John Deere Tractors 6010, SE6010, 6110, SE6110, 6210, 6310, 6410, SE6410, 6510, SE6510, 6610, SE6610, 6810, 6910, 6910S Diagnosis and Tests Service Technical Manual

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere Tractors 6010, SE6010, 6110, SE6110, 6210, 6310, 6410, SE6410, 6510, SE6510, 6610, SE6610, 6810, 6910, 6910S, with workshop information to maintain, test, repair, and service like professional mechanics.

John Deere 2WD or MFWD Tractors 6010, 6110, 6210, 6310, 6410, 6510, 6610, 6810, 6910, 6910S and SE workshop Diagnosis Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm4552 - 6010, 6110, 6210, 6310, 6410, 6510, 6610, 6810, 6910, 6910s and se tractors Technical Manual.pdf

tm4552 - 6010, 6110, 6210, 6310, 6410, 6510, 6610, 6810, 6910, 6910s and se tractors Technical Manual.epub

Total Pages: 5,148 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety

Service Code Diagnostics

BCU Service Code Diagnostics

BIF Service Code Diagnostics

ECU (Level 1 with LUCAS injection pump) Service Code Diagnostics

ECU (Level 4 with BOSCH VP44 injection pump) Service Code Diagnostics

HCU Service Code Diagnostics

PCU Service Code Diagnostics

PEC Service Code Diagnostics

PLC Service Code Diagnostics

RCU Service Code Diagnostics

SFA Service Code Diagnostics

TCU Service Code Diagnostics

UIC Service Code Diagnostics

Observable Symptoms

Electrical System

PowrQuad, PowrQuad Plus and AutoQuad Transmissions

Drive System (except transmission)

Steering and Brakes

Hydraulic System

Engine

Tests

Fuel, Air Intake and Cooling Systems

System Diagnosis

Tests and Adjustments

Fuel System

Air Intake System

Cooling System

Cold-Weather Starting Aids

Electrical System

General

Functional Schematics and Wiring Diagrams (6010-6910S)

Functional Schematics and Wiring Diagrams (SE Tractors)

Functional Schematics and Wiring Diagrams (2-Post ROPS)

Functional Schematics and Wiring Diagrams (AutoPowr)

Circuit Testing (6010-6910S with Cab)

Sub-System Diagnostics (SE Tractors)

Sub-System Diagnostics (2-Post ROPS)

Circuit Testing (AutoPowr Transmission)

Data BUS Systems

Data BUS Systems –– Diagnosis

Adjustments

Component Testing

Electronic Control Units

Operation and General Information on Diagnostics

BCU References

BIF References

ECU (Level 1) References

HCU References

PCU References

PEC References

PLC References

RCU References

SFA References

TCU References

UIC References

SyncroPlus Transmission

Operational Checkout

Troubleshooting

Tests and Adjustments

SyncroPlus Transmission Operation

Perma Clutch II

Gear Transmission

Creeper Transmission

Range Transmission

Power Reverser Transmission

Operational Checkout

Troubleshooting

Test and Adjustments

Power Reverser Operation

Power Reverser Module

Gear Transmission

Power Shift Transmission

Operational Checkout

Troubleshooting

Adjustments

Theory of Operation

AutoPowr Transmission

Diagnosis - UIC

Diagnosis - TCU

Diagnosis - PLC

Tests and Adjustments

Operation

PowrQuad, PowrQuad Plus and AutoQuad II Transmissions

Operational Checkout

POWRQUAD™Transmission Check

Troubleshooting on PowrQuad Plus and AutoQuad II

Tests and Adjustments

PowrQuad Transmission Operation

PowrQuad Plus and AutoQuad II Transmission Operation

Creeper Transmission

Range Transmission

Drive Systems

Operational Checkout

Troubleshooting

Tests

Front-Wheel Drive Clutch

Differential

Final Drives

Rear PTO Options

Front PTO

Steering and Brakes

Operational Checkout

Troubleshooting

Tests and Adjustments

Hydrostatic Steering

Hydraulic Brakes

Handbrake

Hydraulic Trailer Brake

Air Brake System

Hydraulic System

Operational Checkout

PFC Hydraulic System Troubleshooting

PC Hydraulic System Troubleshooting

Tests and Adjustments

PFC Hydraulic System

Charge Oil Pump

Hydraulic Pumps

Valves, Oil Cooler and Filter

Rockshaft

Selective Control Valves and Couplers

Independent Control Valve (ICV)

PC Hydraulic System and Components

Miscellaneous

TLS Front Axle Operational Checkout

TLS Front Axle Troubleshooting

TLS Front Axle Tests and Adjustments

TLS Front Axle Operation

Operators Cab

Operational Checkout

Air Conditioner Troubleshooting

Ventilation and Heater Troubleshooting

Operator's Seat Troubleshooting

Air Conditioner Operation

Ventilation and Heating Operation

Special Tools (Dealer-Fabricated)

tm4552 - 6010, 6110, 6210, 6310, 6410, 6510, 6610, 6810, 6910, 6910s and se tractors

Table of Contents

Foreword

Section 210: Safety

Group 05: Safety

Recognize Safety Information

“Important” - Information

“Note” - Information

Prevent Machine Runaway

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Service Cooling System Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Support Machine Properly

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Safety Information - Air Brake System

Avoid Eye Contact with Radar

Keep ROPS Installed Properly

Replace Safety Signs

Dispose of Waste Properly

Live With Safety

Section 211: Service Code Diagnostics

Group BCU: BCU Service Code Diagnostics

BCU 045-System Voltage Too Low (Idle over 512 rpm)

BCU 046-System Voltage Too Low (idle over 1500 rpm)

BCU 047-System Voltage Too High (Engine Running)

BCU 055-Handbrake Failure

BCU 072-Rear PTO Circuit / Switch Error

BCU 073-Defective Rear PTO Solenoid

BCU 075-Rear PTO Speed Not Present After PTO ON

BCU 080-Differential Lock Still Activated After deactivation

BCU 081-Defective Differential Lock Solenoid

BCU 085-MFWD Control Switch Error

BCU 086-Faulty MFWD Solenoid

BCU 106-Internal BCU Fault

BCU 130-Turn Signal Switch Fault

BCU 131-Turn Signal Circuit Fault

BCU 132-Defective Hazard Warning Light Power Supply Fuse F102 (20A)

BCU 133-PTO Remote Failure

BCU 134-HMS Circuit Fault

Group BIF: BIF Service Code Diagnostics

BIF 001-Fuel Level Sensor Circuit

BIF 002-Fuel Level Sensor Circuit

BIF 003-Fuel Level Sensor Circuit

BIF 010-Engine Coolant Temperature High

BIF 011-Engine Coolant Temperature Very High

BIF 012-Coolant Temperature Sensor-Circuit Open

BIF 013-Coolant Temperature Sensor-Circuit Shorted

BIF 015-Transmission Oil Temperature High

BIF 016-Transmission Oil Temperature Very High

BIF 017-Transmission Oil Temperature Sensor-Circuit Open

BIF 018-Transmission Oil Temperature Sensor-Circuit Shorted

BIF 021-Engine Oil Pressure Low (Pressure Switch)

BIF 023-Missing Engine Speed Signal

BIF 026-Transmission Oil Pressure Low

BIF 030-Engine Air Filter Restricted

BIF 035-Transmission and Hydraulic Oil Filter Restricted

BIF 036-Hydraulic Oil Filter Service Alert Alarm

BIF 045-System Voltage Too Low (Idle over 512 rpm)

BIF 046-System Voltage Too Low (idle over 1500 rpm)

BIF 047-System Voltage Too High (Engine Running)

BIF 049-Alternator D+ voltage too low (Idle over 512 rpm)

BIF 050-Alternator D+ voltage too low (idle over 1500 rpm)

BIF 051-Alternator D+ voltage too high

BIF 106-Internal BIF Fault

BIF 135-BCU Timing Signal not received

BIF 136-Open CCD BUS Lines

BIF 137-Open in CAN BUS Lines

BIF 140-Rear PTO Speed Warning

Group ECU (Level 1): ECU (Level 1 with LUCAS injection pump) Service Code Diagnostics

ECU 011-Foot Throttle Potentiometer ECU Input Voltage Too High

ECU 012-Foot Throttle Potentiometer ECU Input Voltage Too Low

ECU 013-Cruise Control Potentiometer Input Voltage Too High

ECU 014-Cruise Control Potentiometer Input Voltage Too Low

ECU 018-Coolant Temperature Sensor Input Voltage Too High

ECU 019-Coolant Temperature Sensor Input Voltage Too Low

ECU 021-Sensor Supply Voltage Too High

ECU 022-Sensor Supply Voltage Too Low

ECU 039-Engine Speed Input Signal Fault

ECU 041-Missing Engine Start Signal

ECU 042-High Idle Speed Too High

ECU 046-Engine Start Signal Always High

ECU 055-ECU detects Not Related CAN BUS Information

ECU 064-Hand Throttle Calibration Failed

ECU 065-Hand Throttle Calibration Value Error

ECU 081-Internal ECU Failure (Pump Current Feedback Voltage Too High)

ECU 082-Internal ECU Failure (Pump Current Feedback Voltage Too Low)

ECU 083-Injection Pump (Unstable Current Regulation for Actuator Magnet)

ECU 084-Injection Pump (Actuator Magnet Current Regulation cannot be controlled)

ECU 085-Injection Pump (Actuator Magnet Current Regulation Too High While Engine is OFF)

ECU 091-Ground Speed Signal Missing Or Incorrect (CAN BUS Message)

ECU 092-Ground Speed Input in ECU and CAN BUS Message Ground Speed Are Different

ECU 093-Internal Miscalculation (based on Service Codes ECU 091 and ECU 092)

Group ECU (Level 4): ECU (Level 4 with BOSCH VP44 injection pump) Service Code Diagnostics

ECU 011- (000091.03) Foot Throttle Potentiometer Input Voltage Too High

ECU 012-(000091.04) Foot Throttle Potentiometer Input Voltage Too Low

ECU 013-(000028.03) Cruise Control Potentiometer Input Voltage Too High

ECU 014-(000028.04) Cruise Control Potentiometer Input Voltage Too Low

ECU 015-(000029.03) Hand Throttle Potentiometer Input Voltage Too High

ECU 016-(000029.04) Hand Throttle Potentiometer Input Voltage Too Low

ECU 018-(000110.03) Coolant Temperature Sensor Input Voltage Too High

ECU 019-(000110.04) Coolant Temperature Sensor Input Voltage Too Low

ECU 021-(001079.03) Sensor Supply Voltage too High

ECU 022-(001079.04) Sensor Supply Voltage too Low

ECU 023-(000100.03) Oil Pressure Input Voltage too High

ECU 024-(000100.04) Oil Pressure Input Voltage too Low

ECU 027-(000094.03) Fuel Pressure Input Voltage too High

ECU 028-(000094.04) Fuel Pressure Input Voltage too Low

ECU 031-(001080.03) Sensor Supply Voltage too High

ECU 032-(001080.04) Sensor Supply Voltage too Low

ECU 033-(000174.15) Fuel Temperature Is Above Normal Least Severe

ECU 034-(000629.19) ECU To Pump Communication Error

ECU 035-(001077.07) Pump Attempting to Fuel With 0 Command

ECU 036-(001077.31) VP44 Initiated Engine Protection

ECU 037-(000632.02) Fuel Shut Off Error Condition Detected

ECU 038-(000637.08) Crank Signal Missing

ECU 039-(000637.02) Noise Detected On Crank Signal

ECU 039-(000637.10) Crank Pattern Error

ECU 042-(000190.00) High Idle Speed Too High,

ECU 043-(000636.08) Event Sensor Signal Missing

ECU 044-(000636.02) Noise Detected On Event Sensor Signal

ECU 044-(000636.10) Event Sensor Pattern Error

ECU 055-(000639.02) ECU Detects Not Related CAN BUS Information

ECU 057-(000094.18) Fuel Pressure Too Low - Moderately Severe Level

ECU 058-(000094.01) Fuel Pressure Too Low - Most Severe Level

ECU 062-(000110.16) Engine Coolant Temperature Too High - Moderately Severe Level

ECU 063-(000110.00) Engine Coolant Temperature Too High - Most Severe Level

ECU 066-(001076.02) VP44 Detected Defect

ECU 067-(000174.00) Fuel Temperature Is Above Normal - Most Severe Level

ECU 068-(001077.11) VP44 Input Voltage Out Of Range

ECU 071-(000174.16) Fuel Temperature Is Above Normal - Moderately Severe Level

ECU 074-(000100.18) Oil Pressure Too Low - Moderately Severe Level

ECU 075-(000100.01) Oil Pressure Too Low - Most Severe Level

ECU 076-(000627.04) ECU Unswitched Power Fault

ECU 077-(000898.09) CAN Speed Request Not Valid Or Not Received

ECU 086-(000632.05) ECU Fuel Shut Off Non-Functional

ECU 087-(001078.11) Pump Speed Does Not Match Engine Speed

ECU 089-(001485.02) Pump Power Relay Fault

ECU 091-(000084.02) Ground Speed Signal Missing Or Incorrect (CAN BUS Message)

ECU 092-(000810.02) Ground Speed Signal in ECU and CAN BUS Message Ground Speed Are Different

ECU 093-(001069.02) Internal Miscalculation (Based On Service Codes ECU 091 and ECU 092)

ECU 094-(001078.31) VP44 Unable To Achieve Desired Timing

ECU 095-(001078.07) VP44 and ECU Timing Measurement Do Not Agree

ECU 096-(001077.19) VP44 Detected CAN BUS Failure

ECU 097-(001077.12) VP44 Self Test Error

ECU 098-(000174.31) Fuel Temperature Sensor In The Pump Out Of Range

001569.31- Fuel Derate

000189.00- Engine Speed Derate

000629.13- ECU Error

Group HCU: HCU Service Code Diagnostics

HCU 022-System Voltage not in Specification

HCU 027-Calibration not Successful

HCU 028-Calibration Memory Failure

HCU 029-Calibration Memory Failure

HCU 030-Insignificant Fault that has no effect on Tractor Operation

HCU 041-Stepper Motor Circuit open

HCU 042-Stepper Motor Circuit open

HCU 043-Stepper Motor Circuit shorted

HCU 044-Stepper Motor Circuit shorted

HCU 045-Potentiometers and Position Sensor Supply Voltage Out of Range

HCU 046-Draft Sensor Supply voltage Out of Range

HCU 049-Raise/ Lower Rocker Switch Circuit

HCU 050-Stepper Motor Deadband out of range

HCU 051-(L.H.) Draft Sensor Signal Circuit

HCU 052-(R.H.) Draft Sensor Signal Circuit

HCU 053-Load/ Depth Control Potentiometer Circuit

HCU 054-Hitch Control Lever Potentiometer Circuit

HCU 055-Rockshaft Position Sensor Circuit

HCU 056-Raise Limit Control Potentiometer

HCU 057-Rate-of-Drop Control Potentiometer Circuit

HCU 058-Remote Control Switch Circuit

HCU 239-Circuit fault during Calibration

HCU 241-Hitch Position Sensor Circuit fault during Calibration

HCU 242-Hitch Position Sensor Circuit fault during Calibration

HCU 250-(R.H.) Draft Sensor Circuit out of specification during calibration

HCU 251-(R.H.) Draft Sensor Circuit out of specification during calibration

HCU 252-(R.H.) Draft Sensor Circuit out of specification during calibration

HCU 253-(L.H.) Draft Sensor Circuit out of specification during calibration

HCU 254-(L.H.) Draft Sensor Circuit out of specification during calibration

HCU 255-(L.H.) Draft Sensor Circuit out of specification during calibration

Group PCU: PCU Service Code Diagnostics

PCU 004-Top Speed Is Not Calibrated In The PCU

PCU 007-Microprocessor Ran Out Of Execution Time

PCU 008-Manifold Pressure Sensor Input Voltage Out Of Range

PCU 009-Hydraulic Oil Temperature Message Missing

PCU 010-Transmission And Engine Oil Pressure Message Missing

PCU 011-Oil Temperature Is Cold

PCU 012-Transmission Oil Pressure Too Low

PCU 016-Engine Running Too Unevenly During Calibration

PCU 018-Encoder Fault Detected In Diagnostic Mode

PCU 020-Tractor Model Is Not Calibrated Correctly

PCU 021-PCU Addresses Not Calibrated

PCU 023-Engine Speed Sensor Missing

PCU 027-PCU Not Calibrated Correctly Or Calibration Failed

PCU 028-B4 Element Not Calibrated Successfully

PCU 030-Clutch Engaged And Disengaged Switch Conflict (Both Closed At Same Time)

PCU 031-Clutch Engaged And Disengaged Switches OPEN For Too Long (“Riding” The Clutch)

PCU 038-Internal Failure Of PCU

PCU 039-Fault in Reverse Switch Circuit

PCU 040-Fault in Forward Switch Circuit

PCU 041-Forward and Reverse Switch Circuit Conflict

PCU 042-Forward Switch Closed, But Gear Encoder Indicates Reverse

PCU 043-Reverse Switch Closed, But Gear Encoder Indicates Forward

PCU 044-Encoder Indicates A Gear, But Enable Relay Indicates Neutral

PCU 045-Encoder Indicates Neutral, But Enable Relay Indicates NOT Neutral

PCU 047-Shift Lever Has Been Between Neutral And Gear For Too Long

PCU 048-System Voltage Out Of Range

PCU 050-Shift Lever In Gear At Ignition ON

PCU 051-No Tractor Movement Detected With Engine Running

PCU 058-Tractor Movement Detected In Calibration Mode

PCU 063-Controller Error, Shift Pressure Calculation Overflow

PCU 065-Internal PCU Failure During Normal Operation

PCU 066-Shift Lever In Gear At Power Up

PCU 067-Failed Start-In-Gear Circuit

PCU 068-Encoder Fault During Normal Operation

PCU 069-Controller Not Calibrated

Group PEC: PEC Service Code Diagnostics

PEC 028-Calibration Memory Failure

PEC 051-E-ICV No.1 Potentiometer - Voltage Out Of Specification

PEC 052-E-ICV No.2 Potentiometer - Voltage Out Of Specification

PEC 053-E-ICV No.3 Potentiometer - Voltage Out Of Specification

PEC 059-E-ICV Multi-Function Lever - Supply Voltage Out Of Specification

PEC 060-E-ICV Transport Lock Switch Fault

PEC 061-E-ICV Multi-Function Lever Interlock Switch Fault

PEC 070-Upshift or Downshift Switch Pressed With Ignition ON

PEC 071-AutoQuad Switch Or Power/ECO Mode Switch Failure At Power Up

PEC 106-Internal PEC Fault

PEC 128-Stepper Motor Driver (SMD0) Supply Voltage Out Of Range

PEC 129-Stepper Motor Driver (SMD0) Short In/To Stepper Motor (M15)

PEC 130-Stepper Motor Driver (SMD0) Internal Fault

PEC 131-Excessive Deviation Of Stepper Motor Switch Signal And Stepper Motor Position

PEC 132-Stepper Motor Position Switch Problem

PEC 133-Stepper Motor Driver (SMD0) Open Lead To Stepper Motor

PEC 134-Incorrect Internal Voltage Of Stepper Motor Driver

PEC 136-E-ICV No.1 Stepper Motor Driver (SMD) Power Supply Voltage Out Of Spec

PEC 137-E-ICV No.1 Stepper Motor Driver (SMD) Short in/to Stepper Motor

PEC 138-E-ICV No.1 Stepper Motor Driver (SMD) Internal Fault

PEC 141-E-ICV No.1 Stepper Motor Driver (SMD) Open Lead to Stepper Motor

PEC 144-E-ICV No.2 Stepper Motor Driver (SMD) Power Supply Voltage Out Of Spec

PEC 145-E-ICV No.2 Stepper Motor Driver Short in/to Stepper Motor

PEC 146-E-ICV No.2 Stepper Motor Driver (SMD) Internal Fault

PEC 149-E-ICV No.2 Stepper Motor Driver (SMD) Open Lead to Stepper Motor

PEC 152-E-ICV No.3 Stepper Motor Driver (SMD) Power Supply Voltage Out Of Specification

PEC 153-E-ICV No.3 Stepper Motor Driver (SMD) Short in/to Stepper Motor

PEC 154-E-ICV No.3 Stepper Motor Driver (SMD) Internal Fault

PEC 157-E-ICV No.3 Stepper Motor Driver (SMD) Open Lead to Stepper Motor

PEC 200-Stepper Motor Driver (SMD0) Initialization Unsuccessful

PEC 201-E-ICV No.1 Stepper Motor Driver (SMD) Initialization unsuccessful

PEC 202-E-ICV No.2 Stepper Motor Driver (SMD) Initialization unsuccessful

PEC 203-E-ICV No.3 Stepper Motor Driver (SMD) Initialization unsuccessful

PEC 204-up to PEC 206 –– (E-ICV) Incorrect Calibration Value Stored in PEC

PEC 207-(E-ICV) Incorrect Calibration Value Stored in PEC

PEC 210-No Information On Ground Speed At The BUS Line After Engine Started

PEC 219-CAN BUS Inoperative

PEC 220-Stepper Motor Driver Fails During Operation

PEC 221-E-ICV No.1 Stepper Motor Driver (SMD) Not Responding to PEC Command

PEC 222-E-ICV No.2 Stepper Motor Driver (SMD) Not Responding to PEC Command

PEC 223-E-ICV No.3 Stepper Motor Driver (SMD) Not Responding to PEC Command

PEC 230-Stepper Motor Driver Address Pin Problem

Group PLC: PLC Service Code Diagnostics

PLC 010-Sender for Transmission Output Speed (B84), Short to Ground

PLC 012-Transmission Output Speed Sender (B84), Open or Shorted Circuit

PLC 016-Park Lock Pressure Sensor (B90), Shorted Circuit

PLC 017-Park Lock Pressure Sensor (B90), Short to Ground or Open Circuit

PLC 020-Park Lock Solenoid Valve (Y15-2), Short to Ground or Shorted Circuit

PLC 021-Park Lock Solenoid Valve (Y15-2), Open Circuit

PLC 030-TCU Command Invalid, Incorrect or Not Logical

PLC 040-System Voltage Too Low (Less Than 9 Volts)

PLC 050-Acoustic Alarm K202, Open Circuit or Shorted Circuit at Power Supply Line

PLC 051-Acoustic Alarm K202, Shorted Circuit

PLC 061-Signals Received from the Reverse Drive Lever Do Not Agree With the CAN BUS Command from the TCU

PLC 101-Power Supply Line for Park Lock Pressure Sensor, Short to Ground

PLC 102-Power Supply Line for Park Lock Pressure Sensor, Shorted Circuit

PLC 106-Internal Fault in Controller

PLC 240-Controller Connected to Wrong Connector on Harness

Group RCU: RCU Service Code Diagnostics

RCU 015-Fault In Detent Solenoid Circuit

RCU 017-Insignificant Fault That Has No Effect On Tractor Operation

RCU 019-Parking Switch And Reverse Lockout Switch

RCU 025-Fault In Detent Solenoid Circuit

RCU 027-Enable Switch Indicates No Pressure

RCU 029-Enable Pressure Switch Indicates Pressure, But Pressure Is Actually Zero (Diagnostic Mode Only)

RCU 031-Fault In Enable Solenoid Circuit

RCU 032-Park Position, But Valid Neutral Signal Is Missing

RCU 034-Reverse Drive Lever Remains In Direction Too Long While Range Lever Is In "Park" (Diagnostic Mode Only)

RCU 040-Forward And Reverse Switches Open, But Not-Neutral Switch Is Closed

RCU 041-Forward And Reverse Switches Closed At Same Time

RCU 042-Forward Switch Closed, But Not-Neutral Switch Open

RCU 043-Reverse Switch Closed, But Not-Neutral Switch Open

RCU 044-Not-Neutral Relay Open, But Not-Neutral Switch Closed

RCU 045-Direction Of Travel Is Selected, But Enable Solenoid Is Still Closed

RCU 047-No Neutral Signal After Engine Is Started

RCU 048-System Voltage Too Low

RCU 051-Reverse Drive Lever In Direction, But Neutral Start Switch Indicates Neutral

RCU 052-Tractor With Reverse Lockout: Range Selected For Reverse Travel Is Too High

RCU 053-Reverser Drive Lever In Neutral, But Neutral Start Switch Indicates Not Neutral

RCU 055-Enable Solenoid Stuck In Closed Position

RCU 056-Reverser Drive Lever In Forward Or Reverse When Engine Is Started

RCU 057-Transmission Enable Voltage Too Low During Operation

RCU 058-Transmission Enable Voltage Too Low When Engine Is Started

RCU 064-Fault In Memory Of RCU

RCU 065-Fault In RCU

RCU 067-Neutral Start Switch Indicates Not-Neutral Without Cause

Group SFA: SFA Service Code Diagnostics

SFA 027-Incorrect Calibration (Calibration Stopped)

SFA 028-SFA Controller Never Calibrated Or Calibration Memory Failure

SFA 029-Diagnostic Fuse Removed Before Calibration Completed

SFA 031-Failure In SFA Controller (EEPROM)

SFA 041-Internal SFA Controller Malfunction For Valve No. 1 (Y10)

SFA 042-Short To Ground In Circuit Between SFA And Solenoid Valve No. 1 (Y10)

SFA 043-Open Or Shorted Circuit Between SFA And Solenoid Valve No. 1 (Y10)

SFA 044-Internal SFA Controller Malfunction For Valve No. 2 (Y11)

SFA 045-Short To Ground In Circuit Between SFA And Solenoid Valve No. 2 (Y11)

SFA 046-Open Or Shorted Circuit Between SFA And Solenoid Valve No. 2 (Y11)

SFA 048-SFA Controller Commands “DOWN” But TLS Front Drive Axle Moves “UP” During Calibration

SFA 049-SFA Commands “UP” But TLS Front Drive Axle Moves “DOWN” During Calibration

SFA 060-During Calibration, No Cylinder Operation For 80 Seconds After Commanded To Move By SFA Controller

SFA 061-Not During Calibration, No Cylinder Operation For 60 Seconds After Commanded To Move By SFA Controller

SFA 062-While Driving, No Cylinder Operation For 60 Seconds After Commanded To Move By SFA Controller

SFA 063-Position Sensor Supply Voltage Too High

SFA 064-Position Sensor Supply Voltage Too Low

SFA 065-During Downward Movement: Sensor Output Signal Less Than 0.25 Volt

SFA 066-Moved Fully DOWN And Position Sensor Output Voltage Has Not Fallen Below 2.0 Volts

SFA 067-During Upward Movement: Sensor Output Signal More Than 4.75 Volts

SFA 068-Moved Fully UP And Position Sensor Output Voltage Has Not Exceeded 3.0 Volt

SFA 069-Sensor Output Voltage Out Of Range (Tolerance Range: 2-3 Volt) For Axle Mid Position

SFA 071-Engine Speed Signal Missing From CCD BUS Line

SFA 072-Ground Speed Signal Missing From CCD BUS Line

SFA 073-Ground Speed Signal Interrupted While Tractor In Motion

SFA 075-Internal SFA Control Unit Failure

SFA 076-Engine Speed Signal Missing From CCD BUS Line While Tractor in Motion

Group TCU: TCU Service Code Diagnostics

TCU 019-Fault at Clutch Pedal Sensors

TCU 020-Fault in Transmission Enable Circuit

TCU 024-Oil Temperature Sender, Shorted to Ground

TCU 032-Power Supply to Solenoid Valves for Forward and Reverse Travel, Shorted Circuit

TCU 033-Power Supply to Solenoid Valves for Range Elements, Shorted Circuit

TCU 040-Oil Temperature Sender, Shorted or Open Circuit

TCU 048-Transmission Input Speed Sender (B61), Short to Ground

TCU 049-Transmission Output Speed Sender (B63), Short to Ground

TCU 050-Hydrostatic Speed Sending Unit (B62), Short to Ground in Channel 1

TCU 052-Hydrostatic Speed Sending Unit (B62), Short to Ground in Channel 2

TCU 056-Transmission Input Speed Sender (B61), Shorted or Open Circuit

TCU 057-Transmission Output Speed Sender (B63), Shorted or Open Circuit

TCU 058-Hydrostatic Speed Sending Unit (B62), Shorted or Open Circuit in Channel 1

TCU 060-Hydrostatic Speed Sending Unit (B62), Shorted or Open Circuit in Channel 2

TCU 064-TCU Registers Implausible Drop in Speed at Transmission Input Speed Sender (B61)

TCU 069-TCU Registers an Implausible Drop in Speed at the PLC's Transmission Output Speed Sender (B84)

TCU 070-PLC's Sending Unit for Transmission Output B84 is Defective

TCU 072-TCU Transmission Input Speed and ECU Engine Speed Do Not Match

TCU 073-Transmission Output Speed Sending Unit (B63), Channels 1 and 2 Do Not Match

TCU 074-Hydrostatic Speed Sending Unit (B62), Speed in Channel 1 Lower than in Channel 2

TCU 076-Hydrostatic Speed Sending Unit (B62), Speed in Channel 2 Lower than in Channel 1

TCU 077-Transm. Input Speed (B61), Hydrostatic Speed (B62) and Transmission Output Speed (B63) Do Not Match

TCU 079-Current Strength at Proportional Solenoids of Hydrostatic Unit Do Not Match with Calculated Speed

TCU 080-Fault in Warning Light Circuit

TCU 081-C1 Solenoid Valve, Open Circuit

TCU 082-C2 Solenoid Valve, Open Circuit

TCU 083-C3 Solenoid Valve, Open Circuit

TCU 084-C4 Solenoid Valve, Open Circuit

TCU 085-BG Solenoid Valve, Open Circuit

TCU 086-Park Lock Solenoid Valve (Y15-1), Open Circuit

TCU 088-Proportional Solenoid Y1 (Hydrostatic Unit Control Valve), Open Circuit

TCU 089-Proportional Solenoid Y2 (Hydrostatic Unit Control Valve), Open Circuit

TCU 090-Proportional Valve for Forward Clutch (CF), Open Circuit

TCU 091-Proportional Valve for Reverse Clutch (CR), Open Circuit

TCU 097-C1 Solenoid Valve, Short to Ground

TCU 098-C2 Solenoid Valve, Short to Ground

TCU 099-C3 Solenoid Valve, Short to Ground

TCU 100-C4 Solenoid Valve, Short to Ground

TCU 101-BG Solenoid Valve, Short to Ground

TCU 102-Park Lock Solenoid Valve (Y15-1), Short to Ground

TCU 104-Proportional Solenoid Y1 (Hydrostatic Unit Control Valve), Short to Ground

TCU 105-Proportional Solenoid Y2 (Hydrostatic Unit Control Valve), Short to Ground

TCU 106-Proportional Valve for Forward Clutch (CF), Short to Ground

TCU 107-Proportional Valve for Reverse Clutch (CR), Short to Ground

TCU 113-C1 Solenoid Valve, Shorted Circuit

TCU 114-C2 Solenoid Valve, Shorted Circuit

TCU 115-C3 Solenoid Valve, Shorted Circuit

TCU 116-C4 Solenoid Valve, Shorted Circuit

TCU 117-BG Solenoid Valve, Shorted Circuit

TCU 118-Park Lock Solenoid Valve (Y15-1), Shorted Circuit

TCU 120-Proportional Solenoid Y1 (Hydrostatic Unit Control Valve), Shorted Circuit

TCU 121-Proportional Solenoid Y2 (Hydrostatic Unit Control Valve), Shorted Circuit

TCU 122-Proportional Valve for Forward Clutch (CF), Shorted Circuit

TCU 123-Proportional Valve for Reverse Clutch (CR), Shorted Circuit

TCU 128-System Voltage Too High (Over 16 Volts)

TCU 129-System Voltage Too Low (Less Than 9 Volts)

TCU 132-Fault in the Internal Transmission Power Supply (VPS)

TCU 136-Control Unit, Wrong Software Version

TCU 137-Internal Fault in Control Unit

TCU 138-Internal Fault in Control Unit

TCU 139-Control Unit Connected to the Wrong Harness Connector

TCU 140-Incorrect Value Input in TCU

TCU 146-TCU Transmission Speed Signal (B63) and PLC Transmission Speed Signal (B84) Do Not Match

TCU 147-Fault at Park Lock Solenoid Valve (Y15-2)

TCU 149-Park Lock Engaged While in Power Zero

TCU 151-TCU CAN Transmission Speed Signal and PLC CAN Transmission Speed Signal Do Not Match

TCU 152-Transmission Oil Too Hot

TCU 153-Control Unit Not Calibrated

TCU 154-INFORMATION FOR OPERATOR: Drive Speed Too High

TCU 155-INFORMATION FOR OPERATOR: Output Speed Too High

TCU 160-User Interface Controller (UIC), Park Lock Controller (PLC) or Engine Control Unit (ECU) is/are Not Sending any Data

TCU 176-Transmission Oil Filter Clogged, or Fault in Circuit for Filter Restriction Sending Unit (S73)

TCU 177-System Pressure Too Low, or Fault in Circuit for System Pressure Sending Unit (S74)

TCU 178-Fault in Circuit for Filter By-Pass Valve (Cold-Weather Starting)

TCU 196-Engine Control Unit (ECU) Is Sending Incomplete Engine Speed Data

TCU 200-User Interface Controller (UIC) Is Sending Incomplete Data on Desired Acceleration

TCU 202-User Interface Controller (UIC) Is Sending Incomplete Data on Prescribed Value for Clutch Torque

TCU 204-User Interface Controller (UIC) Is Sending Incomplete Data on Prescribed Value for Desired Transmission Ratio

TCU 206-User Interface Controller (UIC) Is Sending Incomplete Data on the Condition of the Park Lock

TCU 208-User Interface Controller (UIC) Is Sending Incomplete Data on Prescribed Value for Desired Direction of Travel

TCU 212-User Interface Controller (UIC) Is Sending Incomplete Data on the Actual State of the Clutch Pedal Sensors

TCU 216-User Interface Controller (UIC) Is Sending Incomplete Data on Activation of the Park Lock

TCU 228-Park Lock Controller (PLC) Is Sending Incomplete Data on Transmission Speed

TCU 230-Park Lock Controller (PLC) Is Sending Incomplete Data on Park Lock Pressure Sender

TCU 232-Park Lock Controller (PLC) Is Sending Incomplete Data on Transmission Speed

TCU 234-Park Lock Controller (PLC) Is Sending Incomplete Data on the Monitored Condition of Transmission Output Speed Sender B84

TCU 236-Park Lock Controller (PLC) Is Sending Incomplete Data on Park Lock Solenoid Valve Y15-2

TCU 240-User Interface Controller (UIC) Is Sending Incomplete Data on the Actual State of the "Come-Home" Feature

TCU 241-User Interface Controller (UIC) Is Sending Incomplete Data on Desired Acceleration During a Change of Direction

TCU 243-User Interface Controller (UIC) Is Sending Insufficient Data to Control Transmission Shift

TCU 244-User Interface Controller (UIC) Is Sending Incomplete Data on the Prescribed Value for a Change of Direction

Group UIC: UIC Service Code Diagnostics

UIC 005-Internal Fault in Controller

UIC 006-Internal Fault in Controller

UIC 009-Defective Solenoid Valve at Trailer Brake Precontrol

UIC 010-Fault at Brake Pedal Sensors

UIC 011-Front-Wheel Drive Speed (B89) Does Not Match Transmission Speed (B63)

UIC 012-INFORMATION FOR OPERATOR: Engine Speed Too High (Over 2700 rpm)

UIC 015-Park Lock Does Not Engage

UIC 016-UIC Is Registering Travel Speed Even Although Park Lock Is Engaged

UIC 021-Cruise Control Potentiometer (A19), Signal Voltage Too Low

UIC 022-Cruise Control Potentiometer (A19), Signal Voltage Too High

UIC 027-AutoPowr Selector (B83), Signal Voltage Too Low

UIC 028-AutoPowr Selector (B83), Signal Voltage Too High

UIC 029-Seat Switch (S40) is Activated for More Than 25.5 Hours

UIC 030-Foot Throttle Potentiometer (B79), Voltages at Channel 1 and Channel 2 Not in Correct Ratio

UIC 032-Foot Throttle Potentiometer (B79), Voltage at Channel 1 Too Low

UIC 033-Foot Throttle Potentiometer (B79), Voltage at Channel 1 Too High

UIC 035-Hand Throttle Potentiometer (B78), Voltages at Channel 1 and Channel 2 Not in Correct Ratio

UIC 037-Hand Throttle Potentiometer (B78), Voltage at Channel 1 Too Low

UIC 038-Hand Throttle Potentiometer (B78), Voltage at Channel 1 Too High

UIC 039-Fault at Clutch Pedal Sensors

UIC 044-Left Brake Pedal Potentiometer (B88), Voltage Too Low

UIC 045-Left Brake Pedal Potentiometer (B88), Voltage Too High

UIC 046-Right Brake Pedal Potentiometer (B88), Voltage Too Low

UIC 047-Right Brake Pedal Potentiometer (B88), Voltage Too High

UIC 050-Speed Wheel, Output Signals Do Not Match

UIC 051-Engine Control Unit (ECU) has Stopped Sending Data about Engine Temperature

UIC 052-Engine Control Unit (ECU) has Stopped Sending Data about Engine Load (max. Injection Rate)

UIC 053-Engine Control Unit (ECU) has Stopped Sending Data about Engine Speed

UIC 054-Transmission Control Unit (TCU) has Stopped Sending Data about Transmission Oil Temperature

UIC 055-Engine Control Unit (ECU) has Stopped Sending Data about Engine Load (current Injection Rate)

UIC 056-Engine Control Unit (ECU) has Stopped Sending Data about Engine Speed

UIC 057-INFORMATION FOR OPERATOR: Transmission Warm-Up Routine Is Active

UIC 058-INFORMATION FOR OPERATOR: Transmission Warm-Up Routine Cannot Be Activated; Engage the Park Lock

UIC 062-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Release the Clutch Pedal

UIC 063-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Put the Reverse Drive Lever in Position for Neutral or Park

UIC 064-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Depress the Clutch Pedal Fully

UIC 065-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Select a Direction of Travel

UIC 066-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Depress the Clutch to Stop

UIC 067-Tractor in "Come-Home" Mode - INFORMATION FOR OPERATOR: Restart

UIC 129-Speed Control Lever Potentiometer (B67), Voltages at Channel 1 and Channel 2 Not in Correct Ratio

UIC 131-Speed Control Lever Potentiometer (B67), Voltage at Channel 1 Too Low

UIC 132-Speed Control Lever Potentiometer (B67), Voltage at Channel 1 Too High

UIC 135-Neutral Switch and One Park Lock Switch on the Reverse Drive Lever are Active Simultaneously for Too Long a Time

UIC 136-Faulty Signals from Reverse Drive Lever

UIC 137-Power Zero Switch, Move Switch and One of the Direction Switches on the Reverse Drive Lever are Active Simultaneously for Too Long a Time

UIC 138-Park Lock Cannot Be Disengaged

UIC 141-Clutch Pedal Potentiometer (B65), Ratio of Voltages at Channels 1 and 2 is Not Correct

UIC 142-Clutch Pedal Potentiometer (B65), Voltage at Channel 1 Too Low

UIC 143-Clutch Pedal Potentiometer (B65), Voltage at Channel 1 Too High

UIC 144-Reverse Drive Lever Switches are Active Simultaneously

UIC 145-No Switch Signal from Reverse Drive Lever

UIC 146-Move Switch or Switch for Power Zero is Open by Mistake

UIC 147-Forward and Reverse Switches Actuated Simultaneously

UIC 148-Forward or Reverse Switch is Opened By Mistake

UIC 149-Neutral Switch or Power Zero Switch is Faulty

UIC 150-Faulty Park Lock Switch

UIC 151-Faulty Neutral Switch

UIC 152-Faulty Move Switch

UIC 153-Faulty Reverse Switch

UIC 154-Faulty Forward Switch

UIC 157-Switch for Set Speed 2 Is Not Active, But the Voltage Range of the Speed Control Lever Potentiometer Is Too High

UIC 158-Switch for Set Speed 2 Is Active, But the Voltage Range of the Speed Control Lever Potentiometer Is Too Low

UIC 160-Faulty Power Supply to Reverse Drive Lever

UIC 179-Faulty 5-Volt Power Supply

UIC 180-5-Volt Power Supply Too Low (Less Than 4.8 Volts)

UIC 184-INFORMATION FOR OPERATOR: Engine Has Stopped - Reverse Drive Lever Still in a Direction of Travel

UIC 185-Fault in Transmission

UIC 189-Fault in Circuit for Transmission Enable Relay

UIC 190-Transmission Control Unit (TCU) has Stopped Sending Data about Direction of Travel, Clutch Switch Signals, Transmission Input Speed and Transmission Output Speed

UIC 207-INFORMATION FOR OPERATOR: Tractor Start with Reverse Drive Lever Not in Neutral or Corner Park Position

UIC 208-Shorted Circuit at the Internal Transmission Power Supply (VPS)

UIC 209-INFORMATION FOR OPERATOR: Reverse Drive Lever in Position for Forward or Reverse Travel During the Starting Procedure

UIC 230-EOL Checksum Error

UIC 240-Control Unit Connected to the Wrong Harness Connector

UIC 250-Input Values in UIC and TCU Do Not Match

Section 212: Observable Symptoms

Group 40: Electrical System

Controller/s not Displayed

Performance Monitor Display Problem

Group 55: PowrQuad, PowrQuad Plus and AutoQuad Transmissions

L.H. Electrical Reverser Lever will not stay in Forward or Reverse Position

Group 56: Drive System (except transmission)

PTO will not run

PTO will not stop turning

PTO Slips Under Load

Front PTO will not run

Front PTO will not stop turning

Front PTO shaft slips under load

Unusual Noise when running or rough PTO engagement

Group 60: Steering and Brakes

Handbrake Insufficient

Group 70: Hydraulic System

Hitch does not Work

Hitch Remote Control does not Work

Section 220: Engine

Group 10: Tests

Safety Measures

Preliminary Engine Tests

Dynamometer Test

Section 230: Fuel, Air Intake and Cooling Systems

Group 10: System Diagnosis

Fuel System

Fuel System (with Bosch VP44 Injection Pump)

Cooling System

Group 15: Tests and Adjustments

General Information

Explanation of Tests

Safety Measures

Special Tools

Specifications

Testing the Air Intake System

Testing the Low-Pressure Switch in Air Intake System

Checking the Cooling System for Leaks

Checking Expansion Tank Cap

Thermostat Opening Temperature Test

Checking the Viscous Fan Drive

Checking the Fuel Transfer Pump

Checking the Fuel Transfer Pump (Tractors with Bosch VP44 Injection Pump)

Testing, Calibrating and Adjusting the Engine Control Unit (ECU)

General Information on Diagnostics

Service Code List (with Bosch VP44 Injection Pump)

Diagnostics Program

Service Code List (ECU)

Electronic Control Unit Identification Addresses

Adjust Hand Throttle Lever and Accelerator Pedal

Adjust Accelerator Pedal (6910S)

Group 20A: Fuel System

General Information

Description

Description of System (Tractors with Bosch VP44 Injection Pump)

Fuel Cooler (Tractors with Bosch VP44 Injection Pump)

Fuel Transfer Pump - Theory of Operation

Group 20B: Air Intake System

Air Cleaner - Theory of Operation

Group 20C: Cooling System

General Information

Description of Radiator

Viscous Fan Drive - Theory of Operation

Automatic Drive Belt Tensioner - Theory of Operation

Group 20D: Cold-Weather Starting Aids

General Information

Electrical Starting Aid - Theory of Operation

Fuel Preheater - Theory of Operation

Coolant Heater - Theory of Operation

Section 240: Electrical System

Group 05: General

Special or Essential Tools

Special Tools

Battery Operation

Troubleshooting on Battery

Procedure for Testing Batteries

Battery Specification

Starting with a Booster Battery

Component Identification Table

How to Read a Functional Schematic

How to Read a Diagnostic Schematic

Symbols in Functional Schematic, Wiring and Harness Diagrams

Electrical System Visual Check

Electrical Circuit Malfunctions

Seven Step Electrical Test Procedure

Group 10: Functional Schematics and Wiring Diagrams (6010-6910S)

Fuses

Part Designations in Functional Schematic and Wiring Harnesses

Identification of Sections in Functional Schematic

Wiring Harness Identification

Functional Schematic (Complete Tractor)

Wiring Harness for 4-Cylinder Engine (W3; AL150218)

Wiring Harness for 6-Cylinder Engine (W3; AL150219)

Wiring Harness for 6-Cylinder Engine on Tractor Model 6910S (W3; AL153134)

Wiring Harness for Electrical Starting Aid (W27; AL119472)

Wiring Harness for Starting Aid on Tractor Model 6910S (W27; AL153193)

Front Grille Worklight Wiring Harness (W14; AL81307)

TLS Front Wheel Drive Axle Wiring Harness (W36; AL113493)

Front PTO Wiring Harness (W39; AL110126)

Cab Wiring Harness (W4; AL150759)

Cab Wiring Harness with Power Shift Transmission (W4; AL116787)

Cab Wiring Harness on Tractor Model 6910S (W4; AL152074)

Shift Console Wiring Harness with Power Shift Transmission (W45; AL150055)

Air Brake Wiring Harness on 50 km/h Tractors (W54; AL150847)

7-Terminal Socket Wiring Harness (W29; AL114898)

3-Terminal Socket Wiring Harness (W31; AL114895)

Wiring Harness for Electronic Control Units (W34; AL150234)

Wiring Harness for Electronic Control Units on Tractor Model 6910S (W34; AL151361)

Wiring Harness for Stepper Motor Drivers (W35; AL114802)

Turn Signal Lever Wiring Harness (W5; AL77212)

Windshield Wiper Switch Wiring Harness without Intermittent Wipe (W6; AL112539)

Windshield Wiper Switch Wiring Harness with Intermittent Wipe (W6; AL112652)

Cab Roof Wiring Harness (W11; AL150601)

Front Cab Roof Worklight Wiring Harness (W18; AL83139)

Windshield Wiper Wiring Harness without Windshield Switch (W7; AL79007)

Windshield Wiper Wiring Harness with Windshield Switch (W7; AL78113)

Rear Window Wiper Harness (W10; AL116455)

Rear Window Wiper Adapter Harness (W38; AL116548)

Air Conditioning and Fan Wiring Harness (W8; AL110248)

Transmission Wiring Harness on Tractor Models 6010 - 6610 (W13; AL114105)

Transmission Wiring Harness on Tractor Models 6810 - 6910 (W13; AL114902)

Transmission Wiring Harness with Electrical Reverser Control (W20; AL112509)

Transmission Wiring Harness with Power Shift Transmission (W44; RE158398)

Group 10A: Functional Schematics and Wiring Diagrams (SE Tractors)

Fuses

Functional Schematic and Wiring Harness Component Identification

Section Designations on Functional Schematics

Wiring Harness Identification

Functional Schematic (Complete Tractor; SE1)

Wiring Harness for 4-Cylinder Engine (W3; AL150218)

Wiring Harness for 6-Cylinder Engine (W3; AL150219)

Wiring Harness for Electrical Starting Aid (W27; AL119472)

Front PTO Wiring Harness (W39; AL110126)

Cab Wiring Harness (W4; AL116099)

Front PTO Wiring Harness (W43; AL116605)

Cab Roof Wiring Harness (W11; AL110101)

Air Conditioner and Fan Wiring Harness (W8; AL110589)

Transmission Wiring Harness (W13; AL111537)

Group 10B: Functional Schematics and Wiring Diagrams (2-Post ROPS)

Fuses

Functional Schematic and Wiring Harness Component Identification

Section Designations on Functional Schematics

Wiring Harness Identification

Functional Schematic (Complete Tractor; SE1)

Wiring Harness for 4-Cylinder Engine (W3; AL117076)

Wiring Harness for 6-Cylinder Engine (W3; AL117524)

Wiring Harness for Electrical Starting Aid (W27; AL119472)

Front Grille Worklight Wiring Harness (W14; AL81307)

Platform Wiring Harness (W4; AL116785)

7-Pin Receptacle Wiring Harness (W29; AL114898)

3-Pin Receptacle Wiring Harness (W31; AL114895)

Front Part of Transmission Wiring Harness (W32; AL115344)

Rear Part of Transmission Wiring Harness (W33; AL116810)

Group 10C: Functional Schematics and Wiring Diagrams (AutoPowr)

Fuses

Part Designations in Functional Schematic and Wiring Harnesses

Identification of Sections in Functional Schematic

Wiring Harness Identification

Functional Schematic (Complete Tractor)

Wiring Harness for 4-Cylinder Engine (W3; AL153450)

Wiring Harness for 6-Cylinder Engine (W3; AL153134)

Wiring Harness for Starting Aid (W27; AL153193)

Front Corner Worklight Wiring Harness (W14; AL81307)

TLS Front Wheel Drive Axle Wiring Harness (W36; AL113493)

Front PTO Wiring Harness (W39; AL110126)

Cab Wiring Harness (W4; AL152072)

7-Terminal Socket Wiring Harness (W29; AL114898)

3-Terminal Socket Wiring Harness (W31; AL114895)

Wiring Harness for Electronic Control Units (W34; AL151361)

Wiring Harness for Stepper Motor Drivers (W35; AL114802)

Windshield Wiper Switch Wiring Harness without Intermittent Wipe (W6; AL112539)

Windshield Wiper Switch Wiring Harness with Intermittent Wipe (W6; AL112652)

Cab Roof Wiring Harness (W11; AL150601)

Front Cab Roof Worklight Wiring Harness (W18; AL83139)

Windshield Wiper Wiring Harness without Windshield Switch (W7; AL79007)

Windshield Wiper Wiring Harness with Windshield Switch (W7; AL78113)

Rear Window Wiper Harness (W10; AL116455)

Rear Window Wiper Adapter Harness (W38; AL116548)

Air Conditioning and Fan Wiring Harness (W8; AL110248)

Transmission Wiring Harness on Tractor Models 6410 - 6610 (W13; AL153446)

Transmission Wiring Harness on Tractor Models 6810 - 6910 (W13; AL153449)

Group 15: Circuit Testing (6010-6910S with Cab)

Special or Essential Tools

SE1-Starter Motor and Charging Circuit

SE2-Basic Informator

SE3-Horn

SE4-Cigarette Lighter and Operator's Seat

SE5-Front PTO

SE6-Lights

SE7-Worklights

SE8-Front Loader Plug

SE9-Radio, Digital Clock, Dome and Console Lights

SE10-Fan and Air Conditioner

SE11-Windshield Wiper and Washer

SE12-Rear Window Wiper and Washer

S13-Beacon Light

SE14-3- and 7-Terminal Power Outlet Sockets

SE15-Electronic Hitch Control

SE16A-Basic Control Unit (BCU) (Braking System)

SE16A-Basic Control Unit (BCU) (Braking System, with FWD and Disk Brake)

SE16B-Basic Control Unit (BCU) (Hazard Flasher and Turn Signal Unit)

SE16C-Basic Control Unit (BCU) (Differential Lock)

SE16D-Basic Control Unit (BCU) (Radar)

SE16E-Basic Control Unit (BCU) (Rear PTO without HMS)

SE16F-Basic Control Unit (BCU) (Handbrake Monitor Unit)

SE16G-Basic Control Unit (BCU) (Front Wheel Drive without HMS)

SE16H-Basic Control Unit (BCU) (Power Supply and Rev Counter Sender)

SE16I-Basic Control Unit (BCU) (with Headland Management System)

SE17-Signal Socket

SE18-Performance Monitor

SE19-Electronic Reverser Control

SE20-TLS Front Wheel Drive Axle

SE21A-PowrQuad Plus Shifting

SE21B-Electronically Controlled Independent Control Valves (EICV)

SE21C-EICV Stepper Motor Driver

SE21D-Stepper Motor Driver for PowrQuad Plus Transmission

SE22-BUS Terminator and Terminating Resistor

SE23-Electronic Engine Control

SE 23A-Electronic Engine Control (6910S)

SE27-PowrShift Transmission Control

Group 15A: Sub-System Diagnostics (SE Tractors)

Special or Essential Tools

SE1-Starting Motor and Charging Circuit

SE2-Basic Informator

SE3-Horn

SE4-Operator's Seat

SE5-Front PTO and Handbrake Monitoring System

SE6-Lighting Circuits

SE7-Work Lights

SE9-Radio, Dome and Console Lights

SE10-Fan and Air Conditioner

SE11-Windshield Wiper and Washer

S13-Beacon Light

SE15-Electronic Hitch Control Unit (HCU)

SE16A-Hazard Warning Flasher and Turn Signal Lights

SE16B-Rear PTO

SE16C-Brake System

SE16D-Differential Lock

SE16E-Front Wheel Drive

Group 15B: Sub-System Diagnostics (2-Post ROPS)

Special or Essential Tools

SE1-Starting Motor and Charging Circuit

SE2-Basic Informator

SE3-Horn

SE6-Lighting Circuits

SE7-Work Lights

SE14-3- and 7-Pin Receptacles and Front Loader Plug

SE15-Electronic Hitch Control Unit (HCU)

SE16A-Hazard Warning Flasher and Turn Signal Lights

SE16B-Rear PTO

SE16C-Brake System

SE16D-Differential Lock

SE16E-Front Wheel Drive

Group 15C: Circuit Testing (AutoPowr Transmission)

Special or Essential Tools

SE1-Starter Motor and Charging Circuit

SE2-Basic Informator

SE3-Horn

SE4-Cigarette Lighter and Operator's Seat

SE5-Front PTO

SE6-Lights

SE7-Work Lights

SE8-Front Loader Plug

SE9-Radio, Digital Clock, Dome and Console Lights

SE10-Fan and Air Conditioner

SE11-Windshield Wiper and Washer

SE12-Rear Window Wiper and Washer

S13-Beacon Light

SE14-3- and 7-Terminal Power Outlet Sockets

SE15-Electronic Hitch Control

SE16-Basic Control Unit (BCU) (Differential Lock, Radar, Handbrake and Rev Counter Sender)

SE16A-Basic Control Unit (BCU) (with Headland Management System)

SE16B-Basic Control Unit (BCU) (without Headland Management System)

SE16D-Basic Control Unit (BCU) (Hazard Flasher and Turn Signal Unit)

SE17-Signal Socket

SE18-Performance Monitor

SE20-TLS Front Wheel Drive Axle

SE21-Electronically Controlled Independent Control Valves (EICV)

SE21A-EICV Stepper Motor Driver

SE22-BUS Terminator and Terminating Resistor

SE23B-Electronic Engine Control

SE26-Transmission Control Unit

SE27-Transmission Shifting

SE28- Electronic Park Lock

SE30A-Seat and Handbrake Switch

Group 16A: Data BUS Systems

Data BUS Systems

CCD BUS System

CAN BUS System

CCD BUS Diagnostic Schematic

CAN BUS Diagnostic Schematic

CCD BUS Diagnostic Schematic (6910S Tractors)

CAN BUS Diagnostic Schematic (6910S Tractors)

CCD BUS Diagnostic Schematic (Tractors with AutoPowr Transmission)

CAN BUS Diagnostic Schematic (Tractors with AutoPowr Transmission)

DATA BUS Systems

DATA BUS Systems on 6910S Tractors

DATA BUS Systems on Tractors with AutoPowr Transmission

Group 16B: Data BUS Systems –– Diagnosis

Explanation of Data Bus System Tests

Safety Measures

Essential Tools

Malfunctions in the Data BUS System

CCD - Test for SE Tractors and 2-Post ROPS Tractors

CCD - Test for Cab Tractors without RCU and/or SFA

CCD - Test for Cab Tractors equipped with RCU and/or SFA

CCD - Test for Cab Tractors with PowrShift Transmission (PST)

11-BIT CAN BUS Test

29-BIT CAN BUS Test

29-BIT CAN BUS - Test for 6910S Tractors

29-BIT CAN BUS - Test for AutoPowr Transmission

Supply Circuit 072 for Electronic Control Units

Group 20: Adjustments

Explanation of BCU, Basic Informator (BIF) and Performance Monitor (PRF) Testing

Safety Measures

Essential Tools

General Information on Basic Control Unit (BCU)

BCU Addresses

Diagnostic Structure (BCU)

Service Code List (BCU)

Diagnostic Address List (BCU)

Diagnostic Addresses (BCU)

Display Address List (BCU)

Display Addresses (BCU)

Calibration (BCU)

Calibration Address List (BCU)

Calibration Addresses (BCU)

General Information Concerning the Basic Informator (BIF)

Basic Informator (BIF) Addresses

Diagnostic Structure (BIF)

Service Code List (BIF)

Diagnostic Address List (BIF)

Diagnostic Addresses (BIF)

Display Address List (BIF)

Display Addresses (BIF)

Calibration (BIF)

Calibration Address List (BIF)

Calibration Addresses (BIF)

General Information about the Performance Monitor (PRF)

Performance Monitor (PRF) Addresses

Diagnostic Structure (PRF)

Calibration (PRF)

Calibration Address List (PRF)

Calibration Addresses (PRF)

Calibrating the Ground Speed Sensor (Radar)

Setting Wheel Slip Back to Zero

Group 25: Component Testing

Special or Essential Tools

Specifications

SE1-Starting Motor and Charging Circuit

Starter Checks

Alternator Checks

Battery Checks

SE2-Instrument Unit and Lighting

SE3-Horn

SE4-Cigarette Lighter and Operator's Seat

SE7-Front PTO

SE6-Lighting Circuits

SE7-Work Lights

SE9-Radio, Dome and Shift Console Lights

SE10-Fan and Air Conditioner

SE11 and SE12-Windshield Wiper and Washer

S13-Beacon

SE16A-Basic Control Unit (BCU) (Braking System)

SE16B-Basic Control Unit (BCU) (Hazard Flasher and Turn Signal Unit)

SE16C-Basic Control Unit (BCU) (Differential Lock)

SE16E-Basic Control Unit (BCU) (Rear PTO)

SE16G-Basic Control Unit (BCU) (Front Wheel Drive)

SE16I-Basic Control Unit (BCU) (Headland Management System)

SE19-Electrical Reverser Control

SE20-TLS Front Wheel Drive Axle

SE21A-PowrQuad Plus Shifting

SE21B-Operation of the Electronic Independent Control Valve

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

General Explanation of Testing Procedures for Electronic Control Units

Safety Measures

Essential Tools

Diagnostics with Digital Display

Diagnosis with the Performance Monitor

Abbreviations Used in Display

Diagnostic Structure

Entering Program Mode

Calling up and Deleting Service Codes

Electronic Control Units - Identification Addresses

Group BCU: BCU References

Supply Circuit 973 (BCU Functions; Not for tractors with AutoPowr Transmission)

Rear PTO Speed Sender Circuit Test

Handbrake Switch Circuit Test

Differential Lock Switch Circuit Test

MFWD Switch Circuit Test

HMS Switch Circuit Test

Rear PTO Switch Circuit Test

Rear PTO-Remote Control Circuit Test

Turn Signal Switch Test

Hazard Flasher Switch Circuit Test

BCU and Tractor System-Voltage-Circuit Test

Group BIF: BIF References

Fuel Level (Gauge) Sensor Test

Coolant Temperature Sensor Circuit Test

Transmission Oil Temperature Sensor Circuit Test

Engine Oil Pressure Sender Test

Engine Speed Signal Circuit Test

Transmission Oil Pressure Switch Circuit Test

Air Filter Switch Circuit Test

Oil Filter Restriction Switch Circuit Test

Oil Filter Restriction Switch Circuit Test for AutoPowr Transmission

BIF Supply Voltage and Tractor System Voltage Test

Alternator Circuit Test

Flasher Cycle Input Signal Circuit Test

Group ECU: ECU (Level 1) References

Foot Throttle Potentiometer Supply Circuit Test

Foot Throttle Potentiometer Output Circuit Test

Cruise Control Potentiometer Supply Circuit Test

Cruise Control Potentiometer Output Circuit Test

Coolant Temperature Sensor Circuit Test

Engine Speed Sensor Circuit Test

Fuel Injection Pump Solenoid Circuit Test

Starting Circuit Test

Group HCU: HCU References

HCU Beep Mode Test (HCU 02)

Quick Raise/Lower Rocker Switch Circuit Test

(L.H.) Draft Sensor Output Circuit Test

(R.H.) Draft Sensor Output Circuit Test

Load/Depth Control Potentiometer Output Circuit Test

Hitch Height Control Potentiometer Output Circuit Test

Position Sensor Potentiometer Output Circuit Test

Raise-Limit Control Potentiometer Output Circuit Test

Rate-of-Drop Control Potentiometer Output Circuit Test

Remote Control Switch Circuit Test

Potentiometer Supply Voltage Circuit Test

Draft Sensor Supply Voltage Circuit Test

Stepper Motor Circuit Test

HCU Power Supply - Circuit Test

Group PCU: PCU References

PCU Beep Mode Test (PCU 02)

Manifold Pressure (MAP) Sensor Circuit Test

Clutch Engaged Switch Circuit Test

Clutch Disengaged Switch Circuit Test

Forward Switch Circuit Test

Reverse Switch Circuit Test

Not-Neutral Switch Circuit Test

Transmission Enable Signal Test

Group PEC: PEC References

PEC Beep Mode Test (PEC 02 and PEC 03)

Upshift Circuit Test

Downshift Circuit Test

Power/ECO Mode Switch Circuit Test

AutoQuad Switch Circuit Test

Stepper Motor Driver (SMD0) Power Supply and Identification Circuit Test

Stepper Motor (M15) and Stepper Motor Driver (SMD0) Circuit Test

E-ICV –– Multi-Function Lever Axis 1 – Test (Forward and Rearward Lever Position)

E-ICV –– Multi-Function Lever Axis 2 – Test (Left and Right Lever Position)

E-ICV –– Multi-Function Lever Axis 3 – Test (Rocker Switch - Upper and Lower Position)

E-ICV –– Multi-Function Lever Potentiometer Supply Circuit Test

E-ICV –– Transport Lock Switch Circuit Test

E-ICV –– Interlock Switch Circuit Test

E-ICV –– Stepper Motor Driver (SMD1, 2 and 3) Power Supply and Identification Circuit Test

E-ICV No.1 –– Stepper Motor (M12) and Stepper Motor Driver (SMD1) Circuit Test

E-ICV No.2 –– Stepper Motor (M13) and Stepper Motor Driver (SMD2) Circuit Test

E-ICV No.3 –– Stepper Motor (M14) and Stepper Motor Driver (SMD3) Circuit Test

Group PLC: PLC References

Preliminary Test for PLC Circuit

Circuit Test for Park Lock Controller (Signals from Reverse Drive Lever)

Circuit Test, Output Speed Sender (B84) on Transmissions with PLC

Circuit Test for Park Lock Solenoid Valve (Y15-2)

Circuit Test for Acoustic Alarm (K202)

Circuit Test for Park Lock Pressure Sensor (B90)

Group RCU: RCU References

Recall Codes Procedure for RCU

RCU Beep Mode Test (RCU 02)

Test Procedure for Diagnostic Address RCU 03

Test Procedure for Diagnostic Address RCU 04

Test Procedure for Diagnostic Address RCU 05

Test Procedure for Diagnostic Address RCU 06

Test Procedure for Diagnostic Address RCU 07

Check Forward Solenoid Circuit

Check Reverse Solenoid Circuit

Group SFA: SFA References

SFA Beep Mode Test (SFA 02)

Solenoid Valve 1 (Y10) Circuit Test

Solenoid Valve 2 (Y11) Circuit Test

Position Sensor (B53) Supply Voltage Circuit Test

Position Sensor (B53) Output Circuit Test

Magnet Sending Unit (B35) Circuit Test

Hall Sending Unit (B09) Circuit Test

Test Procedure for SFA Hydraulic System

Test Procedure for Accumulator Precharge System

Group TCU: TCU References

Adapter Test Harness for AutoPowr Transmission––KJD10265

Preliminary Test for TCU Circuit

Testing the Connectors on the AutoPowr Controllers

Circuit Testing for the Neutral Signal Control Circuit

Circuit Testing for the Control Circuit of the Internal Transmission Power Supply (VPS)

Circuit Test for Oil Temperature Sending Unit

Circuit Test for Transmission Oil Filter Sender S73

Circuit Test for Transmission Oil Pressure Sender S74

Circuit Test for Filter By-pass Valve (Cold-Weather Starting), Sending Unit (B87)

Circuit Test for Transmission Input Speed Sending Unit (B61)

Circuit Test for Transmission Output Speed Sending Unit (B63)

Circuit Test for Hydrostatic Speed Sending Unit (B62)

Circuit Test for Park Lock Solenoid Valve (Y15-1)

C1 Solenoid Valve Circuit Test

C2 Solenoid Valve Circuit Test

C3 Solenoid Valve Circuit Test

C4 Solenoid Valve Circuit Test

BG Solenoid Valve Circuit Test

Circuit Test for Proportional Solenoid Y1

Circuit Test for Proportional Solenoid Y2

Circuit Test for CF Forward Clutch

Circuit Test for CR Reverse Clutch

Test Chart for AutoPowr Transmission

Group UIC: UIC References

Preliminary Check on UIC Circuit

Circuit Test for Reverse Drive Lever (S80)

Circuit Test for Cruise Control Potentiometer (A19)

Circuit Test for AutoPowr Selector (B83)

Circuit Test for Speed Wheel at Speed Control Lever (S108)

Circuit Test for Speed Ranges 1 and 2 at Speed Control Lever (S108 and B67)

Circuit Test for Hand Throttle Potentiometer (B78)

Circuit Test for Foot Throttle Potentiometer (B79)

Circuit Test for Brake Pedal Sensors (B88)

Circuit Test for Clutch Pedal Potentiometer (B65)

Circuit Test for FWD Axle Speed Sending Unit (B89)

Circuit Test for Air Brake Solenoid Valve (Y31)

Circuit Test for Seat Switch (S40)

Circuit Test for Come-Home Function (K201)

Section 250: SyncroPlus Transmission

Group 05: Operational Checkout

Checking If Perma Clutch II Separates Properly

Checking Perma Clutch II for Slippage

Checking the Slip Phase of Perma Clutch II

Checking the Transmission

Checking the Neutral Start Switch

Group 10: Troubleshooting

Essential Tools

Specifications

Safety Precautions

Explanation of System Diagnosis (Troubleshooting)

Hydraulic Oil Warm-Up

Connecting JT07115 Hydraulic Test Kit

Connecting the Sensocontrol© Testing Equipment

Layout of Test Ports and Sending Units

Preliminary Checks

Checking Gear and Range Engagement

Checking Clutch Operation

Transmission Oil Filter Check

Checking System (Engagement) Pressure

Adjusting System (Engagement) Pressure

Check Components Dependent on System (Engagement) Pressure

Checking the Filter Relief Valve

Testing the Engagement Override Valve and Clutch Pedal Valve

Checking the Modulation of the Clutch Pedal Valve

Checking Lubricating Oil Pressure

Checking the Clutch Cooling System

Checking the Flow Rate

Checking the Cooler Relief Valve

Group 15: Tests and Adjustments

Essential Tools

Specifications

Shift Linkage Test

Range Transmission Linkage Test

Adjusting Range Box Shifting

Gear Transmission Linkage Test

Adjusting Shift Linkage at Gear Transmission

Adjusting the Neutral Start Switch

Checking the Neutral Start Switch

Adjusting the Shift Linkage and Parking Lock

Clutch Pedal Adjustment

Group 20: SyncroPlus Transmission Operation

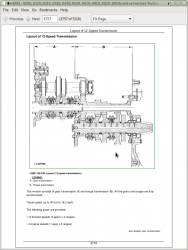

Layout of 12-Speed Transmission

Layout of 12-Speed Transmission with Creeper

Lubrication System

Shift Operation

Synchronization

Transmission Circuit Hydraulic Schematic

Transmission Circuit - Theory of Operation

Group 20A: Perma Clutch II

Exploded View of Perma Clutch II

Clutch Design

Power Flow, Clutch Pedal Depressed

Power Flow, Clutch Pedal Not Depressed

Theory of Operation - Transmission Oil Pump

Hydraulic Schematic of Perma Clutch II

Description of Valves and Other Hydraulic Components

Theory of Operation - Pressure Regulating and Filter Relief Valves

Theory of Operation - Clutch Pedal and Engagement Override Valves

Theory of Operation - Cooling

Group 20B: Gear Transmission

Gear Transmission Design

Power Flow in 1st Gear

Power Flow in 2nd Gear

Power Flow in 3rd Gear

Power Flow in Reverse Gear

Neutral Start Switch

Group 20C: Creeper Transmission

Layout of Creeper Transmission

Power Flow With Creeper Disengaged

Power Flow With Creeper Engaged

Group 20D: Range Transmission

Range Transmission

Layout

Power Flow in Range A

Power Flow in Range B

Power Flow in Range C

Power Flow in Range D

Parking Lock

Section 251: Power Reverser Transmission

Group 05: Operational Checkout

Before You Start

Checking the Neutral Start Switch

Neutral-to-Gear Modulation Check

Reverser Control Modulation Check

Gear Engagement Check

Range Engagement Check

Clutch Modulation Check

Transmission Creep Check

Clutch Engagement Check

Group 10: Troubleshooting

Essential Tools

Specifications

Safety Precautions

Explanation of Troubleshooting

Hydraulic Oil Warm-Up

Connecting the JT07115 Hydraulic Test Kit

Connecting the Sensocontrol© Testing Equipment

Layout of Test Ports and Sending Units

Preliminary Checks

Checking Gear and Range Engagement

Checking Forward/Reverse Modulation

Transmission Oil Filter Check

Checking System (Engagement) Pressure

Adjusting System (Engagement) Pressure

Checking Components Dependent on System (Engagement) Pressure

Checking the Filter Relief Valve

Checking the Engagement Override Valve and Clutch Pedal Valve

Checking the Disk Clutch and Disk Brake

Checking Lubricating Oil Pressure

Checking the Clutch Cooling System

Checking the Flow Rate

Checking the Cooler Relief Valve

Group 15: Test and Adjustments

Special Tool (Dealer-Manufactured)

Shift Linkage Test

Range Transmission Linkage Test

Adjusting Range Transmission Linkage

Gear Transmission Linkage Test

Adjusting Shift Linkage at Gear Transmission

Adjusting the Reverser Control Linkage

Adjusting the Shift Linkage and Parking Lock

Adjusting the Reverse Drive Lever

Clutch Pedal Adjustment

Group 20: Power Reverser Operation

Design of Power Reverser

Description of Transmission Oil Circuit

Group 20A: Power Reverser Module

Components

Design and Powerflow

Power Reverser Module - Sectional View

Theory of Operation - Transmission Oil Pump

Valves and Other Hydraulic Components

Power Reverser - Hydraulic Circuit Diagram

Description of Valves and Other Hydraulic Components

Theory of Operation - Pressure Regulating and Filter Relief Valves

Theory of Operation - Forward/Reverse Modulation

Theory of Operation - Clutch Pedal Valve

Theory of Operation - Engagement Override Valve

Theory of Operation - Cooling

Group 20B: Gear Transmission

Illustration of Gear Transmission

Design and Powerflow

Section 252: Power Shift Transmission

Group 05: Operational Checkout

Before You Start

Group 10: Troubleshooting

Special Tools

Avoid High-Pressure Fluids

Adjust for Correct Pressure and Temperature References

Observe Safety Precautions

PCU Description

Gear Number Display

Element Engagement Chart

Come-Home Feature and Operation

General Information on Diagnostics

Notes on the Diagnostic Program

Service Code List (PCU)

Diagnostic Address List (PCU)

Address 03, Checking the Gear Encoder

Address 20, Troubleshooting the Driver/Element Circuit

Calibration Address List (PCU)

Calibrating the Power Shift Transmission

Calibration Fault

Error Messages

Troubleshooting System Tests

Additional Troubleshooting Test Procedures

Group 15: Adjustments

Adjusting the Parking Lock

Group 20: Theory of Operation

Layout of PowerShift Transmission

PST Transmission (Components)

Planetary Operation

Element Engagement Chart

Hydraulic Control of Transmission

Analog Shift Valve (FEMA Valve)

Analog Shift Valve (Clutch Disengaged)

Analog Shift Valve (Clutch Engaged)

Analog Valve Commands for On-Coming Clutch

Reduction Gear Box

PST Transmission (Components)

Section 253: AutoPowr Transmission

Group 10A: Diagnosis - UIC

General Information on Diagnostics

UIC - Service Code List

UIC - Diagnostic Addresses

UIC - Display Addresses

UIC - Calibration and Input Addresses

Group 10B: Diagnosis - TCU

General Information on Diagnostics

TCU - Service Code List

TCU - Diagnostic Addresses

TCU - Display Addresses

TCU - Calibration and Input Addresses

TCU - Output Test Mode Chart

Group 10C: Diagnosis - PLC

General Information on Diagnostics

PLC - Service Code List

PLC - Diagnostic Addresses

PLC - Display Addresses

PLC - Calibration and Input Addresses

Group 15: Tests and Adjustments

Special Tools

Specifications

Test Ports for Hydraulic Tests (6410 and 6610)

Test Ports for Hydraulic Tests (6810 and 6910)

Checking System Pressure

Checking Reduced System Pressure (Pressure for Other Consumers)

Checking Oil Cooler Pressure

Checking Lube Oil Pressure

Checking Pressure at the C1 Clutch

Checking Pressure at the C2 Clutch

Checking Pressure at the C3 Clutch

Checking Pressure at the C4 Clutch

Checking Pressure at the BG Disk Brake

Checking Pressure at the Forward Clutch (CF)

Checking Pressure at the Reverse Clutch (CR)

Group 20: Operation

Operation

Layout of Transmission Components

Sectional View of Transmission

Transmission Peripherals

Components for Transmission Control

Transmission Control

Description of Transmission Oil Circuit

Description of System Pressure Control Block

Description of Clutch Control Block

Operation of Hydrostatic Unit

Transmission Layout

Element Engagement Chart

Power Flows

Oil Flows

Operation of Park Lock

Shift Controls

Section 255: PowrQuad, PowrQuad Plus and AutoQuad II Transmissions

Group 05: Operational Checkout

Before You Start

Group 10A: POWRQUADPOWRQUAD is a trademark of Deere & Company. Transmission Check

Use Step-by-Step Hydraulic Diagnostic Charts

Special or Essential Tools

Connecting the SensoControl Testing Equipment

Service Equipment and Tools

Other Material

Observe Safety Precautions

Legal Requirements

General Information on Diagnostics

Notes on the Diagnostic Program

Service Code List (RCU)

Diagnostic Address List (RCU)

Calibration Address List (RCU)

Calibrating the RCUReverser Control Unit (electronic control unit for electrical reverser control)

Adjust for Correct Pressure and Temperature References

Shortened Diagnostic Procedure

Test-Driving the Tractor

Troubleshooting System Test

Major System Checks

Additional Troubleshooting Test Procedures

Group 10B: Troubleshooting on PowrQuad Plus and AutoQuad II

Special or Essential Tools

General Information on Diagnostics

Notes on the Diagnostic Program

Service Code List (PEC) - Transmission

Diagnostic Address List (PEC) - Transmission

List of Calibratable Addresses (PEC) - Transmission

Group 15: Tests and Adjustments

Reverser Control Linkage Adjustment (6010 to 6610 Tractors)

Reverser Control Linkage Adjustment (6810 and 6910 Tractors)

Adjusting Shifter and Parking Lock - Reverser Control on Shift Console

Adjusting the Shift Linkage and Parking Lock - Reverser Control on Steering Column

Adjusting the Shift Linkage and Parking Lock

Clutch Pedal Adjustment

Transmission System Pressure Check

Group 20A: PowrQuad Transmission Operation

PowrQuad Transmission Layout (6810 and 6910)

PowrQuad Transmission Layout (6110 to 6610)

PowrQuad Module

Planetary Operation

Air Pump

Transmission Oil Pump

Clutch Oil Manifold

Reverse Brake Housing

Forward/Reverse Controls

Hydraulic Schematic - Mechanical Reverser Control

Hydraulic Schematic - Electrical Reverser Control

Filter Bypass Valve

Pressure Regulating Valve

Forward-Reverse Modulation

EOV Circuit (With Mechanical Reverser Control)

Theory of Operation - Electrical Reverser Control

Positions of the Reverse Drive Lever

Parking Lock Switch

Reverse Lockout Switch (if equipped)

Valve Housing on PowrQuad Module

Relays

Reverser Control Unit (RCU)

Detail of Hydraulic Circuit Diagram (Simplified)

Speed Control Circuit

Speed Modulation

Clutch Cooling Components

Oil Cooler

Clutch Cooling Valve

Forward/Reverse Cooling Control Valve

Oil Cooler and Lube Circuits

Module Lube

Module Lube Flow Paths

Test Ports and Sending Units - With Mechanical Reverser Control

Test Ports and Sending Units - With Electrical Reverser Control

Group 20B: PowrQuad Plus and AutoQuad II Transmission Operation

PowrQuad Module

PowrQuad, PowrQuad Plus and AutoQuadII Transmissions

Comparison of Transmission Versions

PowrQuad Plus, AutoQuad and AutoQuad II Transmission Components

Description of PEC

Electric Shifting

Automatic Speed Matching

Automatic Shifting

Group 20C: Creeper Transmission

Creeper Transmission Sectional View (6810 and 6910 Tractors)

Creeper Transmission Operation (6110-6610 Tractors)

Power Flow with Creeper Disengaged

Power Flow with Creeper Engaged

Group 20D: Range Transmission

Design (16-Speed Transmission)

Design (20-Speed Transmission)

Design (24-Speed Transmission)

Power Flow in Range A (16-Speed Transmission)

Power Flow in Range B (16-Speed Transmission)

Power Flow in Range C (16-Speed Transmission)

Power Flow in Range D (16-Speed Transmission)

Power Flow in Range A (20- and 24-Speed Transmissions)

Power Flow in Range E (20- and 24-Speed Transmissions)

Power Flow in Range F (24-Speed Transmission)

Parking Lock

Sectional View of Range Transmission (6810 and 6910 Tractors)

Section 256: Drive Systems

Group 05: Operational Checkout

Checking the Differential Lock

Checking the Front and Rear PTOs

Checking Front-Wheel Drive

Group 10: Troubleshooting

Differential

Front PTO

Rear PTO

Front-Wheel Drive

Hydraulic Pump Drive

Final Drives

Group 15: Tests

Safety Measures

Special or Essential Tools

Connecting the SensoControl Testing Equipment

Specifications

Testing Front Wheel Drive Clutch System Pressure

Testing Hydraulic Differential Lock System Pressure

Testing the Rear PTO

Front PTO Check

Group 20A: Front-Wheel Drive Clutch

Design (6010-6610 Tractors)

Oil and Power Flows With Front-Wheel Drive Engaged

Oil and Power Flows with Front Wheel Drive Disengaged

Design (6810 and 6910 Tractors)

Oil and Power Flows With Front-Wheel Drive Engaged

Oil and Power Flows with Front Wheel Drive Disengaged

Group 20B: Differential

Design (6010-6610 Tractors)

Design (6810 and 6910)

Power Flow when Moving Straight Ahead

Power Flow when Cornering

Oil Flow With Differential Lock Engaged

Oil Flow With Differential Lock Disengaged

Group 20C: Final Drives

Operation and Layout

Group 20D: Rear PTO Options

Description of Rear PTO Options

PTO Modulating Valve and Solenoid Valve

PTO Clutch and PTO Brake

Lube Cut-Off Valve

PTO Power Flow (540 rpm)

PTO Power Flow (540/1000 rpm, Reversible)

Power Flow for Shiftable 540/1000 rpm and 540/540E/1000 rpm PTO

Group 20E: Front PTO

Front PTO Operation

Independent Hydraulic Circuit

Oil Cooler

Modulating Valve and Solenoid

Hydraulic Pump

Section 260: Steering and Brakes

Group 05: Operational Checkout

Checking the Steering

Checking the Brakes

Checking the Handbrake

Air Brake System Check (Filling Pressure and Leak Test)

Group 10: Troubleshooting

Hydrostatic Steering

Hydraulic Brakes (Without Power Assist)

Handbrake

Hydraulic Trailer Brake

Air Brake System

Group 15: Tests and Adjustments

Special Tools

Connecting the SensoControl Testing Equipment

Specifications

Testing Leaf Springs of Steering Valve

Checking Steering System for External Leakage

Checking the Steering System for Internal Leakage

Steering Valve Leak Check

Steering Valve Hydraulic Connections