John Deere 310SJ, 410J Backhoe Loader with TMC Operation & Test Service Manual (TM10852)

Complete Operation & Tests service manual with electrical wiring diagrams for John Deere 310SJ and 410J Backhoe Loader with Total Machine Control (TMC) (S.N. from 161703), with workshop information to maintain, diagnose, and rebuild like professional mechanics.

John Deere 310SJ, 410J Backhoe Loaders workshop Operation & Tests manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

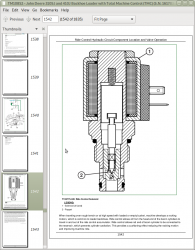

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TABLE OF CONTENTS

Foreword

General Information

Safety Information

Diagnostics

Engine Control Unit (ECU)

Flex Load Controller (FLC)

Standard Display Monitor (SDM)

Flex Hydraulic Controller (FHC)

Intelligent System Planner (ISP)

Left Joystick Controller (JSL)

Right Joystick Controller (JSR)

Sealed Switch Module (SSM)

Boom Distributed Function Control Unit (BOM)

Bucket Distributed Function Control Unit (BUK)

Crowd Distributed Function Control Unit (CWD)

Flow Control Distributed Function Control Unit (HAM)

Swing/Extend Distributed Function Control Unit (SWX)

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Adjustments

Tests

Hydraulic System

Theory of Operation

Diagnostic Information

Adjustments

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

TM10852 - John Deere 310SJ and 410J Backhoe Loader with Total Machine Control (TMC) Technical Manual (Operation & Test Manual).PDF

TM10852 - John Deere 310SJ and 410J Backhoe Loader with Total Machine Control (TMC) Technical Manual (Operation & Test Manual).EPUB

Total Pages: 1,126 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

TABLE OF CONTENTS - Expanded View

9000 - GENERAL INFORMATION

01 - Safety

Add and Operate Attachments Safely

Avoid Backover Accidents

Avoid High-Pressure Fluids

Avoid High-Pressure Oils

Avoid Machine Tipover

Avoid Unauthorized Machine Modifications

Avoid Work Site Hazards

Beware of Exhaust Fumes

Dispose of Waste Properly

Drive Metal Pins Safely

Follow Safety Instructions

Handle Chemical Products Safely

Inspect and Maintain ROPS

Inspect Machine

Keep Riders Off Machine

Make Welding Repairs Safely

Operate Only If Qualified

Operating or Traveling On Public Roads

Park and Prepare for Service Safely

Prepare for Emergencies

Prevent Battery Explosions

Prevent Fires

Prevent Unintended Detonation of Explosive Devices

Prevent Unintended Machine Movement342200224If Equipped With Pilot Controls

Prevent Unintended Machine Movement

Recognize Safety Information

Remove Paint Before Welding or Heating

Service Cooling System Safely

Service Tires Safely

Start Only From Operator's Seat

Stay Clear of Moving Parts

Use and Maintain Seat Belt

Use Special Care When Operating

Use Steps and Handholds Correctly

Wear Protective Equipment

9001 - DIAGNOSTIC TROUBLE CODES (DTC)

010 - Engine Control Unit (ECU) Diagnostic Trouble Codes

000029.03 342200224 Engine Speed Control Short Circuit

000029.04 342200224 Engine Speed Control Open Circuit

000091.03 342200224 Foot Throttle Position Sensor Short Circuit

000091.04 342200224 Foot Throttle Position Sensor Open Circuit

000091.14 342200224 Foot Throttle Position Sensor Out of Range

001075.05 342200224 Fuel Lift Pump Relay Open Circuit

001075.06 342200224 Fuel Lift Pump Relay Short Circuit

001321.05 342200224 Starter Relay Open Circuit

001321.06 342200224 Starter Relay Short Circuit

001321.16 342200224 Crank Cycle Too Long

002023.09 342200224 Hand Throttle Message Missing (Landscape Loader Only)

002047.09 342200224 Can Communication Lost with FLC

002071.09 342200224 Hand Throttle Message Missing (Backhoe Only)

523702.09 342200224 Flex Power Message Missing

Engine Control Unit (ECU) Diagnostic Trouble Codes

020 - Flex Load Controller (FLC) Diagnostic Trouble Codes

000069.07 342200224 MFWD Logic Error

000070.02 342200224 Park Brake Switch (S7) Open Circuit

000070.04 342200224 Park Brake Switch (S7) Short to Ground

000070.07 342200224 Park Brake Switch (S7) Logic Error

000117.19 342200224 Service Brake Pressure Low

000234.02 342200224 Software Revision Mismatch

000237.02 342200224 Model Number in Vehicle Identification Number Not Valid

000525.03 342200224 TCL_Range Switch (S5) Gear Range Input Shorted to Power

000525.04 342200224 TCL_Range Switch (S5) Gear Range Input Voltage Low

000525.05 342200224 TCL_Range Switch (S5) Gear Range Input Open Circuit

000525.12 342200224 TCL_Range Switch (S5) Gear Range Input Logic Error

000629.12 342200224 FLC Watchdog Timeout

000734.05 342200224 Transmission Solenoid (Y1) Open Circuit

000735.05 342200224 Transmission Solenoid (Y2) Open Circuit

000736.05 342200224 Transmission Solenoid (Y3) Open Circuit

000737.12 342200224 Transmission Solenoid (Y4 or Y5) Fault

000738.05 342200224 Transmission Solenoid (Y5) Open Circuit

000739.12 342200224 Transmission Solenoid (Y2 or Y6) Fault

000741.12 342200224 Transmission Solenoid (Y1 or Y3) Fault

000746.07 342200224 Differential Lock Switch (S4) Logic Error

000746.12 342200224 Differential Lock Switch (S4) Short to Power or Ground

000757.05 342200224 Transmission Solenoid (Y4) Open Circuit

000759.05 342200224 Transmission Solenoid (Y6) Open Circuit

001504.05 342200224 Seat Swivel Latch Switch (S18) Short to Ground

001714.04 342200224 Seat Position Front Switch (S17) Short to Ground

001714.07 342200224 Seat Position Rear Switch (S16) and Seat Position Front Switch (S17) Logic Mismatch

001714.10 342200224 Seat Position Front Switch (S17) Short Circuit to Power or Stuck Closed

001715.04 342200224 Seat Position Rear Switch (S16) Short to Ground

002000.09 342200224 CAN Communication Lost with ECU

002023.09 342200224 CAN Communication Lost with SDM

002228.09 342200224 CAN Communication Lost with FHC

002368.12 342200224 Left Turn Signal Driver Output Fault

002370.12 342200224 Right Turn Signal Driver Output Fault

002580.07 342200224 Service Brake Pressure Switch Status Error

002605.12 342200224 Brake Charge Solenoid (Y59) Circuit Fault

002875.04 342200224 4-Way Flasher Switch (S31) Input Short to Ground

002876.12 342200224 Conflicting Turn Signal Switch (S30) Data

003413.04 342200224 Right Door Switch (S99) Input Short to Ground

003416.03 342200224 Right Exit Switch (S99) Circuits Short to Power

003416.04 342200224 Right Exit Switch (S99) Circuits Short to Ground

003416.05 342200224 Right Exit Switch (S99) Open Circuit

298816.14 342200224 Park Brake Did Not Apply When Commanded

522371.04 342200224 FLC Valve Power #5 Voltage Low

522379.12 342200224 Park Brake Release Solenoid (Y7) Fault

522398.14 342200224 Park Brake Did Not Release When Commanded

522411.03 342200224 TCL_Range Switch (S5) Input Voltage High

522411.04 342200224 TCL_Range Switch (S5) Input Voltage Low

522411.05 342200224 TCL_Range Switch (S5) TCL Input Open Circuit

523218.03 342200224 FLC Valve Power #2 Output Stuck ON

523218.04 342200224 FLC Valve Power #2 Output Stuck OFF

523218.05 342200224 FLC Valve Power #2 Output Voltage Low

523219.04 342200224 FLC Valve Power #1 Voltage Low

523702.02 342200224 Flex Power Status Erratic

523702.07 342200224 Flex Power Not Active

523702.08 342200224 Flex Power Time Out

523702.09 342200224 Flex Power ECU Authentication Error

523702.10 342200224 Flex Power Watch Dog Error

523702.13 342200224 Flex Power Mismatch

523911.12 342200224 Hydraulic Pump Control Solenoid (Y56) Fault

523948.12 342200224 Ride Control Solenoid 1 (Y50) or 2 (Y51) Fault

524070.04 342200224 Valve Power # 6 Voltage Low

524075.04 342200224 Valve Power # 5 Voltage Low

524172.00 342200224 Clutch Disconnect Switch Stuck Closed

524172.04 342200224 Switch Short to Ground

524172.07 342200224 Clutch Disconnect Device Fault

524235.12 342200224 MFWD Solenoid (Y11) Output Fault

Flex Load Controller (FLC) Diagnostic Trouble Codes

030 - Standard Display Monitor (SDM) Diagnostic Trouble Codes

000096.03 342200224 Fuel Level Sensor (B8) Input Voltage Low

000096.04 342200224 Fuel Level Sensor (B8) Input Voltage High

000100.01 342200224 Engine Oil Pressure Low

000100.05 342200224 Engine Oil Pressure Switch Open

000107.00 342200224 Engine Air Filter Restricted

000117.01 342200224 Service Brake Pressure Low

000158.00 342200224 System Voltage High

000158.01 342200224 System Voltage Low

000177.00 342200224 Torque Converter Oil Temperature High

000177.03 342200224 Torque Converter Oil Temperature Sensor (B6) Input Voltage High

000177.04 342200224 Torque Converter Oil Temperature Sensor (B6) Input Voltage Low

000234.02 342200224 Software Revision Mismatch

000629.02 342200224 No CAN from ECU

000920.03 342200224 SDM Alarm (H2) Output Voltage High

000920.04 342200224 SDM Alarm (H2) Output Voltage Low

001196.11 342200224 Antitheft Lock Status Not Detected From ECU

001201.11 342200224 Antitheft Unlock Status Not Detected From ECU

001508.00 342200224 Hydraulic Oil Temperature Moderately High

001508.03 342200224 Hydraulic Oil Temperature Sensor (B10) Input Voltage High

001508.04 342200224 Hydraulic Oil Temperature Sensor (B10) Input Voltage Low

001508.16 342200224 Hydraulic Oil Temperature High

001713.00 342200224 Hydraulic Oil Filter Restricted

002000.09 342200224 CAN Communication Lost with ECU

002000.12 342200224 No CAN from ECU

002003.09 342200224 CAN Communication Lost with FLC

002071.09 342200224 CAN Communication Lost with Other Controller

002228.09 342200224 CAN Communication Lost with FHC

298887.13 342200224 SDM_ECU Model Number Mismatch

523569.04 342200224 FLC Switched and_or Unswitched Power Open Circuit

523649.04 342200224 CAN Communication Lost with Hydraulic Controllers

523650.04 342200224 CAN Communication Lost with FHC

523653.04 342200224 Gear Selection_Transmission Direction Circuit Voltages Low

523662.04 342200224 FHC Valve Power Circuit Voltages Low

523665.04 342200224 FLC Valve Power 1 Input Voltage Low

523666.04 342200224 FLC Switched Power Voltage Open Circuit

Standard Display Monitor (SDM) Diagnostic Trouble Codes

040 - Flex Hydraulic Controller (FHC) Diagnostic Trouble Codes

000234.02 342200224 Software Revision Mismatch

000237.02 342200224 Model Number in Vehicle Identification Number Not Valid

000629.12 342200224 FHC Watchdog Timeout

000630.13 342200224 Loader Boom Position Sensor (B73) and Bucket Postion Sensor (B75) Calibration Required

001764.07 342200224 Hydraulic Enable Switch (S70) Logic Error

001903.13 342200224 Invalid Calibration Data Received from ISP for Left Stabilizer Raise Solenoid

001910.13 342200224 Invalid Calibration Data Received from ISP for Left Stabilizer Lower Solenoid

001927.13 342200224 Invalid Calibration Data Received from ISP for Right Stabilizer Raise Solenoid

001951.13 342200224 Invalid Calibration Data Received from ISP for Right Stabilizer Lower Solenoid

001963.13 342200224 Invalid Calibration Data Received from ISP for Loader Auxiliary Positive Solenoid

001975.13 342200224 Invalid Calibration Data Received from ISP for Loader Auxiliary Reverse Solenoid

001987.13 342200224 Invalid Calibration Data Received from ISP for Backhoe Auxiliary Positive Solenoid

001999.13 342200224 Invalid Calibration Data Received from ISP for Backhoe Auxiliary Reverse Solenoid

002140.09 342200224 CAN Communication Lost between the FHC and Other Controllers

002160.09 342200224 No CAN from ISP

002161.09 342200224 No CAN from SWX

002162.09 342200224 No CAN from BOM

002163.09 342200224 No CAN from CWD

002164.09 342200224 No CAN from BUK

002165.09 342200224 No CAN from HAM

002201.09 342200224 No CAN from JSL

002213.09 342200224 No CAN from JSR

002267.13 342200224 Invalid Calibration Data Received from ISP for Loader Boom Lower Solenoid

002279.13 342200224 Invalid Calibration Data Received from ISP for Loader Boom Raise Solenoid

002291.13 342200224 Invalid Calibration Data Received from ISP for Loader Bucket Dump Currents

002303.13 342200224 Invalid Calibration Data Received from ISP for Loader Bucket Curl Solenoid

002660.07 342200224 Right Joystick X-Axis Logic Error

002661.07 342200224 Right Joystick Y-Axis Logic Error

002662.07 342200224 Secondary Loader Joystick (S80) X-Axis Logic Error

002663.07 342200224 Secondary Loader Joystick (S80) Y-Axis Logic Error

002664.07 342200224 Loader Auxiliary Hydraulics Control Logic Error

002697.07 342200224 Left Joystick X-Axis Logic Error

002698.07 342200224 Left Joystick Y-Axis Logic Error

002699.07 342200224 Left Joystick Auxiliary Control Switch (S81) Logic Error

002700.07 342200224 Outer Stabilizer Control Switch (S72) Logic Error

002701.07 342200224 Inner Stabilizer Control Switch (S71) Logic Error

002724.07 342200224 Left Joystick Rocker Switch (S95) Logic Error

002858.07 342200224 FHC Unable to Retrieve Stabilizer Valve Data From ISP

002858.08 342200224 FHC Unable to Retrieve Stabilizer Valve Data From ISP

002858.13 342200224 FHC Unable to Retrieve Stabilizer Valve Data From ISP

522372.04 342200224 Loader Advanced Features Sensor Fault

522372.07 342200224 Loader Boom Position Sensor Error

522377.03 342200224 Loader Boom Position Sensor (B73) Input #1 Voltage High

522377.04 342200224 Loader Boom Position Sensor (B73) Input #1 Voltage Low

522377.12 342200224 Loader Boom Position Sensor (B73) Logic Error

522377.13 342200224 Loader Boom Position Sensor (B73) Invalid Calibration

522378.03 342200224 Loader Boom Position Sensor (B73) Input #2 Voltage High

522378.04 342200224 Loader Boom Position Sensor (B73) Input #2 Voltage Low

522436.03 342200224 Loader Bucket Position Sensor (B75) Input #1 Voltage High

522436.04 342200224 Loader Bucket Position Sensor (B75) Input #1 Voltage Low

522436.12 342200224 Loader Bucket Position Sensor (B75) Logic Error

522436.13 342200224 Loader Bucket Position Sensor (B75) Invalid Calibration

522437.03 342200224 Loader Bucket Position Sensor (B75) Input #2 Voltage High

522437.04 342200224 Loader Bucket Position Sensor (B75) Input #2 Voltage Low

522438.07 342200224 Loader Bucket Position Sensor Error

523216.04 342200224 Valve Power # 4 Voltage Low

523217.04 342200224 Valve Power # 3 Voltage Low

523218.04 342200224 Valve Power # 2 Voltage Low

523219.04 342200224 Valve Power # 1 Voltage Low

523395.00 342200224 Backhoe Swing Calibration System Pressure Not Detected

523395.01 342200224 Backhoe Swing Calibration Stall Pressure Low

523396.00 342200224 Right Stabilizer Calibration System Pressure High

523396.01 342200224 Right Stabilizer Calibration Stall Pressure Low

523397.00 342200224 Backhoe Auxiliary Calibration System Pressure High

523397.01 342200224 Backhoe Auxiliary Calibration Stall Pressure Low

523400.00 342200224 Backhoe Extend Calibration System Pressure Not Detected

523400.01 342200224 Backhoe Extend Calibration Stall Pressure Low

523401.00 342200224 Bucket Calibration System Pressure High

523401.01 342200224 Bucket Calibration Stall Pressure Low

523402.00 342200224 Boom Calibration System Pressure High

523402.01 342200224 Boom Calibration Stall Pressure Low

523403.00 342200224 Left Stabilizer Calibration System Pressure High

523403.01 342200224 Left Stabilizer Calibration Stall Pressure Low

523404.00 342200224 Loader Auxiliary Calibration System Pressure High

523404.01 342200224 Loader Auxiliary Calibration Stall Pressure Low

523705.03 342200224 Hydraulic Valve Power Stuck ON

523705.04 342200224 Hydraulic Valve Power Failure

523705.05 342200224 Hydraulic Valve Power Stuck OFF

523930.05 342200224 Loader Boom Magnitude Solenoid (Y73) Output Voltage Low

523930.06 342200224 Loader Boom Magnitude Solenoid (Y73) Output Voltage High

523931.05 342200224 Loader Boom Direction Solenoid (Y74) Output Voltage Low

523931.06 342200224 Loader Boom Direction Solenoid (Y74) Output Voltage High

523932.05 342200224 Loader Bucket Magnitude Solenoid (Y75) Output Voltage Low

523932.06 342200224 Loader Bucket Magnitude Solenoid (Y75) Output Voltage High

523933.05 342200224 Loader Bucket Direction Solenoid (Y76) Output Voltage Low

523933.06 342200224 Loader Bucket Direction Solenoid (Y76) Output Voltage High

523934.05 342200224 Left Stabilizer Raise Solenoid (Y78) Output Voltage Low

523934.06 342200224 Left Stabilizer Raise Solenoid (Y78) Output Voltage High

523935.05 342200224 Left Stabilizer Lower Solenoid (Y77) Output Voltage Low

523935.06 342200224 Left Stabilizer Lower Solenoid (Y77) Output Voltage High

523936.05 342200224 Right Stabilizer Raise Solenoid (Y80) Output Voltage Low

523936.06 342200224 Right Stabilizer Raise Solenoid (Y80) Output Voltage High

523937.05 342200224 Right Stabilizer Lower Solenoid (Y79) Output Voltage Low

523937.06 342200224 Right Stabilizer Lower Solenoid (Y79) Output Voltage High

523938.05 342200224 Loader Auxiliary Function Magnitude Solenoid (Y71) Output Voltage Low

523938.06 342200224 Loader Auxiliary Function Magnitude Solenoid (Y71) Output Voltage High

523939.05 342200224 Loader Auxiliary Function Direction Solenoid (Y72) Output Voltage Low

523940.05 342200224 Backhoe Auxiliary Function Magnitude Solenoid (Y81) Output Voltage Low

523940.06 342200224 Backhoe Auxiliary Function Magnitude Solenoid (Y81) Output Voltage High

523941.05 342200224 Backhoe Auxiliary Function Direction Solenoid (Y82) Output Voltage Low

523941.06 342200224 Backhoe Auxiliary Function Direction Solenoid (Y82) Output Voltage High

Flex Hydraulic Controller (FHC) Diagnostic Trouble Codes

050 - Intelligent System Planner (ISP) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Coil 1 Open Circuit or Short to Ground

000701.06 342200224 Coil 1 Short to Power

000702.05 342200224 Coil 2 Open Circuit or Short to Ground

000702.06 342200224 Coil 2 Short to Power

000703.05 342200224 Coil 3 Open Circuit or Short to Ground

000703.06 342200224 Coil 3 Short to Power

000704.05 342200224 Coil 4 Open Circuit or Short to Ground

000704.06 342200224 Coil 4 Short to Power

000709.03 342200224 Hydraulic Load Sense Pressure Sensor (B91) Open or Short Circuit

000709.04 342200224 Hydraulic Load Sense Pressure Sensor (B91) Short to Ground

000709.15 342200224 Hydraulic Load Sense Pressure Out of Range High

000710.03 342200224 Hydraulic System Pressure Sensor (B90) Open or Short Circuit

000710.04 342200224 Hydraulic System Pressure Sensor (B90) Short to Ground

000710.15 342200224 Hydraulic System Pressure Out of Range High

000711.02 342200224 ISP Temperature Sensors Out of Range

000711.03 342200224 Hydraulic Load Sense Temperature Sensor Open or Short Circuit

000711.04 342200224 Hydraulic Load Sense Temperature Sensor Short to Ground

000711.15 342200224 Hydraulic Load Sense Temperature High

000711.16 342200224 Hydraulic Load Sense Temperature Moderately High

000712.02 342200224 Intelligent System Planner (ISP) Temperature Sensors Out of Range

000712.03 342200224 Hydraulic System Temperature Sensor Open or Short Circuit

000712.04 342200224 Hydraulic System Temperature Sensor Short to Ground

000712.15 342200224 Hydraulic System Temperature High

000712.16 342200224 Hydraulic System Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

Intelligent System Planner (ISP) Diagnostic Trouble Codes

060 - Left Joystick Controller (JSL) Diagnostic Trouble Codes

000444.01 342200224 Input Voltage Low

001043.02 342200224 Reference Voltage Out of Tolerance

002697.02 342200224 X- or Y-Axis Sensors Conflict

002697.03 342200224 Left X-Axis Sensor Voltage High

002697.04 342200224 Left X-Axis Sensor Voltage Low

002697.13 342200224 No Calibration File for Left Joystick

002697.14 342200224 X-Axis Sensor Redundancy Error

002698.02 342200224 X- or Y-Axis Sensors Conflict

002698.03 342200224 Left Y-Axis Sensor Voltage High

002698.04 342200224 Left Y-Axis Sensor Voltage Low

002698.14 342200224 Left Y-Axis Sensor Redundancy Error

002699.03 342200224 Left Joystick Auxiliary Control Switch (S81) Voltage High

002699.04 342200224 Left Joystick Auxiliary Control Switch (S81) Voltage Low

002699.13 342200224 Left Joystick Auxiliary Control Switch (S81) Out of Neutral at Start Up

002699.14 342200224 Left Joystick Auxiliary Control Switch (S81) Redundancy Error

002700.03 342200224 Outer Stabilizer Control Switch (S72) Input Voltage High

002700.04 342200224 Outer Stabilizer Control Switch (S72) Input Voltage Low

002700.13 342200224 Outer Stabilizer Control Switch (S72) Not in Neutral at Start Up

002700.14 342200224 Outer Stabilizer Control Switch (S72) Input Redundancy Error

002701.03 342200224 Inner Stabilizer Control Switch (S71) Input Voltage High

002701.04 342200224 Inner Stabilizer Control Switch (S71) Input Voltage Low

002701.13 342200224 Inner Stabilizer Control Switch (S71) Not in Neutral at Start Up

002701.14 342200224 Inner Stabilizer Control Switch (S71) Input Redundancy Error

003509.02 342200224 Supply Voltage Out of Tolerance

003510.02 342200224 Reference Voltage Out of Tolerance

522431.12 342200224 RAM Memory Check Failed

523438.12 342200224 Calibration Verification Failed

523455.12 342200224 Temperature Sensor 2 Communication Failure

524152.12 342200224 Flash Image Error

524259.00 342200224 Temperature Sensor Out of Range High

524259.01 342200224 Temperature Sensor Out of Range Low

524259.09 342200224 Temperature Sensor Communication Error

524259.12 342200224 Temperature Sensor 1 Communication Failure

524259.14 342200224 Temperature Sensor Data Mismatch

Left Joystick Controller (JSL) Diagnostic Trouble Codes

070 - Right Joystick Controller (JSR) Diagnostic Trouble Codes

000444.01 342200224 Input Voltage Low

001043.02 342200224 Reference Voltage Out of Tolerance

002660.02 342200224 X- or Y-Axis Sensors Conflict

002660.03 342200224 Right X-Axis Sensor Voltage High

002660.04 342200224 Right X-Axis Sensor Voltage Low

002660.13 342200224 No Calibration File for Right Joystick

002660.14 342200224 Right X-Axis Sensor Redundancy Error

002661.02 342200224 X- or Y-Axis Sensor Conflict

002661.03 342200224 Right Y-Axis Sensor Voltage High

002661.04 342200224 Right Y-Axis Sensor Voltage Low

002661.14 342200224 Right Y-Axis Sensor Redundancy Error

002662.03 342200224 Secondary Loader Joystick (S80) X-Axis Bucket Sensor Voltage High

002662.04 342200224 Secondary Loader Joystick (S80) X-Axis Bucket Sensor Voltage Low

002662.13 342200224 Secondary Loader Joystick (S80) X-Axis Bucket Sensor Out of Neutral at Start Up

002662.14 342200224 Secondary Loader Joystick (S80) X-Axis Bucket Sensor Redundancy Error

002663.03 342200224 Secondary Loader Joystick (S80) Y-Axis Boom Sensor Voltage High

002663.04 342200224 Secondary Loader Joystick (S80) Y-Axis Boom Sensor Voltage Low

002663.13 342200224 Secondary Loader Joystick (S80) Y-Axis Boom Sensor Out of Neutral at Start Up

002663.14 342200224 Secondary Loader Joystick (S80) Y-Axis Boom Sensor Redundancy Error

002664.03 342200224 Right Joystick Auxiliary Control Switch (S82) Voltage High

002664.04 342200224 Right Joystick Auxiliary Control Switch (S82) Voltage Low

002664.13 342200224 Right Joystick Auxiliary Control Switch (S82) Out of Neutral at Start Up

002664.14 342200224 Right Joystick Auxiliary Control Switch (S82) Redundancy Error

003509.02 342200224 Supply Voltage Out of Tolerance

003510.02 342200224 Reference Voltage Out of Tolerance

522431.12 342200224 RAM Memory Check Failed

523438.12 342200224 Calibration Verification Failed

523455.12 342200224 Temperature Sensor 2 Communication Failure

524152.12 342200224 Flash Image Error

524259.00 342200224 Temperature Sensor Out of Range High

524259.01 342200224 Temperature Sensor Out of Range Low

524259.09 342200224 Temperature Sensor Communication Error

524259.12 342200224 Temperature Sensor 1 Communication Failure

524259.14 342200224 Temperature Sensor Data Mismatch

Right Joystick Controller (JSR) Diagnostic Trouble Codes

080 - Sealed Switch Module (SSM) Diagnostic Trouble Codes

000629.12 342200224 SSM Watchdog Timeout

000639.09 342200224 No CAN Message

000639.12 342200224 CAN Message Lost

000639.13 342200224 CAN Warning Limit Exceeded

000639.19 342200224 CAN Bus Off

002033.09 342200224 CAN Communications Lost between the SSM and FHC

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

523523.10 342200224 Pattern Select Keypad Stuck

523524.10 342200224 Auxiliary Hydraulics Control Keypad Stuck

523525.10 342200224 Return-to-Dig Keypad Stuck

523526.10 342200224 Boom Height Kickout Keypad Stuck

523527.10 342200224 Return-to-Carry Keypad Stuck

523528.10 342200224 Parallel Lift Keypad Stuck

523529.10 342200224 Hydraulic Speed Mode Keypad Stuck

523530.10 342200224 Ride Control Keypad Stuck

523531.10 342200224 Beacon Light Keypad Stuck

523532.10 342200224 Keypad 7 Stuck

523533.10 342200224 Auto Idle Keypad Stuck

523534.10 342200224 Keypad 5 Stuck

523535.10 342200224 Keypad 4 Stuck

523536.10 342200224 Keypad 3 Stuck

523537.10 342200224 Keypad 2 Stuck

523538.10 342200224 Keypad 1 Stuck

523607.10 342200224 Override Mode Keypad Stuck

523608.10 342200224 Keypad 19 Stuck

523609.10 342200224 Keypad 18 Stuck

523610.10 342200224 Keypad 17 Stuck

Sealed Switch Module (SSM) Diagnostic Trouble Codes

090 - Boom Distributed Function Control Unit (BOM) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Coil 1 Open Circuit or Short to Ground

000701.06 342200224 Coil 1 Short to Power

000702.05 342200224 Coil 2 Open Circuit or Short to Ground

000702.06 342200224 Coil 2 Short to Power

000703.05 342200224 Coil 3 Open Circuit or Short to Ground

000703.06 342200224 Coil 3 Short to Power

000704.05 342200224 Coil 4 Open Circuit or Short to Ground

000704.06 342200224 Coil 4 Short to Power

000709.03 342200224 Boom Up Work Port Pressure Sensor (B92) Open or Short Circuit

000709.04 342200224 Boom Up Work Port Pressure Sensor (B92) Short to Ground

000709.15 342200224 Boom Up Work Port Pressure Out of Range High

000710.03 342200224 Boom Down Work Port Pressure Sensor (B93) Open or Short Circuit

000710.04 342200224 Boom Down Work Port Pressure Sensor (B93) Short to Ground

000710.15 342200224 Boom Down Work Port Pressure Out of Range High

000711.02 342200224 Boom Work Port Temperature Sensors Out of Range

000711.03 342200224 Boom Up Work Port Temperature Sensor Open or Short Circuit

000711.04 342200224 Boom Up Work Port Temperature Sensor Short to Ground

000711.15 342200224 Boom Up Work Port Temperature High

000711.16 342200224 Boom Up Work Port Temperature Moderately High

000712.02 342200224 Boom Work Port Temperature Sensors Out of Range

000712.03 342200224 Boom Down Work Port Temperature Sensor Open or Short Circuit

000712.04 342200224 Boom Down Work Port Temperature Sensor Short to Ground

000712.15 342200224 Boom Down Work Port Temperature High

000712.16 342200224 Boom Down Work Port Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

Boom Distributed Function Control Unit (BOM) Diagnostic Trouble Codes

100 - Bucket Distributed Function Control Unit (BUK) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Coil 1 Open Circuit or Short to Ground

000701.06 342200224 Coil 1 Short to Power

000702.05 342200224 Coil 2 Open Circuit or Short to Ground

000702.06 342200224 Coil 2 Short to Power

000703.05 342200224 Coil 3 Open Circuit or Short to Ground

000703.06 342200224 Coil 3 Short to Power

000704.05 342200224 Coil 4 Open Circuit or Short to Ground

000704.06 342200224 Coil 4 Short to Power

000709.03 342200224 Bucket Curl Work Port Pressure Sensor (B97) Open or Short Circuit

000709.04 342200224 Bucket Curl Work Port Pressure Sensor (B97) Short to Ground

000709.15 342200224 Bucket Curl Work Port Pressure Out of Range High

000710.03 342200224 Bucket Dump Work Port Pressure Sensor (B96) Open or Short Circuit

000710.04 342200224 Bucket Dump Work Port Pressure Sensor (B96) Short to Ground

000710.15 342200224 Bucket Dump Work Port Pressure Out of Range High

000711.02 342200224 Bucket Work Port Temperature Sensors Out of Range

000711.03 342200224 Bucket Curl Work Port Temperature Sensor Open or Short Circuit

000711.04 342200224 Bucket Curl Work Port Temperature Sensor Short to Ground

000711.15 342200224 Bucket Curl Work Port Temperature High

000711.16 342200224 Bucket Curl Work Port Temperature Moderately High

000712.02 342200224 Bucket Work Port Temperature Sensors Out of Range

000712.03 342200224 Bucket Dump Work Port Temperature Sensor Open or Short Circuit

000712.04 342200224 Bucket Dump Work Port Temperature Sensor Short to Ground

000712.15 342200224 Bucket Dump Work Port Temperature High

000712.16 342200224 Bucket Dump Work Port Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

Bucket Distributed Function Control Unit (BUK) Diagnostic Trouble Codes

110 - Crowd Distributed Function Control Unit (CWD) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Coil 1 Open Circuit or Short to Ground

000701.06 342200224 Coil 1 Short to Power

000702.05 342200224 Coil 2 Open Circuit or Short to Ground

000702.06 342200224 Coil 2 Short to Power

000703.05 342200224 Coil 3 Open Circuit or Short to Ground

000703.06 342200224 Coil 3 Short to Power

000704.05 342200224 Coil 4 Open Circuit or Short to Ground

000704.06 342200224 Coil 4 Short to Power

000709.03 342200224 Crowd Out Work Port Pressure Sensor (B93) Open or Short Circuit

000709.04 342200224 Crowd Out Work Port Pressure Sensor (B93) Short to Ground

000709.15 342200224 Crowd Out Work Port Pressure Out of Range High

000710.03 342200224 Crowd In Work Port Pressure Sensor (B94) Open or Short Circuit

000710.04 342200224 Crowd In Work Port Pressure Sensor (B94) Short to Ground

000710.15 342200224 Crowd In Work Port Pressure Out of Range High

000711.02 342200224 Crowd Work Port Temperature Sensors Out of Range

000711.03 342200224 Crowd Out Work Port Temperature Sensor Open or Short Circuit

000711.04 342200224 Crowd Out Work Port Temperature Sensor Short to Ground

000711.15 342200224 Crowd Out Work Port Temperature High

000711.16 342200224 Crowd Out Work Port Temperature Moderately High

000712.02 342200224 Crowd In Work Port Temperature Sensors Out of Range

000712.03 342200224 Crowd In Work Port Temperature Sensor Open or Short Circuit

000712.04 342200224 Crowd In Work Port Temperature Sensor Short to Ground

000712.15 342200224 Crowd In Work Port Temperature High

000712.16 342200224 Crowd In Work Port Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

Crowd Distributed Function Control Unit (CWD) Diagnostic Trouble Codes

120 - Flow Control Distributed Function Control Unit (HAM) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Coil 1 Open Circuit or Short to Ground

000701.06 342200224 Coil 1 Short to Power

000702.05 342200224 Coil 2 Open Circuit or Short to Ground

000702.06 342200224 Coil 2 Short to Power

000703.05 342200224 Coil 3 Open Circuit or Short to Ground

000703.06 342200224 Coil 3 Short to Power

000704.05 342200224 Coil 4 Open Circuit or Short to Ground

000704.06 342200224 Coil 4 Short to Power

000709.03 342200224 Flow Control Work Port Pressure Sensor (B98) Open or Short Circuit

000709.04 342200224 Flow Control Work Port Pressure Sensor (B98) Short to Ground

000709.15 342200224 Flow Control Work Port Pressure Out of Range High

000710.03 342200224 Flow Control System Pressure Sensor (B99) Open or Short Circuit

000710.04 342200224 Flow Control System Pressure Sensor (B99) Short to Ground

000710.15 342200224 Flow Control System Pressure Out of Range High

000711.02 342200224 Flow Control Work Port Temperature Sensors Out of Range

000711.03 342200224 Flow Control Work Port Temperature Sensor Open or Short Circuit

000711.04 342200224 Flow Control Work Port Temperature Sensor Short to Ground

000711.15 342200224 Flow Control Work Port Temperature High

000711.16 342200224 Flow Control Work Port Temperature Moderately High

000712.02 342200224 Flow Control Work Port Temperature Sensors Out of Range

000712.03 342200224 Flow Control System Temperature Sensor Open or Short Circuit

000712.04 342200224 Flow Control System Temperature Sensor Short to Ground

000712.15 342200224 Flow Control System Temperature High

000712.16 342200224 Flow Control System Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

Flow Control Distributed Function Control Unit (HAM) Diagnostic Trouble Codes

130 - Swing_Extend Distributed Function Control Unit (SWX) Diagnostic Trouble Codes

000158.00 342200224 Battery Voltage High

000158.17 342200224 Battery Voltage Low

000234.02 342200224 Software Revision Mismatch

000628.11 342200224 Program Failed Device Fault

000628.12 342200224 Program Failed Device Fault

000628.13 342200224 Program Failed Calibration Error

000628.2 342200224 Program Failed or Erratic Data

000701.05 342200224 Backhoe Swing Magnitude Solenoid (Y83) Open Circuit or Short to Ground

000701.06 342200224 Backhoe Swing Magnitude Solenoid (Y83) Short to Power

000702.05 342200224 Backhoe Swing Direction Solenoid (Y84) Open Circuit or Short to Ground

000702.06 342200224 Backhoe Swing Direction Solenoid (Y84) Short to Power

000703.05 342200224 Backhoe Extend Magnitude Solenoid (Y85) Open Circuit or Short to Ground

000703.06 342200224 Backhoe Extend Magnitude Solenoid (Y85) Short to Power

000704.05 342200224 Backhoe Extend Direction Solenoid (Y86) Open Circuit or Short to Ground

000704.06 342200224 Backhoe Extend Direction Solenoid (Y86) Short to Power

000709.03 342200224 Swing Right Work Port Pressure Sensor (B88) Open or Short Circuit

000709.04 342200224 Swing Right Work Port Pressure Sensor (B88) Short to Ground

000709.15 342200224 Swing Right Work Port Pressure Out of Range High

000710.03 342200224 Swing Left Work Port Pressure Sensor (B89) Open or Short Circuit

000710.04 342200224 Swing Left Work Port Pressure Sensor (B89) Short to Ground

000710.15 342200224 Swing Left Work Port Pressure Out of Range High

000711.02 342200224 Swing Work Port Temperature Sensors Out of Range

000711.03 342200224 Swing Right Work Port Temperature Sensor Open or Short Circuit

000711.04 342200224 Swing Right Work Port Temperature Sensor Short to Ground

000711.15 342200224 Swing Right Work Port Temperature High

000711.16 342200224 Swing Right Work Port Temperature Moderately High

000712.02 342200224 Swing Work Port Temperature Sensors Out of Range

000712.03 342200224 Swing Left Work Port Temperature Sensor Open or Short Circuit

000712.04 342200224 Swing Left Work Port Temperature Sensor Short to Ground

000712.15 342200224 Swing Left Work Port Temperature High

000712.16 342200224 Swing Left Work Port Temperature Moderately High

002839.02 342200224 Function Wiring Identification Invalid

002839.13 342200224 Backhoe Controller Mismatch

002839.14 342200224 Coil Short to Ground

05 - Theory of Operation

10 - System Operational Checks

15 - Diagnostic Information

20 - Adjustments

25 - Tests

Swing_Extend Distributed Function Control Unit (SWX) Diagnostic Trouble Codes

9005 - OPERATIONAL CHECKOUT PROCEDURE

10 - Operational Checkout Procedure

Operational Checkout Procedure

9010 - ENGINE

05 - Theory of Operation

Engine Cooling System

PowerTech E342204242 4.5L (4045) John Deere Engine

15 - Diagnostic Information

Engine Cooling System Component Location

Engine Fuel System Component Location

Engine Intake and Exhaust Component Location

PowerTech E342204242 4.5L (4045) John Deere Engine

20 - Adjustments

PowerTech E342204242 4.5L (4045) John Deere Engine

25 - Tests

Air in Fuel Test

Air Intake System Leakage Test

Engine Speed Check

Engine Thermostat Test

Fluid Sampling Procedure342200224If Equipped

Intake Manifold Pressure342200224Turbocharger Boost

PowerTech E342204242 4.5L (4045) John Deere Engine

Thermal Bypass Valve Test

9015 - ELECTRICAL SYSTEM

05 - System Information

Electrical Diagram Information

Electrical Schematic Symbols

10 - System Diagrams

Air Conditioning Harness (W16) Component Location

Air Conditioning Harness (W16) Wiring Diagram

Backhoe Boom Harness (W11) Component Location

Backhoe Boom Harness (W11) Wiring Diagram

Backhoe Crowd Harness (W12) Component Location

Backhoe Crowd Harness (W12) Wiring Diagram

Backhoe Flow Control Harness (W13) Component Location

Backhoe Flow Control Harness (W13) Wiring Diagram

Cab Harness (W10) Component Location

Cab Harness (W10) Wiring Diagram

Canopy (ROPS) Harness (W5) Component Location

Canopy (ROPS) Harness (W5) Wiring Diagram

Chassis Harness (W8) Component Location

Chassis Harness (W8) Wiring Diagram

Engine Harness (W7) Component Location

Engine Harness (W7) Wiring Diagram

Fuse and Relay Location and Specifications

JDLink342204242 System Functional Schematic342200224MIG_GTT

JDLink342204242 System Functional Schematic342200224MTG_SAT

JDLink342204242 System Harnesses Component Location342200224MIG_GTT

JDLink342204242 System Harnesses Component Location342200224MTG_SAT

JDLink342204242 System Wiring Diagrams342200224MIG_GTT

JDLinkTM System Wiring Diagrams342200224MTG_SAT

Loader Boom Harness (W6) Component Location

Loader Boom Harness (W6) Wiring Diagram

Loader Coupler Harness (W21, W22) Component Location

Loader Coupler Harness (W21, W22) Wiring Diagram

Radio Harness (W20) Component Location

Radio Harness (W20) Wiring Diagram

Ride Control Harness (W18) Component Location

Ride Control Harness (W18) Wiring Diagram

Roof Harness (W15) Component Location

Roof Harness (W15) Wiring Diagram

Seat Harness (W14) Component Location

Seat Harness (W14) Wiring Diagram

System Functional Schematic and Section Legend

System Functional Schematic, Wiring Diagram, and Component Location Legend

Transmission Harness (W9) Component Location

Transmission Harness (W9) Wiring Diagram

15 - Sub-System Diagnostics

Controller Area Network (CAN) Circuit Theory of Operation

Engine Control Unit (ECU) Circuit Theory of Operation

Flex Hydraulic Controller (FHC) Circuit Theory of Operation

Flex Load Controller (FLC) Circuit Theory of Operation

Intelligent System Planner (ISP) and Distributed Functions Circuit Theory of Operation

JDLink342204242 Circuit Theory of Operation342200224If Equipped

Joystick Controllers Circuit Theory of Operation

Standard Display Monitor (SDM) Circuit Theory of Operation

Starting and Charging Circuit Theory of Operation

16 - Monitor Operation

Anti-Theft Security System Configuration

Anti-Theft Security System Enable_Disable

Anti-Theft Security System Operation

Standard Display Monitor (SDM)342200224Clear Codes

Standard Display Monitor (SDM)342200224Diagnostics

Standard Display Monitor (SDM)342200224Hide_Unhide Main Menu

Standard Display Monitor (SDM)342200224Machine Calibration

Standard Display Monitor (SDM)342200224Machine Options

Standard Display Monitor (SDM)342200224Restore Monitor Defaults

Standard Display Monitor (SDM)342200224Service Menu

Standard Display Monitor (SDM)342200224Setting Hour Meter

20 - References

Alternator Test Procedure

Backhoe Swing Calibration

CINCH342204242 Connector Remove and Install

CINCH342204242 Contact Installation

CINCH342204242 CP Connector Remove and Install

CINCH342204242 CP Contact Installation

Controller Area Network (CAN) Circuit Test

Controller Area Network (CAN) Resistor Test

Crank Position Sensor Test

DEUTSCH302256 Connector Remove and Install

DEUTSCH302256 Contact Installation

Diagnostic Trouble Code (DTC) Monitor Messages

Electrical Component Specifications

Electro-Hydraulic Spool Valve Calibration

Flex Hydraulic Controller (FHC) Output Test

Flex Load Controller (FLC) Output Test

JDLink342204242 Connection Procedure342200224If Equipped

JDLink342204242 System Identification

Joystick Controller Disassemble and Assemble

Joystick Controller Remove and Install

Loader Boom and Bucket Sensor Calibration Procedure

Metri-Pack302256 Connector Remove and Install

Reading Diagnostic Trouble Codes (DTCs)

Register Section Control Number

Seat Position Switches Remove and Install

Service ADVISOR342204242 Connection Procedure

Solenoid Coil Test

Throttle Position Sensor Test

Transmission Control Circuit Test

Transmission Control Lever (TCL) Test

Transmission Solenoid Circuit Test

WEATHER PACK302256 Connector Remove and Install

WEATHER PACK302256 Contact Installation

Wire Harness Test

9020 - POWER TRAIN

05 - Theory of Operation

Clutch and Mechanical Front Wheel Drive (MFWD) Operation

Clutch Modulation Operation

Differential Lock Operation

Differential Operation

MFWD Differential Operation342200224Equal Traction342200224If Equipped

MFWD Differential Operation342200224Unequal Traction

MICO Power Boost Brake Valve342200224Both Pedals Applied, Engine Off Position

MICO Power Boost Brake Valve342200224Both Pedals Applied Position

MICO Power Boost Brake Valve342200224Neutral Position

MICO Power Boost Brake Valve342200224One Pedal Applied Position

Park Brake Operation

Power Shift Power Train Overview

Power Shift Transmission Clutch Engagement And Solenoids Activated

Power Shift Transmission Gear Flow

Service Brake Operation

Torque Converter Operation

Transmission Filter Operation

Transmission Pump Operation

15 - Diagnostic Information

Diagnose Transmission Malfunctions

Differential Lock Slips or Chatters When Engaged

Differential Lock Will Not Release

Excessive Power Train Noise

Hydraulic Circuit342200224Symbols

Machine Lacks Power or Moves Slow

No Differential Lock Operation

No Power to Mechanical Front Wheel Drive (MFWD)

No Power to One Wheel of Mechanical Front Wheel Drive (MFWD)

Park Brake Piston Leak

Park Brake Will Not Hold

Park Brake Will Not Release

Poor Service Brakes

Power Train Component Location

Power Train Schematic342200224First Forward Mechanical Front Wheel Drive (MFWD) Engaged

Power Train Schematic342200224First Reverse

Power Train Schematic342200224Fourth Forward

Power Train Schematic342200224Neutral

Rear Axle Overfilled With Oil

Service Brakes Chatter or Noisy

Service Brakes Will Not Release

Transmission Overheats

Transmission Slippage

20 - Adjustments

Brake Bleeding Procedure

Brake Pedal Adjustment

Park Brake Release for Towing

Steering Angle Check and Adjust

Toe-In Check and Adjust

Tracking Angle Check and Adjust

25 - Tests

Brake Valve Leakage Test

Clutch Pressure Test

Cooler In and Cooler Out Pressure Test

Differential Lock Pressure Test

Mechanical Front Wheel Drive (MFWD) Pressure Test

Park Brake Release Pressure Test

Power Shift Transmission Overall Test Connections, Ports, and Locations

Solenoid Circuit Leakage Test

Torque Converter-In Relief Valve Test

Torque Converter Stall Speed Test

Transmission Oil Sampling Procedure342200224If Equipped

Transmission Oil Warm-Up Procedure

Transmission Pump Flow Test

Transmission System Pressure Test

9025 - HYDRAULIC SYSTEM

05 - Theory of Operation

Attachment Coupler Hydraulic Operation

Backhoe Distributed Function Valve Assembly Theory of Operation342200224Boom Raise_Lower Operation

Backhoe Distributed Function Valve Assembly Theory of Operation342200224Bucket Curl_Dump Operation

Backhoe Distributed Function Valve Assembly Theory of Operation342200224Crowd In_Out Operation

Backhoe Distributed Function Valve Assembly Theory of Operation

Distributed Function Control Valve Operation342200224Flow Control Distributed Function Control Unit (HAM)

Distributed Function Valve Assembly Circuit Relief Valve Theory of Operation

Electro-Hydraulic Solenoid Logic

Electro-Hydraulic Spool Valve Anticavitation Valve and Plug Assembly Theory of Operation

Electro-Hydraulic Spool Valve Assembly Load Sense Isolator and Pressure Compensator Theory of Operation

Electro-Hydraulic Spool Valve Backhoe Extend Theory of Operation

Electro-Hydraulic Spool Valve Backhoe Stabilizer Valve Theory of Operation

Electro-Hydraulic Spool Valve Backhoe Swing Valve Theory of Operation

Electro-Hydraulic Spool Valve Direction and Magnitude Solenoids Theory of Operation

Electro-Hydraulic Spool Valve Loader Boom, Bucket, Loader Auxiliary and Backhoe Auxiliary Valves Theory of Operation

Electro-Hydraulic Spool Valve Mid-Inlet Theory of Operation

Electro-Hydraulic Spool Valve Relief Valve Theory of Operation

Electro-Hydraulic System Theory of Operation

Hydraulic Filter Operation

Hydraulic Pump Operation

Hydraulic Thumb Operation342200224If Equipped

Power Limiting Valve Operation

Ride Control Hydraulic Circuit Component Location and Valve Operation

Steering Valve Operation

15 - Diagnostic Information

All Backhoe Functions (Boom, Crowd, Bucket, Hammer) Fast

All Backhoe Functions (Boom, Crowd, Bucket, Hammer) Slow

All Functions Chatter

All Spool Valve Functions (Loader, Swing, Extend, Stabilizer) Too Fast

All Spool Valve Functions (Loader, Swing, Stabilizer, Auxiliary) Slow

Backhoe Boom Valve Noise342200224In Neutral

Backhoe Function Drift

Backhoe Functions Do Not Stop

Erratic (342200234Spongy342200235) Steering

Excessive Engine Pulldown (All Functions)

Excessive Engine Pulldown (Single Backhoe Function)

Excessive Pump Noise

Excessive Steering Wheel Turns To Steer Machine

Excessive Vibration of the Steering Wheel

Foaming Oil

Hard Steering

Hydraulic Oil Overheats

Hydraulic Pump Leaking

Hydraulic Schematic

Hydraulic System Component Location

Load Sense Regulation Valve

Low Hydraulic Power

Machine Turns in Opposite Direction

Machine Turns when Steering Valve is in Neutral

No Backhoe Functions

No Hydraulics

No Loader or Steering Hydraulics

No Response when Steering Wheel is Turned

No Spool Valve (Loader, Swing, Extend, Stabilizer, Auxiliary) Hydraulics

No Stabilizer Function

No Steering Hydraulics

No Swing Function

One Function Slow in Combined Operation (Backhoe Functions)

One Function Slow in Combined Operation (Spool Valve Functions)

Poor Centering of Steering Wheel (Wheels Continue to Move After Steering Wheel is Stopped)

Single Backhoe Function (Boom, Crowd, Bucket, Hammer) Fast

Single Backhoe Function (Boom, Crowd, Bucket, Hammer) Slow

Single Backhoe Function Chatter

Single Spool Valve Function (Loader, Auxiliary) Chatter

Single Spool Valve Function (Loader, Swing, Stabilizer, Auxiliary) Slow

Single Spool Valve Functions (Swing, Extend) Too Fast

Slow Steering Hydraulics

Spool Valve Function Only Moves in One Direction

Spool Valve Functions Do Not Stop

Spool Valve Function (Swing, Extend) Chatter

Steering Valve Does Not Return to Neutral

Steering Wheel Kickback

Steering Wheel Locks Up

Steering Wheel or Front Wheels Slowly Turn by Themselves When Using Backhoe or Loader

Steering Wheel Turns Apply Rear Axle Service Brakes

Steering Wheel Turns Freely With No Resistance or Action On Steered Wheels

Steering Wheel Turns With Slight Resistance and No Action On Steered Wheels

Swing Wag

Wander342200224Vehicle Will Not Stay in a Straight Line

20 - Adjustments

Pilot Control Manifold Valve Accumulator Discharge Procedure

Pilot Control Pressure Adjustment

Ride Control Accumulator Charge Check Procedure

Ride Control Accumulator Charge Procedure

Ride Control Accumulator Hydraulic Pressure Release Procedure

25 - Tests

Circuit Relief Valve Test With Remote Pump

Function Drift Test

Hydraulic Circuit Pressure Release

Hydraulic Cylinder Leakage Test

Hydraulic Oil Cooler Restriction Test

Hydraulic Oil Sampling Procedure342200224If Equipped

Hydraulic Oil Warmup Procedure

Hydraulic Pump Flow Test

Hydraulic Return Pressure Test

JT02156A Digital Pressure and Temperature Analyzer Kit Installation

Load Sense Relief Valve Pressure Test

Power Limiting Valve Test

Pump Load Sense Differential Pressure Test

Steering Cylinder Leakage Test

Steering System Leakage Test

9031 - HEATING AND AIR CONDITIONING

05 - Theory of Operation

Air Conditioning System Cycle Of Operation

15 - Diagnostic Information

Air Conditioner Does Not Cool Interior of Cab

Air Conditioner Runs Constantly, Too Cold

Air Conditioning System Does Not Operate

Heater Does Not Warm Interior of Cab

Heater System Does Not Operate

Interior Windows Continue to Fog

25 - Tests

Air Conditioning and Heater System Component Location

Air Conditioning Switch Test

Air Conditioning System Leak Test

Binary Pressure Switch Test

Blower Resistor Test

Blower Switch Test

Compressor Clutch Coil Test

Expansion Valve Operation Test

Freeze Control Switch Test

Heater Blower Motor Test

Operating Pressure Diagnostic Chart

Proper Refrigerant Handling

R134a Air Conditioning System Test

R134a Refrigerant Cautions

Refrigerant Hoses And Tubing Inspection

John Deere 310SJ, 410J Backhoe Loaders with TMC Operation & Test Service Manual (TM10852)