John Deere Tractors 6100, SE6100, 6200, SE6200, 6300, SE6300, 6400, SE6400, 6506, 6600 Repair Service Manual (TM4493)

Complete Repair Service Technical Manual for John Deere Tractors 6100, SE6100, 6200, SE6200, 6300, SE6300, 6400, SE6400, 6506, 6600, with workshop information to maintain, repair, and service like professional mechanics.

John Deere 2WD or MFWD Tractors 6100, 6200, 6300, 6400, 6506, 6600, SE6100, SE6200, SE6300 workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

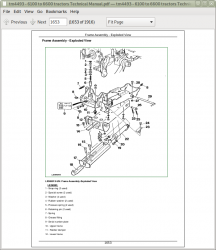

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm4493 - 6100 to 6600 tractors Technical Manual.pdf

tm4493 - 6100 to 6600 tractors Technical Manual.epub

Total Pages: 1,916 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety Measures

General Information

Specifications

Tune-Up

Predelivery Inspection

Engine

Engine Removal and Installation

Fuel, Air Intake, Cooling and Exhaust Systems

Speed Control Linkage

Fuel System

Air Intake System

Cooling System

Cold Weather Starting Aids

Exhaust System

Electrical System

Connectors

Wiring Harnesses

Charging Circuit

Starting Motor Circuit

Switches, Relays and Solenoids

Monitoring System

Auxiliary Lighting and Electrical Components

Convenience and Accessory Components

SyncroPlus™ Transmission

Removal and Installation of Transmission Components

Summary of Important Specifications

Transmission Shift Controls

PERMA-CLUTCH 2™

Gear Transmission

Creeper Transmission

Option Transmission

Range Transmission

PowrReverserPowrRever™

Removal and Installation of PowrReverser PowrRever™ Module

Transmission Shift Controls

PowrReverserPowrRever™ Module

Gear Transmission

PowrQuad™ Transmission

Removal and Installation of PowrQuad™ Module

Transmission Shift Controls

PowrQuad™ Module

Drive Systems

Component Removal and Installation

U-Jointed Shafts and Torsion Damper

Front Wheel Drive Clutch Up to Transmission Serial No. 114447

Front Wheel Drive Clutch, Transm. Serial No. 114448 to 161066

Front Wheel Drive Clutch from Transmission Serial No. 161067

Differential

Hydraulic Pump Drive

Final Drives

Rear PTO Options

Front PTO

Front Implement Drive

Steering and Brakes

Hydrostatic Steering

Steering Cylinders

Brake Valve

Rear Brakes

Handbrake

Hydraulic Trailer Brake

Air Brakes

Hydraulic System

Controls

Hydraulic Pump and Charge Pump

Hydraulic Pump on SE Tractors

Valves

Valves on SE Tractors

Rockshaft and Rockshaft Cylinder

Three-Point Hitch

Selective Control Valves and Couplers

Independent Control Valve

Miscellaneous

Component Removal and Installation

Main Frame

Front Axle

Front and Rear Wheels

Trailer Hitch

Pick-Up Hitch up to Tractor Serial No. 176448

Pick-Up Hitch From Tractor Serial No. 176449

Swinging Drawbar

Operator's Cab and 4-Post Roll Guard

Tilting, Removing and Installing the Operator's Cab

Tilting, Removing and Installing the Operator's Cab (SE Tractors)

Controls and Instruments

Electronic Hitch Control Components

Air-Conditioning System

Heating System (6100-6600)

Heating System (SE Tractors)

Operator's Cab

Seats

Radio

Special Tools (Dealer-Fabricated)

Special Tools (Dealer-Fabricated)

tm4493 - 6100 to 6600 tractors

Table of Contents

Foreword

Section 05: Safety

Group 05: Safety Measures

Recognize Safety Information

Prevent Machine Runaway

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Avoid Heating Near Pressurized Fluid Lines

Remove Paint Before Welding or Heating

Safety Information - Air Brake System

Avoid Eye Contact with Radar

Keep ROPS Installed Properly

Service Tires Safely

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Live With Safety

Service Front-Wheel Drive Tractor Safely

Section 10: General Information

Group 05: Specifications

Specifications

Diesel Engine Oil

Transmission and Hydraulic Oil

Front Wheel Drive Axle Oil

Diesel Engine Coolant

Grease

Oil Filters

Mixing of Lubricants

Alternative and Synthetic Lubricants

Lubricant Storage

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Serial Number Plates

Product Identification Number and Component Serial Numbers

Group 10: Tune-Up

Specifications

Using High-Pressure Washers

Preliminary Engine Test

Tractor Tune-Up

Checking Fuel Filter

Bleeding the Fuel System

Neutral Start Circuit

Neutral Start Circuit

Final Engine Check

Tractor Operation Check

Group 15: Predelivery Inspection

Predelivery Inspection

Section 20: Engine

Group 00: Engine Removal and Installation

Special or Essential Tools

Specifications

Removing Engine (6100 - 6400, and SE)

Installing the Engine

Bleeding Fuel System

Installing the Engine (6506 and 6600)

Installing the Engine

Replacing the Engine Mountings (6100 to 6400, and SE)

Replacing the Engine Mountings (6506 and 6600)

Front Engine Mountings

Rear Engine Mountings

Section 30: Fuel, Air Intake, Cooling and Exhaust Systems

Group 05: Speed Control Linkage

Specifications

Adjusting Throttle Hand Lever and Pedal

Adjusting Speed Control Linkage

Exploded View of Hand Throttle Lever (On Older Tractors)

Exploded View of Hand Throttle Lever (On Newer Tractors)

Exploded View of Accelerator Pedal

Exploded View of Accelerator Pedal (SE Tractors with Low Profile Cab)

Group 10: Fuel System

Special Tool (Dealer-Manufactured)

General Information

Removing Fuel Tank

Installing Fuel Tank

Replacing the Fuel Gauge Sending Unit

Replacing Fuel Transfer Pump

Bleeding the Fuel System

Changing Fuel Filter

Group 15: Air Intake System

General Information

Air Intake System - 6100 to 6400 Tractors

Air Intake System - 6506 and 6600 Tractors

Group 20: Cooling System

General Information

Specifications

Removing Radiator

Replacing Fan and Viscous Fan Drive

Installing Radiator

Relieving Drive Belt

Replacing Drive Belt

Replacing Drive Belt Tensioner

Repairing Drive Belt Tensioning Device

Aligning the Hydraulic Drive Belt Tensioner From tractor serial no. 107753 to 152341

Hydraulic Drive Belt Tensioner Up to tractor serial no. 159438 - Exploded View

Hydraulic Drive Belt Tensioner From tractor serial no. 107753 to 152341 - Exploded View

Group 25: Cold Weather Starting Aids

Fuel Preheater

Electric Starting Aid

Coolant Heater

Group 30: Exhaust System

Specifications

Installing the Muffler

Installing the Muffler Pipe

Installing the Exhaust Pipe

Replacing the Auxiliary Muffler

Replacing the Exhaust Pipe

Installing the Exhaust Pipe

Section 40: Electrical System

Group 05: Connectors

Special or Essential Tools

General Information

Disconnecting Electrical Circuit

METRI PACKMETRI PACK is a trademark of Packard Electric.. Connector

WEATHER PACKWEATHER PACK is a trademark of Packard Electric Connector

CRIMP SNAP INCRIMP SNAP IN is a trademark of the AMP Company. Connector

CPCCPC is a trademark of AMP Inc. Connector

Replace Load Center Connector

Replace Power Distribution Center Connectors

Replacing Female Terminal on 45-Pin Plug

Installing Terminal

Changing Terminals

Stripping Wire Ends

Installing Terminal

Group 10: Wiring Harnesses

Ground Point Locations

Removing and Installing Engine Wiring Harness

Removing and Installing Cab Wiring Harness (Without HMS)

Removing and Installing Cab Wiring Harness (With HMS)

Removing and Installing Cab Wiring Harness (With Electrical Reverser Control)

Removing and Installing Cab Wiring Harness (SE Tractors)

Removing and Installing 4-Post ROPS Harness

Removing and Installing Wiper and Air-Conditioning Harness

Removing and Installing Fan Wiring Harness (SE Tractors)

Removing and Installing Cab Roof Wiring Harness

Removing and Installing Cab Roof Wiring Harness (SE Tractors)

Removing and Installing Transmission Wiring Harness

Removing and Installing Transmission Wiring Harness (With Electrical Reverser Control)

Group 15: Charging Circuit

Repair Alternator-Use CTM

General

Specifications

Removing Alternator

Relieving Drive Belt

Group 20: Starting Motor Circuit

Special or Essential Tools

Specifications

Repair Starter-Use CTM

Removing the Starting Motor

Group 25: Switches, Relays and Solenoids

Disconnecting Electrical Circuit

Specifications

Replace Stop Light Switch

Removing and Installing the Thermostat Switch up to Tractor Serial No. 170 667

Removing and Installing the Thermostat Switch From Tractor Serial No. 170 668Not SE tractors

Removing and Installing the Thermostat Switch From SE Tractors

Removing and Installing the High/Low Pressure Switch

Replacing Blower Switch

Replacing Blower Switch on SE Tractors

Replacing Air Conditioning Switch

Removing HMS (Headland Management System) Switch

Remote Control of Rockshaft and PTO

Replace MFWD Switch

Differential Lock Switch

Replace PTO Switch

Replace Hitch Control Potentiometer and Switch

Replacing the Sensitivity Potentiometer

Replacing the Position Sensor

Removing the Draft Sensor

Replacing the Neutral Start Switch

Replace Main Switch

Replace Light Switch and Hazard Warning Light Switch

Replacing the Work Light Switch

Replace Switches on Multi-Function Unit (Tractors Without Electrical Reverser Control)

Replace Switches on Multi-Function Unit (Tractors With Electrical Reverser Control)

Replace Dome Light Switch

Replacing the Coil on the Solenoid Valve (Front-Wheel Drive)

Replacing the Coils on the Solenoid Valves of the Differential Lock and Rear PTO

Replacing the Coils on the Solenoids for Electrical Reverser Control

Replace Fuel Shut-Off Solenoid

Replacing the Starting Motor Relay

Main Fuses

Fuse Box (Load Center) 1 (6100-6400 Tractors Up to Serial No. 127538)

Fuse Box (Load Center) 2 (6100-6400 Tractors Up to Serial No. 127538)

Fuse Box (Load Center) 1 (6100-6400 Tractors From Serial No. 127539)

Load Center 2 (6100-6400 Tractors From Serial No. 127539)

Fuse Box (Load Center) 1 (6600 Tractors Up to Serial No. 139832)

Fuse Box (Load Center) 2 (6600 Tractors Up to Serial No. 139832)

Fuse Box (Load Center) 1 (6600 With or without HMS from serial no. 139833 and 6100-6506With performance monitor and/or HMS Tractors)

Load Center 2 (6600With or without HMS from serial no. 139833 and 6100-6506With performance monitor and/or HMS Tractors)

Group 30: Monitoring System

Special Tool (Dealer-Manufactured)

Disconnecting Electrical Circuit

Replace PTO Speed Sending Unit

Replacing Engine Oil Pressure Sending Unit

Replacing Engine Speed Sending Unit

Replacing Air Cleaner Sending Unit

Replacing Coolant Temperature Sending Unit

Replacing the Fuel Gauge Sending Unit

Replace Speed Sending Unit

Replacing Overvoltage Protection

Temperature and Pressure Sending Units

Removing Instrument Unit

Group 40: Auxiliary Lighting and Electrical Components

Replace Seven-Terminal Outlet Socket

Replace Three-Terminal Outlet Socket

Group 45: Convenience and Accessory Components

Disconnecting Electrical Circuit

Removing and Installing Fan and Radiator

Removing and Installing Fan and Radiator on SE Tractors

Replace Wiper Motor

Section 50: Transmission

Group 00: Removal and Installation of Transmission Components

Special or Essential Tools

Dealer-Manufactured Special Tools

Specifications

Removing Clutch Housing

Installing Clutch Housing

Removing Gear Transmission

Installing Gear Transmission

Removing Creeper or Option Transmissions

Installing Creeper or Option Transmissions

Removing Range Transmission Housing

Installing Range Transmission Housing

Group 01: Summary of Important Specifications

Summary of Important Specifications

Group 05: Transmission Shift Controls

Specifications

Gear Shift Linkage (Up to Tractor Serial No. 182777)

Range Shift Linkage (Up to Tractor Serial No. 182777)

Gear Shift Linkage (From Tractor Serial No. 182778)

Range Shift Linkage (From Tractor Serial No. 182778)

Adjusting Shift Linkage and Parking Lock (Up to Tractor Serial No. 182777)

Adjusting Shift Linkage and Parking Lock (From Tractor Serial No. 182778)

Clutch Pedal Adjustment (Up to Tractor Serial No. 130420)

Clutch Pedal Adjustment (From Tractor Serial No. 130421)

Group 10: PERMA-CLUTCH 2PERMA-CLUTCH 2 is a trademark of Deere & Company.

Special or Essential Tools

Specifications

Preliminary Work

Removing Clutch

Removing the Transmission Oil Pump

Transmission Oil Pump Components

Assembling the Transmission Oil Pump

Installing the Transmission Oil Pump

Disassembling Clutch

Exploded View of Clutch

Assembling Clutch

Installing the Clutch

Final Assembly

Valves

Engagement Override Valve

Clutch Cooling Valve

Clutch Cooling Pilot Valve

Filter Relief Valve

Pressure Regulating Valve

Lube Relief Valve

Cooler Relief Valve

Removing Clutch Pedal Valve

Installing Clutch Pedal Valve

Solenoid ValveUp to component serial no. 102256

Clutch Cooling Sending Unit Up to component serial no. 102256

Temperature and Pressure Sending Units

Test Ports

Group 15: Gear Transmission

Special or Essential Tools

Specifications

Preliminary Work

Disassembling Gear Shift Transmission

Assembling Drive Shaft

Installing Shafts

Final Assembly

Measuring the Gaps at the Connecting Ring

Installing Transmission Housing

Adjusting Shifting Mechanism

Adjusting Neutral Start Switch

Checking Neutral Start Switch

Group 20: Creeper Transmission

Specifications

Creeper Transmission

Preliminary Work

Disassembling Creeper Transmission

Assembling Creeper Transmission

Shift Linkage - Sectional View

Installing the Shift Linkage

Repairing the Shift Cover

Final Assembly

Group 25: Option Transmission

Specifications

Option Transmission

Preliminary Work

Disassembling Option Transmission

Assembling Countershaft

Installing Shafts

Final Assembly

Adjusting Shifter Fork

Group 30: Range Transmission

Specifications

Range Transmission-Sectional Views

Preliminary Work

Disassembling Range Transmission

Exploded View of Differential Drive Shaft

Exploded View of Countershaft and Parking Lock

Exploded View of Shift Mechanism

Repairing the Shift Cover

Assembling Range Transmission

Cone Point Adjustment

Adjusting Shift Mechanism

Final Assembly

Section 51:

Group 00: Removal and Installation of PowrReverser PowrReverser is a trademark of Deere & Company. Module

Special or Essential Tools

Dealer-Manufactured Special Tools

Specifications

Removing the PowrReverser PowrReverser is a trademark of Deere & Company. Module

Installing the PowrReverser PowrReverser is a trademark of Deere & Company. Module

Removing and Installing the Gear Transmission

Group 05: Transmission Shift Controls

Specifications

Forward/Reverse Linkage

Range Shift Linkage

Gear Shift Linkage

Adjusting the Reverse Drive Linkage

Adjusting the Shift Linkage and Parking Lock

Clutch Pedal Adjustment

Group 10: PowrReverserPowrReverser is a trademark of Deere & Company. Module

Special or Essential Tools

Specifications

PowrReverserPowrReverser is a trademark of Deere & Company. Module - Sectional View

Components of Power Train

Preliminary Work

Repair Instructions

Removing the Disk Brake

Removing the Clutch and Planet Carrier

Removing the Transmission Oil Pump

Disassembling the Transmission Oil Pump

Exploded View of Transmission Oil Pump

Assembling the Transmission Oil Pump

Installing the Transmission Oil Pump

Disassembling the Clutch and Planet Carrier

Exploded View of Clutch and Planet Carrier

Assembling the Clutch and Planet Carrier

Installing the Clutch and Planet Carrier

Exploded View of Disk Brake

Repairing and Installing the Disk Brake

Final Assembly

Valves and Other Hydraulic Components

Repair Instructions

Replacing the Oil Filter

Repairing the Pressure Regulating Valve

Repairing the Cooling Pilot Valve

Repairing the Clutch Cooling Valve

Repairing the Engagement Override Valve

Repairing the Filter Relief Valve

Repairing the Cooler Relief Valve

Repairing the Lube Relief Valve

Repairing the Sump Valve

Repairing the Accumulator Piston

Repairing the Forward/Reverse Valve

Repairing the Fwd/Rev Cooling Control Valve

Repairing the Modulator Valve

Repairing the Connecting Valve

Repairing the Clutch Pedal Valve

Repairing the Temperature and Pressure Sending Units

Replacing the Neutral Start Switch

Test Ports

Group 15: Gear Transmission

Special Tool (Dealer-Manufactured)

Specifications

Preliminary Work

30 km/h (18.5 mph) Gear Transmission

40 km/h (25 mph) Gear Transmission

Disassembling the Gear Transmission

Assembling the Drive Shaft

Installing Shafts

Final Assembly

Measuring the Gaps at the Connecting Ring

Installing Transmission Housing

Adjusting the Shift Mechanism

Section 55: Transmission

Group 00: Removal and Installation of PowrQuad PowrQuad is a trademark of Deere & Company. Module

Special or Essential Tools

Dealer-Manufactured Special Tools

Special Tool (Dealer-Fabricated)

Specifications

Removing the PowrQuad PowrQuad is a trademark of Deere & Company. Module

Installing the PowrQuad PowrQuad is a trademark of Deere & Company. Module

Group 05: Transmission Shift Controls

Specifications

Gear Shift Linkage (Reverser Control on Switch Console) Up to Tractor Serial No. 182335 (4-Cyl.) or 184326 (6-Cyl.)

Range Shift Linkage (Reverser Control on Switch Console) Up to Tractor Serial No. 182335 (4-Cyl.) or 184326 (6-Cyl.)

Gear Shift Linkage (Reverser Control on Switch Console) From Tractor Serial No. 182336 (4-Cyl.) or 184327 (6-Cyl.)

Range Shift Linkage (Reverser Control on Switch Console) From Tractor Serial No. 182336 (4-Cyl.) or 184327 (6-Cyl.)

Gear Shift Linkage (Reverser Control on Steering Column)

Range Shift Linkage (Reverser Control on Steering Column)

Adjusting the Reverse Drive Linkage

Adjusting Shift Linkage and Parking Lock - Reverser Control on Switch Console

Adjusting the Shift Linkage and Parking Lock - Reverser Control on Switch Console

Adjusting the Shift Linkage and Parking Lock - Reverser Control on Steering Column

Clutch Pedal Adjustment (Up to Tractor Serial No. 130420)

Clutch Pedal Adjustment (From Tractor Serial No. 130421)

Group 10: PowrQuadPowrQuad is a trademark of Deere & Company. Module

Special or Essential Tools

Service Equipment and Tools

Other Material

Specifications

Transmission Components

Install Transmission in Repair Stand

Remove Transmission Front Cover/Front Valve Housing

Remove Front Valve Housing

Valves in Front Valve Housing

Valves in the Front Transmission Cover

Removing the Clutch Pedal Valve

Installing the Clutch Pedal Valve

Transmission Pump-Cross-Sectional View

Repair Transmission Pump

Install Front Valve Housing

Installing the Front Valve Housing

Install Transmission Front Cover/Front Valve Housing

Remove Shift Control Valve Housing

Replace Forward-Reverse/Speed Selector Shifter Levers/Shaft Seals

Replace Forward-Reverse/Speed Selector Shifter Shafts/Shifter Arms

Valves in Shift Valve Housing (Older Tractor Series)

Modulator Valve - Cross-Sectional View

Planetary Housing Valves

Forward/Reverse Control Valve - Cross-Sectional View (Older Tractor Series)

Forward/Reverse Control Valve - Cross-Sectional View (Newer Tractor Series)

Forward/Reverse Control Valve - Cross-Sectional View (Electrical Reverser Control)

Speed Valve - Cross-Sectional View (Older Tractor Series)

Speed Valve - Cross-Sectional View (Newer Tractor Series)

Assembling and Installing the Shift Valve Housing (Older Tractor Series)

Assembling and Installing the Shift Valve Housing (Newer Tractor Series)

Disassemble Planetary/Reverse Brake Housing Assembly

Recondition Input Planetary Carrier

Input Planetary Assembly-Cross-Sectional View

Disassemble Reverse Brake Housing Components

Reverser Carrier/Vehicle Clutch Assembly - Cross-Section

Recondition Reverser Carrier/Traction Clutch Assembly

Disassemble Planetary Housing Components

Direct Drive Clutch Assembly-Cross-Sectional View

Recondition Direct Drive Clutch Assembly

Assemble Planetary Housing Components

Assemble Reverse Brake Housing Components

Assemble Planetary/Reverse Brake Housing Assembly

Section 56: Drive Systems

Group 00: Component Removal and Installation

Special or Essential Tools

Dealer-Fabricated Tool

Specifications

Removing Front Wheel Drive Clutch

Installing Front Wheel Drive Clutch

Removing Differential Housing

Installing Differential Housing

Removing Final Drives

Installing the Final Drives

Removing Rear PTO

Installing PTO Housing

Removing Front PTO

Installing the Front PTO

Group 05: U-Jointed Shafts and Torsion Damper

Specifications

Removing U.J. Shaft (FWD)

Installing U.J. Shaft (FWD)

Removing U.J. Shaft (Engine)

Removing the Torsion Damper

Installing the Torsion Damper

Installing the U.J. Shaft (Engine)

Disassemble Universal Jointed Drive Shaft

Assembling Jointed Shaft

Group 10A: Front Wheel Drive Clutch Up to Transmission Serial No. 114447

Special Tool (Dealer-Manufactured)

Specifications

Preliminary Work

Disassembling Front Wheel Drive Clutch

Assembling Front Wheel Drive Clutch

Final Assembly

Group 10B: Front Wheel Drive Clutch, Transm. Serial No. 114448 to 161066

Special Tool (Dealer-Fabricated)

Specifications

Preliminary Work

Disassembling Front Wheel Drive Clutch

Assembling Front Wheel Drive Clutch

Final Assembly

Group 10C: Front Wheel Drive Clutch from Transmission Serial No. 161067

Special Tool (Dealer-Manufactured)

Specifications

Preliminary Work

Disassembling Front Wheel Drive Clutch

Assembling Front Wheel Drive Clutch

Final Assembly

Group 15: Differential

Specifications

Preliminary Work

Removing Differential

Disassembling Differential Housing

Assembling the Differential

Installing Differential

Adjusting Taper Roller Bearing

Adjusting Backlash

Final Assembly

Group 20: Hydraulic Pump Drive

Special or Essential Tools

Specifications

Pump Drive Specifications

Removing Pump Drive

Pump Drive - Sectional View

Installing Pump Drive

Final Assembly

Adjusting the Pump Drive

Group 25: Final Drives

Special or Essential Tools

Specifications

Preliminary Work

Disassembling Final Drives

Assembling Final Drives

Adjusting Rear Axle Rolling Drag Torque

Final Assembly

Group 30: Rear PTO Options

Special or Essential Tools

Special Tools (Dealer Fabricated)

Specifications

Replacing Output Shaft Seal Ring

Changing the O-Ring on Reversible PTO

Removing PTO Housing

PTO (540 1/min) - Sectional View

PTO (540/1000 rpm Reversible) - Cross-Sectional View

PTO (540/1000 rpm Shiftable and 540/540E/1000 rpm)

Removing PTO Clutch

Repairing the PTO Clutch

Adjusting Play at Hub

Installing PTO Clutch

Replacing PTO Brake

Output Shaft (540 1/min) - Sectional View

Output Shaft and Countershaft (540/1000 rpm Reversible) - Cross-Sectional View

Output Shaft and Countershaft (540/1000 rpm Shiftable and 540/540E/1000 rpm)

Disassembling PTO Drive Train

Repairing the Output Shaft

Output Shaft (540/1000 rpm Reversible)

Repairing the Output Shaft

Output Shaft (540/1000 rpm Shiftable, 540/540E/1000 rpm)

Countershaft (540/1000 and 540/540E/1000 rpm)

Assembling the PTO Shifter (540/1000 rpm Shiftable and 540/540E/1000 rpm)

Assembling PTO Drive Train

Adjusting Taper Roller Bearing at Output Shaft

Adjusting Taper Roller Bearings at Output Shaft

Adjusting Taper Roller Bearing of Countershaft

Adjusting Taper Roller Bearings

Installing PTO Housing

Removing the PTO Modulating Valve

Repairing the PTO Modulating Valve

Installing the PTO Modulating Valve

Repairing the Solenoid Valve

Replacing PTO Speed Sending Unit If equipped

PTO Shifting Parts

Changing and Adjusting the Bowden Cable

Adjusting the Indicator Light Switch

Group 35: Front PTO

Special or Essential Tools

Specifications

Front PTO (Running Clockwise)

Front PTO (Running Counterclockwise)

Front PTO - Sectional View

Removing Front PTO Shaft

Disassembling Front PTO Shaft

PTO (Clockwise Running) - Exploded View

PTO (Counterclockwise Running) - Exploded View

PTO Clutch and Brake - Clockwise Running PTO

PTO Clutch and Brake - Counterclockwise Running PTO

Front PTO Housing

Assembling Front PTO

Determining Preload of Input Shaft and PTO Shaft Taper Roller Bearings

Installing Front PTO Shaft

Repairing Solenoid Valve

Oil Lines

Group 40: Front Implement Drive

Special or Essential Tools

Specifications

Front Implement Drive - Exploded View

Changing the Driver

Replacing the Damper

Section 60: Steering and Brakes

Group 05: Hydrostatic Steering

Special or Essential Tools

Specifications

Preliminary Work

Removing the Steering Valve (Without Steering Column)

Removing Steering Column and Steering Valve

Steering Valve- Exploded View

Repairing Steering Valve

Disassembling the Steering Valve

Exploded View of Steering Valve

Assembling the Steering Valve

Adjusting Double-Acting Shock Valves

Steering Wheel and Steering Column (6100 to 6600 Tractors With Cab)

Steering Wheel and Steering Column (SE Tractors and Tractors Without Cab)

Repairing the Steering Column

Installing Steering Valve (Without Steering Column)

Installing Steering Column and Steering Valve

Group 10: Steering Cylinders

General Information

Special or Essential Tools

Special Tools

Specifications

Removing Steering Cylinder

Disassembling Steering Cylinder

Assembling Steering Cylinder

Installing Steering Cylinder

Group 15: Brake Valve

Special or Essential Tools

Specifications

Checking Brake Piston Travel

Preliminary Work

Removing the Control Valve

Checking Valve Seat

Peening the Valve Seat

Measuring Thickness of Shim

Bleeding the Brake Valve

Checking Opening Pressure of Control Valve

Adjusting the Stop Light Switch

Final Assembly

Repair Kit AL70575

Removing Brake Valve

Brake Valve - Sectional View

Disassembling Brake Valve

Assembling the Brake Valve

Installing Brake Valve

Adjusting Brake Pedals

Bleeding the Brakes

Adjusting the Stop Light Switch

Final Assembly

Group 20: Rear Brakes

Special or Essential Tools

Specifications

Removing Rear Brakes

Installing Rear Brake

Checking Brake Pistons for Return Movement and Leakage

Final Assembly

Bleeding the Brakes

Group 25: Handbrake

Specifications

Preliminary Work

Removing the Handbrake

Installing Handbrake

Final Assembly

Handbrake Components

Replacing the Handbrake Cable

Handbrake Test

Adjusting Handbrake

Group 30: Hydraulic Trailer Brake

Special or Essential Tools

Specifications

Repair Information

Replacing Trailer Brake Valve

Cleaning Trailer Brake Valve

Cleaning the Screen

Replacing the Check Valve

Bleeding the Trailer Brake Valve

Checking Trailer Brake Valve

Group 35: Air Brakes

Special or Essential Tools

Specifications

General Information

Installing the Screw Unions

Changing the Compressor

Gaskets for the Compressor

Changing the Compressed Air Tank

Changing the Pressure Control Valve

Changing the Pressure Control Valve

Changing the Pressure-Limiting Valve

Changing the Trailer Control Valve

Changing the Pressure Gauge

Changing the Coupling Ends

Test Sequence

Leak Test

Checking the Handbrake (Dual-Line Brakes)

Checking the Handbrake (Single-Line Brakes)

Adjusting the Handbrake

Checking the “Supply” Coupling End

Section 70: Hydraulic System

Group 05: Controls

General Information

Specifications

Replacing the Bowden Cable

Connecting the Bowden Cable

Adjusting the Bowden Cable

Installing the Multi-Function Lever

Adjusting Multi-Function Lever

Group 10: Hydraulic Pump and Charge Pump

Service Equipment and Tools

Other Material

Specifications

Repair Instructions

Removing the Charge Pump

Disassembling Charge Pump

Assembling Charge Pump

Installing the Charge Pump

Checking the Lube Oil Valve

Restrictor in Oil Tank

Check Valve in Oil Leak-Off Line

Changing the Hydraulic Pump Controller

Hydraulic Pump Controller-Exploded View

Disassemble, Inspect, and Assemble Hydraulic Controller

Adjusting the Controller

Removing the Hydraulic Pump

Installing Hydraulic Pump

Hydraulic Pump 40 cm3 (2.4 cu.in) - Exploded View

Hydraulic Pump 25 cm3 (1.5 cu.in) - Exploded View

Disassemble, Inspect and Assemble Hydraulic Pump

Adjust Swashplate Bearing Preload

Adjust Shaft Bearing Preload 40 cm3 (2.4 cu.in) Pump

Group 11: Hydraulic Pump on SE Tractors

Specifications

Repair Instructions

Removing the Hydraulic Pump

Exploded View

Repairing the Hydraulic Pump

Removing the Installation Plate

Changing the Lube Valve

Installing the Installation Plate

Installing the Hydraulic Pump

Group 15: Valves

Special or Essential Tools

Special Tools (Dealer Fabricated)

Specifications

Repair Instructions

Direct Control of Rockshaft

Removing the Rockshaft Valve

Repairing Rockshaft Valve

Depth to Which Pressure and Discharge Valves are Screwed In

Changing the Stepper Motor

Centering the Stepper Motor

Installing Rockshaft Valve

Installing the Shuttle Valves

Shuttle Valve with Hydraulic Trailer Brake

Shuttle Valve with Independent Control Valve

Removing the Main Block

Repairing the Main Block - Exploded View

Checking the Check Valve If equipped

Installing the Main Block

Checking Oil Filter Head

Filter Relief Valve

Power Beyond Application Valve - Exploded View (New Version)

Power Beyond Application Valve - Exploded View (Old Version)

Connecting the Power Beyond Application Valve

Adjusting the Power Beyond Application Valve

Converting the Power Beyond Application Valve

Connecting the Power Beyond Application Valve

Adjusting the Power Beyond Application Valve

Group 16: Valves on SE Tractors

Note

Specifications

Repair Instructions

Installing Shuttle Valves on SE Tractors

Shuttle Valve with Hydraulic Trailer Brake

Removing the Main Block

Repairing the Main Block - Exploded View

Checking the By-Pass Valve

Checking the Priority Inlet Valve

Changing the Pressure Limiting Valve For steering pressure

Changing the Pressure Relief Valve For system (engagement) pressure

Installing the Main Block

Checking the Filter By-Pass Valve and Oil Filter Head

Changing the Lube Valve

Group 20: Rockshaft and Rockshaft Cylinder

Specifications

Electronic Hitch Control Unit (HCU)

Removing Position Sensor and Toothed Segment

Attaching the Toothed Segment

Assembling the Position Sensor

Installing the Position Sensor

Removing Rockshaft

Assembling Rockshaft

Removing Rockshaft Cylinders

Repairing Rockshaft Cylinder

Changing the Rockshaft Cylinder Gasket

Assembling Rockshaft Cylinder

Installing Rockshaft Cylinder

Group 25: Three-Point Hitch

Special or Essential Tools

Self-Manufactured Special Tools

Specifications

Removing Draft-Sensing Pins or Draft Link Bearing Pins

Assembling Draft-Sensing Pins

Installing the Draft-Sensing Pin

Checking and Adjusting the Draft Sensor

Automatic Stabilizer Rod (Left-Hand)

Adjustable Stabilizer Rod (Left-Hand)

Adjustable Stabilizer Rod (Right-Hand)

Group 30: Selective Control Valves and Couplers

Special Tools (Dealer Fabricated)

Other Material

Specifications

Repair Instructions

SCV Identification

Removing Selective Control Valves

Series 100/101 Selective Control Valve - Exploded View

Repairing the Selective Control Valve - 100/101 Series

Series 200/201 Selective Control Valve-Exploded View

Series 300/301 Selective Control Valve-Exploded View

Replace Control Knobs

Inspect Poppet Load-Check Valves

Inspect Pressure Compensator Valve-300/301 Series

Inspect Metering Valve-300/301 Series

Inspect Metering Valve-200/201 Series

Repairing the Control Valve-300/301 Series

Repairing the Control Valve-200/201 Series

Installing Selective Control Valves

Installing the Shuttle Valves

Installing Shuttle Valves on SE Tractors

Installing the Left-Hand Endplate

Installing the Right-Hand Endplate

Adjustment of Pressure Limit at Selective Control Valves (300 Series)

Changing Couplers

Deluxe Coupler - Exploded View

Repairing the Deluxe Coupler

Checking Couplers for Leaks

Group 35: Independent Control Valve

Specifications

Repair Instructions

Removing the Independent Control Valve

Repairing the Independent Control Valve

Changing the Pressure-Limiting Valve

Assembling the Independent Control Valve

Installing the Independent Control Valve

Section 80: Miscellaneous

Group 00: Component Removal and Installation

Special or Essential Tools

Dealer-Manufactured Special Tools

Dealer-Fabricated Tool

Specifications

Removing the Main Frame, 6100-6400 Tractors, and SE Tractors

Installing Main Frame

Removing Main Frame, 6506 and 6600 Tractors

Installing the Main Frame

Removing Front Axle

Installing Front Axle

Removing Front Wheel Drive Axle

Installing Front Wheel Drive Axle

Removing Front Axle Support (6506 and 6600 Tractors)

Installing Front Axle Support

Group 05: Main Frame

Specifications

Removing and Installing the Main Frame

Group 10: Front Axle

General Information

Specifications

Removing Front Axle

Dissassembling Front Axle

Assembling Front Axle

Adjusting Knuckle and Spindle Assembly Axial Play

Assembling Wheel Hub

Adjusting Wheel Bearings

Assembling Axle Center Section

Installing Front Axle

Installing Tie-Rod

Checking Front Wheel Toe-In

Adjusting Front Wheel Toe-In

Group 15: Front and Rear Wheels

Special or Essential Tools

Specifications

Removing a Wheel (Front or Rear)

Assembling Rear Wheel (With Rack-and-Pinion Axle)

Attaching Cast Rim

Attaching Front Wheel

Attaching Rear Wheel

Group 20: Trailer Hitch

Specifications

Installing Rigid Trailer Mounting

Installing Guide Rails

Trailer Mounting (Height-Adjustable, 4-Position)

Trailer Mounting (Height-Adjustable, 9-Position)

Repairing the Automatic Trailer Hitch

Remote Control for Automatic Trailer Hitch

Adjusting the Remote Control

Functional Check

Group 25A: Pick-Up Hitch up to Tractor Serial No. 176448

Specifications

Installing Upper Frame

Frame Assembly - Exploded View

Operating Lever and Lift Links - Exploded View

Hydraulic Parts

Repairing Hydraulic Cylinder

Adjusting Lift Links

Adjusting Guide Stop

Changing the Bowden Cable

Adjusting the Bowden Cable

Operational Check

Group 25B: Pick-Up Hitch From Tractor Serial No. 176449

Specifications

Installing Upper Frame

Frame Assembly - Exploded View

Operating Lever and Lift Links - Exploded View

Hydraulic Parts

Repairing the Retainer Spring

Repairing the Latch Housing

Repairing Hydraulic Cylinder

Adjusting the Lift Links

Adjusting the Guide Stop

Operational Check

Group 30: Swinging Drawbar

Torques for Hardware - Swinging Drawbar

Torques for Hardware - Swinging Drawbar With Pick-Up Trailer Hitch

Adjusting the Retaining Strap

Section 90: Operator's Cab and 4-Post Roll Guard

Group 00: Tilting, Removing and Installing the Operator's Cab

Special or Essential Tools

Dealer-Manufactured Special Tools

Specifications

4-Post Roll Guard

Tilting the Cab Upward

Tilting the Operator's Cab Downward

Clutch Pedal Adjustment (Up to Tractor Serial No. 130420)

Clutch Pedal Adjustment (From Tractor Serial No. 130421)

Removing the Operator's Cab

Installing Operator's Cab

Group 01: Tilting, Removing and Installing the Operator's Cab (SE Tractors)

Special or Essential Tools

Dealer-Manufactured Special Tools

Specifications

Tilting Flat-Floor Cabs on SE Tractors

Tipping Up Low Profile Cabs on SE Tractors

Tilting the Cab Up

Tilting the Operator's Cab Downward

Clutch Pedal Adjustment (From Tractor Serial No. 130421)

Removing the Operator's Cab from SE Tractors

Installing the Operator's Cab on SE Tractors

Group 05: Controls and Instruments

Disconnecting Electrical Circuit

Removing the Control Panel

Replacing a Bulb on the Control Panel

Replacing Bulbs on the Instrument Unit

Replacing Basic Control Module (BCU)

Replacing Reverser Control Unit (RCU) Not SE tractors

Adjusting the Instrument Unit

Adjusting Digital Control

Group 10: Electronic Hitch Control Components

Disconnecting Electrical Circuit

Replacing the Hitch Control Unit (HCU)

Replacing the Operation Unit

Group 15: Air-Conditioning System

Special or Essential Tools

Specifications

Torques for Tightening Refrigerant Hoses

Safety at Work

Handling Refrigerant

In an Emergency

Safety Equipment

Storage of Refrigerant Containers

R134a Refrigerant

Important

Discharging the System On SE tractors, the high/low pressure switch is located at the rear of the operator's cab. The procedure for “Discharging The System” is nonetheless the same.

Evacuating the System On SE tractors, the high/low pressure switch is located at the rear of the operator's cab. The procedure for “Evacuating The System” is nonetheless the same.

Filling with Refrigerant Oil On SE tractors, the high/low pressure switch is located at the rear of the operator's cab. The procedure for “Filling With Refrigerant Oil” is nonetheless the same.

Filling the System On SE tractors, the high/low pressure switch is located at the rear of the operator's cab. The procedure for “Filling The System” is nonetheless the same.

Topping up a Partly Discharged System On SE tractors, the high/low pressure switch is located at the rear of the operator's cab. The procedure for “Topping Up A Partly Discharged System” is nonetheless the same.

Leak Test

Removing the Compressor

Checking Level in the Compressor

Disassembling the Compressor Clutch

Checking Clutch Hub Clearance

Checking the Compressor Manifold

Installing the Compressor

Removing and Installing the Condenser

Removing and Installing the Receiver-Drier

Removing and Installing the Evaporator and Expansion ValveNot SE tractors

Replacing the Expansion Valve

Removing and Installing the Evaporator and Expansion Valve on SE Tractors

Installing Condensation Water Drain Hoses Not SE tractors

Arrangement of Condensation Water Drain Hoses on SE Tractors

Removing the Heater/Evaporator Housing from SE Tractors

Removing and Installing the Thermostat Switch Up to Tractor Serial No. 170667

Removing and Installing the Thermostat Switch From Tractor Serial No. 170668Not SE tractors

Adjusting Thermostat Switch Bowden Cables Not SE tractors

Removing and Installing the Thermostat Switch From SE Tractors

Removing and Installing the High/Low Pressure Switch

Group 20: Heating System (6100-6600)

Ventilator and Heater, Exploded View

Removing and Installing Fan and Radiator

Removing and Installing Heater Valve Up to Serial No. 171080

Removing and Installing Heater Valve From Serial No. 171081

Adjusting Bowden Cables of Heater Valve

Removing the Cab Air Filter

Group 21: Heating System (SE Tractors)

Ventilator and Heater, Exploded View

Removing the Cab Air Filter

Removing and Installing Fan and Radiator

Removing and Installing the Heater Valve

Removing the Heater/Evaporator Housing

Group 25: Operator's Cab

Specifications

Removing Cab Frame

Removing and Installing the Cab Bearings (6100-6400 and SE Tractors)

Removing and Installing the Cab Bearings (6506-6600)

Installing Windshield

Installing Rear Window

Adjusting Window Contact Pressure

Removing Cab Door

Installing Cab Door

Installing Door Lock

Installing Door Holding Bracket

Replacing Handrail or Rear View Mirror

Removing Hatch

Removing Outer Roof

Removing the Inner Section of the Roof

Removing Inner Roof Trim

Group 30: Seats

Specifications

Comfort Seat DS44-07, Exploded View

Comfort Seat DS44-06, Exploded View

Super Comfort Seat S85/90-05, Exploded View - Upper Section

Super Comfort Seat DS85H1-02, Exploded View - Lower Section

Air Comfort Seat MSG95A-00, Lower Section

Passenger Seat, Exploded View

Group 35: Radio

Radio, Loudspeakers and Aerial, Exploded View

Section 99: Special Tools (Dealer-Fabricated)

Group 05: Special Tools (Dealer-Fabricated)

Lifting Device

Lifting Device

Holding Tool

Wooden Prism

Driver

Assembly and Guide Mandrels

Turning Device

Suspension Eyes for Operator's Cab

Holding Device

Bushing

Spring Compressor

Bushing

Socket Wrench Insert

Special Key

DFRW79-Piston Holding Tool

John Deere Tractors 6100, SE6100, 6200, SE6200, 6300, SE6300, 6400, SE6400, 6506, 6600 Repair Service Manual (TM4493)