John Deere 4WD Loader 244H Repair Service Manual (TM1629)

Complete service repair manual for John Deere 4WD Loader 244H, with all the shop information to maintain, repair, and rebuild like professional mechanics.

John Deere 4WD Loader 244H workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM1629 -John Deere 244H 4WD Loader Technical Manual - Repair.PDF

TM1629 -John Deere 244H 4WD Loader Technical Manual - Repair.epub

Total Pages: 722 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

HELP!! HELP!! HELP!! HELP!!

General Information

Safety

General Specifications

Torque Values

Fuels And Lubricants

Wheels

Powered Wheels And Fastenings

Axles And Suspension Systems

Removal And Installation

Differential Or Bevel Drive

Input Drive Shafts And U-Joints

Axle Shaft, Bearings, And Gears

Transmission

Removal And Installation

Controls Linkage

Gear, Shafts, And Power Clutches

Hydraulic System

Engine

Removal And Installation

Engine Auxiliary Systems

Cold Weather Starting Aids

Cooling System

Speed Controls

Intake System

External Exhaust Systems

External Fuel Supply Systems

Dampener Drive (Flex Coupling)

Elements

Steering System

Hydraulic System

Service Brakes

Active Elements

Controls Linkage

Hydraulic System

Park Brake

Active Elements

Controls Linkage

Electrical System

Batteries, Support, And Cables

Alternator, Regulator, And Wiring

Lighting System

Wiring Harness And Switches

System Controls

Instruments And Indicators

Frame Or Supporting Structure

Frame Installation

Chassis Weights

Operator’s Station

Removal And Installation

Operator Enclosure

Seat And Seat Belt

Heating System

Sheet Metal And Styling

Hood Or Engine Enclosure

Safety And Convenience

Horn And Warning Devices

Loader

Bucket

Controls Linkage

Frames

Hydraulic System

Dealer Fabricated Tools

tm1629 - 244h loader repair

Table of Contents

Foreword

HELP!! HELP!! HELP!! HELP!!

Section 00: General Information

Group 01: Safety

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Keep ROPS Installed Properly

Service Tires Safely

Avoid Harmful Asbestos Dust

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Live With Safety

Group 02: General Specifications

244H Specifications

Refill Capacities

Operating Information

Group 03: Torque Values

Hardware Torque Specifications

Metric Bolt and Cap Screw Torque Values

Additional Metric Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values

Check Oil Lines And Fittings

Service Recommendations for O-Ring Boss Fittings

Service Recommendations for Flat Face O-Ring Seal Fittings

Service Recommendations For Flared Connections-Straight or Tapered Threads

Service Recommendations for Metric Series Four Bolt Flange Fitting

Service Recommendations For Inch Series Four Bolt Flange Fittings

Group 04: Fuels And Lubricants

Diesel Fuel

Low Sulfur Diesel Fuel Conditioner

Handling and Storing Diesel Fuel

Do Not Use Galvanized Containers

Fuel Tank

Diesel Engine Oil

Transmission Oil, Hydraulic System Oil And Differential Oil

Brake Oil

Grease

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Section 01: Wheels

Group 0110: Powered Wheels And Fastenings

Service Equipment And Tools

Specifications

Remove And Install Wheel

Remove And Install Tire

Section 02: Axles And Suspension Systems

Group 0200: Removal And Installation

Service Equipment And Tools

Other Material

Specifications

Remove And Install Front Axle

Remove And Install Rear Axle

Remove Rear Axle And Differential

Install Rear Axle And Differential

Group 0210: Differential Or Bevel Drive

Service Equipment And Tools

Other Material

Specifications

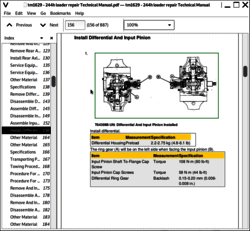

Remove Differential And Input Pinion

Disassemble Differential

Assemble Differential

Disassemble Input Pinion

Assemble Input Pinion

Install Differential And Input Pinion

Group 0225: Input Drive Shafts And U-Joints

Other Material

Specifications

Transporting Precautions

Towing Procedure-Engine Operational

Procedure For Towing Machine Less Than 460 M (500 YD)-Engine Non-Operational

Procedure For Towing Machine More Than 460 M (500 YD)-Engine Non-Operational

Remove And Install Front And Center Differential Drive Shafts And Support Bearing

Disassemble And Assemble Front And Center Differential Drive Shafts

Remove And Install Rear Differential Drive Shaft

Disassemble And Assemble Rear Differential Drive Shaft

Group 0250: Axle Shaft, Bearings, And Gears

Other Material

Specifications

Disassemble Axle

Assemble Axle

Section 03: Transmission

Group 0300: Removal And Installation

Other Material

Service Equipment And Tools

Specifications

Hydrostatic System Bleed Procedure

Remove And Install Hydrostatic Motor

Remove And Install High-Low Range Transmission

Remove And Install Hydrostatic Pump

Group 0315: Controls Linkage

Remove And Install FNR Lever And Switch

Remove And Install Service Brake And Inching Pedal Linkage

Adjust Brake Switch, Service Brake And Inching Pedal Linkage

Group 0350: Gear, Shafts, And Power Clutches

Specifications

Remove And Install Transmission Gear Train

Disassemble And Assemble Input Shaft And Gear

Disassemble And Assemble High And Low Range Clutch Packs And Shaft

Disassemble And Assemble Output Shaft And Gears

Group 0360: Hydraulic System

Service Equipment And Tools

Other Material

Specifications

Hydrostatic System Bleed Procedure

Remove And Install Transmission Charge Pump

Disassemble And Assemble Transmission Charge Pump

Remove And Install Transmission Charge Oil Filter And Bypass Valve

Remove And Install Transmission Pressure Regulating Valve

Remove And Install Transmission High-Low Range Control Valve

Disassemble And Assemble Transmission High-Low Range Control Valve

Remove And Install Transmission High-Low Range Solenoid Valve

Remove And Install Suction Screen

Remove And Install Reservoir

Remove And Install Hydrostatic Charge Pump

Disassemble And Assemble Hydrostatic Charge Pump

Remove Hydrostatic Pump Drive

Install Hydrostatic Pump Drive

Remove And Install Hydrostatic Pump

Disassemble Hydrostatic Pump

Assemble Hydrostatic Pump

Remove And Install Hydrostatic Pump Cold Start Dump Valve

Remove And Install Hydrostatic Pump High Pressure Relief Valves

Remove And Install Hydrostatic Pump Neutral Charge Relief Valve

Remove And Install Hydrostatic Pump Forward And Reverse Solenoid Valves

Remove And Install Hydrostatic Pump Pressure Compensator Valves

Remove And Install Hydrostatic Pump Inching Relief Valve

Remove And Install Hydrostatic Pump Sequence Valve

Remove And Install Hydrostatic Motor

Disassemble And Assemble Hydrostatic Motor

Remove And Install Hydrostatic Motor Bypass Valve

Remove And Install Hydrostatic Motor Shuttle Valve

Remove And Install Hydrostatic Motor Operating Charge Relief Valve

Remove And Install Hydrostatic Motor Displacement Control Valve

Remove And Install Hydrostatic Oil Cooler

Remove And Install Hydrostatic Oil Cooler Bypass Valve

Remove And Install Hydrostatic Charge Oil Filter And Bypass Valve

Reconditioning Components Using Lapping Table

Section 04: Engine

Group 0400: Removal And Installation

4TNE98 YANMAR Engine Repair-Use CTM119

Service Equipment And Tools

Specifications

Remove Engine

Install Engine

Remove And Install Fuel Injection Lines And Nozzles

Remove And Install Oil Pan

Remove Fuel Injection Pump

Repair Injection Pump

Install Fuel Injection Pump

Install Fuel Injection Pump-Alternate Method

Injection Pump Static Timing Adjustment

Remove And Install Fuel Filter

Remove And Install Fuel Transfer Pump

Bleed Fuel System

Remove And Install Water Pump

Remove And Install Thermostat

Remove And Install Intake Manifold

Remove And Install Exhaust Manifold

Check And Adjust Engine Valve Lash-Clearance

Remove And Install Starter

Section 05: Engine Auxiliary Systems

Group 0505: Cold Weather Starting Aids

Remove And Install Engine Intake Air Pre-Heater

Group 0510: Cooling System

Specifications

Remove And Install Fan, Shroud, And Guard

Remove And Install Fan Belt

Adjust Fan Belt

Remove And Install Radiator

Remove And Install Coolant Recovery Tank

Group 0515: Speed Controls

Remove And Install Speed Control Linkage

Adjusting Engine Speed Linkage

Group 0520: Intake System

Remove And Install Air Cleaner

Replace Air Cleaner Elements

Remove And Install Air Intake

Test Air Intake System For Leaks

Group 0530: External Exhaust Systems

Remove And Install Muffler

Group 0560: External Fuel Supply Systems

Service Equipment And Tools

Specifications

Remove And Install Fuel Tank

Section 07: Dampener Drive (Flex Coupling)

Group 0752: Elements

Other Material

Specifications

Remove Hydrostatic Dampener Drive (Flex Coupling)

Install Hydrostatic Dampener Drive (Flex Coupling)

Section 09: Steering System

Group 0960: Hydraulic System

Special Or Essential Tools

Other Material

Specifications

Remove And Install Steering Valve

Disassemble Steering Valve

Assemble Steering Valve

Remove And Install Steering Cylinder

Disassemble And Assemble Steering Cylinder

Remove And Install Cylinder Bushings

Section 10: Service Brakes

Group 1011: Active Elements

Specifications

Remove Brake Pressure Plate And Disk

Install Brake Pressure Plate And Disk

Service Brake Pan Inspection

Group 1015: Controls Linkage

Remove And Install Service Brake And Inching Pedal Linkage

Adjust Brake Switch, Service Brake And Inching Pedal Linkage

Group 1060: Hydraulic System

Specifications

Remove And Install Master Brake Cylinder

Disassemble And Assemble Master Brake Cylinder

Remove And Install Brake Reservoir

Brake Bleed Procedure

Section 11: Park Brake

Group 1111: Active Elements

Specifications

Remove And Install Park Brake

Disassemble And Assemble Park Brake

Remove And Install Park Brake Spring Cylinder

Disassemble And Assemble Park Brake Spring Cylinder

Remove And Install Park Brake Solenoid Valve

Group 1115: Controls Linkage

Park Brake Adjustment

Section 16: Electrical System

Group 1671: Batteries, Support, And Cables

Service Equipment And Tools

Specifications

Handle Batteries Safely

Procedure For Testing Batteries

Check Battery Electrolyte Specific Gravity

Check Battery Electrolyte Level And Terminals

Using Booster Batteries-24 Volt System

Charge Battery

Removing Battery

Adding 12-Volt Accessories

Group 1672: Alternator, Regulator, And Wiring

Specifications

Remove And Install Alternator

Group 1673: Lighting System

Replace Halogen Bulbs

Remove And Install Drive Lights

Remove And Install Brake And Tail Lights

Remove And Install Turn And Warning Signal Lights

Remove And Install Dome Light

Fuse Identification

Group 1674: Wiring Harness And Switches

Essential Tools

Other Material

Specifications

Light Harness Component Location

Machine Harness Component Location

Instrument Panel And Relays Component Location

Engine Harness Component Location

Remove And Install Horn Switch

Remove And Install Instrument Panel

Remove And Install FNR Lever And Switch

Remove And Install Turn Signal Switch, Drive Light Switch, And Hazard Light Switch

Remove And Install Under Dash Diodes

Remove And Install Turn Signal Flasher

Remove And Install Relays

Remove And Install Park Brake Warning Alarm

Remove And Install Monitor Warning Alarm

Remove And Install Key Switch

Remove And Install Fuse Box

Remove And Install Hydrostatic Oil Temperature Indicator Switch

Remove And Install Engine Intake Air Pre-Heater Relay

Remove And Install Engine Intake Air Pre-Heater 15-Second Timer

Remove And Install Engine Coolant Temperature Sender

Remove And Install Engine Shut-Off Motor

Remove And Install Oil Pressure Indicator Switch

Remove And Install Transmission Controller

Remove And Install Transmission Control Relay

Remove And Install Fuel Gauge Level Sender

Remove And Install Heater Blower Switch

Remove And Install Park Brake Switch

Park Brake Adjustment

Remove And Install Transmission Speed Sensor

Remove And Install Transmission High-Low Range Solenoid

Remove And Install Brake Light Switch

Adjust Brake Light Switch

Remove And Install Bucket Return-To-Dig Solenoid

Remove And Install Bucket Return-To-Dig Switch

Adjust Return-To-Dig

Remove And Install Fuse Box For Upper Cab

Remove And Install Service Lights, Wiper, Washer And Dome Light Switches

Remove And Install Forward And Reverse Shift Solenoids

Remove And Install Hydraulic Oil Filter Restriction Indicator Switch

Remove And Install Safety Relay

Remove And Install Safety Relay Controller Diode

Remove And Install Alternator Rectifier

Remove And Install Hydrostatic Oil Pressure Indicator Switch

Remove And Install Hydrostatic Oil Filter Restriction Indicator Switch

Remove Connector Body From Blade Terminals

Replace AMP AMP is a trademark of AMP Incorporated. Econoseal J Series Contact

Group 1675: System Controls

Remove And Install Bucket Return-To-Dig Switch

Adjust Return-To-Dig

Group 1676: Instruments And Indicators

Remove And Install Meter Panel

Section 17: Frame Or Supporting Structure

Group 1740: Frame Installation

Service Equipment And Tools

Specifications

Welding Repair Of Major Structures

Separate Engine And Loader Frames

Remove And Install Upper And Lower Pivot Bushings And Seals

Group 1749: Chassis Weights

Specifications

Remove And Install Counterweight And Drawbar

Section 18: Operator’s Station

Group 1800: Removal And Installation

Specifications

Remove And Install Cab

Group 1810: Operator Enclosure

Remove And Install Cab Windowpanes And Moldings

Windowpane Dimensions

Remove And Install Cab Door Or Window

Remove And Install Door Latch

Remove And Install Window Latch

Remove And Install Windshield Washer

Adjust Windshield Washer Nozzles

Remove And Install Wiper Motor

Group 1821: Seat And Seat Belt

Remove And Install Seat

Remove And Install Seat Belt

Group 1830: Heating System

Remove And Install Heater And Blower Motor

Remove And Install Heater Blower Motor Resistor

Section 19: Sheet Metal And Styling

Group 1910: Hood Or Engine Enclosure

Specifications

Remove And Install Hood

Adjust Hood Latch

Remove And Install Rear Frame Cover And Engine Enclosure

Remove And Install Service Doors

Section 20: Safety And Convenience

Group 2004: Horn And Warning Devices

Remove And Install Reverse Warning Alarm

Section 31: Loader

Group 3102: Bucket

Specifications

Remove And Install Bucket Teeth

Remove And Install Tooth Shank And Tips

Remove And Install Bucket

Remove And Install Cutting Edges (For Bucket With Wear Plates)

Replace Welded Bucket Cutting Edges

Repair Cracked Cutting Edge

Group 3115: Controls Linkage

Specifications

Disassemble And Assemble Control Valve Linkage And Lock

Adjust Control Valve Linkage And Lock

Group 3140: Frames

Service Equipment And Tools

Other Material

Specifications

Remove Bucket Link

Install Bucket Link

Remove And Install Bellcrank

Remove And Install Boom

Inspect Pins

Remove And Install Bushings And Seals

Group 3160: Hydraulic System

Service Equipment And Tools

Specifications

Remove And Install Reservoir

Remove And Install Suction Screen

Remove And Install Steering And Main Hydraulic Pump

Disassemble Steering And Main Hydraulic Pump

Inspect Steering And Main Hydraulic Pump

Assemble Steering And Main Hydraulic Pump

Remove And Install Priority Valve

Disassemble And Assemble Priority Valve

Inspect System Relief Valve

Inspect Circuit Relief Valves

Remove And Install Control Valve

Disassemble And Assemble Control Valve

Repair Bucket Valve Section With Return-To-Dig

Repair Boom Valve Section

Repair Auxiliary Valve Section

Remove And Install Bucket Cylinder

Remove And Install Boom Cylinder

Disassemble And Assemble Bucket Or Boom Cylinder

Remove And Install Return Filter And Bypass Valve

Section 99: Dealer Fabricated Tools

Group 9900: Dealer Fabricated Tools

DFT1107 Hydrostatic Pump Pipe Clamp

DFT1119 Pump Support

John Deere 4WD Loader 244H Repair Service Manual (TM1629)