John Deere 1050C Crawler Dozer Operation & Test Service Manual (TM2300)

Complete Operation & Test manual with Electrical Wiring Diagrams for John Deere 1050C Crawler Dozer, with all the shop information to maintain, diagnose, and repair like professional mechanics.

John Deere 1050C Crawler Dozer workshop Operation & Test manual includes:

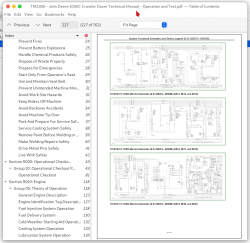

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM2300 - John Deere 1050C Crawler Dozer Technical Manual - Operation and Test.PDF

TM2300 - John Deere 1050C Crawler Dozer Technical Manual - Operation and Test.epub

PRODUCT DETAILS:

Total Pages: 701 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Adjustments

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

JDG10470376 Diagnostic Test Box

References

Power Train

Theory of Operation

Diagnostic Information

Pneumatic System

Theory of Operation

Diagnostic Information

Hydraulic System

Theory of Operation

Diagnostic Information

Adjustments

Tests

Hydrostatic System

Theory of Operation

Diagnostic Information

Adjustments

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

Dealer Fabricated Tools

TABLE OF CONTENTS...1

Section 9000: General Information...12

Group 01: Safety...12

Recognize Safety Information...14

Follow Safety Instructions...15

Operate Only If Qualified...16

Wear Protective Equipment...17

Avoid Unauthorized Machine Modifications...18

Inspect Machine...19

Add Cab Guarding For Special Uses...20

Stay Clear of Moving Parts...21

Avoid High-Pressure Oils...22

Beware of Exhaust Fumes...23

Prevent Fires...24

Prevent Battery Explosions...25

Handle Chemical Products Safely...26

Dispose of Waste Properly...27

Prepare for Emergencies...28

Start Only From Operator's Seat...29

Use and Maintain Seat Belt...30

Prevent Unintended Machine Movement...31

Avoid Work Site Hazards...32

Keep Riders Off Machine...33

Avoid Backover Accidents...34

Avoid Machine Tip Over...35

Park And Prepare For Service Safely...37

Service Cooling System Safely...38

Remove Paint Before Welding or Heating...39

Make Welding Repairs Safely...40

Drive Metal Pins Safely...41

Live With Safety...42

Section 9005: Operational Checkout Procedure...43

Group 10: Operational Checkout Procedure...43

Operational Checkout...81

Section 9010: Engine...118

Group 05: Theory of Operation...118

General Engine Description...123

Engine Identification Tag Description...127

Fuel Injection System Operation...128

Fuel Delivery System...130

Cold Weather Starting Aid Operation...132

Cooling System Operation...133

Lubrication System Operation...135

Charge Air System Operation...137

Turbocharger Operation...139

Engine Overspeed Protection Operation...140

Engine Auxiliary Systems...141

Group 15: Diagnostic Information...118

Diagnose Engine Malfunctions...150

Engine Overheating—Flowchart...158

Engine Cooling System Component Location...159

Engine Fuel System Component Location...161

Engine Intake and Exhaust Component Location...163

Group 20: Adjustments...118

Fast and Slow Idle Adjustment...167

Engine Speed Cable Adjustment...169

Valve Clearance Adjustment...173

Belt Tension Adjustment...176

Fuel Injection Pump Timing—Spill Port Method (S.N. 005600— )...178

Group 25: Tests...118

Intake Manifold Pressure Test—Turbocharger Boost...184

Cylinder Compression Test...186

Oil Pump Pressure Test...188

Fuel Injection Pressure Test...189

Glow Plug Test...191

Fuel Supply Pump Pressure Test...192

Section 9015: Electrical System...194

Group 05: System Information...194

Electrical Diagram Information...203

Explanation of Wire Markings...209

Circuit Breaker and Relay Specifications...210

Component Identification Table...212

Fuse (Blade-Type) Color Codes...214

Group 10: System Diagrams...194

System Functional Schematic, Wire Diagram, and Component Location Master Legend (S.N. 005072—005599)...220

System Functional Schematic and Section Legend (S.N. 005072—005599)...225

System Functional Schematic, Wire Diagram, and Component Location Master Legend (S.N. 005600—005615)...230

System Functional Schematic and Section Legend (S.N. 005600—005615)...235

System Functional Schematic, Wire Diagram, and Component Location Master Legend (S.N. 005616— )...240

System Functional Schematic and Section Legend (S.N. 005616— )...245

Main Wire Harness (W10) and Engine Wire Harness (W13) Component Location...251

Main Wire Harness (W10) and Engine Wire Harness (W13) Wire Diagram...254

Instrument Panel Wire Harness (W11) Component Location...257

Instrument Panel Wire Harness (W11) Wire Diagram...260

Overhead Console Wire Harness (W12) Component Location...263

Overhead Console Wire Harness (W12) Wire Diagram...265

Air Conditioning Wire Harness (W14 and W15) Component Location...268

Air Conditioning Wire Harness (W14 and W15) Wire Diagram...269

Group 15: Sub-System Diagnostics...194

Power Circuit Theory of Operation...272

Starting and Charging Circuit Theory of Operation...274

Park Brake Release Circuit Theory of Operation...276

Transmission Control Unit (TCU) Operation...277

Travel Warning Alarm Theory of Operation...286

Cooling Fan Drive Circuit Theory of Operation...287

Group 17: JDG10470376 Diagnostic Test Box...194

Overview...290

JDG10470376 Diagnostic Test Box Connection...291

JDG10470376 Diagnostic Test Box Connection Troubleshooting...294

JDG10470376 Diagnostic Test Box Basic Operation...295

JDG10470376 Diagnostic Test Box Test 1—Basic Engine Controls...296

JDG10470376 Diagnostic Test Box Test 2—Transmission Control Lever (TCL)...298

JDG10470376 Diagnostic Test Box Test 3—Hydrostatic Solenoid Resistance...305

JDG10470376 Diagnostic Test Box Test 4—Engine Speed Sensor...307

JDG10470376 Diagnostic Test Box Test 5—Straight Run Test...309

JDG10470376 Diagnostic Test Box Test 6—Base Adjustment of Left Track...314

JDG10470376 Diagnostic Test Box Test 7—Adjustment of Right Track...317

Group 20: References...195

Diagnostic Trouble Code (DTC) Retrieval Procedure...325

Diagnostic Trouble Code Quick Reference List...330

Diagnostic Trouble Code (DTC)—090...335

Diagnostic Trouble Code (DTC)—111...336

Diagnostic Trouble Code (DTC)—112...337

Diagnostic Trouble Code (DTC)—121...338

Diagnostic Trouble Code (DTC)—122...339

Diagnostic Trouble Code (DTC)—211...340

Diagnostic Trouble Code (DTC)—212...341

Diagnostic Trouble Code (DTC)—250...342

Diagnostic Trouble Code (DTC)—251...343

Diagnostic Trouble Code (DTC)—252...344

Diagnostic Trouble Code (DTC)—311...345

Diagnostic Trouble Code (DTC)—312...346

Diagnostic Trouble Code (DTC)—313...347

Diagnostic Trouble Code (DTC)—321...348

Diagnostic Trouble Code (DTC)—322...349

Diagnostic Trouble Code (DTC)—323...350

Diagnostic Trouble Code (DTC)—331...351

Diagnostic Trouble Code (DTC)—332...352

Diagnostic Trouble Code (DTC)—333...353

Diagnostic Trouble Code (DTC)—341...354

Diagnostic Trouble Code (DTC)—342...355

Diagnostic Trouble Code (DTC)—343...356

Diagnostic Trouble Code (DTC)—401...357

Diagnostic Trouble Code (DTC)—402...358

Diagnostic Trouble Code (DTC)—404...359

Diagnostic Trouble Code (DTC)—405...360

Diagnostic Trouble Code (DTC)—406...361

Diagnostic Trouble Code (DTC)—407...362

JDG9796653 Diagnostic Test Box Connection...363

JDG9796653 Diagnostic Test Box Operation...367

Adjustment Checklist (S.N. 005600—006199)...391

Adjustment Checklist Quick Reference and Explanations (S.N. 005600—006199)...406

Adjustment Checklist (S.N. 006200— )...415

Adjustment Checklist Quick Reference and Explanations (S.N. 006200— )...430

Inching Pedal Test and Adjustment...439

Selected Engine Speed Sensor (R5) Adjustment...442

Electrical Component Specifications...446

DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Replace Connectors...196

DEUTSCH DEUTSCH is a trademark of Deutsch Co. Replace Rectangular or Triangular Connectors...196

DEUTSCH DEUTSCH is a trademark of Deutsch Co. Install Contact...196

Amp Connector Replace Contact...456

Cannon Connector Replace Contact...459

Remove Connector Body from Blade Terminals...460

Speed Range Selector Switch Test...461

Counter Rotation Switch Test...463

Section 9020: Power Train...465

Group 05: Theory of Operation...465

Dampener Drive Operation...468

Splitter Drive Operation...470

Final Drive Operation...473

Metal Face Seal Operation...476

Group 15: Diagnostic Information...465

Diagnose Power Train Malfunctions...480

Section 9022: Pneumatic System...482

Group 05: Theory of Operation...482

Air Suspension Seat Operation...484

Group 15: Diagnostic Information...482

Air Suspension Seat Schematic...486

Section 9025: Hydraulic System...487

Group 05: Theory of Operation...487

Main Hydraulic System Relief Valves with Anti-Cavitation Operation...491

Quick-Drop Solenoid Valve Operation...493

Quick-Drop Return Cut-Off Solenoid Valve Operation...495

Float Solenoid Valve Operation...496

Fan Pump Operation...498

Fan Pump Regulator Operation...500

Reversible Fan Drive Operation (S.N. 005600— )...503

Group 15: Diagnostic Information...487

Diagnose Hydraulic System Malfunctions...515

Function Drift—Flowchart...523

Slow Hydraulics—Lift Cylinder—Flowchart...524

Slow Hydraulic Functions—Flowchart...525

Hydraulic System Noise—Flowchart...526

Dozer Hydraulic System Component Location...527

Scraper-Puller Hydraulic System Schematic...529

Ripper Hydraulic System Schematic...531

Dozer Hydraulic System Schematic...533

Group 20: Adjustments...487

Case Drain Filter Inspection...538

Main Hydraulic Pump Load Sense (LS) Adjustment...541

Main Hydraulic Pump Standby Pressure Adjustment...545

Main Hydraulic Pump Maximum Angle Stop Adjustment...548

Fan Pump Cut-Off and Standby Pressure Adjustment...549

Hydraulic Cylinder Repair Specifications...556

Group 25: Tests...487

JT05801 Clamp-On Electronic Tachometer Installation...561

JT02156A Digital Pressure/Temperature Analyzer Installation...562

Hydraulic Oil Warm-Up Procedure...563

Hydraulic System Discharging...564

Hydraulic Accumulator Discharging...565

Hydraulic Accumulator Precharge Test...566

Main Hydraulic Pump Cut-Off Pressure Test...569

Main Hydraulic Pump Load Sense (LS) Test...572

Main Hydraulic Pump Standby Pressure Test...575

Main Hydraulic System Relief Valve Test...577

Circuit Relief Valve Test...582

Main Hydraulic Pump Flow Test...587

Main Hydraulic Pump Case Drain Test...590

Pilot Control Valve Test and Adjustment...593

Fan Pump Standby Pressure Test...598

Fan Pump Cut-Off Pressure Test...600

Fan Drive Pump Case Drain Test...603

Fan Pump Flow Test (Fan Speed)...606

Lift and Tilt Cylinder Circuit Drift Test...608

Lift Cylinder Leakage Test...610

Section 9026: Hydrostatic System...613

Group 05: Theory of Operation...613

Hydrostatic Pump Operation...616

Cold Start Relief Operation...617

Charge Oil Relief Valve Operation...618

Park Brake Circuit Operation...619

Group 15: Diagnostic Information...613

Hydraulics/Hydrostatics Overheating—Flowchart...622

Low Charge Oil Pressure—Flowchart...623

Mistrack/Indexes—Flowchart...624

Machine Will Not Reach Full Speed—Flowchart...625

Low Power In One Track—Flowchart...626

Engine Starts But Machine Will Not Move—Either Side or Stops Moving—Flowchart...627

Diagnostic Test Port Component Location...628

Hydrostatic Transmission System Component Location...631

Hydrostatic Transmission System Schematic (S.N. —005599)...633

Hydrostatic Transmission System Schematic (S.N. 005600— )...636

Reversible Fan Drive System Schematic (S.N. 005600— )...639

Group 20: Adjustments...613

Hydrostatic Transmission Oil Warm-Up Procedure...642

Bleed Brake System...643

Hydrostatic Pump Neutral Adjustment...644

Group 25: Tests...613

Releasing Park Brake to Tow the Machine...648

Park Brake Towing Circuit Test...649

Park Brake Circuit Relief Valve Test and Adjustment...654

Hydrostatic Pump Neutral Position Pressure Test...659

Hydrostatic Pump High Pressure Relief Valve Test...661

Charge Oil Relief Valve Test...665

Cold Start Relief Valve Test and Adjustment...668

Charge Pump Flow Test...671

Hydrostatic Motor Case Drain Test...674

Hydrostatic Motor Operating Charge Relief Pressure Test...678

Hydrostatic Motor Minimum Angle Stop Test and Adjustment...682

Travel Speed and Straight Run Test and Adjustment (Using JDG9796653 Diagnostic Test Box)...686

Hydrostatic Motor Regulating Range Test and Adjustment (Using JDG9796653 Diagnostic Test Box)...693

Hydrostatic Pump Regulating Range Test and Adjustment (Using JDG9796653 Diagnostic Test Box)...695

Travel Speed and Straight Run Test and Adjustment (Using JDG10470376 Diagnostic Test Box)...698

Hydrostatic Pump Regulating Range Test and Adjustment (Using JDG10470376 Diagnostic Test Box)...706

Hydrostatic Motor Regulating Range Test and Adjustment (Using JDG10470376 Diagnostic Test Box)...709

Hydrostatic Motor Minimum Angle Stop Test and Adjustment (Using JDG10470376 Diagnostic Test Box)...711

Section 9031: Heating and Air Conditioning...715

Group 05: Theory of Operation...715

Air Conditioning System Cycle Of Operation...718

Air Conditioning Circuit...720

Group 15: Diagnostic Information...715

Diagnose Air Conditioning System Malfunctions...725

Diagnose Heater System Malfunctions...728

Air Conditioning Component Location...729

Group 25: Tests...715

Proper Refrigerant Handling...732

R134a Refrigerant Cautions...733

R134a Oil Charge Capacity...734

R134a Refrigerant Charge Capacity...735

Refrigerant Hoses And Tubing Inspection...736

R134a Air Conditioning System Test...737

Operating Pressure Diagnostic Chart...740

Expansion Valve Operating Test...745

Blower Motor Switch Test...747

Blower Motor Resistor Test...748

Heater Blower Motor Test...749

Air Conditioner Low Pressure Switch Test...750

Air Conditioner High Pressure Switch Test...752

Air Conditioning Air Temperature Sensor and Evaporator Temperature Sensor Test...754

Leak Testing...756

Section 9900: Dealer Fabricated Tools...757

Group 99: Dealer Fabricated Tools...757

DFT1262 Split Flange Test Plate...759

DFT1263 Split Flange Test Plate...760

John Deere 1050C Crawler Dozer Operation & Test Service Manual (TM2300)