John Deere 790D, 790D-LC, 892D-LC Excavator Operation and Test Service Manual (TM1395)

Complete Diagnostics, Operation and Test manual with Electrical Wiring Diagrams for John Deere 790D, 790D-LC, 892D-LC Excavator, with all the technical information to maintain, diagnose, and service like professional mechanics.

John Deere 790D, 790D-LC, 892D-LC Excavator workshop Operation and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM1395 - John Deere 790D, 790D-LC, 892D-LC Excavator Technical Manual - Operation and Test.PDF

TM1395 - John Deere 790D, 790D-LC, 892D-LC Excavator Technical Manual - Operation and Test.EPUB

t660iap - 892DLC Hydraulic Schematic.pdf

t6444ad - 790dlc schematics.pdf

t6467aa - 790DLC Hydraulic Schematic.pdf

Total Pages: 612 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory Of Operation

System Operational Checks

Diagnostic Information

Adjustments

Tests

Electrical System

Theory Of Operation

System Operational Checks

Diagnostic Information

Tests

Power Train

Theory Of Operation

System Operational Checks

Diagnostic Information

Adjustments

Tests

Hydraulic System

Theory Of Operation

System Operational Checks

Diagnostic Information

Adjustments

Tests

Heating And Air Conditioning

Theory Of Operation

System Operational Checks

Adjustments

Test

tm1395 - 790D, 790D-LC and 892D-LC Excavator

Table of Contents

Foreword

Section 9005: Operational Checkout Procedure

Group 10: Operational Checkout Procedure

Operational Checkout Record Sheet—790D, 892D-LC

Operational Checkout Procedure

Section 9010: Engine

Group 05: Theory Of Operation

6466 John Deere Engine—Use CTM1

Description

Cross Section Of Engine

Engine Speed Control System Operation

Group 10: System Operational Checks

6466 John Deere Engine—Use CTM1

System Operational Checks

Group 15: Diagnostic Information

6466 John Deere Engine—Use CTM1

Diagnose Engine Malfunctions

Group 20: Adjustments

6466 John Deere Engine—Use CTM1

Fan Belt Tension Adjustment

Engine Speed Control Linkage Adjustment

Speed Control Lever Tension Adjustment

Engine Speed Adjustments

Fuel Shut-Off Cable Adjustment

Group 25: Tests

6466 John Deere Engine—Use CTM1

JT05801 Clamp-On Electronic Tachometer Installation

JT05800 Digital Thermometer Installation

Fuel Line Leakage Test

Engine Power Test Using Turbocharger Boost Pressure

Air Filter Restriction Indicator Test

Air Intake System Leakage Test

Radiator Air Flow Test

JT05529 Air Flowmeter Test Record

Section 9015: Electrical System

Group 05: Theory Of Operation

Battery Operation

Diagnose Battery Malfunctions

CHECK BATTERY ELECTROLYTE LEVEL AND TERMINALS

Procedure For Testing Batteries

Using Booster Batteries—24 Volt System

Visually Inspect Electrical System

Multimeter

Battery Specifications

Replacing Fuses

Power Circuit Operation

Starting Circuit Operation

Charging Circuit Operation

Alternator Operation

Charge System Load Dump Circuit Operation

Gauge And Indicator Circuit

Accessory Circuits

Engine Speed And Pump Displacement Control System Operation

Engine Speed And Pump Displacement Electrical Control Circuit Operation

Engine Speed And Pump Displacement Control Operational Chart

Group 10: System Operational Checks

System Operational Procedure

Group 15: Diagnostic Information

Diagnose Electrical System Malfunctions

Wiring Diagram Information

Connector And Ground Locations

Component Location

Group 25: Tests

Service Equipment And Tools

HOW TO USE THE TEST SECTION

Common Circuit Test

Battery Testing

Battery Specifications

Replacing Fuses

Power Circuit Test

Start Circuit Testing

Charging Circuit Test

Load Dump Relay Test

Gauge And Indicator Test

Engine Coolant Temperature Gauge Sender

Fuel Gauge Sender

Accessory Circuit Test

Accessory Circuit (Wiper And Air Conditioning Circuits)

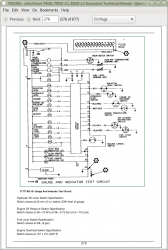

Engine Speed And Pump Displacement Control Circuit Test Diagrams

Engine Speed And Pump Displacement Control Circuit Test

Electrical Schematic Symbols

Section 9020: Power Train

Group 05: Theory Of Operation

Track Adjuster Operation

Propel Gearbox Operation

Propel Motor Operation

Propel Circuit Operation—790D

Propel Circuit Operation—892D-LC

Rotary Manifold Operation

Propel Control Valve Operation

Counterbalance Valve Neutral Operation

Counterbalance Valve Propel Operation

Counterbalance Valve Braking Operation

Propel Motor Crossover Relief Valve Operation—(Serial No. —010999)

Propel Brake Operation

Group 10: System Operational Checks

System Operational Procedure

Group 15: Diagnostic Information

Diagnose Undercarriage Components Malfunctions

Diagnose Propel System Malfunctions

Measure Track Bushing Wear

Measure Track Chain Pitch

Measure Track Link Wear

Measure Track Shoe Grouser Wear

Measure Track Lower Roller Wear

Measure Upper Track Roller Wear

Undercarriage Component Location

790D Propel Circuits Component Location

892D-LC Propel Circuits Component Location

Group 20: Adjustments

Adjust Track Sag

Group 25: Tests

JT05801 Clamp-On Electronic Tachometer Installation

JT05800 Digital Thermometer Installation

Propel Speed Cycle Time

Propel System Relief Valve Test And Adjustment—790D

Propel System Relief Valve Test And Adjustment—892D-LC

Propel Motor Crossover Relief Valve Test And Adjustment—790D

Propel Motor Crossover Relief Valve Test And Adjustment—892D-LC

Propel Motor Operating Leakage Test

Swing Bearing Wobble Test

Section 9025: Hydraulic System

Group 05: Theory Of Operation

Hydraulic System

Pilot Pump Operation

Pilot System Operation—790D

Pilot System Operation—892D-LC

Pilot Filter Operation

Solenoid Valve And Pilot Pressure Regulating Valve Operation

Solenoid Valve Operation—Energized

Engine Speed Control Operation

Check Block Operation

Main Hydraulic Pump Displacement Operation

Shut-Off Valve Operation

Pilot Controller Operation—Neutral

Pilot Controller Operation—Metering

Pilot Controller Operation—Full Stroke

Propel Pilot Controller Operation—Neutral

Pilot Operation Of Main Control Valve

Flow Regulator Operation

Warm-Up Circuit Operation

Pump Inlet And Delivery Circuits Operation

Return Circuit Operation

Drain Circuit Operation

Return Filter Operation

Main Control Valve Operation—790D

Control Valve Passages—790D

Control Valve Passages—892D-LC

Main Control Valve 892D-LC

System Relief Valve Circuit Operation—790D

System Relief Valve Circuit—892D-LC

System Relief And Swing Circuit Relief Valve Operation

Dig System Relief Valve Operation—892D-LC

Circuit Relief Valve Operation

Flow Combiner And Swing Brake Release Valve Circuit—790D

Flow Combiner And Swing Brake Release Valve Circuit—892D-LC

Flow Sensing Valve Operation

Bucket And Auxiliary Work Circuits Operation

Boom Raise Work Circuit Operation

Boom Lower Work Circuit Operation

Arm In Work Circuit Operation

Arm Out Work Circuit Operation

Swing Work Circuit Operation

Combined Functions Operation

Swing Motor Operation—790D Serial No. (—007786) 892D-LC (—005477)

Swing Motor Operation—790D Serial No. (007787—) 892D-LC (005478—)

Swing Crossover Relief And Make-Up Valves Operation

Brake Release Circuit Operation

Swing Gearbox Operation

Cylinder Operation

Splitter Drive Operation

Main Hydraulic Pump Operation

Pump Regulator Components Operation

Pump Minimum Displacement Operation

Pump Displacement Increasing Operation

Pump Maximum Displacement Operation

Pump Displacement Decreasing Operation

Constant Horsepower System Operation

Summation System Operation

High-Low Maximum Displacement Operation

Group 10: System Operational Checks

System Operational Procedure

Group 15: Diagnostic Information

Diagnose Hydraulic System Malfunctions

Diagnose Pilot Circuit Malfunctions

Diagnose Dig Circuit Malfunctions

Diagnose Swing Circuit Malfunctions

Hydraulic Circuit Symbols

Pressure And Return Circuits Component Location

Boom, Arm, Bucket And Swing Circuits Component Location

Pilot Circuit — Controllers To Flow Regulator Component Location

790D Pilot Circuit — Flow Regulator To Main Control Valve Assembly Component Location

892D-LC Pilot Circuit —Flow Regulator To Main Control Valve Assembly Component Location

790D Pilot Circuit — Swing Motor, Engine Speed, And Pump Displacement Controls Component Location

892D-LC Pilot Circuit — Swing Motor, Engine Speed, And Pump Displacement Controls Component Location

Pilot Control Lever Pattern Information

Group 20: Adjustments

Pilot Shut-Off Valve Linkage

Main Hydraulic Pump Displacement Adjustment

Group 25: Tests

JT05801 Clamp-On Electronic Tachometer Installation

JT05800 Digital Thermometer Installation

Cycle Time Test

Hydraulic Pump Start-Up Procedure

Pilot System Regulating Valve Test And Adjustment—790D And 892D-LC

System Relief Valve Test And Adjustment—790D

System Relief Valve Test And Adjustment —892D-LC

Circuit Relief Valve Test And Adjustment

Swing Motor Crossover Relief Valve Test And Adjustment

Flow Sensing Valve Test

Hydraulic Pump Regulator Test And Adjustment—Minimum Flow—790D

Hydraulic Pump Regulator Test And Adjustment—Minimum Flow—892D-LC

Hydraulic Pump Regulator Test And Adjustment—Maximum Flow/High—Low Maximum Flow

Hydraulic Pump Regulator Test And Adjustment (Engine Pulldown)—790D

Hydraulic Pump Regulator Test And Adjustment (Engine Pulldown)—892D-LC

Hydraulic Pump Flow Test—790D

Hydraulic Pump Flow Test—892D-LC

Cylinder Drift Test—Boom, Arm And Bucket

Swing Motor Leakage Test

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy

Pilot Hydraulic Pump Flow Test — 790D/892D-LC

Section 9031: Heating And Air Conditioning

Group 05: Theory Of Operation

Proper Refrigerant Handling

R12 And R134A Refrigerant Cautions

Air Conditioning System Operation

Receiver—Dryer Operation

Expansion Valve Operation

Temperature Control Switch Operation

Compressor Relief Valve Operation

Group 10: System Operational Checks

Air Conditioning Operational Checks

Group 20: Adjustments

Proper Refrigerant Handling

R12 And R134A Refrigerant Cautions

R12 Component Oil Charge

R12 Refrigerant Recovery, Recycling Station Installation Procedure

R12 Refrigerant Evacuation And Charging Station Installation Procedure

Recover R12 System

Evacuate R12 System

Charge R12 System

R134A Component Oil Charge

R134A Refrigerant Recovery, Recycling And Charging Station Installation Procedure

Recover R134A System

Evacuate R134A System

Charge R134A System

Check And Adjust Compressor Belt Tension

Group 25: Test

Proper Refrigerant Handling

R12 And R134A Refrigerant Cautions

Pressure Diagnostic Chart

Expansion Valve Operating Test

Expansion Valve Bench Test And Adjustment

Temperature Control Switch Operating Test

Temperature Control Switch Bench Test And Adjustment

Low Pressure Switch Test

Refrigerant Hoses And Tubing Inspection

Leak Testing

Electrical Wiring Diagram And Schematic—892D-LC

Electrical Wiring Diagram And Schematic—790D

Hydraulic Schematic—892D-LC

Hydraulic Schematic—790D

John Deere 790D, 790D-LC, 892D-LC Excavator Operation and Test Service Manual (TM1395)