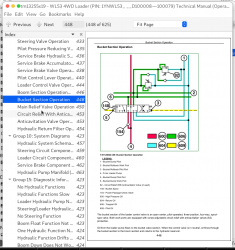

John Deere 4WD Loaders WL53 Operation and Test Service Manual (TM13255X19)

Complete Operation and Test manual with Electrical Wiring Diagrams for John Deere WL53 4WD Loader (SN.D100008—100079)(PIN: 1YNWL53***D100008—100079), with all the workshop information to maintain, diagnose, and rebuild like professional mechanics.

John Deere WL53 4WD Loader workshop service Operation and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm13255x19 - WL53 4WD Loader (PIN: 1YNWL53_ __D100008—100079) Technical Manual (Operation and Test).pdf

tm13255x19 - WL53 4WD Loader (PIN: 1YNWL53_ __D100008—100079) Technical Manual (Operation and Test).epub

Total Pages: 625 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Manual Identification-READ THIS FIRST!

General Information

Safety

Diagnostics

Engine Control Unit (ECU) Diagnostic Trouble Codes

JDLink (JDL) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

References

Power Train

Theory of Operation

Diagnostic Information

Adjustments

Tests

Hydraulic System

Theory of Operation

Diagnostic Information

Adjustments

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

TABLE OF CONTENTS........1

Section 9000: General Information........16

Group 01: Safety........16

Recognize Safety Information........19

Follow Safety Instructions........20

Operate Only If Qualified........21

Wear Protective Equipment........22

Avoid Unauthorized Machine Modifications........23

Add Cab Guarding for Special Uses........24

Inspect Machine........25

Stay Clear of Moving Parts........26

Avoid High-Pressure Fluids........27

Avoid High-Pressure Oils........28

Work In Ventilated Area........29

Prevent Fires........30

Clean Debris from Machine........31

Prevent Battery Explosions........32

Handle Chemical Products Safely........33

Dispose of Waste Properly........34

Prepare for Emergencies........35

Use Steps and Handholds Correctly........36

Start Only From Operator's Seat........37

Use and Maintain Seat Belt........38

Prevent Unintended Machine Movement........39

Avoid Work Site Hazards........40

Use Special Care When Operating Loader........42

Keep Riders Off Machine........43

Avoid Backover Accidents........44

Avoid Machine Tip Over........45

Operating on Slopes........47

Operating or Traveling On Public Roads........48

Inspect and Maintain ROPS........49

Add and Operate Attachments Safely........50

Park and Prepare for Service Safely........51

Service Cooling System Safely........52

Follow Tire Recommendations........53

Service Tires Safely........54

Remove Paint Before Welding or Heating........55

Make Welding Repairs Safely........56

Drive Metal Pins Safely........57

Section 9001: Diagnostics........58

Group 10: Engine Control Unit (ECU) Diagnostic Trouble Codes........60

Engine Control Unit (ECU) Diagnostic Trouble Codes........60

000091.03 - Primary Analog Throttle Out of Range High........58

000091.04 - Engine Throttle Open or Short........58

000190.00 - Engine Speed Extremely High........58

Group 20: JDLink (JDL) Diagnostic Trouble Codes........74

JDLink (JDL) Diagnostic Trouble Codes........74

002251.09 - JDLink Network Antenna........58

520638.00 - Modular Telematic Gateway (MTG) Vandalism........58

520638.15 - Remote Start Inhibit (RSI) Active........58

520638.16 - Remote Start Inhibit (RSI) Active........58

520649.00 - Remote Start Inhibit (RSI) Active........58

Section 9005: Operational Checkout Procedure........80

Group 10: Operational Checkout Procedure........80

Operational Checkout........102

Section 9010: Engine........123

Group 05: Theory of Operation........123

John Deere Engine........158

Group 10: System Diagrams........123

Engine Fuel System Component Location........128

Engine Cooling System Component Location........130

Engine Intake and Exhaust Component Location........132

Diesel Fired Coolant Heater (A4) Component Location—If Equipped........134

Group 15: Diagnostic Information........123

John Deere Engine........158

Engine Cranks/Will Not Start........123

Engine Misfires-Runs Irregularly........123

Engine Does Not Develop Full Power........123

Engine Emits Excessive White Exhaust Smoke........123

Engine Emits Excessive Black or Gray Exhaust Smoke........123

Engine Will Not Crank........123

Engines Idles Poorly........123

Abnormal Engine Noise........123

Excessive Fuel Consumption........123

Fuel in Oil........123

Low Pressure Fuel System Check........123

Group 20: Adjustments........123

John Deere Engine........158

Group 25: Tests........123

John Deere Engine........158

Section 9015: Electrical System........159

Group 05: Theory of Operation........159

Start and Charge Circuits Theory of Operation........167

Controller Area Network (CAN) Circuits Theory of Operation........173

Engine Control Unit (ECU) Circuits Theory of Operation........175

Display Unit Circuits Theory of Operation........180

JDLink™ Circuit Theory of Operation—IF Equipped........183

Group 10: System Diagrams........159

Electrical Diagram Information........189

Electrical Schematic Symbols........193

System Functional Schematic, Wiring Diagram, and Component Location Master Legend........196

System Functional Schematic........201

Power and Ground Cables (W20) Component Location........210

Load Center Harness (W21) Component Location........211

Load Center Harness (W21) Wiring Diagram........213

Engine-Transmission Harness (W22) Component Location........216

Engine-Transmission Harness (W22) Wiring Diagram........218

Loader Frame Harness (W23) Component Location........219

Loader Frame Harness (W23) Wiring Diagram........221

Rear Frame Harness (W24) Component Location........222

Rear Frame Harness (W24) Wiring Diagram........224

Roof Harness (W25) Component Location........225

Roof Harness (W25) Wiring Diagram........226

Radio Harness (W27) Component Location........227

Radio Harness (W27) Wiring Diagram........228

Return-to-Dig (RTD) and Boom Height Kickout (BHKO) Harness (W28) Component Location—If Equipped........229

Return to Dig (RTD) and Boom Height Kickout (BHKO) Harness (W28) Wiring Diagram—If Equipped........230

Air Heater Harness (W29, W30, W34) Component Location—If Equipped........231

Air Heater Harness (W29, W30, W34) Wiring Diagram—If Equipped........232

JDLink™ Harness (W31) Component Location—If Equipped........234

JDLink™ Harness (W31) Wiring Diagram—If Equipped........235

Clutch Cut-off Harness (W32) Component Location—If Equipped........237

Clutch Cut-off Harness (W32) Wiring Diagram—If Equipped........238

Heater and Air Conditioner Harness (W33, W38) Component Location........239

Heater and Air Conditioner Harness (W33, W38) Wiring Diagram........241

Diesel Fired Coolant Heater Harness (W35, W36) Component Location—If Equipped........242

Diesel Fired Coolant Heater Harness (W35, W36) Wiring Diagram—If Equipped........243

Auxiliary Fuel Filter Harness (W37) Component Location—If Equipped........245

Auxiliary Fuel Filter Harness (W37) Wiring Diagram—If Equipped........246

Group 15: Diagnostic Information........160

Service ADVISOR™ Diagnostic Application........249

Service ADVISOR™ Connection Procedure........250

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application........253

Intermittent Diagnostic Trouble Code (DTC) Diagnostics........256

Diagnostic Trouble Codes—After Machine Repair........257

Group 20: Adjustments........160

Boom Height Kickout (BHKO) Adjustment........259

Return-to-Dig Adjustment........260

Group 25: Tests........160

Electrical Component Specifications........266

Fuse and Relay Specifications........269

Alternator Test........272

Connector Terminal Test........274

Section 9020: Power Train........277

Group 05: Theory of Operation........277

AR15MTL Inboard Planetary Axle........280

Power Train Operation........281

Torque Converter Operation........282

Overrunning Clutch Operation........284

Transmission Operation........286

Park Brake Operation........291

Group 10: System Diagrams........277

Transmission System Schematic—Neutral........294

Power Train Component Location........296

Transmission Component Location........297

Transmission Hydraulic System and Transmission Control Valve Component Operation........298

Group 15: Diagnostic Information........277

Transmission Clutch Slippage........277

Machine Will Not Move in Either Direction........277

Machine Will Not Shift Correctly........277

Transmission System Pressure Is Low in Neutral........277

Transmission Pressure Is Low........277

Transmission Shifts Too Slow........277

Transmission Shifts Too Fast........277

Machine Creeps in Neutral........277

Transmission Hydraulic System Overheats........277

Transmission Excessive Noise........277

Oil Aerated........277

Oil Ejected from Filler Tube........277

Machine Vibrates........277

Machine Power and Acceleration Low........277

Torque Converter Stall RPM........277

Differential Oil Level Rises........277

Differential Oil Level Low........277

Differential and Axle Noise Excessive........277

Axle Overheats........278

Service Brakes Poor or Do Not Apply........278

Service Brakes Aggressive........278

Service Brakes Dragging........278

Service Brakes Lock Up........278

Service Brakes Chatter........278

Service Brake Warning Light On........278

Driveline Excessive Vibration or Noise........278

Park Brake Will Not Hold........278

Park Brake Will Not Release........382

Park Brake Overheats........278

Park Brake Light Does Not Come On........278

Park Brake Will Not Apply........278

Group 20: Adjustments........278

Service Brake Bleeding Procedure........391

External Service Brake Inspection........393

Service Brake Accumulator........396

Group 25: Tests........278

Transmission Oil Warm-Up Procedure........399

Transmission Pump Flow Test........401

Transmission System Pressure Test........403

Transmission Reverse Clutch Pressure Test........405

Torque Converter-Out Pressure Test........408

Torque Converter-In Pressure Test........411

Torque Converter-Out Flow Test........414

Torque Converter Stall Speed Test........416

Transmission Oil Cooler Restriction Test........418

Axle Breather Test........421

Section 9025: Hydraulic System........423

Group 05: Theory of Operation........423

Loader Hydraulic System Operation........427

Loader Hydraulic Pump Operation........428

Hydraulic Pump Manifold Operation........430

Steering System Component Operation........432

Steering Valve Operation........433

Pilot Pressure Reducing Valve Operation........435

Service Brake Hydraulic System Operation........436

Service Brake Accumulator Operation........437

Service Brake Valve Operation........438

Pilot Control Lever Operation........440

Loader Control Valve Operation........444

Boom Section Operation—Boom Down and Steering........446

Bucket Section Operation........448

Main Relief Valve Operation........450

Circuit Relief With Anticavitation Valve Operation........453

Anticavitation Valve Operation........453

Hydraulic Return Filter Operation........454

Group 10: System Diagrams........423

Hydraulic System Schematic........457

Steering Circuit Component Location........459

Loader Circuit Component Location........460

Service Brake Component Location........462

Hydraulic Pump Manifold (Hydraulic System Component Location)........463

Group 15: Diagnostic Information........423

No Hydraulic Functions........423

Hydraulic Functions Slow........423

Loader Hydraulic Pump Noisy........423

Steering/Loader Hydraulic Pump Noisy........423

No Steering Function........423

Boom Float Function Not Working........423

One Hydraulic Function Not Working........424

Hydraulic Function Drifts Down........424

Boom Down Does Not Work (Engine Off)........424

Oil Overheats........424

Hydraulic Oil Foams........424

Constant Steering Required to Maintain Straight Travel........424

Slow Steering Wheel Movement Will Not Cause Frame Movement........424

Steering Wheel Turns Without Resistance and Causes No Frame Movement........424

Steering Erratic........424

Steering Wheel Free Play........424

Orbital Steering Valve Binds or Locks Up........424

Steering Wheel Turns By Itself........424

Machine Turns in Opposite Direction as Steering Wheel........424

Steering Wheel Kickback........424

Steering Jerky........424

Group 20: Adjustments........424

Pilot Control Lever Adjustment........516

Accumulator Precharge........517

Group 25: Tests........424

Hydraulic Oil Sampling Procedure........520

Hydraulic Oil Warm-Up Procedure........521

Vacuum Pump Installation........523

Hydraulic System Pressure and Accumulators Discharge........524

JT02156A Digital Pressure and Temperature Analyzer Kit Installation........525

Steering/Loader Hydraulic Pump Flow Test........529

Loader Hydraulic Pump Flow Test........529

Main Relief Valve Pressure Test........532

Circuit Relief With Anticavitation Valve Pressure Test........536

Loader Cylinder Drift Test........540

Boom, Bucket, and Steering Cylinder Leakage Test........543

Hydraulic Oil Cooler Restriction Test........545

Orbital Steering Valve Leakage Test........548

Steering Cylinder Drift Test........552

Pilot Control Valve Pressure Test........556

Pilot Pressure Reducing Valve Pressure Test........562

Pilot Accumulator Gas Precharge Test........565

Cycle Time Test........568

Service Brake Accumulator Low Brake Pressure Warning Test........569

Service Brake Valve Pressure Test........572

Service Brake Valve Leakage Test........575

Hydraulic Oil Filter Inspection Procedure........578

Section 9031: Heating and Air Conditioning........579

Group 05: Theory of Operation........579

Air Conditioning System Cycle of Operation........582

Group 10: System Diagrams........579

Air Conditioner and Heater Component Location........585

Group 15: Diagnostic Information........579

Air Conditioning System Does Not Operate........579

Air Conditioner Does Not Cool Interior of Cab........579

Air Conditioning Runs Constantly, Too Cold........579

Heater System Does Not Operate........579

Heater Does Not Warm Interior of Cab........579

Interior Windows Continue to Fog........579

Group 25: Tests........579

Refrigerant Cautions and Proper Handling........610

R134a Refrigerant Cautions........611

R134a Oil Charge Capacity........612

R134a Refrigerant Charge Capacity........613

Refrigerant Hoses and Tubing Inspection........614

R134a Air Conditioning System Test........615

Operating Pressure Diagnostic Chart........618

Air Conditioning High/Low Pressure Switch Test........620

Freeze Control Switch Test........622

Refrigerant Leak Testing........623

John Deere 4WD Loaders WL53 Operation and Test Service Manual (TM13255X19)