John Deere Hay and Forage Large Square Balers Models L330, L330C, L340, L340C Diagnosis and Repair Technical Service Manual (TM133219)

Complete Diagnostics and Repair manual with electrical wiring diagrams for John Deere Hay and Forage Large Square Balers Models L330, L330C, L340, and L340C, with technical information to maintain, diagnose, repair, and service like professional mechanics.

John Deere Hay and Forage Large Square Balers Models L330, L330C, L340, and L340C workshop Diagnosis Operation Test Service Repair Manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm133219 - John Deere Hay and Forage Large Square Balers Models L330, L330C, L340, L340C Diagnosis and Repair Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,847 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General

Safety

Specifications

General Information

Lubrication

Drive Train

Diagnosing Malfunctions

Drive Train Protection

Gear Case Repair

Driveline Repair

Auto Grease System

General Information

Diagnosing Malfunctions

Auto Grease Repair

Divider Blocks

Electrical System

Connector Repair

Electrical Schematics

Tests and Adjustments

Control Units and Power Distribution

ISOBUS Monitor

Wire Harness Routing

Sensors

Hydraulic System

General Information

Diagnosing Malfunctions

Hydraulic Functional Schematics

Valves, Pumps and Motors

Cylinders

Accumulators

Miscellaneous

Pickup and Rotor

General Information

Diagnosing Malfunctions

Pickup Repair

Rotor Repair

Precutter

General Information

Diagnosing Malfunctions

3x3 Pickup Precutter

3x4 Pickup Precutter

Feeding System

General Information

Diagnosing Malfunctions

Adjust Feeding System

Feeding System Repair

Bale Chamber

General Information

Diagnosing Malfunctions

Plunger

Tension Panels and Channels

Bale Chamber

Last Bale Ejection

Bale Chute

Tying System

General Information

Diagnosing Malfunctions

Knotter Repair

Knotter System Repair

Needle Repair

Replacing Brakes

Knotter Trip Mechanism

Adjusting Knotter

Adjusting Needles

Knotter Fan

Brakes and Suspension

General Information

Diagnosing Malfunctions

Hydraulic Brake System

Brake Components

Wheels, Axles, and Steering

Body Repair

Front Shield and Gull Wings Doors

Twine Boxes and Work Platforms

Fiberglass Repair

Dealer Fabricated Tools

Dealer Fabricated Tools

Electrical Component Information

Electrical Assemblies

Sensors

Lights

Fuses

Motors

Interconnects and Ground Points

Electronically Actuated Mechanical Devices

Hydraulic Component Information

Accumulator

Sensor or Gauge

Cylinder, Actuator, or Piston

Filter

Valve Block, Assembly, or Gear Case

Cooler

Motor

Orifice

Pump

Reservoir or Tank

Valve

Solenoid Valve

tm133219 - Large Square Balers

Table of Contents

Foreword

Section 10: General

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Handle Fluids Safely—Avoid Fires

Prepare for Emergencies

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Avoid High-Pressure Fluids

Wait Before Opening High-Pressure Fuel System

Maximum Hydraulic Operating Pressure

Service Accumulator Systems Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Follow Tire Recommendations

Service Tires Safely

Avoid Harmful Asbestos Dust

Practice Safe Maintenance

Use Proper Tools

Construct Dealer-Made Tools Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Servicing Electronic Control Units

Welding Near Electronic Control Units

Keep Electronic Control Unit Connectors Clean

Precautions for Welding

Protect Against High Pressure Spray

Live With Safety

Group 10: Specifications

Large Square Baler Specifications

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures

Face Seal Fittings Assembly and Installation—All Pressure Applications

Service Recommendations For 37° Flare and 30° Cone Seat Connectors

Tighten Bearing Locking Collars

Prevent Hydraulic System Contamination

Check Oil Lines and Fittings

Group 15: General Information

Specifications

Machine Description

Baler Serial Number Plate

Select Tractor PTO Speed

Adjust Baler Hitch

Adjust Tractor Drawbar

Transporting Large Square Baler Safely

Group 20: Lubrication

Other Material

Specifications

Lubricate and Maintain Machine Safely

Observe Service Intervals

Grease

Gear Oil

Use of Gear Oil

Hydraulic Oil

Use of Hydraulic Oil

Section 20: Drive Train

Group 10: Diagnosing Malfunctions

Diagnosing Driveline

Diagnosing Gear Case

Diagnosing Drive Chain

Group 15: Drive Train Protection

Other Material

Specifications

Remove and Install Friction and Automatic Overload Clutch

Friction and Automatic Overload Clutch Exploded View

Replace Flywheel Shear Bolt

Disassemble and Assemble Flywheel Shear Bolt Assembly

Friction Clutch Adjustment

Remove and Install Feeder Fork Drive Slip Clutch

Remove and Install Rotor Clutch

Remove and Install Pickup Clutch

Replace Needle Frame Drive Shear Bolts

Group 20: Gear Case Repair

Essential or Recommended Tools

Other Material

Specifications

Remove and Install Main Drive Gear Case

Remove and Install Feeder Fork Drive Gear Case

Disassemble and Assemble Feeder Fork Drive Gear Case

Feeder Fork Drive System Exploded View

Feeder Fork Gear Case Exploded View

Remove and Install Upper Knotter Gear Case

Disassemble and Assemble Upper Knotter Gear Case

Upper Knotter Gear Case Exploded View

Remove and Install Knotter Clutch Drive Lug

Remove and Install Knotter Clutch External Stop

Remove and Install 3x4 Lower Knotter Gear Case

Remove and Install 3x3 Lower Knotter Gear Case

Disassemble and Assemble Lower Knotter Gear Case

Lower Knotter Gear Case Exploded View

Group 30: Driveline Repair

Essential or Recommended Tools

Other Material

Specifications

Remove and Install PTO Driveline Pedestal Bearings

Remove and Install Flywheel

Remove and Install Flywheel Bearings

Remove and Install Main Drive Gear Case Drive Arms

Replace Flywheel Brake Belt

Remove and Install Rear Drive Shaft Bearing

Remove and Install Swinging Shaft

Remove and Install Swinging Shaft Roller Arms

3x4 Swinging Shaft Exploded View

Section 30: Auto Grease System

Group 05: General Information

Other Material

Automatic Grease System

Group 10: Diagnosing Malfunctions

Grease System Difficulties

Group 15: Auto Grease Repair

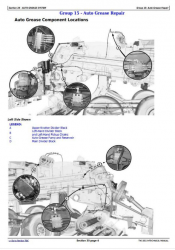

Auto Grease Component Locations

Auto-Grease Line Routing

Automatic Grease System Schematics

Remove and Install Pump Piston

Remove and Install Grease Pump Assembly

Priming Grease System

Bleeding Automatic Grease System Pump

Auto Grease System Blockage

Remove and Install Knotter Grease Line

Repair Low and High Pressure Grease Lines

Group 20: Divider Blocks

Other Material

Remove and Install Knotter Divider Blocks

Remove and Install Divider Blocks

Section 40: Electrical System

Group 05: Connector Repair

Essential or Recommended Tools

Other Material

Use Electrical Insulating Compound

Using High-Pressure Washers

Electrical System Visual Inspection

Basic Electrical Component Handling / Precautions for Vehicles Equipped with Computer Controlled Systems

Electrical Connector / Wiring Harness Handling and Repair

Installation of Repair Wire Assembly (RWA)

Repair Procedure R-A

Repair Procedure R-C

Repair Procedure R-D

Repair Procedure R-E

Repair Procedure R-F

Repair Procedure R-G

Repair Procedure R-I

Repair Procedure R-J

Repair Procedure R-AE

Repair Procedure R-AJ

Group 15: Electrical Schematics

Auto Greasing Electrical Schematic

Bale Accumulator (Optional) Electrical Schematic

Bale Quality Electrical Schematic

Drivetrain Electrical Schematic

Feeding System Electrical Schematic

ISOBUS - Power Supply Electrical Schematic

LED Work Lights (Optional) Electrical Schematic

Lighting Electrical Schematic

Tying System Electrical Schematic

ISOBUS Battery Wiring Schematic

ISOBUS Cab Wiring Schematic

Group 20: Tests and Adjustments

Service Equipment and Tools

Diagnostic Screens—ISOBUS Display

Sensors—Test Input Screens

Sensors—Test Output Screens

Calibrate Slack Arm Sensors—ISOBUS Display

Baler Settings—ISOBUS Display

Next VT Function

Advanced and Factory Settings—ISOBUS Display

Common Circuit Test

Welding on Baler Equipped with ISOBUS Display and Electrical Control Unit (ECU)

Group 25: Control Units and Power Distribution

Remove and Install Electronic Control Unit (ECU)

Programming Control Units—Service ADVISOR (Recommended)

Group 30: ISOBUS Monitor

Home Screen Layout

Remove and Install Display

ISOBUS Display Power Up

Install Display in a John Deere Vehicle with an ISOBUS Display

Baler Application Screen

Monitor Warning Screens

Default ISOBUS Display Settings

Group 35: Wire Harness Routing

Replace Harness

Wiring Diagram—Baler

Wiring Diagram—Lighting

Wiring Diagram—Main Gear Case and Load Pin

ISOBUS Battery Wiring Harness

ISOBUS Cab Wiring Harness

Group 40: Sensors

Essential or Recommended Tools

Other Material

Specifications

Sensor Locations

Remove and Install Main Gear Case Speed Sensor

Remove and Install Pressure Sensor

Remove and Install Greasing System Sensor

Remove and Install Bale Length Sensor

Remove and Install Bale Chute Sensor

Remove and Install Load Pin Sensors

Remove and Install Slack Arm Sensors

Remove and Install Lighting Enhancement Module

Section 50: Hydraulic System

Group 05: General Information

Avoid High-Pressure Fluids

Zero Pressure in System

Hydraulic Component Identification

Pickup and Jack Stand Selector Valve Operation

Auxiliary Valve Stack Control Operation

Steering Axle Lock Control Valve

Knife Control Valve Operation

Knife Drawer Control Valve Operation

Group 10: Diagnosing Malfunctions

Diagnosing Hydraulics

Group 15: Hydraulic Functional Schematics

Hydraulic Circuit Symbols

Auxiliary Hydraulics—3x3, 3x3C, and 3x4

Auxiliary Hydraulics—3x4C

Brake System (If Equipped)

Main Hydraulics—3x4C

Main Hydraulics—3x3 and 3x4

Main Hydraulics—3x3C

Precutter Hydraulics—3x4C

Tandem Steerable Axle Schematic

Group 20: Valves, Pumps and Motors

Specifications

Hydraulic Control Valve Component Identification

Hydraulic Control Valve Exploded View

Auxiliary Valve Component Identification

Knife Selector Control Valve Component Identification

Knife Selector Control Valve Exploded View

3x4C Knife Drawer Control Valve Component Identification and Location

3x3C Knife Control Valve Component Identification and Location

Remove and Install Knotter Fan Drive Motor

Remove and Install Hydraulic Pumps

Group 25: Cylinders

Specifications

Remove and Install Single Acting Jack Stand Cylinder

Repair Single Acting Jack Stand Cylinder

Remove and Install Pickup Lift Cylinders

Remove and Install 3x3 Knife Engagement Cylinder

Remove and Install 3x4C Pickup Knife Drawer Lift Cylinder

Remove and Install 3x4 Knife Cylinder

Remove and Install Tension Panel Cylinders

Remove and Install Hydraulic Brake Cylinder

Remove and Install Steering Lock Cylinders

Remove and Install Bale Eject Cylinder

Remove and Install Bale Chute Cylinder

Adjust Steering Lock Cylinders

Group 30: Accumulators

Essential or Recommended Tools

Specifications

Bleed 23-Knife Precutter Accumulators

Accumulator General Information

Checking Accumulator Pressure

Group 35: Miscellaneous

Specifications

Knotter Fan Hose Routing

Remove and Install Oil Coolers

Remove and Install Hydraulic Reservoir

Section 60: Pickup and Rotor

Group 05: General Information

Pickup and Rotor Description

Adjust Pickup Height

Adjust Pickup Float Springs

Adjust Roller Baffle

Group 10: Diagnosing Malfunctions

Diagnosing Crop Flow

Diagnosing Pickup

Group 15: Pickup Repair

Specifications

Gauge Wheels Exploded View

Adjust Pickup Chain Tension

Remove and Install Pickup Spring Tooth

Remove and Install Toothbar

Remove and Install Toothbar Bearings

Remove and Install Pickup

Remove and Install Pickup Clutch Stub Shaft Bearings

Remove and Install Roller Baffle and Compressor Rack

Remove and Install Roller Baffle Bearings

Remove and Install Pickup Cam and Reel

Remove and Install Reel Bearings

Remove and Install Cam Arms and Follower Bearings

Group 20: Rotor Repair

Other Material

Specifications

Rotor Exploded View

Remove and Install Rotor

Remove and Install Rotor Bearings

Remove and Install Rotor Tine Scraper

Rotor Drive Chain Tension Adjust

Section 70: Precutter

Group 05: General Information

Remove and Install 3x3 Precutter Knives

Remove and Install 3x4 Precutter Knives

Sharpen Knives

Group 10: Diagnosing Malfunctions

Diagnosing Precutter

Group 20: 3x3 Pickup Precutter

Remove and Install 3x3 Precutter

Remove and Install 3x3 Precutter Spring and Roller

Remove and Install 3x3 Precutter Knife Supports

Group 25: 3x4 Pickup Precutter

Remove and Install Knife Drawer

Remove and Install Knife Support Pivot Rod

Remove and Install Knife Drawer Wear Pads

Remove and Install Knife Drawer Bearings

Adjust Knife Slot Alignment

Remove and Install Knife Arm Pivot Rod

Section 80: Feeding System

Group 05: General Information

Feeder System Description

Bale Forming

Clearing Debris from Precompression Chamber

Group 10: Diagnosing Malfunctions

Diagnosing Packer System

Group 20: Adjust Feeding System

Specifications

Check Feeder Fork Timing

Adjust Feeder Fork Timing

Locking Pin Adjustment

Check and Adjust Hook Synchronization

Check and Adjust Hook Lifting Mechanism

Check and Repair Hook Lift Mechanism for Wear

Precompression Chamber Density Adjustment

Group 25: Feeding System Repair

Other Material

Specifications

Hook Lifting Mechanism Exploded View

Swinging Shaft Exploded View

Feeder Hook Mechanism Exploded View

Locking Pin Exploded View

Remove and Install Feeder Arms and Feeder Fork

Remove and Install Feeder Fork Locking Mechanism

Remove and Install Measuring Plate Shaft

1:1 Lever and Linkage Exploded View

Remove and Install Short and Long Crank Arms

Remove and Install Precompression Chamber Door

Section 90: Bale Chamber

Group 05: General Information

Plunger and Bale Chamber Component Identification and Location

Group 10: Diagnosing Malfunctions

Diagnosing Baling

Diagnosing Plunger

Diagnosing Last Bale Ejector

Group 15: Plunger

Essential or Recommended Tools

Other Material

Specifications

Remove and Install Plunger

Knife Adjustment

Remove and Install Plunger Roller

Replace Plunger Roller Bearing

Roller Scraper Adjustment

Plunger Rollers, Scrapers, and Track Exploded View

Plunger Scraper Adjustment

Roller Adjustment

Guide Block Adjustment

Group 20: Tension Panels and Channels

Specifications

Remove and Install Upper Tension Beam

Remove and Install Side Tension Panels

Remove and Install Star Wheel Bearings

Group 25: Bale Chamber

Other Material

Specifications

Remove and Install Removable Hay Dogs

Remove and Install Plunger Hay Dogs

Remove and Install Counter Knife

Group 30: Last Bale Ejection

Specifications

Remove and Install Sliding Block

Remove and Install Ejector Tooth

Adjust Bale Ejector

Remove and Install Bale Ejector Hook Plate Bushing

Group 35: Bale Chute

Remove and Install Roller Bale Chute

Remove and Install Bale Chute Roller

Remove and Install Bale Chute Roller Bearing

Section 100: Tying System

Group 05: General Information

Tying System Inspection

Knotter Table Component Identification and Location

Knotter Component Identification and Location

Knotter Theory of Operation

Adjust Upper and Lower Twine Tension

Group 10: Diagnosing Malfunctions

Diagnosing Knotter

Diagnosing Knotter Clutch

Diagnosing Needles

Diagnosing Mis-Ties

Group 15: Knotter Repair

Other Material

Specifications

Knotter Exploded Views

Remove and Install Knotter

Replace Twine Knife and Wiper Plate

Remove and Install Wiper Arm Assembly

Remove and Install Twine Disk Spindle Assembly

Remove and Install Twine Disk Assembly

Remove and Install Intermittent Gear

Remove and Install Billhook Pressure Arm and Spring

Remove and Install Billhook Assembly

Group 20: Knotter System Repair

Other Material

Specifications

Remove and Install Tucker Finger Shaft and Bearings

Remove and Install Twine Placement Hex Shaft and Bearings

Remove and Install Twine Placement Arm and Needle Roller

Remove and Install Upper Slack Arm

Remove and Install Lower Slack Arm

Replace Slack Arm Needle Roller and Bushings

Remove and Install Twine Tension Gears

Adjust Upper and Lower Slack Arm Tension

Remove and Install Knotter Shaft Bearing

Remove and Install Knotter Shaft

Remove and Install Twine Placement and Tucker Finger Cams and Hub

Remove and Install Tucker Finger and Bearing

Remove and Install Tucker Finger Link

Tucker Finger Plate and Link Adjust

Replace Knotter Cam Follower Bearings

Remove and Install Hay Dog

Remove and Install Twine Guide

Group 25: Needle Repair

Other Material

Specifications

Remove and Install Needle

Remove and Install Needle Rollers

Remove and Install Needle Frame Bearings

Group 30: Replacing Brakes

Specifications

Remove and Install Knotter Shaft Brake

Adjust Knotter Shaft Brake

Group 35: Knotter Trip Mechanism

Other Material

Specifications

Remove and Install Knotter Clutch

Knotter Clutch Trip Arm Exploded View

Remove and Install Crank and Rocker Arm

Disassemble and Assemble Crank and Rocker Arm

Disassemble and Assemble Sector Arm, Wheel, and Linkage

Adjust Knotter Clutch

Group 40: Adjusting Knotter

Specifications

Wiper Arm Adjust

Wiper Plate Adjust

Twine Disk Timing

Twine Holder Pressure

Billhook Tongue Pressure Setting

Intermittent Gear Clearance Adjustment

Adjust Knotter Assembly to Intermittent Gear

Group 45: Adjusting Needles

Specifications

Place Needles in Top Dead Center Position

Adjust Needles to Knotter Frame

Adjust Needles to Plunger Timing

Group 50: Knotter Fan

Remove and Install Knotter Fan Shaft Bearings

Section 110: Brakes and Suspension

Group 05: General Information

Hydraulic Brake System

Steering Axle

Group 10: Diagnosing Malfunctions

Diagnosing Brake System

Diagnosing Brake Drum

Group 20: Hydraulic Brake System

Specifications

Remove and Install Parking and Emergency Brake Lever Assembly

Remove and Install Parking and Emergency Brake Tension Cable

Adjust Parking and Emergency Brake Cable

Hydraulic Brake Hose Routing

Bleed Hydraulic Brake System

Adjust Hydraulic Brakes

Group 25: Brake Components

Other Material

Specifications

Inspect Brake Drum, Brake Shoes, and Brake Linings

Remove and Install Brake Shoes

Remove and Install Brake Cam Shaft

Remove and Install Slack Arm Adjuster

Group 30: Wheels, Axles, and Steering

Other Material

Specifications

Tire Recommendations

Tire Size and Inflation Pressure Information

Remove and Install Wheels

Replace and Lubricate Wheel Bearings

Check and Adjust Wheel Bearing Play

Steering Axle Exploded View

Check and Adjust Steering Axle Alignment

Remove and Install Steering Stabilizer (Tandem Axle Only)

Remove and Install Kingpin

Check and Adjust Kingpin Clearance

Remove and Install Tie Rod (Tandem Axle Only)

Section 120: Body Repair

Group 10: Front Shield and Gull Wings Doors

Remove and Install Gull Wing Doors and Front Shield

Group 20: Twine Boxes and Work Platforms

Remove and Install Ladder

Remove and Install Twine Boxes

Remove and Install Twine Box Rollers

Remove and Install Twine Box Skid Plates

Group 30: Fiberglass Repair

General Information and Materials

Repair Surface Scratches and Gouges

Preparing Backing Patch

Using Backing Patch

Repair Small Cracks

Repair Small Fractures

Repair Large Fractures

Finishing Surface

Section 199: Dealer Fabricated Tools

Group 05: Dealer Fabricated Tools

DFEXT6—Main Gear Case Straps

DFEXT7—Load Pin Extractor and Installer

DFEXT8—Feeder Fork Gear Case Shaft Extractor

DFEXT9—Plunger Roller Extractor

Section 211: Diagnostic Trouble Codes

Group 00: Diagnostic Trouble Codes

General Information

Group 10A: Large Square Baler

LSB 168.16 - Battery Voltage Too High

LSB 168.18 - Battery Voltage Too Low

LSB 191.08 - Feeder Forks Plugged

LSB 3025.03 - Greasing System Motor Short to Battery

LSB 3025.04 - Electrical Greasing Motor Is Shorted to Ground

LSB 3025.05 - Electrical Greasing Motor Open Load

LSB 3509.03 - Sensor Supply Voltage Too High

LSB 3509.04 - Sensor Supply Voltage Too Low

LSB 3755.07 - Feeding System Plugged

LSB 3766.07 - Electrical Tie Motor Not Starting

LSB 3778.07 - Precutter Knives Not Engaged

LSB 3778.07 - Precutter Knives Not Disengaged

LSB 3778.14 - Unexpected Movement of Knives from the Previous State

LSB 3779.15 - Oversize Bale

LSB 516254.03 - Pressure Selector Valve (Y1) Short

LSB 516254.04 - Pressure Selector Valve (Y1) Short

LSB 516254.05 - Pressure Selector Valve (Y1) Open Load

LSB 516429.14 - Feeder Fork Continuously Feeding

LSB 516430.06 - Bale Drop Sensor Malfunction

LSB 516464.03 - Tension Panel Pressure Lock Valve (Y7) Short to Battery

LSB 516464.04 - Tension Panel Pressure Lock Valve (Y7) Short to Ground

LSB 516464.05 - Tension Panel Pressure Lock Valve (Y7) Open Load

LSB 516863.02 - Bale Length Sensor Channel Failure

LSB 516864.02 - Plunger Pressure Decreased

LSB 516864.02 - Plunger Home Sensor Is Not Working

LSB 516865.13 - Maximum Machine Load Reduced (Right-Hand Side)

LSB 516865.14 - Maximum Machine Load Reduced (Right-Hand Side)

LSB 516866.14 - Tension System Pressure Over Limit

LSB 516867.05 - Tension Panel Pressure Sensor Short

LSB 516868.05 - Feeder Forks Not Filling

LSB 516868.14 - Feeder Fork Sensor Always Active

LSB 516870.02 - Bale Length Sensor Not Working

LSB 516871.03 - Precutter Knives Actuator Valve (Y6) Short

LSB 516871.04 - Precutter Knives Actuator Valve (Y6) Short

LSB 516871.05 - Precutter Knives Actuator Valve (Y6) Open Load

LSB 516872.14 - Flywheel Brake Engaged

LSB 516873.11 - Gear Case Speed Sensor Fails

LSB 516874.11 - Knotter Cycling Continuously

LSB 516875.03 - Right Knotter Light Does Not Illuminate

LSB 516875.04 - Right Knotter Light Does Not Illuminate

LSB 516875.05 - Right Knotter Light Does Not Illuminate

LSB 516876.03 - Needle Light Does Not Illuminate

LSB 516876.04 - Needle Light Does Not Illuminate

LSB 516876.05 - Needle Light Does Not Illuminate

LSB 516877.03 - Right Gull Wing Door Does Not Illuminate

LSB 516877.04 - Right Gull Wing Door Does Not Illuminate

LSB 516877.05 - Right Gull Wing Door Does Not Illuminate

LSB 516878.03 - Left Knotter Light Does Not Illuminate

LSB 516878.04 - Left Knotter Light Does Not Illuminate

LSB 516878.05 - Left Knotter Light Does Not Illuminate

LSB 516879.03 - Left Gull Wing Door Does Not Illuminate

LSB 516879.04 - Left Gull Wing Door Does Not Illuminate

LSB 516879.05 - Left Gull Wing Door Does Not Illuminate

LSB 516913.13 - Maximum Machine Load Reduced (Left-Hand Side)

LSB 516913.14 - Maximum Machine Load Reduced (Left-Hand Side)

LSB 516914.03 - Precutter Knives Disengage Actuator Not Functioning

LSB 516914.04 - Precutter Knives Disengage Actuator Not Functioning

LSB 516914.05 - Precutter Knives Disengage Actuator Not Functioning

LSB 516915.03 - Precutter Knives Engage Actuator Not Functioning

LSB 516915.04 - Precutter Knives Engage Actuator Not Functioning

LSB 516915.05 - Precutter Knives Engage Actuator Not Functioning

LSB 517216.15 - Phiber Not Identified

LSB 517216.16 - Phiber Connection Lost

LSB 517216.17 - Phiber Dump Command Failed

LSB 521079.03 - Tension Panel Valve (Y5) Low Side Short

LSB 521079.04 - Tension Panel Valve (Y5) High Side Short

LSB 521079.05 - Tension Panel Valve (Y5) Open Load

LSB 522022.02 - Calibration Mirror Section Checksum Failure

LSB 522023.02 - Field Mirror Section Checksum Failure

LSB 522024.02 - User Mirror Section Checksum Failure

LSB 522025.02 - Automation Mirror Section Checksum Failure

LSB 522026.02 - Dealer Mirror Section Checksum Failure

LSB 522027.02 - Factory Mirror Section Checksum Failure

LSB 522028.02 - Calibration Checksum Failure without Power Down

LSB 522028.12 - Calibration Checksum Failure with Power Down

LSB 522029.02 - Field Checksum Failure without Power Down

LSB 522029.12 - Field Checksum Failure with Power Down

LSB 522030.02 - User Checksum Failure without Power Down

LSB 522030.12 - User Checksum Failure with Power Down

LSB 522031.02 - Automation Checksum Failure without Power Down

LSB 522031.12 - Automation Checksum Failure with Power Down

LSB 522032.02 - Dealer Checksum Failure without Power Down

LSB 522032.12 - Dealer Checksum Failure with Power Down

LSB 522033.02 - Factory Checksum Failure without Power Down

LSB 522033.12 - Factory Checksum Failure with Power Down

LSB 523836.07 - Greasing System Not Working

LSB 524111.03 - Twine Slack Arm Sensor #6 Shorted High (If Equipped)

LSB 524111.04 - Twine Slack Arm Sensor #6 Shorted to Ground (If Equipped)

LSB 524111.13 - Twine Slack Arm Sensor #6 Not Calibrated (If Equipped)

LSB 524111.15 - Twine in Knotter #6 (If Equipped)

LSB 524111.17 - No Twine Tension in Knotter #6 (If Equipped)

LSB 524112.03 - Twine Slack Arm Sensor #5 Shorted High (If Equipped)

LSB 524112.04 - Twine Slack Arm Sensor #5 Shorted to Ground (If Equipped)

LSB 524112.13 - Twine Slack Arm Sensor #5 Not Calibrated (If Equipped)

LSB 524112.15 - Twine in Knotter #5 (If Equipped)

LSB 524112.17 - No Twine Tension in Knotter #5 (If Equipped)

LSB 524113.03 - Twine Slack Arm Sensor #4 Shorted High

LSB 524113.04 - Twine Slack Arm Sensor #4 Shorted to Ground

LSB 524113.13 - Twine Slack Arm Sensor #4 Not Calibrated

LSB 5241123.15 - Twine in Knotter #4

LSB 524113.17 - No Twine Tension in Knotter #4

LSB 524114.03 - Twine Slack Arm Sensor #3 Shorted High

LSB 524114.04 - Twine Slack Arm Sensor #3 Shorted to Ground

LSB 524114.13 - Twine Slack Arm Sensor #3 Not Calibrated

LSB 524114.15 - Twine in Knotter #3

LSB 524114.17 - No Twine Tension in Knotter #3

LSB 524115.03 - Twine Slack Arm Sensor #2 Shorted High

LSB 524115.04 - Twine Slack Arm Sensor #2 Shorted to Ground

LSB 524115.13 - Twine Slack Arm Sensor #2 Not Calibrated

LSB 524115.15 - Twine in Knotter #2

LSB 524115.17 - No Twine Tension in Knotter #2

LSB 524116.03 - Twine Slack Arm Sensor #1 Shorted High

LSB 524116.04 - Twine Slack Arm Sensor #1 Shorted to Ground

LSB 524116.13 - Twine Slack Arm Sensor #1 Not Calibrated

LSB 524116.15 - Twine in Knotter #1

LSB 524116.17 - No Twine Tension in Knotter #1

LSB 524118.07 - Bale Chute Is Up

LSB 524129.07 - Knotter Shaft Position Error

LSB 524129.14 - Needle Shear Bolt Failure

Section 249: Electrical Component Information

Group 40A: Electrical Assemblies

XA1-1 — Electronic Control Unit (ECU) J1

XA1-2 — Electronic Control Unit (ECU) J2

XA1-3 — Electronic Control Unit (ECU) J3

XA1-4 — Electronic Control Unit (ECU) Power J4

XA2 — Flasher Module

XA5 — Implement Controller Area Network (CAN) Bus Passive Terminator

Group 40B: Sensors

XB1 — Rotor Speed Sensor

XB2 — Knives Status Sensor

XB3 — Flywheel Brake Sensor

XB4 — Pressure Sensor

XB5 — Greasing System Sensor

XB6 — Feeder Fork Sensor

XB7 — Filling Sensor

XB8 — Shear Bolt Sensor

XB9 — Bale Length Sensor

XB10 — Bale Chute Sensor

XB12 — Needle Home Position Sensor

XB14 — Bale Drop Sensor

XB15 — Gear Case Speed Sensor

XB16 — Gear Case Home Sensor

XB17 — Right-Hand Load Pin Sensor

XB18 — Left-Hand Load Pin Sensor

XB19 — Slack Arm 1 Sensor

XB20 — Slack Arm 2 Sensor

XB21 — Slack Arm 3 Sensor

XB22 — Slack Arm 4 Sensor

XB23 — Slack Arm 5 Sensor

XB24 — Slack Arm 6 Sensor

Group 40E: Lights

XE1 — Right-Hand Door Light

XE2 — Left-Hand Door Light

XE3 — Left-Hand Knotter Light

XE4 — Right-Hand Knotter Light

XE5 — Left-Hand Work Light

XE6 — Right-Hand Work Light

XE7 — Right-Hand Red Tail Light

XE8 — Right-Hand Amber Tail Light

XE9 — Left-Hand Red Tail Light

XE10 — Left-Hand Amber Tail Light

XE11 — Needles Light

XE12 — Right-Hand LED Work Light

XE13 — Left-Hand LED Work Light

Group 40F: Fuses

XF1 — Fuse

Group 40M: Motors

XM1 — Greasing Motor

Group 40X: Interconnects and Ground Points

XX100 — Main Harness to International Standards Organization Binary Unit System (ISOBUS)

XX200 — Lighting Harness to Tractor Interconnect

XX300 — Main Harness to Load Pin Harness Interconnect

XX400 — Main Harness to Lighting Harness Interconnect

XX500 — Vehicle Connector

XX600 — Lighting Harness to Right-Hand Light Emitting Diode (LED) Adapter Harness Interconnect

XX700 — Lighting Harness to Left-Hand Light Emitting Diode (LED) Adapter Harness Interconnect

Group 40Y: Electronically Actuated Mechanical Devices

XY1 — Pressure Selector Solenoid Valve

XY2 — Engage Knives Solenoid Valve

XY3 — Disengage Knives Solenoid Valve

XY5 — Tension Panel Solenoid Valve

XY6 — Precutter Knife Lockout Solenoid Valve

XY7 — Tension Panel Locking Solenoid Valve

Section 279: Hydraulic Component Information

Group 40A: Accumulator

A1 — 11-Knife Accumulator

A2 — 12-Knife Accumulator

Group 40B: Sensor or Gauge

B1 — Tension Panel Pressure Gauge

B2 — 11-Knife Pressure Gauge

B3 — 12-Knife Pressure Gauge

B4 — Pressure Sensor

Group 40C: Cylinder, Actuator, or Piston

C1 — Left-Hand Tension Panel Cylinder

C2 — Top Left-Hand Tension Panel Cylinder (3x4)

C3 — Top Right-Hand Tension Panel Cylinder (3x4)

C4 — Right-Hand Tension Panel Cylinder

C5 — Top Tension Panel Cylinder (3x3)

C6 — Bale Chute Cylinder

C7 — Bale Eject Cylinder

C9 — Right-Hand Steerable Axle Cylinder

C10 — Left-Hand Steerable Axle Cylinder

C11 — Right-Hand Front Tandem Axle Brake Cylinder

C12 — Left-Hand Front Tandem Axle Brake Cylinder

C13 — Right-Hand Rear Tandem Axle Brake Cylinder

C14 — Left-Hand Rear Tandem Axle Brake Cylinder

C15 — Right-Hand Single Axle Brake Cylinder

C16 — Left-Hand Single Axle Brake Cylinder

C17 — Single Acting Jack

C18 — Right-Hand Knife Drawer Lift Cylinder (3x4C)

C19 — Left-Hand Knife Drawer Lift Cylinder (3x4C)

C20 — Right-Hand Pick-Up Lift Cylinder (3x4 and 3x4C)

C21 — Left-Hand Pick-Up Lift Cylinder (3x4 and 3x4C)

C22 — Right-Hand Pick-Up Lift Cylinder (3x3 and 3x3C)

C23 — Left-Hand Pick-Up Lift Cylinder (3x3 and 3x3C)

C24 — Right-Hand Knife Engagement Cylinder (3x3C)

C25 — Left-Hand Knife Engagement Cylinder (3x3C)

C26-C48 — 3x4C Knife Engagement Cylinders 1-23

Group 40F: Filter

F1 — Non-Cutter Control Valve Filter

F2 — Precutter Control Valve Filter

F3 — Reservoir Filter

Group 40G: Valve Block, Assembly, or Gear Case

G1 — Non-Precutter Control Valve

G2 — Precutter Control Valve

G3 — Auxiliary Valve Assembly

G4 — 23-Knife Selector Control Valve (3x4C)

G5 — Knife Drawer Control Valve (3x4C)

G6 — Knife Control Valve (3x3C)

G7 — Main Drive Gear Case

Group 40H: Cooler

H1 — Primary Oil Cooler

H2 — Secondary Oil Cooler

Group 40M: Motor

M1 — Knotter Fan Drive Motor

Group 40O: Orifice

O1 — Orifice

Group 40P: Pump

P2 — Control Valve Pump

P1 — Knotter Fan Pump

Group 40R: Reservoir or Tank

R1 — Hydraulic Reservoir

Group 40V: Valve

V4 — Knife Selector Safety Valve

V6 — Precutter Knife Lockout Valve (3x3C)

V8 — Check Valve

V9 — Tension System Relief Valve

V10 — Pressure Relief Valve

V11 — Bale Chute Control Lever Valve

V12 — Last Bale Eject Control Lever Valve

V13 — 11-Knife Control Valve

V14 — 12-Knife Control Valve

V16 — Knife Drawer Control Valve (3x4C)

V18 — Pickup and Jackstand Selector Valve

V19 — Pressure Relief Valve

Group 40Y: Solenoid Valve

Y1 — Pressure Selector Solenoid Valve

Y2 — Engage Knives Solenoid Valve

Y3 — Disengage Knives Solenoid Valve

Y5 — Tension Panel Solenoid Valve

Y6 — Precutter Knife Lockout Solenoid Valve

Y7 — Tension Panel Locking Solenoid Valve

John Deere Hay and Forage Large Square Balers Models L330, L330C, L340, L340C Diagnosis and Repair Technical Service Manual (TM133219)