John Deere Wheeled Excavator 190DW Operation & Test Technical Service Manual (TM10542)

Complete Technical Diagnostics, Operation and Test Manual with electrical wiring diagrams for John Deere 190DW, with all the technical information to maintain, diagnose, rebuild like professional mechanics.

John Deere 190DW Wheeled Excavator workshop Operation and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM10542 - John Deere 190DW Wheeled Excavator Technical Manual - Operation and Test.pdf|

PRODUCT DETAILS:

Total Pages: 1,833 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

Technical Information Feedback Form

General Information

Safety

Diagnostic Trouble Codes (DTC)

Main Controller (MCF) Diagnostic Trouble Codes

Engine Control Module (ECM) Diagnostic Trouble Codes

Information Controller (ICF) Diagnostic Trouble Codes

Air Conditioner Controller (ACF) Diagnostic Trouble Codes

Monitor Controller (MON) Diagnostic Trouble Codes

Option Controller (URF) Diagnostic Trouble Codes

Steering Column Monitor (SCM) Diagnostic Trouble Codes

Operational Checkout Procedure

Operational Checkout Procedure

Engine

Theory of Operation

Diagnostic Information

Tests

Electrical System

System Information

System Diagrams

Sub-System Diagnostics

Monitor Operation

References

Power Train

Theory of Operation

Diagnostic Information

Tests and Adjustments

Hydraulic System

Theory of Operation

Diagnostic Information

Tests

Heating and Air Conditioning

Theory of Operation

Diagnostic Information

Tests

Reference Material

Terminology Cross Reference Chart

Dealer Fabricated Tools

TABLE OF CONTENTS....1

Section 9000: General Information....23

Group 01: Safety....23

Recognize Safety Information....26

Follow Safety Instructions....27

Operate Only If Qualified....28

Wear Protective Equipment....29

Avoid Unauthorized Machine Modifications....30

Add Cab Guarding for Special Uses....31

Inspect Machine....32

Stay Clear of Moving Parts....33

Avoid High-Pressure Fluids....34

Avoid High-Pressure Oils....35

Beware of Exhaust Fumes....36

Prevent Fires....37

Prevent Battery Explosions....38

Handle Chemical Products Safely....39

Dispose of Waste Properly....40

Prepare for Emergencies....41

Use Steps and Handholds Correctly....42

Start Only From Operator's Seat....43

Use and Maintain Seat Belt....44

Prevent Unintended Machine Movement....45

Avoid Work Site Hazards....46

Keep Riders Off Machine....48

Avoid Backover Accidents....49

Avoid Machine Tip Over....50

Use Special Care When Lifting Objects....51

Add and Operate Attachments Safely....52

Park and Prepare for Service Safely....53

Service Cooling System Safely....54

Remove Paint Before Welding or Heating....55

Service Tires Safely....56

Make Welding Repairs Safely....57

Drive Metal Pins Safely....58

Section 9001: Diagnostic Trouble Codes (DTC)....59

Group 10: Main Controller (MCF) Diagnostic Trouble Codes....68

Main Controller (MCF) Diagnostic Trouble Codes....68

11000.02 - Abnormal EEPROM....59

11001.02 - Abnormal RAM....59

11002.02 - Abnormal A-D Conversion....59

11003.02 - Abnormal Sensor Voltage....59

11004.02 - Abnormal CAN Communication....59

11100.02 - Abnormal Engine Speed....59

11101.03 - Engine Control Dial Sensor Voltage High....59

11101.04 - Engine Control Dial Sensor Voltage Low....59

11200.03 - Pump 1 Delivery Pressure Sensor Voltage High....59

11200.04 - Pump 1 Delivery Pressure Sensor Voltage Low....59

11202.03 - Pump 2 Delivery Pressure Sensor Voltage High....59

11202.04 - Pump 2 Delivery Pressure Sensor Voltage Low....59

11203.03 - Steering Pump Delivery Pressure Sensor Voltage High....59

11203.04 - Steering Pump Delivery Pressure Sensor Voltage Low....59

11206.03 - Pump 1 Control Pressure Sensor Voltage High....59

11206.04 - Pump 1 Control Pressure Sensor Voltage Low....59

11208.03 - Pump 2 Control Pressure Sensor Voltage High....59

11208.04 - Pump 2 Control Pressure Sensor Voltage Low....59

11301.03 - Swing Pilot Pressure Sensor Voltage High....59

11301.04 - Swing Pilot Pressure Sensor Voltage Low....59

11302.03 - Boom-up Pilot Pressure Sensor Voltage High....59

11302.04 - Boom-up Pilot Pressure Sensor Voltage Low....59

11303.03 - Arm-in Pilot Pressure Sensor Voltage High....59

11303.04 - Arm-in Pilot Pressure Sensor Voltage Low....59

11305.03 - Travel Forward Pressure Sensor Voltage High....59

11305.04 - Travel Forward Pressure Sensor Voltage Low....59

11306.03 - Travel Reverse Pressure Sensor Voltage High....59

11306.04 - Travel Reverse Pressure Sensor Voltage Low....59

11307.03 - Front Attachment Pressure Sensor Voltage High....59

11307.04 - Front Attachment Pressure Sensor Voltage Low....59

11310.03 - Brake Pressure Sensor Voltage High....60

11310.04 - Brake Pressure Sensor Voltage Low....60

11311.03 - Brake Remaining Pressure Sensor Voltage High....60

11311.04 - Brake Remaining Pressure Sensor Voltage Low....60

11400.02 - Pump 2 Flow Rate Limit Solenoid Feedback Current Abnormal....60

11400.03 - Pump 2 Flow Rate Limit Solenoid Feedback Current High....60

11400.04 - Pump 2 Flow Rate Limit Solenoid Feedback Current Low....60

11401.02 - Torque Control Solenoid Feedback Current Abnormal....60

11401.03 - Torque Control Solenoid Feedback Current High....60

11401.04 - Torque Control Solenoid Feedback Current Low....60

11403.02 - Arm Regenerative Solenoid (SC) Feedback Current Abnormal....60

11403.03 - Arm Regenerative Solenoid (SC) Feedback Current High....60

11403.04 - Arm Regenerative Solenoid (SC) Feedback Current Low....60

11404.02 - Power Dig Solenoid (SG) Feedback Current Abnormal....60

11404.03 - Power Dig Solenoid (SG) Feedback Current High....60

11404.04 - Power Dig Solenoid (SG) Feedback Current Low....60

11410.02 - Pump 1 Flow Rate Limit Solenoid Feedback Current Abnormal....60

11410.03 - Pump 1 Flow Rate Limit Solenoid Feedback Current High....60

11410.04 - Pump 1 Flow Rate Limit Solenoid Feedback Current Low....60

11422.02 - Travel Speed Solenoid Feedback Current Abnormal....60

11422.03 - Travel Speed Solenoid Feedback Current High....60

11422.04 - Travel Speed Solenoid Feedback Current Low....60

11423.02 - Travel Make-up Solenoid Feedback Current Abnormal....60

11423.03 - Travel Make-up Solenoid Feedback Current High....60

11423.04 - Travel Make-up Solenoid Feedback Current Low....60

11424.02 - Axle Lock Solenoid (SI) Feedback Current Abnormal....60

11424.03 - Axle Lock Solenoid (SI) Feedback Current High....60

11424.04 - Axle Lock Solenoid (SI) Feedback Current Low....60

11425.02 - Work Brake Solenoid (SF) Feedback Current Abnormal....60

11425.03 - Work Brake Solenoid (SF) Feedback Current High....60

11425.04 - Work Brake Solenoid (SF) Feedback Current Low....60

11502.02 - Travel Motor Overspeed....60

11901.03 - Hydraulic Oil Temperature Sensor Voltage High....60

11901.04 - Hydraulic Oil Temperature Sensor Voltage Low....61

11910.02 - Engine Speed CAN Message Abnormal....61

11911.02 - Security Signal CAN Message Abnormal....61

11914.02 - Engine Coolant Temperature CAN Message Abnormal....61

11915.02 - Pilot Shutoff Signal CAN Message Abnormal....61

11918.02 - Work Mode CAN Message Abnormal....61

11920.02 - Fuel Flow Rate CAN Message Abnormal....61

11921.02 - Incorrect Odometer Value....61

Group 20: Engine Control Module (ECM) Diagnostic Trouble Codes....319

Engine Control Module (ECM) Diagnostic Trouble Codes....319

100.03 - Engine Oil Pressure Sensor Voltage Low (P0522)....61

100.04 - Engine Oil Pressure Sensor Voltage High (P0523)....61

102.03 - Boost Pressure Sensor Voltage Low (P0237)....61

102.04 - Boost Pressure Sensor Voltage High (P0238)....61

105.03 - Boost Temperature Sensor Voltage High (P1113)....61

105.04 - Boost Temperature Sensor Voltage Low (P1112)....61

108.03 - Barometric Pressure Sensor Voltage Low (P0107)....61

108.04 - Barometric Pressure Sensor Voltage High (P0108)....61

110.00 - Engine Coolant Temperature Hight (P1173)....61

110.03 - Engine Coolant Temperature Sensor Voltage High (P0118)....61

110.04 - Engine Coolant Temperature Sensor Voltage Low (P0117)....61

157.00 - Fuel Rail Pressure Abnormal (First Stage) (P0088)....61

157.00 - Fuel Rail Pressure Abnormal (Second Stage) (P0088)....61

157.02 - Fuel Rail Pressure High (Pump Over-Pressure) (P0089)....61

157.03 - Fuel Rail Pressure Sensor Voltage High (P0193)....61

157.04 - Fuel Rail Pressure Sensor Voltage Low (P0192)....61

172.03 - Intake Air Temperature Sensor Voltage High (P0113)....61

172.04 - Intake Air Temperature Sensor Voltage Low (P0112)....61

174.03 - Fuel Temperature Sensor Voltage High (P0183)....61

174.04 - Fuel Temperature Sensor Voltage Low (P0182)....61

190.00 - Engine Overspeed (P0219)....61

628.02 - Abnormal ROM (P1603)....61

633.07 - Pressure Limiter Open (P1095)....61

636.02 - Abnormal Cam Angle Sensor (No Signal) (P0340)....62

636.02 - Abnormal Cam Angle Sensor (Abnormal Signal) (P0341)....62

636.07 - Phase Mismatch of Cam Angle Sensor (P1345)....62

639.02 - CAN Communication Error (U2104)....62

639.03 - CAN Time Out (U2106)....62

651.03 - Injector 1 Drive System Open Circuit (P0201)....62

652.03 - Injector 2 Drive System Open Circuit (P0202)....62

653.03 - Injector 3 Drive System Open Circuit (P0203)....62

654.03 - Injector 4 Drive System Open Circuit (P0204)....62

723.02 - Abnormal Crank Speed Sensor (No Signal) (P0335)....62

723.02 - Abnormal Crank Speed Sensor (Abnormal Signal) (P0336)....62

987.03 - Abnormal Check Engine Lamp (P0650)....62

1077.02 - Abnormal IC for CPU Watching (P0601)....62

1079.02 - 5 Volt Power Source 1 Voltage Abnormal (P1632)....62

1080.02 - 5 Volt Power Source 2 Voltage Abnormal (P1633)....62

1239.01 - No Pressure To Pump (P0087)....62

1240.01 - No Pressure To Pump (P1093)....62

1347.00 - Suction Control Valve Drive Circuit Open or Shorted (P0090)....62

1381.03 - High Voltage Fault of Fuel Differential Pressure Sensor....62

1381.04 - Low Voltage Fault of Fuel Differential Pressure Sensor....62

1485.02 - Engine Control Module (ECM) Relay Abnormal (P1625)....62

10001.03 - Abnormal EGR Position (P0487)....62

10002.02 - Abnormal EGR Valve Control (P0488)....62

10003.02 - Injector Drive System Common 1 Abnormal (P1262)....62

10004.02 - Injector Drive System Common 2 Abnormal (P1262)....62

10005.01 - Charge Circuit Abnormal Bank 1 (P0611)....62

10006.1 - Charge Circuit Abnormal Bank 2 (P0612)....62

10007.02 - Abnormal CPU (P0606)....62

10008.02 - Abnormal A-D Conversion (P1630)....62

10009.02 - 5 Volt Power Source 3 Voltage Abnormal (P1634)....62

10010.02 - 5 Volt Power Source 4 Voltage Abnormal (P1635)....62

10011.02 - 5 Volt Power Source 5 Voltage Abnormal (P1261)....62

10013.02 - Abnormal EEPROM (P1631)....62

Group 30: Information Controller (ICF) Diagnostic Trouble Codes....377

Information Controller (ICF) Diagnostic Trouble Codes....377

14000.02 - Abnormal CAN Communication....63

14001.02 - Flash Memory: Read - Write Error....63

14002.02 - External RAM: Read - Write Error....63

14003.02 - EEPROM: Sum Check Error....63

14006.02 - Satellite Communication Terminal: Communication Error....63

14008.02 - Abnormal Internal RAM....63

14100.02 - Satellite Communication Terminal: Abnormal EEPROM....63

14101.02 - Satellite Communication Terminal: Abnormal IB-OB Queue....63

14102.02 - Satellite Communication Terminal: Abnormal Local Loop Back....63

14103.02 - Satellite Communication Terminal: Satellite Cannot Be Found....63

14104.02 - Satellite Communication Terminal: Remote Loop Back Failure 1....63

14105.02 - Satellite Communication Terminal: Remote Loop Back Failure 2....63

14106.02 - Satellite Communication Terminal: Received Data is Not Same With Sent Data....63

Group 40: Air Conditioner Controller (ACF) Diagnostic Trouble Codes....417

Air Conditioner Controller (ACF) Diagnostic Trouble Codes....417

21 - Mix Door Open Circuit....63

Section 9005: Operational Checkout Procedure....771

Group 10: Operational Checkout Procedure....771

Operational Checkout....835

Section 9010: Engine....898

Group 05: Theory of Operation....898

Engine Component Location....901

Engine Fuel System Operation....902

Cooling System Operation....908

Engine Lubrication System Operation....910

Engine Intake and Exhaust System Operation....912

Engine Turbocharger Operation....913

Exhaust Gas Recirculation (EGR) Operation....914

Quick On System Operation....916

Engine Speed Control System Operation....917

Group 15: Diagnostic Information....898

4HK1 Isuzu Diesel Engine....924

Diagnose Engine Malfunctions....925

Engine Cranks But Will Not Start....898

Engine Misfires Or Runs Irregularly....898

Engine Does Not Develop Full Power....898

Engine Overheats....898

Auto-Idle Does Not Work....898

Coolant Temperature Too Low....898

Coolant in Oil or Oil in Coolant....898

Low Engine Oil Pressure....898

High Engine Oil Pressure....898

Engine Uses Too Much Oil....898

Engine Uses Too Much Fuel....898

Engine Emits Excessive Black or Gray Exhaust Smoke....898

Engine Emits Excessive White Exhaust Smoke....898

Turbocharger Excessively Noisy or Vibrates....898

Oil Dripping From Turbocharger Adapter....898

Excessive Drag in Turbocharger Rotating Members....898

Fuel In Oil....898

Engine Speed Can Not Be Controlled With Travel Pedal (Travel Pedal Engine Speed Control)....898

Group 25: Tests....899

Serpentine Belt Check and Adjust....976

High Pressure Fuel Pump Timing Check....978

Engine Valve Lash (Clearance) Check and Adjust....980

Engine Compression Pressure Test....984

Air Filter Restriction Indicator Switch Test....986

Engine Power Test Using Turbocharger Boost Pressure....988

Engine Oil Pressure Test....992

Section 9015: Electrical System....994

Group 05: System Information....994

Electrical Diagram Information....1005

Group 10: System Diagrams....994

Explanation of Wire Markings....1012

Fuse and Relay Specifications....1013

System Functional Schematic, Component Location, and Wiring Diagram Master Legend....1016

System Functional Schematic....1026

Cab Harness (W1) Component Location....1038

Cab Harness (W1) Wiring Diagram....1043

Machine Harness (W2) Component Location....1050

Machine Harness (W2) Wiring Diagram....1052

Monitor Harness (W3) Component Location....1056

Monitor Harness (W3) Wiring Diagram....1058

Engine Harness (W4) Component Location....1059

Engine Harness (W4) Wiring Diagram....1060

Floor Harness (W5) Component Location....1061

Floor Harness (W5) Wiring Diagram....1063

Chassis Harness (W6) Component Location....1064

Chassis Harness (W6) Wiring Diagram....1066

Right Console Harness (W7) Component Location....1068

Right Console Harness (W7) Wiring Diagram....1070

Pump Harness (W8) Component Location....1071

Pump Harness (W8) Wiring Diagram....1073

Left Console Harness (W9) Component Location....1074

Left Console Harness (W9) Wiring Diagram....1075

Air Suspension Seat Harness (W10) Component Location....1077

Air Suspension Seat Harness (W10) Wiring Diagram....1079

Right Pilot Control Lever Harness (W11) Component Location....1080

Right Pilot Control Lever Harness (W11) Wiring Diagram....1081

Swing Park Brake Solenoid Harness (W12) Component Location....1082

Swing Park Brake Solenoid Harness (W12) Wiring Diagram....1084

Blade and/or Outrigger Control Lever Harness (W13) Component Location....1085

Blade and/or Outrigger Control Lever Harness (W13) Wiring Diagram....1086

Boom Positioning and/or Assist Pressure Sensor Harness (W14) Component Location....1087

Boom Positioning and/or Assist Pressure Sensor Harness (W14) Wiring Diagram....1088

Digital Assist Harness (W17) Component Location—If Equipped....1089

Digital Assist Harness (W17) Wiring Diagram—If Equipped....1090

Digital or Analog Assist Solenoid Harness (W18) Component Location....1091

Digital or Analog Assist Solenoid Harness (W18) Wiring Diagram....1092

Cab Light Timer Harness (W19) Component Location....1093

Cab Light Timer Harness (W19) Wiring Diagram....1095

Boom Positioning and/or Auxiliary Select Harness (W20) Component Location....1096

Boom Positioning and/or Auxiliary Select Harness (W20) Wiring Diagram....1097

Seat Heater Switch Harness (W21) Component Location—If Equipped....1099

Seat Heater Switch Harness (W21) Wiring Diagram—If Equipped....1100

Left Pilot Control Lever Harness (W22) Component Location....1101

Left Pilot Control Lever Harness (W22) Wiring Diagram....1103

Travel Alarm Cancel Switch Harness (W24) Component Location....1104

Travel Alarm Cancel Switch Harness (W24) Wiring Diagram....1105

Travel Alarm Cancel Switch Sub Harness (W25) Component Location....1106

Travel Alarm Cancel Switch Sub Harness (W25) Wiring Diagram....1107

Travel Alarm Harness (W26) Component Location....1108

Travel Alarm Harness (W26) Wiring Diagram....1109

Attachment Harness (W27) Component Location—If Equipped....1110

Attachment Harness (W27) Wiring Diagram—If Equipped....1112

Auxiliary Solenoid Harness (W29) Component Location....1114

Auxiliary Solenoid Harness (W29) Wiring Diagram....1116

Positioning Harness (W30) Component Location....1117

Positioning Harness (W30) Wiring Diagram....1118

Rear Cab Light Relay Harness (W31) Component Location....1119

Rear Cab Light Relay Harness (W31) Wiring Diagram....1121

Rear Cab Light Harness (W32) Component Location....1122

Rear Cab Light Harness (W32) Wiring Diagram....1123

12-Volt Power Converter Harness (W33) Component Location....1124

12-Volt Power Converter Harness (W33) Wiring Diagram....1125

Beacon Harness (W34) Component Location....1126

Beacon Harness (W34) Wiring Diagram....1128

Beacon Relay Harness (W35) Component Location....1129

Beacon Relay Harness (W35) Wiring Diagram....1130

Beacon Switch Harness (W36) Component Location....1131

Beacon Switch Harness (W36) Wiring Diagram....1132

Beacon Lamp Harness (W37) Component Location....1133

Beacon Lamp Harness (W37) Wiring Diagram....1134

Front Cab Light 1 Relay Harness (W38) Component Location....1135

Front Cab Light 1 Relay Harness (W38) Wiring Diagram....1137

Front Cab Light 2 Relay Harness (W40) Component Location....1138

Front Cab Light 2 Relay Harness (W40) Wiring Diagram....1139

Front Cab Light 2 Harness (W41) Component Location....1140

Front Cab Light 2 Harness (W41) Wiring Diagram....1141

Pilot Shutoff Switch Harness (W42) Component Location....1142

Pilot Shutoff Switch Harness (W42) Wiring Diagram....1143

Service Advisor Connector Harness (W43) Component Location....1145

Service Advisor Connector Harness (W43) Wiring Diagram....1148

Front Cab Light Harness (W44) Component Location....1150

Front Cab Light Harness (W44) Wiring Diagram....1151

JDLink™ System Harnesses Component Location—MIG/GTT....1152

JDLink™ System Harnesses Component Location—MTG/SAT....1154

JDLink™ System Wiring Diagrams—MIG/GTT....1156

JDLink™ System Wiring Diagrams—MTG/SAT....1161

Group 15: Sub-System Diagnostics....996

Controller Area Network (CAN) Theory of Operation....1164

Starting and Charging Circuit Theory of Operation....1166

Monitor Controller Circuit Theory of Operation....1169

Engine Control Module (ECM) Circuit Theory of Operation....1175

Main Controller (MCF) Circuit Theory of Operation....1180

Information Controller (ICF) Circuit Theory of Operation....1190

Option Controller (URF) Circuit Theory of Operation....1192

Steering Column Monitor (SCM) Circuit Theory of Operation....1198

Travel Alarm Circuit Theory of Operation....1201

Windshield Wiper and Washer Circuit Theory of Operation....1203

Pilot Shutoff Circuit Theory of Operation....1205

Attachment Control Circuit Theory of Operation....1207

Lights Circuit Theory of Operation....1214

Blade and/or Outrigger Control Circuit Theory of Operation....1218

JDLink™ Circuit Theory of Operation—If Equipped....1222

Group 16: Monitor Operation....997

Monitor Menu Operation....1226

Monitor Service Menu Operation....1227

Group 20: References....997

Monitor Data Items....1233

Reading Diagnostic Trouble Codes with Monitor Display....1235

Service ADVISOR™ Diagnostic Application....1237

Service ADVISOR™ Connection Procedure....1238

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application....1240

Service ADVISOR™ Interactive Tests....1243

JDLink™ System Identification....1244

JDLink™ Connection Procedure—If Equipped....1247

Information Controller (ICF) Recorded Data....1248

Fuse Test....1251

Relay Test....1257

Pressure Sensor Test....1258

Solenoid Test....1261

Proportional Solenoid Test....1262

Temperature Sensor Test....1263

Alternator Test....1264

Electrical Component Checks....1266

Battery Remove and Install....1272

Rear Cover Remove and Install....1275

Main Controller (MCF) Remove and Install....1277

Engine Control Module (ECM) Remove and Install....1279

Information Controller (ICF) Remove and Install....1281

Option Controller (URF) Remove and Install....1282

Steering Column Monitor (SCM) Remove and Install....1283

Monitor Controller Remove and Install....1285

Key Switch Remove and Install....1288

Switch Panel Remove and Install....1289

Travel Alarm Remove and Install....1291

Left Console Switch Remove and Install....1292

Disconnect Tab Retainer Connectors....1293

Disconnecting Spring Wire Clip Connectors....1294

Replace DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Connectors....998

Replace DEUTSCH DEUTSCH is a trademark of Deutsch Co. Rectangular or Triangular Connectors....998

Install DEUTSCH DEUTSCH is a trademark of the Deutsch Co. Contact....998

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector....998

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact....998

Replace (Pull Type) Metri-Pack™ Connectors....1305

Replace (Push Type) Metri-Pack™ Connectors....1307

Replace CINCH CINCH is a trademark of the Cinch Co. Connectors....998

Install CINCH CINCH is a trademark of the Cinch Co. Contact....998

Repair 32 and 48 Way CINCH CINCH is a trademark of the Cinch Co. Connectors....998

Remove Connector Body from Blade Terminals....1316

Section 9020: Power Train....1317

Group 05: Theory of Operation....1317

Travel Hydraulic System Diagram and Operation....1482

Brake System Diagram and Operation....1323

Travel Pilot Control Valve Operation....1542

Travel Shockless Valve Operation....1327

Travel Motor and Regulator Operation....1328

Counterbalance Valve Operation....1340

Transmission Operation....1344

Shift Interlock Operation....1350

Transmission Disconnect Operation....1351

Transmission Control Valve....1353

Park Brake Operation....1358

Service Brake Circuit Operation....1360

Brake Accumulator Charging Valve Operation....1366

Axle Lock Circuit Operation....1369

Group 15: Diagnostic Information....1317

Diagnose Transmission Malfunctions....1317

Diagnose Brake Malfunctions....1317

Travel Hydraulic System Schematic....1692

Travel Hydraulic System Component Location....1703

Travel Hydraulic System Line Identification....1436

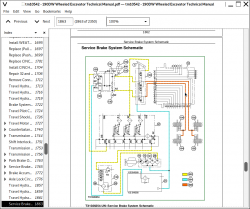

Service Brake System Schematic....1437

Service Brake System Component Location....1439

Service Brake System Line Identification....1441

Axle Lock System Line Identification....1442

Axle Lock System Schematic....1444

Axle Lock System Component Location....1445

Group 20: Tests and Adjustments....1317

Transmission Manual Disconnection Procedure....1449

Brake Bleeding Procedure....1451

Brake Warning Set Pressure (Decrease)....1453

Brake Warning Set Pressure (Increase)....1459

Brake Warning Set Pressure (Increase)....1459

Rear Brake Pressure Test....1462

Front Brake Pressure Test....1465

Transmission Control Valve Pressure Test....1468

Brake Accumulator Pressure Test....1471

Measure Swing Bearing Wear....1474

Section 9025: Hydraulic System....1477

Group 05: Theory of Operation....1477

Hydraulic System Diagram and Operation....1482

Pilot System Diagram and Operation....1484

Steering System Diagram and Operation....1494

Blade and/or Outrigger System Diagram and Operation....1496

Hydraulic Assist Diagram and Operation....1498

Two Piece Boom Positioning Diagram and Operation....1501

Pilot Pump, Pressure Regulating Valve and Filter Operation....1505

Pilot Shutoff Solenoid Valve Operation....1507

Pilot Control Valve Operation....1542

Travel Pilot Control Valve Operation....1542

Pilot Operation of Control Valve Operation....1542

Pilot Signal Manifold Operation....1519

Pump 1, Pump 2 and Drive Gearbox Operation....1529

Pump 1 and Pump 2 Regulator Operation....1532

Engine Speed Sensing Control Circuit Operation....1540

Control Valve Operation....1542

Control Valve Check Valves Identification and Operation....1554

Main Relief Valve Circuit Operation....1558

Circuit Relief and Anticavitation Valve Operation....1560

Auxiliary Flow Combiner Valve Operation....1562

Boom Regenerative Valve Circuit Operation....1567

Arm Regenerative Valve Circuit Operation....1570

Bucket Regenerative Valve Circuit Operation....1573

Boom and Arm Reduced Leakage Valves Operation....1576

Bucket Flow Rate Control Valve Circuit Operation....1580

Auxiliary Flow Rate Control Valve Circuit Operation....1583

Swing Reduction Gearbox Operation....1584

Swing Motor, Crossover Relief Valve, and Make-Up Check Valve Operation....1585

Swing Motor Dampener Valve....1589

Swing Motor Park Brake Release Circuit Operation....1599

Swing Shockless Valve Operation....1600

Center Joint Operation....1602

Steering Valve Operation....1604

Blade and/or Outrigger Check Valve Operation....1610

Cylinder Holding Valve Operation....1612

Cylinder Operation....1616

Return Filter Operation....1618

Group 15: Diagnostic Information....1478

Diagnose Hydraulic System Malfunctions....1478

Diagnose Pilot Circuit Malfunctions....1478

Diagnose Dig Circuit Malfunctions....1478

Diagnose Swing Circuit Malfunctions....1478

Diagnose Steering Circuit Malfunctions....1478

Diagnose Blade and/or Outrigger Circuit Malfunctions....1478

Pump 1, Pump 2, and Pilot Pump Line Identification....1682

Control Valve Line Identification....1683

Swing Motor Line Identification....1686

Pilot Control Valve-to-Pilot Signal Manifold Component Location—Excavator Pattern....1687

Pilot Signal Manifold-to-Control Valve Line Connection....1688

Steering System Component Location....1689

Steering System Line Connection....1690

Hydraulic System Schematic....1692

Hydraulic System Component Location....1703

Hydraulic System Line Connections....1706

Group 25: Tests....1478

JT05800 Digital Thermometer Installation....1708

JT02156A Digital Pressure/Temperature Analyzer Installation....1709

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy....1710

Hydraulic Oil Warm-Up Procedure....1711

Pilot Pressure Regulating Valve Test and Adjustment....1714

Control Valve Spool Actuating Pilot Pressure Test....1718

Arm Regenerative Solenoid Valve Test and Adjustment....1722

Torque Control Solenoid Valve Test and Adjustment....1727

Axle Lock Solenoid Valve Test and Adjustment....1731

Work Brake Solenoid Valve Test and Adjustment....1736

Pump Control Pilot Pressure Signal Test....1741

Main Relief Valve Test and Adjustment....1744

Circuit Relief Valve Test and Adjustment....1749

Swing Motor Crossover Relief Valve Test and Adjustment....1757

Steering Relief Valve Pressure Test....1762

Two Piece Boom Positioning and Hydraulic Assist Relief Valve Test and Adjustment....1765

Pump Flow Test....1770

Swing Motor Leakage Test....1779

Steering System Leakage Test....1782

Steering Cylinder Leakage Test....1784

Cylinder Drift Test—Boom, Arm, and Bucket....1786

Section 9031: Heating and Air Conditioning....1788

Group 05: Theory of Operation....1788

Air Conditioning System Cycle of Operation....1791

Group 15: Diagnostic Information....1788

Diagnose Air Conditioning System Malfunctions....1796

Diagnose Heating System Malfunctions....1799

Heater and Air Conditioner Diagnostic Trouble Code Check....1801

Heater and Air Conditioner Component Location....1807

Group 25: Tests....1788

R134a Refrigerant Cautions and Proper Handling....1809

Heater and Air Conditioner Operational Checks....1810

R134a Air Conditioning System Test....1824

Air Conditioner Compressor Clutch Test....1817

Refrigerant Leak Test....1818

Refrigerant Hoses and Tubing Inspection....1819

Air Conditioner High/Low-Pressure Switch Test....1820

Air Conditioner Freeze Control Switch Test....1823

Air Conditioning System Test....1824

Air Conditioner Compressor Belt Check and Adjustment....1827

Operating Pressure Diagnostic Chart....1828

Section 9050: Reference Material....1830

Group 05: Terminology Cross Reference Chart....1833

Terminology Cross Reference Chart....1833

Section 9900: Dealer Fabricated Tools....1835

Group 99: Dealer Fabricated Tools....1835

DFT1218 Split Flange Hose Cap....1837

John Deere Wheeled Excavator 190DW Operation & Test Technical Service Manual (TM10542)