John Deere Crawler Dozer 850J Operation and Test Service Manual (TM12322)

Complete Operation and Test manual with Electrical Wiring Diagrams for John Deere Crawler Dozer 850J, with all the technical information to maintain, diagnose, and rebuild like professional mechanics.

John Deere Crawler Dozer 850J workshop Operation and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM12322 -John Deere 850J Crawler Dozer Technical Manual - Operation and Test.PDF

TM12322 -John Deere 850J Crawler Dozer Technical Manual - Operation and Test.EPUB

Total Pages: 832 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

Technical Information Feedback Form

General Information

Safety

Diagnostic Trouble Codes (DTCs)

Standard Display Monitor (SDM) Diagnostic Trouble Codes

Engine Control Unit (ECU) Diagnostic Trouble Codes

Transmission Control Unit (TCU) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Hydraulics

Theory

Diagnostic Information

Tests

Hydrostatic System

Theory of Operation

Diagnostic Information

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

tm12322 - 850J Crawler Dozer

Table of Contents

Foreword

Technical Information Feedback Form

Section 9000: General Information

Group 01: Safety

Recognize Safety Information

Follow Safety Instructions

Operate Only If Qualified

Wear Protective Equipment

Avoid Unauthorized Machine Modifications

Inspect Machine

Stay Clear of Moving Parts

Avoid High-Pressure Fluids

Beware of Exhaust Fumes

Prevent Fires

Prevent Battery Explosions

Handle Chemical Products Safely

Dispose of Waste Properly

Prepare for Emergencies

Add Cab Guarding For Special Uses

Use Steps and Handholds Correctly

Start Only From Operator's Seat

Use and Maintain Seat Belt

Prevent Unintended Machine Movement

Avoid Work Site Hazards

Keep Riders Off Machine

Avoid Backover Accidents

Avoid Machine Tip Over and Machine Damage

Add and Operate Attachments Safely

Park and Prepare for Service Safely

Service Cooling System Safely

Remove Paint Before Welding or Heating

Make Welding Repairs Safely

Drive Metal Pins Safely

Section 9001: Diagnostic Trouble Codes (DTCs)

Group 10: Standard Display Monitor (SDM) Diagnostic Trouble Codes

000096.03 - Fuel Level Sensor Open or Short

000096.04 - Fuel Level Sensor Short to Ground

000107.03 - Engine Air Filter Restriction Indicator Switch Short to Power

000107.04 - Engine Air Filter Restricted

002000.09 - CAN Communication Error, No ECU Configuration

002003.09 - Loss of CAN Communication With TCU

Group 20: Engine Control Unit (ECU) Diagnostic Trouble Codes

000091.09 - CAN Throttle Missing From TCU

001568.02 - Torque Curve Selection Data Intermittent or Incorrect

002000.13 - Security Violation

Group 30: Transmission Control Unit (TCU) Diagnostic Trouble Codes

000070.00 - Park Lock Lever Inputs Both ON

000070.01 - Park Lock Lever Inputs Both OFF

000091.03 - Throttle Sensor Short to Power

000091.04 - Throttle Sensor Open or Short

000116.00 - Brake Pressure High

000116.01 - Brake Pressure Low

000116.03 - Brake Pressure Short to Power

000116.04 - Brake Pressure Open or Short

000158.03 - TCU System Volts Too High

000158.04 - TCU System Volts Too Low

000168.04 - Unswitched System Volts Too Low

000177.00 - Transmission Over Temp

000177.03 - Transmission Oil Temperature Sensor Short to Power

000177.04 - Transmission Oil Temperature Sensor Short to Ground

000177.16 - Transmission Oil Temperature High

000190.09 - CAN Communication Error No Engine Speed

000190.19 - CAN Communication Error Invalid Engine Speed

000521.00 - Decel Sensor Input Greater Than Maximum Calibration Value

000521.01 - Decel Sensor Input Less Than Minimum Calibration Value

000521.03 - Decel Sensor Short to Power

000521.04 - Decel Sensor Open or Short

000521.05 - Decel Sensor Brake Calibration Value Too Low

000521.06 - Decel Sensor Brake Calibration Value Too High

000521.13 - Decelerator Sensor Brake Calibration Too High

000521.15 - Decel Sensor Minimum Calibration Value Too High

000521.16 - Decel Sensor Maximum Calibration Value Too Low

000521.17 - Decel Sensor Minimum Calibration Value Too Low

000521.18 - Decel Sensor Maximum Calibration Value Too Low

000581.00 - Speed Buttons Input Greater Than Maximum Calibration Value

000581.01 - Speed Buttons Input Less Than Minimum Calibration Value

000581.03 - Speed Buttons Short to Power

000581.04 - Speed Buttons Open or Short

000581.07 - Speed Buttons Stuck Button

000581.13 - Speed Buttons Not Calibrated

000581.15 - Speed Buttons Minimum Calibration Value Too High

000581.16 - Speed Buttons Maximum Calibration Value Too High

000581.17 - Speed Buttons Minimum Calibration Value Too Low

000581.18 - Speed Buttons Maximum Calibration Value Too Low

000604.03 - FNR Neutral Switch Open Circuit

000604.04 - FNR Neutral Switch Short Circuit

000604.15 - FNR Neutral Switch Minimum Calibration Value Too High

000604.16 - FNR Neutral Switch Maximum Calibration Value Too High

000604.17 - FNR Neutral Switch Minimum Calibration Value Too Low

000604.18 - FNR Neutral Switch Maximum Calibration Value Too Low

000619.05 - Brake Solenoid No Response

000619.06 - Brake Solenoid Short to Ground

000629.12 - TCU Watchdog Timeout

000907.03 - Left Speed Sensor Short to Power

000907.04 - Left Speed Sensor Short

000907.07 - Left Speed Sensor No Response

000907.12 - Left Speed Sensor Open

000908.03 - Right Speed Sensor Short to Power

000908.04 - Right Speed Sensor Short

000908.07 - Right Speed Sensor No Response

000908.12 - Right Speed Sensor Open

000977.05 - Fan Reverse Solenoid No Response

000977.06 - Fan Reverse Solenoid Short to Ground

001071.05 - Fan Drive Solenoid Open Circuit

001071.06 - Fan Drive Solenoid Short Circuit

001638.00 - Hydraulic Oil Temperature High

001638.03 - Hydraulic Oil Temperature Short to Power

001638.04 - Hydraulic Oil Temperature Short to Ground

001638.16 - Hydraulic Temperature Moderately High

001713.31 - Hydraulic Oil Filter Restricted

002000.09 - Loss of CAN Communication With ECU

002023.09 - Loss of CAN Communication With SDM

002660.00 - Steer Sensor Input Greater Than Maximum Calibration Value

002660.01 - Steer Sensor Input Less Than Minimum Calibration Value

002660.03 - Steer Sensor Short to Power

002660.04 - Steer Sensor Open or Short

002660.07 - Steer Sensor Neutral Calibration Out of Range

002660.13 - Steer Sensor Not Calibrated

002660.15 - Steer Sensor Minimum Calibration Value Too High

002660.16 - Steer Sensor Maximum Calibration Value Too Low

002660.17 - Steer Sensor Minimum Calibration Value Too Low

002660.18 - Steer Sensor Maximum Calibration Value Too Low

002661.00 - FNR Sensor Input Greater Than Maximum Calibration Value

002661.01 - FNR Sensor Input Less Than Minimum Calibration Value

002661.04 - FNR Sensor Open or Short

002661.03 - FNR Sensor Short to Power

002661.07 - FNR Sensor Neutral Calibration Out of Range

002661.13 - FNR Sensor Not Calibrated

002661.15 - FNR Sensor Minimum Calibration Value Too High

002661.16 - FNR Sensor Maximum Calibration Value Too Low

002661.17 - FNR Sensor Minimum Calibration Value Too Low

002661.18 - FNR Sensor Maximum Calibration Value Too Low

003359.31 - Transmission Oil Filter Restricted

003509.03 - Sensor Supply 1 Voltage OOR High

003509.04 - Sensor Supply 1 Voltage OOR Low

003510.03 - Sensor Supply 2 Voltage OOR High

003510.04 - Sensor Supply 2 Voltage OOR Low

003511.03 - Sensor Supply 3 Voltage OOR High

003511.04 - Sensor Supply 3 Voltage OOR Low

003512.03 - Sensor Supply 4 Voltage OOR High

003512.04 - Sensor Supply 4 Voltage OOR Low

520709.00 - Fan Oil Filter Restricted

522439.05 - Tank Bypass Solenoid Open Circuit

522439.06 - Tank Bypass Solenoid Short to Power

522440.05 - Blade Left Solenoid Open Circuit

522440.06 - Blade Left Solenoid Short Circuit

522441.05 - Blade Right Solenoid Open Circuit

522441.06 - Blade Right Solenoid Short Circuit

522442.00 - Blade Buttons Input Greater Than Maximum Calibration Value

522442.01 - Blade Buttons Input Less Than Minimum Calibration Value

522442.03 - Blade Buttons Short to Power

522442.04 - Blade Buttons Open or Short

522442.07 - Blade Buttons Stuck Button

522444.00 - Charge Pressure High

522444.01 - Charge Pressure Low

522444.03 - Charge Pressure Short to Power

522444.04 - Charge Pressure Open or Short

522447.05 - Right Forward Pump Coil Open

522447.06 - Right Forward Pump Coil Short

522447.15 - Right Forward Pump Threshold Calibration Value Too High

522447.16 - Right Forward Pump Max Speed Calibration Value Too High

522447.17 - Right Forward Pump Threshold Calibration Value Too Low

522447.18 - Right Forward Pump Max Speed Calibration Value Too Low

522448.05 - Right Reverse Pump Coil Open

522448.06 - Right Reverse Pump Coil Short

522448.15 - Right Reverse Pump Threshold Calibration Value Too High

522448.16 - Right Reverse Pump Max Speed Calibration Value Too High

522448.17 - Right Reverse Pump Thresh Calibration Value Too Low

522448.18 - Right Reverse Pump Max Speed Calibration Value Too Low

522449.05 - Left Reverse Pump Coil Open

522449.06 - Left Reverse Pump Coil Short

522449.15 - Left Reverse Pump Threshold Calibration Value Too High

522449.16 - Left Reverse Pump Max Speed Calibration Value Too Low

522449.17 - Left Reverse Pump Threshold Calibration Value Too Low

522449.18 - Left Reverse Pump Max Speed Calibration Value Too Low

522450.05 - Left Forward Pump Coil Open

522450.06 - Left Forward Pump Coil Short

522450.15 - Left Forward Pump Threshold Calibration Value Too High

522450.16 - Left Forward Pump Max Speed Calibration Value Too High

522450.17 - Left Forward Pump Threshold Calibration Value Too Low

522450.18 - Left Forward Pump Max Speed Calibration Value Too Low

522451.05 - Cooler Bypass Solenoid No Response

522451.06 - Cooler Bypass Solenoid Short to Power

523108.13 - TCU Not Calibrated High Speed Not Done

523108.14 - TCU Not Calibrated Sensor/Pump/Motor

523577.05 - Left Motor Solenoid Open Circuit

523577.06 - Left Motor Solenoid Short Circuit

523577.13 - Motor High Speed Not Calibrated

523577.16 - Left Motor Maximum Calibration Value Too High

523577.18 - Left Motor Maximum Calibration Value Too Low

523578.05 - Right Motor Solenoid Open Circuit

523578.06 - Right Motor Solenoid Short Circuit

523578.16 - Right Motor Maximum Calibration Value Too High

523578.18 - Right Motor Maximum Calibration Value Too Low

524089.00 - Left System Pressure High

524089.01 - Left System Pressure Low

524089.03 - Left System Pressure Short to Power

524089.04 - Left System Pressure Open or Short

524090.00 - Right System Pressure High

524090.01 - Right System Pressure Low

524090.03 - Right System Pressure Short to Power

524090.04 - Right System Pressure Open or Short

524233.07 - Hydrostatic Drive System Not Responding

Section 9005: Operational Checkout Procedure

Group 10: Operational Checkout Procedure

Operational Checkout

Section 9010: Engine

Group 05: Theory of Operation

PowerTech™ E 6.8 L (6068) John Deere Engine

Group 15: Diagnostic Information

Diagnose Engine Malfunctions

Engine Cooling System Component Location

Engine Fuel System Component Location

Engine Intake and Exhaust Component Location

Group 25: Tests

PowerTech™ E 6.8 L (6068) John Deere Engine

Intake Manifold Pressure Test—Turbocharger Boost

Fuel Supply Pump Pressure Test

Section 9015: Electrical System

Group 05: System Information

Electrical Diagram Information

Electrical Schematic Symbols

Group 10: System Diagrams

Fuse and Relay Specifications

System Functional Schematic, Wiring Diagram, and Component Location Legend

System Functional Schematic and Section Legend

JDLink™ System Functional Schematic—If Equipped

Operator's Station Harness (W7) Component Location

Operator's Station Harness (W7) Wiring Diagram

Canopy Roof Harness (W8) Component Location

Canopy Roof Harness (W8) Wiring Diagram

Cab Roof Harness (W9) Component Location

Cab Roof Harness (W9) Wiring Diagram

Engine Harness (W10) Component Location

Engine Harness (W10) Wiring Diagram

Transmission Harness (W11) Component Location

Transmission Harness (W11) Wiring Diagram

Fuel Tank Harness (W12) Component Location

Fuel Tank Harness (W12) Wiring Diagram

Air Conditioning Harness (W14) Component Location

Air Conditioning Harness (W14) Wiring Diagram

Radio Harness (W15) Component Location

Radio Harness (W15) Wiring Diagram

Pressure Sensor Harness (W27) Wiring Diagram

JDLink™ Harnesses (W6002 and W6003) Component Location—If Equipped

JDLink™ Modular Telematics Gateway (MTG) Harness (W6002) Wiring Diagram—If Equipped

JDLink™ Satellite (SAT) Harness (W6003) Wiring Diagram—If Equipped

Group 15: Sub-System Diagnostics

Starting and Charging Circuit Theory of Operation

Controller Area Network (CAN) Circuit Theory of Operation

Engine Control Unit (ECU) Circuit Theory of Operation

Transmission Control Unit (TCU) Circuit Theory of Operation

Standard Display Monitor (SDM) Circuit Theory of Operation

Horn, Light, and Wiper Circuit Theory of Operation

JDLink™ Circuit Theory of Operation—If Equipped

Group 16: Monitor Operation

Standard Display Monitor (SDM) Menu Structure-Service Mode

Standard Display Monitor (SDM)—Codes

Standard Display Monitor (SDM)—Machine Settings

Standard Display Monitor (SDM)—Diagnostics

Standard Display Monitor (SDM)—Monitor

Standard Display Monitor (SDM)—Calibrate

Standard Display Monitor (SDM)—TCU Diagnostics

Standard Display Monitor (SDM) Setting Hour Meter

Group 20: References

Electrical Component Specifications

Service ADVISOR™ Diagnostic Application

Service ADVISOR™ Connection Procedure

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application

Alternator Test Procedure

CAN Circuit Test

Transmission Control Unit (TCU) Calibration

Wire Harness Test

Decelerator/Brake Pedal Adjustment

Engine Speed Control Remove and Install

Rotary Sensor Remove and Install

Transmission Control Lever (TCL) Adjustment

Engine Control Unit (ECU) Remove and Install

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors

Replace DEUTSCH DEUTSCH is a trademark of Deutsch Co. Rectangular or Triangular Connectors

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact

Replace CINCH CINCH is a trademark of the Cinch Co. Connectors

Install CINCH CINCH is a trademark of the Cinch Co. Contact

Repair 32 and 48 Way CINCH CINCH is a trademark of the Cinch Co. Connectors

Replace (Pull Type) Metri-Pack™ Connectors

Replace (Push Type) Metri-Pack™ Connectors

Section 9025: Hydraulics

Group 05: Theory

Hydraulic System Operation

Hydraulic Pump Operation

Hydraulic Control Valve Operation

Load Sense Circuit Operation

Load Sense Isolator Operation

Circuit Relief Valve with Anticavitation Operation

Hydraulic System Relief Valve Operation

Hydraulic Oil Filter Manifold Operation

Blade Angle Operation

Ripper Operation

Hydraulic Cylinder Operation

Quick-Drop Valve Operation

Group 15: Diagnostic Information

Hydraulic System Schematic

Main Hydraulic Component Location

Ripper Ready Hydraulic Component Location

Winch Ready Hydraulic Component Location

Hydraulic System Diagnose Malfunctions

Group 25: Tests

JT02156A Digital Pressure/Temperature Analyzer Installation

Ultra Clean® Hand Launcher

Hydraulic Oil Cleanup Procedure

Hydraulic System Relief Valve Test

Circuit Relief Valve Test

Pump Load Sense Differential and System Pressure (Pump Cutoff) Test and Adjustment

Lift and Tilt Cylinder Function Drift Test

Hydraulic Cylinder Drift Test

Cylinder Leakage Test

Pressure Reducing Valve Pressure Test and Adjustment

Blade Down Accumulator Hydraulic Discharge

Blade Down Accumulator Precharge Test

Hydraulic Pump Flow Test

Hydraulic Pump Case Drain Test

Section 9026: Hydrostatic System

Group 05: Theory of Operation

Hydrostatic System

Transmission Control Circuit Operation (Flow Chart)

Charge Pump Operation

Hydrostatic Charge Oil Filter Operation

Neutral Charge Relief Valve Operation

Multi-Function Valve Operation

Hydraulic Integrated Circuit (HIC) Valve Operation

Park Brake Valve Operation

Oil Cooler and Reservoir Bypass Operation

Pump Pressure Control Pilot (PCP) Operation

Pump Displacement Control Valve (PDCV) Operation

Hydrostatic Pump Operation

Flushing Valve and Operating Charge Relief Valve Operation

Hydrostatic Motor Operation

Hydraulic Reversing Fan Drive Operation

Hydraulic Non-Reversing Fan Drive Operation

Hydraulic Fan Return Filter Operation

Group 15: Diagnostic Information

Overheating Malfunctions

Low Charge Pressure Malfunctions

Mistrack/Index Malfunctions

Machine Full Speed Malfunctions

Low Power Malfunctions

Track Malfunctions

TCU Calibration Malfunctions

Hydrostatic System Component Location

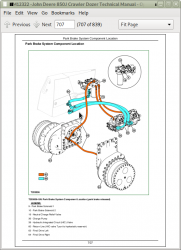

Park Brake System Component Location

Hydrostatic System Schematic—Neutral (Park Brake On)

Hydrostatic System Diagram—Neutral (Park Brake On)

Hydrostatic System Diagram—Reverse (Slow Speed)

Hydrostatic System Diagram—Forward (Fast Speed)

Group 25: Tests

JT02156A Digital Pressure/Temperature Analyzer Installation

Ultra Clean® Hand Launcher

Machine Supporting Procedure

Transmission Oil Warm-Up Procedure

Releasing Park Brake to Tow the Machine

Hydrostatic Pump and Motor Initial Start-Up Procedure

Hydrostatic Pump Flushing Procedure

Hydraulic Oil Cleanup Procedure

Pressure Control Pilot (PCP) Manual Override Test

Pressure Control Pilot (PCP) Test

Pressure Control Pilot (PCP) Internal Adjustment

Multi-Function Relief Valve Test

Transmission Efficiency Test

Neutral Charge Relief and Operating Charge Relief Pressure Test

Pump Displacement Control Valve (PDCV) Neutral (Null) Adjustment

Pump Servo Pressure Test

Motor Displacement Control Valve (MDCV) Adjustment

Hydrostatic Motor Min./Max. Angle Servo Piston Pressure Test

Charge Pump Flow Test

Charge Pressure Sensor Test

Hydrostatic Oil Cooler Bypass Test

Hydrostatic Oil Reservoir Bypass Test

Park Brake Test

Park Brake Relief Valve Test

Cab Tilt Relief Valve Test

Hand Pump Bleed Procedure

Fan Pump Pressure Test

Fan Pump Flow Test

Fan Motor Speed Test

Fan Motor Case Drain Test

Section 9031: Heating and Air Conditioning

Group 05: Theory of Operation

Air Conditioning System Cycle Theory Of Operation

Group 15: Diagnostic Information

Diagnose Air Conditioning System Malfunctions

Diagnose Heater System Malfunctions

Group 25: Tests

Proper Refrigerant Handling

R134a Refrigerant Cautions

R134a Oil Charge Capacity

R134a Refrigerant Charge Capacity

Refrigerant Hoses And Tubing Inspection

R134a Air Conditioning System Test

Operating Pressure Diagnostic Chart

Air Conditioner Low Pressure Switch Test

Air Conditioner High Pressure Switch Test

Freeze Control Switch Test

Leak Testing