John Deere 750J Crawler Dozer Operation and Test Service Manual (TM12709)

Complete Diagnosis and Test manual with electrical wiring diagrams for John Deere 750J Crawler Dozer, with all the shop information to maintain, diagnose, and rebuild like professional mechanics.

John Deere 750J Crawler Dozer workshop Operation and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM12709 - John Deere 750J (S.N. 141344-219962) Crawler Dozer Technical Manual (Operation and Test).PDF

TM12709 - John Deere 750J (S.N. 141344-219962) Crawler Dozer Technical Manual (Operation and Test).EPUB

Total Pages: 1,030 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

TABLE OF CONTENTS....1

Section 9000: General Information....19

Group 01: Safety....19

Recognize Safety Information....21

Follow Safety Instructions....22

Operate Only If Qualified....23

Wear Protective Equipment....24

Avoid Unauthorized Machine Modifications....25

Inspect Machine....26

Stay Clear of Moving Parts....27

Avoid High-Pressure Fluids....28

Avoid High-Pressure Oil....29

Beware of Exhaust Fumes....30

Prevent Fires....31

Prevent Battery Explosions....32

Handle Chemical Products Safely....33

Dispose of Waste Properly....34

Prepare for Emergencies....35

Add Cab Guarding For Special Uses....36

Use Steps and Handholds Correctly....37

Start Only From Operator's Seat....38

Use and Maintain Seat Belt....39

Prevent Unintended Machine Movement....40

Avoid Work Site Hazards....41

Keep Riders Off Machine....43

Avoid Backover Accidents....44

Avoid Machine Tip Over and Machine Damage....45

Add and Operate Attachments Safely....47

Prevent Unintended Detonation of Explosive Devices....48

Park and Prepare for Service Safely....49

Service Cooling System Safely....50

Remove Paint Before Welding or Heating....51

Make Welding Repairs Safely....52

Drive Metal Pins Safely....53

Section 9001: Diagnostic Trouble Codes (DTC)....54

Group 10: Standard Display Monitor (SDM) Diagnostic Trouble Codes....54

000096.03 - Fuel Level Sensor Open or Short....54

000096.04 - Fuel Level Sensor Short to Ground....54

000107.03 - Engine Air Filter Restriction Indicator Switch Short to Power....54

000107.04 - Engine Air Filter Restricted....54

002000.09 - CAN Communication Error, No ECU Configuration....54

002003.09 - Loss of CAN Communication With TCU....54

Group 20: Engine Control Unit (ECU) Diagnostic Trouble Codes....72

Engine Control Unit (ECU) Diagnostic Trouble Codes....72

000091.09 - CAN Throttle Missing from TCU....54

000091.14 - Throttle Voltage Out of Range....54

000100.01 - Engine Oil Pressure Signal Extremely Low....54

000100.03 - Eng Oil Press Short to Power....54

000100.04 - Engine Oil Pressure Signal Out of Range Low....54

000171.03 - Ambient Air Temp Open or Short....54

000171.04 - Ambient Air Temp Short to Gnd....54

000627.01 - Injector Current Incorrect....54

000651.00 - Cyl 1 Injector Max Cal....54

000651.01 - Cyl 1 Injector Min Cal....54

000652.00 - Cyl 2 Injector Max Cal....54

000652.01 - Cyl 2 Injector Min Cal....54

000653.00 - Cyl 3 Injector Max Cal....54

000653.01 - Cyl 3 Injector Min Cal....54

000654.00 - Cyl 4 Injector Max Cal....54

000654.01 - Cyl 4 Injector Min Cal....54

000655.00 - Cyl 5 Injector Max Cal....54

000655.01 - Cyl 5 Injector Min Cal....54

000656.00 - Cyl 6 Injector Max Cal....54

000656.01 - Cyl 6 Injector Min Cal....54

Group 30: Transmission Control Unit (TCU) Diagnostic Trouble Codes....54

000070.00 - Park Lock Lever Inputs Both ON....54

000070.01 - Park Lock Lever Inputs Both OFF....55

000091.03 - Throttle Sensor Short to Power....55

000091.04 - Throttle Sensor Open or Short....55

000116.00 - Brake Pressure High....55

000116.01 - Brake Pressure Low....55

000116.03 - Brake Pressure Short to Power....55

000116.04 - Brake Pressure Open or Short....55

000158.03 - TCU System Volts Too High....55

000158.04 - TCU System Volts Too Low....55

000168.04 - Unswitched System Volts Too Low....55

000177.00 - Transmission Over Temp....55

000177.03 - Transmission Oil Temperature Sensor Short to Power....55

000177.04 - Transmission Oil Temperature Sensor Short to Ground....55

000177.16 - Transmission Oil Temperature High....55

000190.09 - CAN Communication Error No Engine Speed....55

000190.19 - CAN Communication Error Invalid Engine Speed....55

000521.00 - Decel Sensor Input Greater Than Maximum Calibration Value....55

000521.01 - Decel Sensor Input Less Than Minimum Calibration Value....55

000521.03 - Decel Sensor Short to Power....55

000521.04 - Decel Sensor Open or Short....55

000521.05 - Decel Sensor Brake Calibration Value Too Low....55

000521.06 - Decel Sensor Brake Calibration Value Too High....55

000521.13 - Decelerator Sensor Brake Calibration Too High....55

000521.15 - Decel Sensor Minimum Calibration Value Too High....55

000521.16 - Decel Sensor Maximum Calibration Value Too Low....55

000521.17 - Decel Sensor Minimum Calibration Value Too Low....55

000521.18 - Decel Sensor Maximum Calibration Value Too Low....55

000581.00 - Speed Buttons Input Greater Than Maximum Calibration Value....55

000581.01 - Speed Buttons Input Less Than Minimum Calibration Value....55

000581.03 - Speed Buttons Short to Power....55

000581.04 - Speed Buttons Open or Short....55

000581.07 - Speed Buttons Stuck Button....55

000581.13 - Speed Buttons Not Calibrated....55

000581.15 - Speed Buttons Minimum Calibration Value Too High....56

000581.16 - Speed Buttons Maximum Calibration Value Too High....56

000581.17 - Speed Buttons Minimum Calibration Value Too Low....56

000581.18 - Speed Buttons Maximum Calibration Value Too Low....56

000604.03 - FNR Neutral Switch Open Circuit....56

000604.04 - FNR Neutral Switch Short Circuit....56

000604.15 - FNR Neutral Switch Minimum Calibration Value Too High....56

000604.16 - FNR Neutral Switch Maximum Calibration Value Too High....56

000604.17 - FNR Neutral Switch Minimum Calibration Value Too Low....56

000604.18 - FNR Neutral Switch Maximum Calibration Value Too Low....56

000619.05 - Brake Solenoid No Response....56

000619.06 - Brake Solenoid Short to Ground....56

000629.12 - TCU Watchdog Timeout....56

000907.03 - Left Speed Sensor Short to Power....56

000907.04 - Left Speed Sensor Short....56

000907.07 - Left Speed Sensor No Response....56

000907.12 - Left Speed Sensor Open....56

000908.03 - Right Speed Sensor Short to Power....56

000908.04 - Right Speed Sensor Short....56

000908.07 - Right Speed Sensor No Response....56

000908.12 - Right Speed Sensor Open....56

000977.05 - Fan Reverse Solenoid No Response....56

000977.06 - Fan Reverse Solenoid Short to Ground....56

001071.05 - Fan Drive Solenoid Open Circuit....56

001071.06 - Fan Drive Solenoid Short Circuit....56

001638.00 - Hydraulic Oil Temperature High....56

001638.03 - Hydraulic Oil Temperature Short to Power....56

001638.04 - Hydraulic Oil Temperature Short to Ground....56

001638.16 - Hydraulic Temperature Moderately High....56

001713.31 - Hydraulic Oil Filter Restricted....56

002000.09 - Loss of CAN Communication With ECU....56

002023.09 - Loss of CAN Communication With SDM....56

002660.00 - Steer Sensor Input Greater Than Maximum Calibration Value....56

002660.01 - Steer Sensor Input Less Than Minimum Calibration Value....57

002660.03 - Steer Sensor Short to Power....57

002660.04 - Steer Sensor Open or Short....57

002660.07 - Steer Sensor Neutral Calibration Out of Range....57

002660.13 - Steer Sensor Not Calibrated....57

002660.15 - Steer Sensor Minimum Calibration Value Too High....57

002660.16 - Steer Sensor Maximum Calibration Value Too Low....57

002660.17 - Steer Sensor Minimum Calibration Value Too Low....57

002660.18 - Steer Sensor Maximum Calibration Value Too Low....57

002661.00 - FNR Sensor Input Greater Than Maximum Calibration Value....57

002661.01 - FNR Sensor Input Less Than Minimum Calibration Value....57

002661.04 - FNR Sensor Open or Short....57

002661.03 - FNR Sensor Short to Power....57

002661.07 - FNR Sensor Neutral Calibration Out of Range....57

002661.13 - FNR Sensor Not Calibrated....57

002661.15 - FNR Sensor Minimum Calibration Value Too High....57

002661.16 - FNR Sensor Maximum Calibration Value Too Low....57

002661.17 - FNR Sensor Minimum Calibration Value Too Low....57

002661.18 - FNR Sensor Maximum Calibration Value Too Low....57

003359.31 - Transmission Oil Filter Restricted....57

003509.03 - Sensor Supply 1 Voltage OOR High....57

003509.04 - Sensor Supply 1 Voltage OOR Low....57

003510.03 - Sensor Supply 2 Voltage OOR High....57

003510.04 - Sensor Supply 2 Voltage OOR Low....57

003511.03 - Sensor Supply 3 Voltage OOR High....57

003511.04 - Sensor Supply 3 Voltage OOR Low....57

003512.03 - Sensor Supply 4 Voltage OOR High....57

003512.04 - Sensor Supply 4 Voltage OOR Low....57

520709.00 - Fan Oil Filter Restricted....57

522439.05 - Tank Bypass Solenoid Open Circuit....57

522439.06 - Tank Bypass Solenoid Short to Power....57

522440.05 - Blade Left Solenoid Open Circuit....57

522440.06 - Blade Left Solenoid Short Circuit....57

522441.05 - Blade Right Solenoid Open Circuit....58

522441.06 - Blade Right Solenoid Short Circuit....58

522442.00 - Blade Buttons Input Greater Than Maximum Calibration Value....58

522442.01 - Blade Buttons Input Less Than Minimum Calibration Value....58

522442.03 - Blade Buttons Short to Power....58

522442.04 - Blade Buttons Open or Short....58

522442.07 - Blade Buttons Stuck Button....58

522444.00 - Charge Pressure High....58

522444.01 - Charge Pressure Low....58

522444.03 - Charge Pressure Short to Power....58

522444.04 - Charge Pressure Open or Short....58

522447.05 - Right Forward Pump Coil Open....58

522447.06 - Right Forward Pump Coil Short....58

522447.15 - Right Forward Pump Threshold Calibration Value Too High....58

522447.16 - Right Forward Pump Max Speed Calibration Value Too High....58

522447.17 - Right Forward Pump Threshold Calibration Value Too Low....58

522447.18 - Right Forward Pump Max Speed Calibration Value Too Low....58

522448.05 - Right Reverse Pump Coil Open....58

522448.06 - Right Reverse Pump Coil Short....58

522448.15 - Right Reverse Pump Threshold Calibration Value Too High....58

522448.16 - Right Reverse Pump Max Speed Calibration Value Too High....58

522448.17 - Right Reverse Pump Thresh Calibration Value Too Low....58

522448.18 - Right Reverse Pump Max Speed Calibration Value Too Low....58

522449.05 - Left Reverse Pump Coil Open....58

522449.06 - Left Reverse Pump Coil Short....58

522449.15 - Left Reverse Pump Threshold Calibration Value Too High....58

522449.16 - Left Reverse Pump Max Speed Calibration Value Too Low....58

522449.17 - Left Reverse Pump Threshold Calibration Value Too Low....58

522449.18 - Left Reverse Pump Max Speed Calibration Value Too Low....58

522450.05 - Left Forward Pump Coil Open....58

522450.06 - Left Forward Pump Coil Short....58

522450.15 - Left Forward Pump Threshold Calibration Value Too High....58

522450.16 - Left Forward Pump Max Speed Calibration Value Too High....58

522450.17 - Left Forward Pump Threshold Calibration Value Too Low....59

522450.18 - Left Forward Pump Max Speed Calibration Value Too Low....59

522451.05 - Cooler Bypass Solenoid No Response....59

522451.06 - Cooler Bypass Solenoid Short to Power....59

523108.13 - TCU Not Calibrated High Speed Not Done....59

523108.14 - TCU Not Calibrated Sensor/Pump/Motor....59

523577.05 - Left Motor Solenoid Open Circuit....59

523577.06 - Left Motor Solenoid Short Circuit....59

523577.13 - Motor High Speed Not Calibrated....59

523577.16 - Left Motor Maximum Calibration Value Too High....59

523577.18 - Left Motor Maximum Calibration Value Too Low....59

523578.05 - Right Motor Solenoid Open Circuit....59

523578.06 - Right Motor Solenoid Short Circuit....59

523578.16 - Right Motor Maximum Calibration Value Too High....59

523578.18 - Right Motor Maximum Calibration Value Too Low....59

524089.00 - Left System Pressure High....59

524089.01 - Left System Pressure Low....59

524089.03 - Left System Pressure Short to Power....59

524089.04 - Left System Pressure Open or Short....59

524090.00 - Right System Pressure High....59

524090.01 - Right System Pressure Low....59

524090.03 - Right System Pressure Short to Power....59

524090.04 - Right System Pressure Open or Short....59

524233.07 - Hydrostatic Drive System Not Responding....59

Group 40: Electrohydraulic Controller (EHC) Diagnostic Trouble Codes....336

Electrohydraulic Controller (EHC) Diagnostic Trouble Codes....336

000158.03 - EHC System Volts Too High....59

000158.04 - EHC System Volts Too Low....59

000620.03 - Sensor Short to Power....59

000620.04 - Sensor Short to GND....59

001903.00 - Aux 1 PVE Open Circuit....59

001903.01 - Aux 1 PVE Low or Open Circuit....59

001903.03 - Aux 1 PVE Short to Power....59

001903.04 - Aux 1 PVE Short to GND....60

001903.31 - Aux 1 PVE Spool Pos Error....60

001915.00 - Aux 2 PVE Open Circuit....60

001915.01 - Aux 2 PVE Low or Open Circuit....60

001915.03 - Aux 2 PVE Short to Power....60

001915.04 - Aux 2 PVE Short to GND....60

001915.31 - Aux 2 PVE Spool Pos Error....60

002697.09 - CAN Joystick Pos Missing From BCJ....60

002712.00 - Hyd Enable Sw Inputs Both On....60

002712.01 - Hyd Enable Sw Inputs Both Off....60

003157.03 - Incr / Decr Buttons Short to Power....60

003157.04 - Incr / Decr Buttons Open or Short....60

003751.31 - Incr / Decr Buttons Invalid Output....60

522442.31 - Blade Buttons Invalid Output....60

523779.00 - Blade Rotate Current Above Max....60

523779.01 - Blade Rotate Current Below Min....60

523780.00 - Tilt PVE Open Circuit....60

523780.01 - Tilt PVE Low or Open Circuit....60

523780.03 - Tilt PVE Short to Power....60

523780.04 - Tilt PVE Short to GND....60

523780.31 - Tilt PVE Spool Pos Error....60

523781.00 - Height PVE Open Circuit....60

523781.01 - Height PVE Low or Open Circuit....60

523781.03 - Height PVE Short to Power....60

523781.04 - Height PVE Short to GND....60

523781.31 - Height PVE Spool Pos Error....60

524059.00 - Aux 2 Jstk Sensor 2 Volts High....60

524059.01 - Aux 2 Jstk Sensor 2 Volts Low....60

524059.03 - Aux 2 Jstk Sensor 2 Short to Power....60

524059.04 - Aux 2 Jstk Sensor 2 Short to GND....60

524059.31 - Aux 2 Jstk Sensor 2 Invalid Output....60

524062.00 - Aux 1 Jstk Sensor 2 Volts High....60

524062.01 - Aux 1 Jstk Sensor 2 Volts Low....60

524062.03 - Aux 1 Jstk Sensor 2 Short to Power....61

524062.04 - Aux 1 Jstk Sensor 2 Short to GND....61

524062.31 - Aux 1 Jstk Sensor 2 Invalid Output....61

524085.00 - Aux 2 Jstk Sensor 2 Volts High....61

524085.01 - Aux 2 Jstk Sensor 2 Volts Low....61

524085.03 - Aux 2 Jstk Sensor 1 Short to Power....61

524085.04 - Aux 2 Jstk Sensor 1 Short to GND....61

524085.14 - Aux 2 Jstk Sensor Mismatch....61

524085.31 - Aux 2 Jstk Sensor 1 Invalid Output....61

524086.00 - Aux 1 Jstk Sensor 1 Volts High....61

524086.01 - Aux 1 Jstk Sensor 1 Volts Low....61

524086.03 - Aux 1 Jstk Sensor 1 Short to Power....61

524086.04 - Aux 1 Jstk Sensor 1 Short to GND....61

524086.14 - Aux 1 Jstk Sensor Mismatch....61

524086.31 - Aux 1 Jstk Sensor 1 Invalid Output....61

Group 50: Blade Control Joystick (BCJ) Diagnostic Trouble Codes....61

Diagnostic Trouble Code (DTC) Quick Reference List—Blade Control Joystick (BCJ)....440

2697.03 - Voltage Too High (X Axis)....61

2697.04 - Voltage Too Low (X Axis)....61

2697.13 - Input Not Calibrated (X Axis)....61

2697.14 - Redundant Input Failure (X Axis)....61

2698.03 - Voltage Too High (Y Axis)....61

2698.04 - Voltage Too Low (Y Axis)....61

2698.13 - Input Not Calibrated (Y Axis)....61

2698.14 - Redundant Input Failure (Y Axis)....61

Section 9005: Operational Checkout Procedure....449

Group 10: Operational Checkout Procedure....449

Operational Checkout....471

Section 9010: Engine....492

Group 05: Theory of Operation....492

PowerTech™ E 6.8 L (6068) John Deere Engine....496

Group 15: Diagnostic Information....492

PowerTech™ E 6.8 L (6068) John Deere Engine....496

Engine Cooling System Component Location....497

Engine Fuel System Component Location....499

Engine Intake and Exhaust Component Location....501

Group 25: Tests....492

Slow and Fast Idle Test....505

Intake Manifold Pressure Test—Turbocharger Boost....507

Fuel Supply Pump Pressure Test....511

Section 9015: Electrical System....513

Group 05: System Information....513

Electrical Diagram Information....520

Group 10: System Diagrams....513

Fuse and Relay Specifications....527

System Functional Schematic, Wiring Diagram, and Component Location Legend....530

System Functional Schematic and Section Legend....537

JDLink™ System Functional Schematic—If Equipped....548

Operator's Station Harness (W7) Component Location....549

Operator's Station Harness (W7) Wiring Diagram....551

Canopy Roof Harness (W8) Component Location....555

Canopy Roof Harness (W8) Wiring Diagram....557

Cab Roof Harness (W9) Component Location....558

Cab Roof Harness (W9) Wiring Diagram....560

Engine Harness (W10) Component Location....563

Engine Harness (W10) Wiring Diagram....566

Transmission Harness (W11) Component Location....569

Transmission Harness (W11) Wiring Diagram....571

Fuel Tank Harness (W12) Component Location....574

Fuel Tank Harness (W12) Wiring Diagram....575

Air Conditioning Harness (W14) Component Location....576

Air Conditioning Harness (W14) Wiring Diagram....578

Radio Harness (W15) Component Location....579

Radio Harness (W15) Wiring Diagram....580

IGC Machine Harness (W21) and IGC Cab Harness (W22) Component Location—If Equipped....581

Integrated Grade Control (IGC) Machine Harness (W21) Wiring Diagram—If Equipped....583

Integrated Grade Control (IGC) Cab Harness (W22) Wiring Diagram—If Equipped....586

JDLink™ Harnesses (W6002 and W6003) Component Location—If Equipped....587

JDLink™ Modular Telematics Gateway (MTG) Harness (W6002) Wiring Diagram—If Equipped....589

JDLink™ Satellite (SAT) Harness (W6003) Wiring Diagram—If Equipped....591

Group 15: Sub-System Diagnostics....513

Starting and Charging Circuit Theory of Operation....594

Controller Area Network (CAN) Circuit Theory of Operation....596

Engine Control Unit (ECU) Circuit Theory of Operation....598

Transmission Control Unit (TCU) Circuit Theory of Operation....604

Standard Display Monitor (SDM) Circuit Theory of Operation....618

Integrated Grade Control (IGC) Theory of Operation—If Equipped....620

Horn, Light, and Wiper Circuit Theory of Operation....626

Hydraulic System Circuits Theory of Operation....630

JDLink™ Circuit Theory of Operation—If Equipped....631

Group 16: Monitor Operation....514

Standard Display Monitor (SDM) Menu Structure-Service Mode....635

Standard Display Monitor (SDM)—Codes....637

Standard Display Monitor (SDM)—Machine Settings....638

Standard Display Monitor (SDM)—Diagnostics....641

Standard Display Monitor (SDM)—Monitor....644

Standard Display Monitor (SDM)—Calibrate....646

Standard Display Monitor (SDM)—TCU Diagnostics....647

Standard Display Monitor (SDM) Setting Hour Meter....648

Group 20: References....514

Electrical Component Specifications....655

Service ADVISOR™ Diagnostic Application....660

Service ADVISOR™ Connection Procedure....661

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application....662

Alternator Test Procedure....665

CAN Circuit Test....667

Transmission Control Unit (TCU) Calibration....672

Wire Harness Test....674

Decelerator/Brake Pedal Adjustment....675

Engine Speed Control Remove and Install....677

Rotary Sensor Remove and Install....679

Transmission Control Lever (TCL) Adjustment....681

Engine Control Unit (ECU) Remove and Install....686

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector....514

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact....514

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors....515

Replace DEUTSCH DEUTSCH is a trademark of Deutsch Co. Rectangular or Triangular Connectors....515

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact....515

Install CINCH CINCH is a trademark of the Cinch Co. Contact....515

Repair 32 and 48 Way CINCH CINCH is a trademark of the Cinch Co. Connectors....515

Replace (Pull Type) Metri-Pack™ Connectors....704

Replace (Push Type) Metri-Pack™ Connectors....706

Section 9025: Hydraulics....707

Group 05: Theory....707

Hydraulic System Operation....710

Hydraulic Pump Operation....711

Hydraulic Control Valve Operation....717

Hydraulic Control Valve Operation—IGC....719

Load Sense Circuit Operation....724

Load Sense Isolator Operation....725

Circuit Relief Valve with Anticavitation Operation....726

Hydraulic System Relief Valve Operation....728

Hydraulic Oil Filter Manifold Operation....729

Blade Angle Operation....731

Ripper Operation....734

Ripper Operation—IGC....737

Quick-Drop Valve Operation....739

Group 15: Diagnostic Information....707

Hydraulic System Schematic....751

Hydraulic System Schematic—IGC....761

Main Hydraulic Component Location....763

Ripper Ready Hydraulic Component Location....764

Winch Ready Hydraulic Component Location....765

Main Hydraulic Component Location—IGC....766

Ripper Hydraulic Component Location—IGC....767

Hydraulic System Diagnose Malfunctions....707

Hydraulic System Diagnose Malfunctions—IGC....707

Group 25: Tests....707

JT02156A Digital Pressure/Temperature Analyzer Installation....930

Ultra Clean® Hand Launcher....931

Hydraulic Oil Cleanup Procedure....946

Hydraulic System Relief Valve Test....806

Hydraulic System Relief Valve Test—IGC....808

Circuit Relief Valve Test....810

Circuit Relief Valve Test—IGC....812

Pump Load Sense Differential and System Pressure (Pump Cut-Off) Test and Adjustment....814

Pump Load Sense Differential and System Pressure Test and Adjustment—IGC....818

Lift and Tilt Cylinder Function Drift Test....821

Cylinder Leakage Test....824

Pressure Reducing Valve Pressure Test and Adjustment....826

Blade Down Accumulator Hydraulic Discharge....828

Blade Down Accumulator Precharge Test....829

Hydraulic Pump Flow Test....831

Hydraulic Pump Case Drain Test....834

Section 9026: Hydrostatic System....840

Group 05: Theory of Operation....837

Hydrostatic System....840

Transmission Control Circuit Operation (Flow Chart)....841

Charge Pump Operation....843

Hydrostatic Charge Oil Filter Operation....844

Neutral Charge Relief Valve Operation....846

Multi-Function Valve Operation....847

Hydraulic Integrated Circuit (HIC) Valve Operation....849

Park Brake Valve Operation....851

Oil Cooler and Reservoir Bypass Operation....853

Pump Pressure Control Pilot (PCP) Operation....855

Pump Displacement Control Valve (PDCV) Operation....857

Hydrostatic Pump Operation....859

Flushing Valve and Operating Charge Relief Valve Operation....861

Hydrostatic Motor Operation....863

Hydraulic Reversing Fan Drive Operation....865

Hydraulic Non-Reversing Fan Drive Operation....868

Hydraulic Fan Return Filter Operation....871

Group 15: Diagnostic Information....837

Overheating Malfunctions....837

Low Charge Pressure Malfunctions....837

Mistrack/Index Malfunctions....837

Machine Full Speed Malfunctions....837

Low Power Malfunctions....837

Track Malfunctions....837

TCU Calibration Malfunctions....837

Hydrostatic System Component Location....920

Park Brake System Component Location....922

Hydrostatic System Schematic—Neutral (Park Brake On)....924

Hydrostatic System Diagram—Neutral (Park Brake On)....926

Hydrostatic System Diagram—Reverse (Slow Speed)....927

Hydrostatic System Diagram—Forward (Fast Speed)....928

Group 25: Tests....838

JT02156A Digital Pressure/Temperature Analyzer Installation....930

Ultra Clean® Hand Launcher....931

Machine Supporting Procedure....932

Transmission Oil Warm-Up Procedure....935

Releasing Park Brake to Tow the Machine....939

Hydrostatic Pump and Motor Initial Start-Up Procedure....942

Hydrostatic Pump Flushing Procedure....944

Hydraulic Oil Cleanup Procedure....946

Pressure Control Pilot (PCP) Manual Override Test....947

Pressure Control Pilot (PCP) Test....950

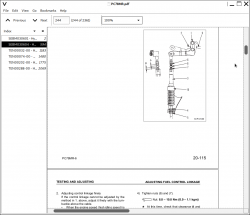

Pressure Control Pilot (PCP) Internal Adjustment....955

Multi-Function Relief Valve Test....959

Transmission Efficiency Test....965

Neutral Charge Relief and Operating Charge Relief Pressure Test....970

Pump Displacement Control Valve (PDCV) Neutral (Null) Adjustment....974

Pump Servo Pressure Test....978

Motor Displacement Control Valve (MDCV) Adjustment....982

Hydrostatic Motor Min./Max. Angle Servo Piston Pressure Test....986

Charge Pump Flow Test....989

Charge Pressure Sensor Test....991

Hydrostatic Oil Cooler Bypass Test....993

Hydrostatic Oil Reservoir Bypass Test....997

Park Brake Test....1001

Park Brake Relief Valve Test....1008

Cab Tilt Relief Valve Test....1010

Fan Pump Pressure Test....1012

Fan Pump Flow Test....1014

Fan Motor Speed Test....1018

Fan Motor Case Drain Test....1020

Section 9031: Heating and Air Conditioning....1022

Group 05: Theory of Operation....1022

Air Conditioning System Cycle Of Operation....1025

Group 15: Diagnostic Information....1022

Air Conditioning System Diagnose Malfunctions....1022

Heater System Diagnose Malfunctions....1022

Group 25: Tests....1022

Proper Refrigerant Handling....1059

R134a Refrigerant Cautions....1060

R134a Oil Charge Capacity....1061

R134a Refrigerant Charge Capacity....1062

Refrigerant Hoses And Tubing Inspection....1063

R134a Air Conditioning System Test....1064

Operating Pressure Diagnostic Chart....1067

Air Conditioner High/Low Pressure (Binary) Switch Test....1072

Freeze Control Switch Test....1074

Leak Testing....1075

John Deere 750J Crawler Dozer Operation and Test Service Manual (TM12709)