheels and Rear Wheels

Removing Front and Rear Wheels

Repairing Front and Rear Wheels

Installing Front and Rear Wheels

Group 25: Swinging Drawbar

Swinging Drawbar — Reconditioning (Summary of References)

Specifications

Checking Swinging Drawbar Wear

Swinging Drawbar

Adjusting Retention Rod

Section 90: Operator's Platform

Group 05: Open Operator Station

Specifications

Removing Operating Platform

Installing Operating Platform

Checking and Adjusting of Shifting Mechanisms/Links

Group 15: Roll-Over Protective Structure (ROPS)

Keep ROPS Installed Properly

Attaching Torques while Mounting Platform (with 2-Column ROPS)

Section 99: Special Tools

Group 05: Special Tools

Suspension Device

Suspension Device

Retaining Device

Retention Tool

Wooden Block

DFRW79 - Piston Retainer Tool

Socket Wrench Insert

Retainer Installer

Retainer

Assembling and Guide Drivers

Turning Tool

Bushing

Retainer Installer

Socket Wrench Insert

Special Wrench

Quick Coupler Securing Support

Lifting Tool

John Deere Tractors Models 6110E, 6125E, 6415, 6615 Repair Service Manual (TM800419)