John Deere 4WD Loader 524K (T3) with Engine 6068HDW74 Operation and Test Service Manual (TM10686)

Complete Operation and Test manual with Electrical Wiring Diagrams for John Deere 4WD Loader 524K (T3) with Engine 6068HDW74 (SN. before 642245), with all the workshop information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere 4WD Loader 524K workshop Diagnosis and Test Technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM10686 - John Deere 4WD Loader 524K Engine 6068HDW74 (T3) Technical Manual (Operation and Test).PDF

TM10686 - John Deere 4WD Loader 524K Engine 6068HDW74 (T3) Technical Manual (Operation and Test).epub

Total Pages: 1,903 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety Information

Diagnostic Trouble Codes (DTC)

Engine Control Unit (ECU) Diagnostic Trouble Codes

Transmission Control Unit (TCU) Diagnostic Trouble Codes

Flex Load Controller (FLC) Diagnostic Trouble Codes

Sealed Switch Module (SSM) Diagnostic Trouble Codes

Advanced Display Unit (ADU) Diagnostic Trouble Codes

Radar Object Detection (ROD) Diagnostic Trouble Codes

Ground Speed Radar (RDR) Diagnostic Trouble Codes

Tire Pressure Monitoring (TPM) System Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Adjustments

Tests

Hydraulic System

Theory of Operation

Diagnostic Information

Adjustments

Test

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

Table of Contents - Expanded View

9000 - GENERAL INFORMATION

01 - Safety

Add and Operate Attachments Safely

Add Cab Guarding For Special Uses

Avoid Backover Accidents

Avoid High-Pressure Fluids

Avoid High-Pressure Oils

Avoid Machine Tip Over

Avoid Unauthorized Machine Modifications

Avoid Work Site Hazards

Beware of Exhaust Fumes

Clean Debris from Machine

Dispose of Waste Properly

Drive Metal Pins Safely

Follow Safety Instructions

Handle Chemical Products Safely

Inspect and Maintain ROPS

Inspect Machine

Keep Riders Off Machine

Make Welding Repairs Safely

Operate Only If Qualified

Operating on Slopes

Operating or Traveling On Public Roads

Park And Prepare For Service Safely

Prepare for Emergencies

Prevent Battery Explosions

Prevent Fires

Prevent Unintended Machine Movement

Recognize Safety Information

Remove Paint Before Welding or Heating

Service Cooling System Safely

Service Tires Safely

Start Only From Operator's Seat

Stay Clear of Moving Parts

Use and Maintain Seat Belt

Use Special Care When Operating Loader

Use Steps and Handholds Correctly

Wear Protective Equipment

9001 - DIAGNOSTIC TROUBLE CODES (DTC)

10 - Engine Control Unit (ECU) Diagnostic Trouble Codes

000107.00 — Eng Air Filter Restricted_{0518}

000107.00 — Eng Air Filter Restricted

000171.03 — Ambient Air Temperature Out of Range High_{0526}

000171.03 — Ambient Air Temperature Out of Range High

000171.04 — Ambient Air Temperature Out of Range Low_{0533}

000171.04 — Ambient Air Temperature Out of Range Low

000627.01 — ECU Unswitched Power Short to Ground_{0540}

000627.01 — ECU Unswitched Power Short to Ground

000676.05 — Engine Heat Open or Short_{0547}

000676.05 — Engine Heat Open or Short

001253.13 — Injector Cal Required_{0553}

001253.13 — Injector Cal Required

001321.31 — Starter Solenoid Open Circuit_{0600}

001321.31 — Starter Solenoid Open Circuit

002003.09 — CAN Communication Lost for TCU_{0607}

002003.09 — CAN Communication Lost for TCU

002033.09 — CAN Communication Lost for FLC_{0614}

002033.09 — CAN Communication Lost for FLC

Engine Control Unit (ECU) Diagnostic Trouble Codes_{0512}

Engine Control Unit (ECU) Diagnostic Trouble Codes

20 - Transmission Control Unit (TCU) Diagnostic Trouble Codes

000091.09 — Timeout EEC2 Message

000513.02 — Percent Torque Invalid

000513.09 — Timeout EEC1 Message

000514.02 — Friction Invalid

000514.09 — Timeout EEC3 Message

000544.02 — Ref Torque Invalid

000544.09 — Timeout Engine Config Message

000777.02 — TC Clutch Slippage

000777.03 — TC Lockup Sol Short to Power

000777.04 — TC Lockup Sol Short to Gnd

000777.05 — TC Lockup Sol Open Circuit

000928.03 — Axle Disconnect Solenoid Short to Power

000928.04 — Axle Disconnect Solenoid High Current

000928.05 — Axle Disconnect Solenoid Open Circuit

002033.09 — CAN Communication Lost for FLC

002141.09 — CAN Communication Lost for SSM

522344.00 — Torque Converter Output Temperature Too High

522350.15 — Transmission Input Torque Overload

522364.07 — Transmission Clutch Calibration Failed

522364.13 — Transmission Clutch Calibration Fault

522365.13 — Limp Home Mode Requested

522366.13 — Application Invalid

522367.13 — TCU Configuration Invalid

522368.02 — TCU Memory Failure

522369.03 — Remote Display Short to Power

522370.02 — TCU Valve Power Supply 2 Short Circuit

522371.02 — TCU Valve Power Supply 1 Short Circuit

522373.03 — Power Supply High Voltage

522373.04 — Power Supply Low Voltage

522374.03 — Sensor Supply Short to Power

522374.04 — Sensor Supply Short to Ground

522375.00 — Transmission Oil Filter Restricted

522376.00 — Transmission Oil Temperature Over Maximum Value

522379.03 — Park Brake Release Solenoid Short to Power

522379.04 — Park Brake Release Solenoid Short to Ground

522379.05 — Park Brake Release Solenoid Open Circuit

522382.03 — Backup Alarm Short to Power

522382.04 — Backup Alarm Short to Ground

522383.02 — Transmission Clutch KR Slippage

522383.03 — Clutch Reverse Solenoid Short to Power

522383.04 — Clutch Reverse Solenoid Short to Ground

522383.05 — Clutch Reverse Solenoid Open Circuit

522386.02 — Transmission Clutch KV Slippage

522386.03 — Clutch Forward Solenoid Short to Power

522386.04 — Clutch Forward Solenoid Short to Ground

522386.05 — Clutch Forward Solenoid Open Circuit

522389.02 — Transmission Clutch K4 Slippage

522389.03 — Clutch K4 Solenoid Short to Power

522389.04 — Clutch K4 Solenoid Short to Ground

522389.05 — Clutch K4 Solenoid Open Circuit

522392.02 — Transmission Clutch K3 Slippage

522392.03 — Clutch K3 Solenoid Short to Power

522392.04 — Clutch K3 Solenoid Short to Ground

522392.05 — Clutch K3 Solenoid Open Circuit

522395.02 — Transmission Clutch K2 Slippage

522395.03 — Clutch K2 Solenoid Short to Power

522395.04 — Clutch K2 Solenoid Short to Ground

522395.05 — Clutch K2 Solenoid Open Circuit

522399.02 — Transmission Clutch K1 Slippage

522399.03 — Clutch K1 Solenoid Short to Power

522399.04 — Clutch K1 Solenoid Short to Ground

522399.05 — Clutch K1 Solenoid Open Circuit

522401.02 — Output Shaft Speed Sensor Fault

522401.03 — Output Shaft Speed Sensor Open or Short

522401.04 — Output Shaft Speed Sensor Short to Ground

522401.12 — Output Shaft Speed Sensor Fault

522401.15 — Output Shaft Speed Sensor Overspeed

522402.03 — Clutch Speed Sensor Open or Short

522402.04 — Clutch Speed Sensor Short to Ground

522402.12 — Clutch Speed Sensor Fault

522403.03 — Converter Output Speed Sensor Open or Short

522403.04 — Converter Output Speed Sensor Short to Ground

522403.12 — Converter Output Speed Sensor Fault

522404.03 — Converter Input Speed Sensor Open or Short

522404.04 — Converter Input Speed Sensor Short to Ground

522404.12 — Converter Input Speed Sensor Fault

522406.03 — Transmission Oil Temperature Sensor Open or Short

522406.04 — Transmission Oil Temperature Sensor Short to Ground

522407.03 — Clutch Cut-off Sensor Short to Power

522407.04 — Clutch Cut-off Sensor Open or Short

522409.05 — 2nd FNR Open Circuit

522409.12 — 2nd FNR Multiple Inputs

522411.05 — 1st FNR Open Circuit

522411.12 — 1st FNR Multiple Inputs

522412.12 — Gear Selection Error

522419.02 — Clutch Cut-off Disabled

522420.02 — Manual Downshift Disabled

522421.02 — Auto to 1st Disabled

524048.00 — Transmission Output Torque Exceeded

524049.00 — Transmission Input Torque Exceeded

524287.00 — Configure Machine Model

Transmission Control Unit (TCU) Diagnostic Trouble Codes

30 - Flex Load Controller (FLC) Diagnostic Trouble Codes

000096.04 — Fuel Level Short to Ground

000096.05 — Fuel Level Open or Short

000167.16 — Alternator High Voltage

000167.18 — Alternator Low Voltage

000168.16 — High Battery Voltage

000234.02 — Invalid TCU Software Rev

000444.05 — 12 Volt Center Tap Open or Short

000444.18 — Battery Voltage Imbalance

000521.00 — Brake Pedal High Voltage

000628.12 — Controller Not Programmed

000629.12 — FLC Watchdog Time Out

000639.12 — FLC CAN Failure

000639.14 — FLC CAN Bus Off

000746.05 — Differential Lock Solenoid Open or Short

000746.06 — Differential Lock Solenoid High Current

000785.05 — Pilot Solenoid Open or Short

000785.06 — Pilot Solenoid High Current

000880.06 — Brake Lights High Current

000977.05 — Reverse Fan Solenoid Open or Short

000977.06 — Reverse Fan Solenoid High Current

001069.02 — Tire Size Incorrect

001071.05 — Fan Speed Solenoid Open or Short

001071.06 — Fan Speed Solenoid High Current

001503.04 — Arm Rest Down Switch Short to Ground

001503.11 — Arm Rest Position Undetermined

001550.06 — AC Clutch High Current

001565.04 — Arm Rest Up Switch Short to Ground

001638.00 — Hydraulic Oil High Temperature

001638.04 — Hydraulic Oil Temperature Sensor Short to Ground

001713.01 — Hydraulic Oil Filter Restricted

001762.03 — Hydraulic Pressure Sensor Short to Power

001762.04 — Hydraulic Pressure Sensor Open or Short

002000.09 — CAN Communication Lost for ECU

002003.09 — CAN Communication Lost for TCU

002040.09 — CAN Communication Lost for ADU

002051.09 — CAN Communication Lost for TPM_{3133}

002051.09 — CAN Communication Lost for TPM

002052.09 — CAN Communication Lost for JSC

002129.09 — CAN Communication Lost for JSV

002132.09 — CAN Communication Lost for ROD

002141.09 — CAN Communication Lost for SSM

002169.09 — CAN Communication Lost for RDR

002350.05 — Drive Lamps Open or Short

002350.06 — Drive Lamps High Current

002355.05 — Front Work Lights Open or Short

002355.06 — Front Work Lights High Current

002356.05 — Front Work Lights Open or Short

002356.06 — Front Work Lights High Current

002359.05 — Machine Work Lights Open Circuit

002359.06 — Machine Work Lights High Current

002362.05 — Rear Work Lights Open or Short

002362.06 — Rear Work Lights High Current

002367.04 — Left Turn Switch Short to Ground

002368.05 — Left Turn Lights Open or Short

002368.06 — Left Turn Lights High Current

002369.04 — Right Turn Switch Short to Ground

002370.05 — Right Turn Lights Open or Short

002370.06 — Right Turn Lights High Current

002378.06 — Marker _ Tail Lights High Current

002386.06 — Beacon Light High Current

002680.05 — RTC _ Float Detent Open or Short

002680.06 — RTC _ Float Detent High Current

002697.02 — Timeout JSC Message

002717.05 — RTD Detent Open or Short

002717.06 — RTD Detent High Current

002754.05 — BHKO Detent Open or Short

002754.06 — BHKO Detent High Current

002875.04 — Hazard Wakeup Short to Ground

003509.04 — FLC Sensor 1 Voltage Low

003510.04 — FLC Sensor 2 Voltage Low

003511.04 — FLC Sensor 3 Voltage Low

299621.02 — Machine Configuration Invalid

522280.01 — Brake Pressure Low

522341.05 — Heated Mirror Open or Short

522341.06 — Heated Mirror Short to Ground

522426.04 — Rear Wiper Park Short to Ground

522427.04 — Front Wiper Park Short to Ground

522431.02 — Memory Test Failure

522432.06 — Rear Wiper High Speed High Current

522433.05 — Rear Wiper Low Speed Open or Short

522433.06 — Rear Wiper Low Speed High Current

522434.05 — Front Wiper Low Speed Open or Short

522434.06 — Front Wiper Low Speed High Current

522435.06 — Front Wiper High Speed High Current

522436.03 — Bucket Position Short to Power

522436.04 — Bucket Position Open or Short

522437.04 — Return-to-Dig Switch Short to Ground

522438.05 — Pin Disconnect Solenoid Open or Short

522438.06 — Pin Disconnect Solenoid High Current

522543.03 — Boom Cyl Rod Press Open or Short

522543.04 — Boom Cyl Rod Press Short to Ground

522544.03 — Boom Cyl Head Press Open or Short

522544.04 — Boom Cyl Head Press Short to Ground

522796.05 — Rear Washer Pump Open or Short

522796.06 — Rear Washer Pump High Current

522797.05 — Front Washer Pump Open or Short

522797.06 — Front Washer Pump High Current

523137.01 — Steering Pressure Low

523137.04 — Steering Pressure Switch Short to Ground

523219.04 — Switched Power Voltage Low

523440.04 — Unswitched Power Voltage Low

523489.05 — Engine Light Open Circuit

523577.05 — Secondary Steering Pump Open or Short

523577.06 — Secondary Steering Pump High Current

523689.04 — Differential Lock Switch Short to Ground

523767.04 — Joystick Steering Activation Switch Short to Ground

523767.10 — Joystick Steering Activation Switch Button Stuck

523786.03 — Boom Position Sensor Short to Power

523795.05 — JSV Power Open or Short

523795.06 — JSV Power High Current

523837.01 — Brake Pressure Low—Rear

523837.03 — Rear Brake Pressure Sensor Short to Power

523837.04 — Rear Brake Pressure Open or Short

523840.01 — Brake Pressure Low—Front

523840.03 — Front Brake Pressure Short to Power

523840.04 — Front Brake Pressure Open or Short

523865.04 — Add Truck Switch Short to Ground

523867.04 — Counter Switch Short to Ground

523868.04 — Add Bucket Switch Short to Ground

523948.05 — Ride Control Solenoid Open Circuit

523948.06 — Ride Control Solenoid High Current

524044.01 — Axle Oil Filter Restricted

524044.03 — Axle Oil Filter Short to Power

524250.31 — Inspect Park Brake

524265.19 — Check Sum Error

Flex Load Controller (FLC) Diagnostic Trouble Codes

40 - Sealed Switch Module (SSM) Diagnostic Trouble Codes

000629.12 — SSM Watchdog Time Out

002033.09 — SSM Lost Communications

002634.04 — SSM Ignition Relay Signal Short to Ground

002634.05 — SSM Ignition Relay Signal Open Circuit

520752.04 — Button 17 Keypad Stuck

520752.09 — Button 17 LED Message

520753.04 — Front Washer Keypad Stuck

520754.04 — Front Wiper Keypad Stuck

520754.09 — Lost Front Wiper LED Message

520755.04 — Drive Lights Keypad Stuck

520755.09 — Lost Drive Lights LED Message

523335.04 — Work Lights Keypad Stuck

523335.09 — Lost Work Lights LED Message

523336.04 — Rear Wiper Keypad Stuck

523336.09 — Lost Rear Wiper LED Message

523338.04 — Rear Washer Keypad Stuck

523339.04 — Axle Disconnect Keypad Stuck

523339.09 — Lost Axle Disconnect LED Message

523340.04 — Button 21 Keypad Stuck

523340.09 — Button 21 LED Message

523349.09 — Lost A _ C LED Message

523849.04 — A _ C Keypad Stuck

523850.04 — Pin Disconnect Keypad Stuck

523850.09 — Lost Pin Disconnect LED Message

523852.04 — Spin Control Keypad Stuck

523852.09 — Lost Spin Control LED Message

523854.04 — Diff Lock Keypad Stuck

523854.09 — Lost Diff Lock LED Message

523855.04 — RTCarry Keypad Stuck

523855.09 — Lost RTC LED Message

523856.04 — BHKO Keypad Stuck

523856.09 — Lost BHKO LED Message

523857.04 — Clutch Cut-off Keypad Stuck

523857.09 — Lost Clutch Cut-off LED Message

523858.04 — Ride Control Keypad Stuck

523858.09 — Lost Ride Control LED Message

523860.04 — Auto Transmission Keypad Stuck

523860.09 — Lost Auto Trans LED Message

523861.04 — Return to Dig Keypad Stuck

523861.09 — Lost RTD LED Message

523862.04 — Park Brake Keypad Stuck

523862.09 — Lost Park Brake LED Message

523863.04 — Pilot Enable Keypad Stuck

523863.09 — Lost Pilot Enable LED Message

523864.04 — Hazards Keypad Stuck

523864.09 — Lost Hazard LED Message

523865.04 — Beacon Light Keypad Stuck

523865.09 — Lost Beacon LED Message

523867.04 — Ignition Off Keypad Stuck

523868.04 — Ignition On Keypad Stuck

523868.09 — Lost Ign On LED Message

Sealed Switch Module (SSM) Diagnostic Trouble Codes

50 - Advanced Display Unit (ADU) Diagnostic Trouble Codes

000158.03 — Switched Power Voltage High

000158.04 — Switched Power Voltage Low

000168.03 — High Battery Voltage

000168.04 — Low Battery Voltage

000442.00 — Display Temp High

000442.01 — Display Temp Low

001491.11 — LCD Backlight Failure

003597.02 — 5 Volt Power Supply Invalid

003598.02 — 1.5 Volt Power Supply Invalid

003599.02 — 3.3 Volt Power Supply Invalid

523436.14 — ADU Watchdog Time Out

523438.31 — Memory Error

523651.02 — Memory Stack Overflow

523773.03 — CAN HIGH Voltage High

523773.04 — CAN HIGH Voltage Low

523774.03 — CAN LOW Voltage High

523774.04 — CAN LOW Voltage Low

524076.10 — Information Button Stuck

524077.10 — Back Key Button Stuck

524078.10 — Menu Select Button Stuck

524080.10 — Down Arrow Button Stuck

524082.10 — Up Arrow Button Stuck

Advanced Display Unit (ADU) Diagnostic Trouble Codes

60 - Radar Object Detection (ROD) Diagnostic Trouble Codes

000896.12 — ROD Unit Failure_{0828}

000896.12 — ROD Unit Failure_{0833}

000896.12 — ROD Unit Failure

Radar Object Detection (ROD) Diagnostic Trouble Codes

70 - Ground Speed Radar (RDR) Diagnostic Trouble Codes

000628.12 — Controller Not Programmed_{0851}

000628.12 — Controller Not Programmed

523456.18 — Degraded Mode

Ground Speed Radar (RDR) Diagnostic Trouble Codes

80 - Tire Pressure Monitoring (TPM) Diagnostic Trouble Codes

000108.12 — Ambient Pressure Fault

000241.01 — Second Level Alarm Low Pressure

000241.16 — First Level Alarm High Pressure

000241.18 — First Level Alarm Low Pressure

000242.16 — Tire High Temperature

000929.12 — Sensor Fault

000929.31 — Memory Error

001697.04 — TPM Sensor Low Battery

9005 - OPERATIONAL CHECKOUT PROCEDURE

10 - Operational Checkout Procedure

Operational Checkout

9010 - ENGINE

05 - Theory of Operation

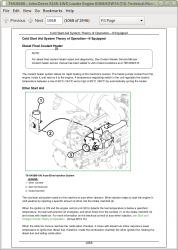

Cold Start Aid System Theory of Operation—If Equipped

PowerTech ETM 6.8 L John Deere Engine

15 - Diagnostic Information

Abnormal Engine Noise

Engine Cooling System Component Location

Engine Cranks _ Will Not Start

Engine Does Not Develop Full Power

Engine Emits Excessive Black or Gray Exhaust Smoke

Engine Emits Excessive White Exhaust Smoke

Engine Fuel System Component Location

Engine Idles Poorly

Engine Intake and Exhaust Component Location

Engine Misfires _ Runs Irregularly

Engine Will Not Crank

Excessive Fuel Consumption

Fuel in Oil

Low Pressure Fuel System Check

PowerTech E™ 6.8 L John Deere Engine

25 - Tests

Engine Idle Speeds and Auto Shutdown Check

Engine Slow Idle Speed Adjustment

Fluid Sampling Procedure

Intake Manifold Pressure Test—Turbocharger Boost

PowerTech E™ 6.8 L John Deere Engine

9015 - ELECTRICAL SYSTEM

05 - System Information

Electrical Diagram Information

Electrical Schematic Symbols

10 - System Diagrams

Cab Roof Harness (W19) Component Location

Cab Roof Harness (W19) Wiring Diagram

Engine Frame Harness (W5) Component Location

Engine Frame Harness (W5) Wiring Diagram

Engine Harness (W6) Component Location

Engine Harness (W6) Wiring Diagram

Front Console Harness (W4) Component Location

Front Console Harness (W4) Wiring Diagram (S.N. —635782)

Front Console Harness (W4) Wiring Diagram (S.N. 635783— )

Fuse and Relay Specifications

Heater and Air Conditioner Harness (W20) Component Location

Heater and Air Conditioner Harness (W20) Wiring Diagram

JDLink™ System Functional Schematic—MIG _ GTT

JDLink™ System Functional Schematic—MTG _ SAT

JDLink™ System Harnesses Component Location—MIG _ GTT

JDLink™ System Harnesses Component Location—MTG _ SAT

JDLink™ System Wiring Diagrams—MIG _ GTT

JDLink™ System Wiring Diagrams—MTG _ SAT

Load Center Harness (W3) Component Location

Load Center Harness (W3) Wiring Diagram

Loader Frame Harness (W2) Component Location

Loader Frame Harness (W2) Wiring Diagram

Power and Ground Cables (W1) Component Location

Radar Object Detection Harness (W21) Component Location—If Equipped

Radar Object Detection Harness (W21) Wiring Diagram

Radio Harness (W23) Component Location

Radio Harness (W23) Wiring Diagram

Rear Frame Harness (W13) Component Location

Rear Frame Harness (W13) Wiring Diagram

Secondary Steering Harness (W17) Component Location

Secondary Steering Harness (W17) Wiring Diagram

System Functional Schematic and Section Legend

System Functional Schematic, Wiring Diagram, and Component Location Master Legend

Tire Pressure Monitoring (TPM) System Harness (W35) Component Location

Tire Pressure Monitoring (TPM) System Harness (W35) Wiring Diagram

Transmission Harness (W10) Component Location

Transmission Harness (W10) Wiring Diagram

15 - Sub-System Diagnostics

Advanced Display Unit (ADU) Circuit Theory of Operation

Auto-Differential Lock Circuit Theory of Operation—If Equipped

Controller Area Network (CAN) Circuit Theory of Operation

Embedded Payload Scale (EPS) Circuit Theory of Operation

Engine Control Unit (ECU) Circuit Theory of Operation

Flex Load Controller (FLC) Circuit Theory of Operation

JDLink™ Circuit Theory of Operation—If Equipped

Park Brake Circuit Theory of Operation

Radar Object Detection (ROD) Circuit Theory of Operation

Start and Charge Circuits Theory of Operation

Tire Pressure Monitoring (TPM) System Theory of Operation

Transmission Control Unit (TCU) Circuit Theory of Operation

16 - Monitor Operation

Advanced Display Unit (ADU)—Auto Idle

Advanced Display Unit (ADU)—Auto Shutdown

Advanced Display Unit (ADU)—Clear Codes

Advanced Display Unit (ADU)—Enable Options

Advanced Display Unit (ADU)—Fan Speed

Advanced Display Unit (ADU)—Hide _ Unhide Main Menu

Advanced Display Unit (ADU)—Maximum High Gear

Advanced Display Unit (ADU)—Service Mode

Advanced Display Unit (ADU)—Slow Idle Adjust

Advanced Display Unit (ADU)—Tire Size

Advanced Display Unit (ADU)—Transmission Clutch Calibration

20 - References

Advanced Display Unit (ADU) Remove and Install

Alternator Test

Boom Height Kickout (BHKO) Adjustment

Boom Height Kickout _ Return-to-Carry (BHKO _ RTC) Position Sensor Calibration

Boom Height Kickout _ Return-to-Carry (BHKO _ RTC) Position Sensor Disassemble and Assemble

Boom Height Kickout _ Return-to-Carry (BHKO _ RTC) Position Sensor Remove and Install

CAN Circuit Test

Change Backup Alarm Volume

Clutch Cut-Off Sensor Check

Connector Terminal Test

Diagnostic Trouble Codes—After Machine Repair

Electrical Component Specifications

Embedded Payload Scale (EPS) Diagnostics

Engine Control Unit (ECU) Remove and Install

Flex Load Controller (FLC) Remove and Install

Hydraulic Pressure Sensor Test

Install CINCH™ Contact

Install DEUTSCH® Contact

Install WEATHER PACK® Contact

Intermittent Diagnostic Trouble Code (DTC) Diagnostics

JDLink™ Connection Procedure—If Equipped

JDLink™ System Identification

Pressure Switches and Sensors Remove and Install

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application

Remove Connector Body from Blade Terminals

Repair 32 and 48 Way CINCH™ Connectors

Replace CINCH™ Connectors

Replace DEUTSCH® Circular Connectors

Replace DEUTSCH® Rectangular or Triangular Connectors

Replace Metri-Pack® Connectors

Replace Metri-Pack® (Push Type) Connectors

Replace WEATHER PACK® Connector

Return-to-Carry (RTC) Adjustment

Return-to-Dig Adjustment—Z-Bar Linkage

Sealed Switch Module (SSM) Remove and Install

Service ADVISOR™ Connection Procedure

Service ADVISOR™ Diagnostic Application

This procedure assumes that the EPS system is activated. If activation of the EPS system is needed, contact your Loadrite representative._{4344}

TPM—Activating Tire Pressure Monitoring System

TPM—Alarm Setup

TPM—Cold Inflation Pressure Setup

TPM—Delete Sensors

TPM—Programming Sensors with SmartWave® Advanced Maintenance Tool

TPM—Programming Using Sensor Identification Numbers

TPM—SmartWave® Advanced Maintenance Tool Diagnostics

TPM—Tire Pressure Sensor Remove and Install

Transmission Control Unit (TCU) Remove and Install

Transmission Control Valve Solenoid Check

9020 - POWER TRAIN

05 - Theory of Operation

Axle Circulation Dual Pump Operation—If Equipped

Differential Lock Operation

Park Brake Operation

Power Train Operation

Rear Axle Disconnect Operation

Standard Differential Operation

TeamMate™ Axles

Thermal Bypass Valve Operation

Torque Converter Operation

Transmission Clutch Modulation Operation

Transmission Clutch Pack Engagement and Solenoids Activated

Transmission Control Valve Component Operation

Transmission Filter Bypass Valve Operation

Transmission Operation—First Gear Forward

Transmission Operation

15 - Diagnostic Information

Axle Overheats

Axle Wheel Hub Face Seal Leaking

Differential and Axle Noise Excessive

Differential Lock Slips and Chatters

Differential Lock Will Not Disengage

Differential Lock Will Not Engage

Differential Oil Level Low

Differential Oil Level Rises

Driveline Excessive Vibration or Noise

Machine Creeps in Neutral

Machine Power and Acceleration Low

Machine Vibrates

Machine Will Not Move in Either Direction

Machine Will Not Shift Correctly

Oil Aerated

Oil Ejected from Filler Tube

Park Brake Light Does Not Come On

Park Brake Light Flashes During Each Shift

Park Brake Light Flashes When Shifting From Forward to Reverse

Park Brake Overheats

Park Brake Will Not Apply

Park Brake Will Not Hold

Park Brake Will Not Release

Power Train Component Location

Rear Axle Disconnect Does Not Disengage (2WD state)

Rear Axle Disconnect Does Not Engage (4WD state)

Service Brakes Aggressive

Service Brakes Chatter

Service Brakes Dragging

Service Brakes Lock Up

Service Brakes Poor or Do Not Apply

Service Brake Warning Light On

Torque Converter Stall RPM

Transmission Clutch Slippage

Transmission Control System

Transmission Excessive Noise

Transmission Hydraulic System Overheats

Transmission Pressure Is Low (One or Two Gear Ranges)

Transmission Shifts Too Fast

Transmission Shifts Too Slow

Transmission System Pressure Is Low in Neutral

Transmission System Schematic—First Forward

20 - Adjustments

External Service Brake Inspection

Service Brake Bleeding Procedure

Transmission Control Unit (TCU)—Electronic Clutch Calibration

25 - Tests

Axle Breather Test

Axle Circulation Pump Flow Test

Differential Lock Pressure Test

Park Brake Drag Test

Park Brake Pressure Test

Torque Converter—In Pressure Test

Torque Converter—Out Flow Test

Torque Converter—Out Pressure Test

Torque Converter Relief Pressure Test

Torque Converter Stall Speed Test

Transmission Clutch Pressure Test

Transmission Element Leakage Test

Transmission Lube Pressure Test

Transmission Oil Cooler Restriction Test

Transmission Oil Cooler Thermal Bypass Valve Pressure Test

Transmission Oil Cooler Thermal Bypass Valve Temperature Test

Transmission Oil Sampling Procedure

Transmission Oil Warmup Procedure

Transmission Pump Flow Test

Transmission System Pressure Test

9025 - HYDRAULIC SYSTEM

05 - Theory of Operation

Anticavitation Valve Operation

Auxiliary Section—Operating and Boom Raise

Auxiliary Section—Spool Stroke Adjuster Operation

Boom Section Operation—Boom Down and Steering

Bucket Section Operation—Boom Raise and Bucket Dump (High-Lift Option)

Bucket Section Operation—Boom Raise and Bucket Dump

Circuit Relief With Anticavitation Valve Operation

Control Valve Pilot Orifice Check Valve Operation

Hydraulic Fan Operation

Hydraulic Pump Manifold Operation

Hydraulic Return Filter Operation

Hydraulic Reversing Fan Operation—If Equipped

Loader Control Valve Operation

Loader Control Valve—Outlet Section Operation

Loader Hydraulic System Operation

Load Sense Circuit Operation—Boom Raise and Bucket Dump

Load Sense Circuit Operation—Neutral

Load Sense Circuit Operation—Steering and Boom Down

Load Sense Circuit Operation—Steering

Load Sense Relief Valve Operation

Main Hydraulic Pump Operation

Main Relief Valve Operation

Orbital Steering System Component Operation

Orbital Steering Valve Operation

Pilot Control Lever Operation

Pilot Pressure Reducing Valve Operation

Pin Disconnect Operation

Ride Control Operation—If Equipped

Secondary Steering System Operation—If Equipped

Secondary Steering Valve Operation—If Equipped

Service Brake Accumulator Operation

Service Brake Hydraulic System Operation

Service Brake Valve Operation

15 - Diagnostic Information

Boom Down Does Not Work (Engine Off)

Boom Float Function Not Working

Constant Steering Required to Maintain Straight Travel

Hydraulic Fan Does Not Reach Full Speed

Hydraulic Fan Does Not Spin

Hydraulic Fan Runs at Full Speed Only

Hydraulic Fan Will Not Reverse Direction—If Equipped

Hydraulic Function Drifts Down

Hydraulic Functions Slow

Hydraulic Oil Foams

Hydraulic System Component Location

Hydraulic System Schematic

Machine Turns in Opposite Direction as Steering Wheel

Main Hydraulic Pump Noisy

No Hydraulic Functions

No Orbital Steering Function

Oil Overheats

One Hydraulic Function Not Working

Orbital Steering Jerky

Orbital Steering Valve Binds or Locks Up

Pin Disconnect Cylinders Will Not Retract—If Equipped

Ride Control Not Working

Secondary Steering Motor Will Not Operate—If Equipped

Secondary Steering Pump Runs But Will Not Steer Machine—If Equipped

Slow Steering Wheel Movement Will Not Cause Frame Movement

Steering Erratic

Steering Wheel Free Play

Steering Wheel Kickback

Steering Wheel Turns by Itself

Steering Wheel Turns Without Resistance and Causes No Frame Movement

20 - Adjustments

Auxiliary Pilot Control Lever Adjustment

Auxiliary Valve Section—Stroke Adjustment

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy

Pilot Control Lever Adjustment

Ride Control Accumulator Draining Procedure

Ride Control Accumulator Gas Charge Procedure

25 - Tests

Auxiliary Pilot Control Valve Pressure Test

Boom, Bucket, and Steering Cylinder Leakage Test

Circuit Relief With Anticavitation Valve Pressure Test

Cycle Time Test

Hydraulic Fan Motor Case Drain Test

Hydraulic Fan Motor Speed Test

Hydraulic Fan Pump Flow Test

Hydraulic Fan Pump Pressure Test

Hydraulic Oil Cooler Restriction Test

Hydraulic Oil Filter Inspection Procedure

Hydraulic Oil Sampling Procedure

Hydraulic Oil Warmup Procedure

Hydraulic Reversing Fan Test—If Equipped

Hydraulic System Operating and Standby Pressure Test

Hydraulic System Pressure and Accumulators Discharge

JT02156A Digital Pressure and Temperature Analyzer Kit Installation

Loader Cylinder Drift Test

Load Sense Relief Valve Pressure Test and Adjustment

Main Hydraulic Pump Case Drain Test

Main Hydraulic Pump Control Valve Test and Adjustment

Main Hydraulic Pump Flow Test

Main Relief Valve Pressure Test

Pilot Accumulator Gas Precharge Test

Pilot Control Valve Pressure Test

Pilot Pressure Reducing Valve Pressure Test

Pin Disconnect Pressure Test—If Equipped

Secondary Steering Pump Pressure Relief Valve Test—If Equipped

Secondary Steering Valve—Hydraulic System Isolation Check Valve Leakage Test—If Equipped

Secondary Steering Valve—Secondary Steering Pump Isolation Check Valve Leakage Test—If Equipped

Service Brake Accumulator Gas Precharge and Low Brake Pressure Warning Test

Service Brake Accumulator Inlet Check Valve Leakage Test

Service Brake Valve Leakage Test

Service Brake Valve Pressure Test

Steering Cylinder Drift Test

9031 - HEATING AND AIR CONDITIONING

05 - Theory of Operation

Air Conditioning System Cycle of Operation

15 - Diagnostic Information

Air Conditioner and Heater Component Location

Air Conditioner Does Not Cool Interior of Cab

Air Conditioner Runs Constantly, Too Cold

Air Conditioning System Does Not Operate

Heater Does Not Warm Interior of Cab

Heating System Does Not Operate

Interior Windows Continue to Fog

25 - Tests

Air Conditioning High _ Low Pressure Switch Test

Freeze Control Switch Test

Interior Windows Continue to Fog_{2329}

Interior Windows Continue to Fog

Operating Pressure Diagnostic Chart

R134a Air Conditioning System Test

R134a Oil Charge Capacity

R134a Refrigerant Cautions

R134a Refrigerant Charge Capacity

Refrigerant Cautions and Proper Handling

Refrigerant Hoses and Tubing Inspection

Refrigerant Leak Testing

John Deere 4WD Loader 524K (T3) with Engine 6068HDW74 Operation and Test Service Manual (TM10686)